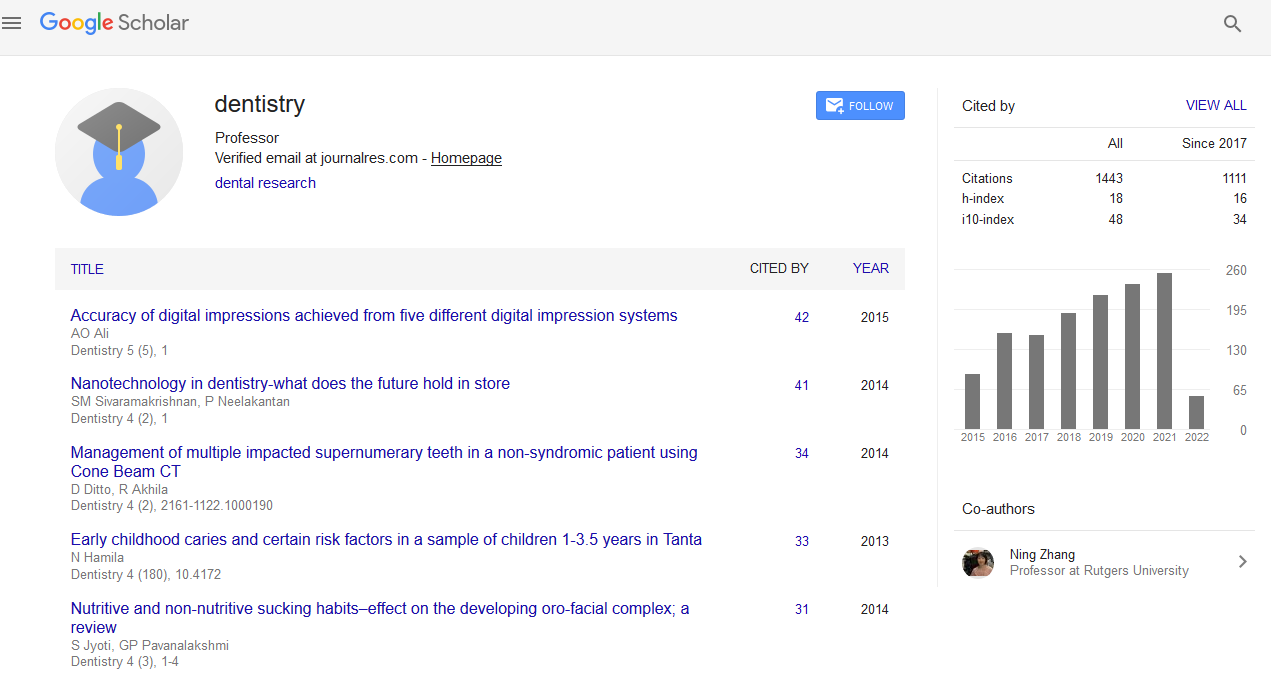

Citations : 1817

Dentistry received 1817 citations as per Google Scholar report

Indexed In

- Genamics JournalSeek

- JournalTOCs

- CiteFactor

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

A Unique Technique For Designing And Fabrication Of Dental Appliances

International Conference on Dental & Oral Health

August 19-21, 2013 Embassy Suites Las Vegas, NV, USA

Noor Al Mortadi

Scientific Tracks Abstracts: Dentistry

Abstract:

T he research was carried out to explore the concept of whether or not it is possible to apply the latest developments in Additive Manufacturing (AM) construction and uniquely apply them to build several types of dental appliances and a sleep apnea device requiring rotating hinges, and evaluate the resultant appliances. The AM method was used, in an attempt to speed the process and decrease the laboratory work chain, and improve quality when compared to the conventional laboratory-based technique. Three dimensional (3D) scans of dental casts were imported into an appropriate Computer Aided Design (CAD) called FreeForm software connected to phantom arm to design the dental appliances. The designs were then exported as a STereoLithography (STL) file and transferred for three dimensional printing to an additive manufacture machine. The appliances were developed using a novel AM technology. The study was carried out at the Cardiff Metropolitan University (CMU) and National Centre of Product Design and Development Research (PDR). The resultant devices were fitted to the casts and evaluated for their fit and finish. Also a scoring system for evaluation the fit was also completed. The devices were judged to be clinically satisfactory without adjustment.

Biography :

Noor Al Mortadi graduated with honours in Dental Technology from Jordan University of Science and Technology (J.U.S.T). In 2009 she finished her Master of Dental Sciences (MDSc) by research at the University of Dundee- Scotland. She returned to Jordan to work as a full time lecturer and academic coordinator in the Applied Dental Sciences/ J.U.S.T. Currently, she is a scholar from J.U.S.T undertaking research leading to a Ph.D. in Cardiff Metropolitan University