Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

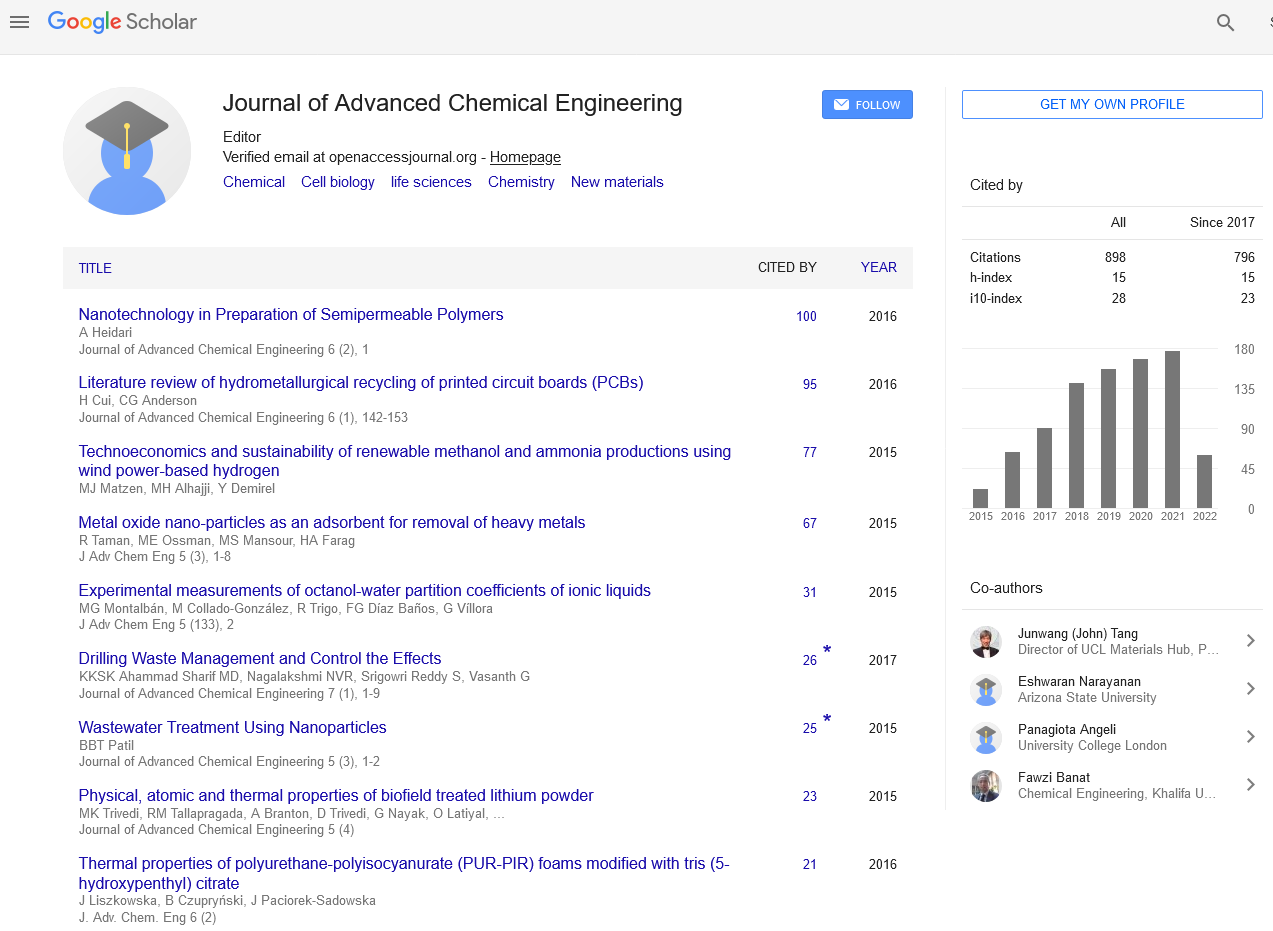

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Conceptual Design of a Separation Process for Higher Alcohols Made by Catalytic Condensation of Ethanol

Venkat K. Rajendran, Andreas Menne and Axel Kraft

A downstream process for the separation of n-butanol from a product mixture containing unreacted ethanol, higher alcohols, aldehydes, water and traces of other chemical species was studied and therewith a conceptual design for the separation train has been devised. A novel approach and a newly developed catalyst were introduced to produce n-butanol (or iso-butanol) from ethanol as a raw material through an alternative path. The product stream from the reactor outlet consists of various chemical species ranging from saturated alcohol mixture, to aldehydes, to traces of aromatics and high boilers, and is ought to be separated into individual components based on their commercial/industrial applicability. Nine azeotropes of which one being ternary and the remaining eight binary azeotropes were identified between the various product components. Due to the chemical complexity, a multicolumn downstream separation unit is needed therefore the schema containing several distillation units is likely to be energy intensive. The goal of this work was primarily to assess the technical and commercial feasibility of such separation technology; further process intensification however, is a subject for later studies.