Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

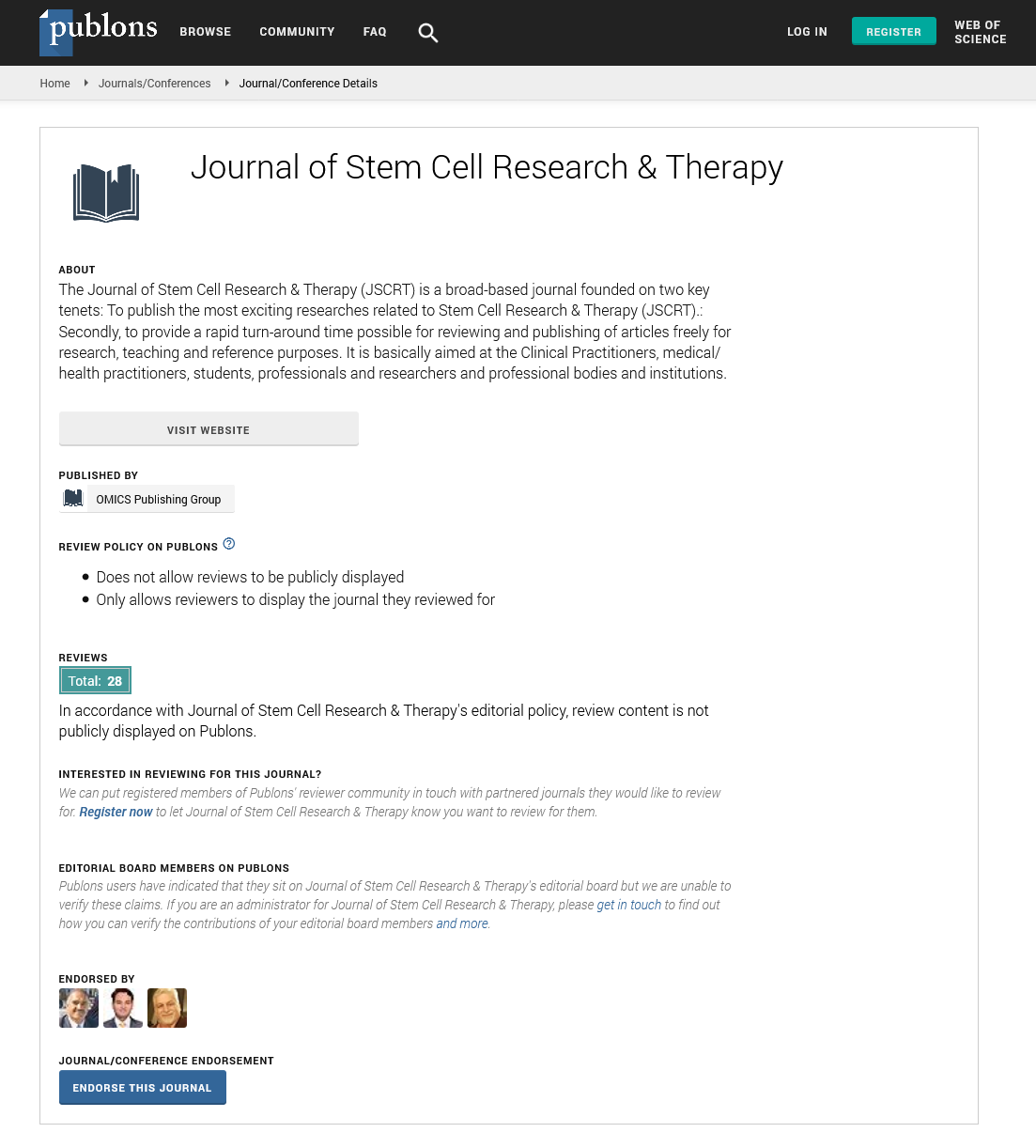

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

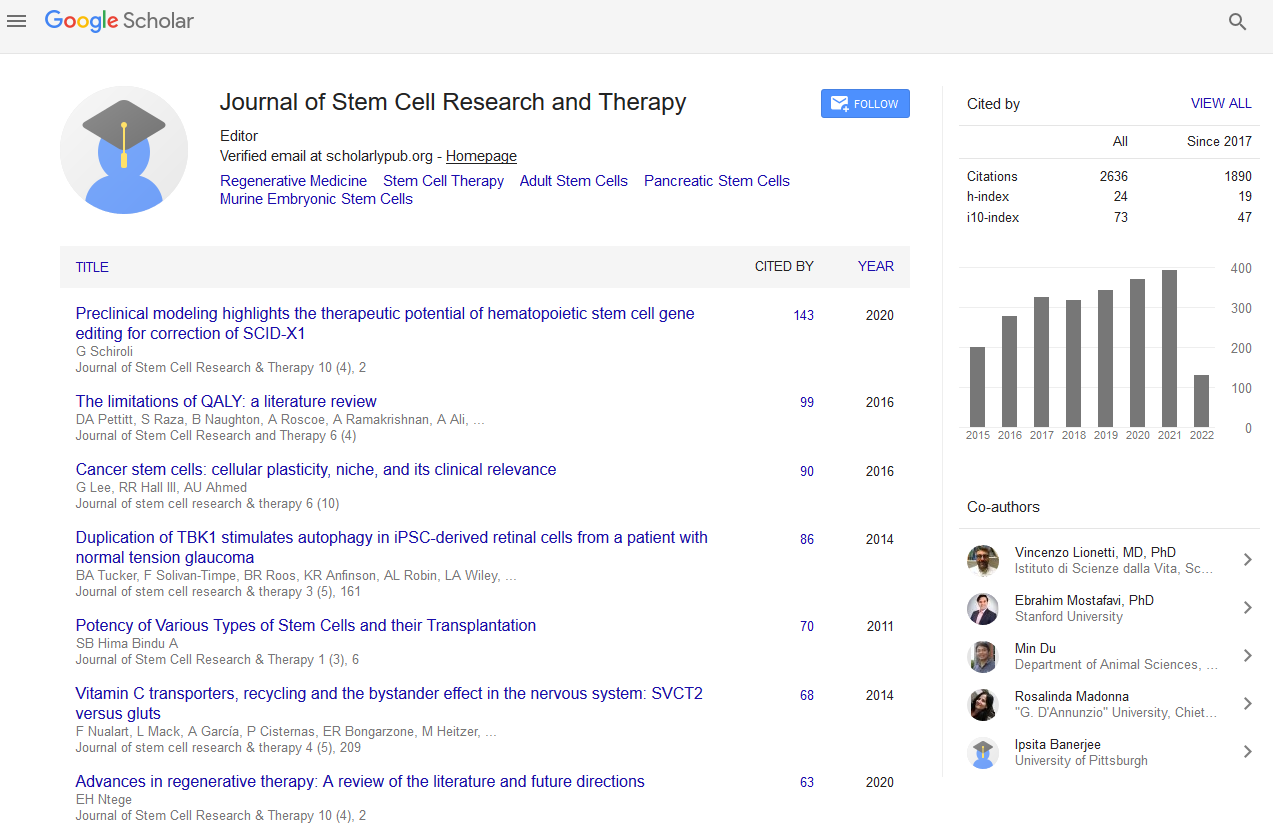

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

The challenges and possible solutions for transferring cell therapy from the bench to the industry, quality, cost and manufacturing efficiency

2nd International Conference and Exhibition on Cell & Gene Therapy

October 23-25, 2013 Holiday Inn Orlando International Airport, Orlando, FL, USA

Ohad Karnieli

Scientific Tracks Abstracts: J Stem Cell Res Ther

Abstract:

In the last decade, it has been proven that cell therapy works in the lab, in preclinical settings and in small scale clinical trials. The need for large quantities of cells with high quality becomes crucial as product candidates advance into clinical trials. Technologies are evolving to allow production of large quantities of cells under GMP conditions including cell factories, hollow fibers and bioreactors. Nevertheless, high quantities of cells open new questions and challenges of cell quality, identity, reproducibility and cost. Bioreactor technology brings to the cell therapy industry the opportunity to manufacture large quantities of cells in a tightly controlled and monitored manner, lowering relatively the cost of goods manufactured resulting in a product and process for cell therapy commercialization. This advantage however holds within it many unmet challenges due to its pioneering nature. These challenges include the fact that most of the data and understanding of cells culturing that was generated over the years was collected on 2 dimensional, semi-controlled growth conditions, whereas, bioreactors are 3 dimensional and fully controlled, these changes in conditions have been proven to effect the cell characterization and phenotype. Once the growth conditions have been established the bioreactor advantages kicks in opening new challenges of downstream processing leading to automation to insure cell quality. The talk will describe some of the main challenges accounted during the development of the GMP manufacturing technology for PLX (PLacental eXpanded) cell product candidates and some of the bottlenecks opening methods developed in Pluristem?s pilot and manufacturing facilities.

Biography :

Ohad Karnieli earned his Ph.D. in Biotechnology and genetic engineering from the Sackler School of medicine at Tel Aviv University. Furthermore, he earned an MBA from the graduate school of Management at the Haifa University. In his Ph.D., he developed insulin secreting cells from human mesenchymal stem cells using genetic modulations. Prior to joining Pluristem, he served as the general manager of High Tech Lipids, an innovative IV nutrition company; the vice president of research and development in an innovative nano-biotechnology startup; and as the vice president, head of the Biomedical division at Goji solutions, where medical devices are developed using radio frequency technology. He is the founder of Karnieli Ltd., a leading molecular diagnostic and development lab.