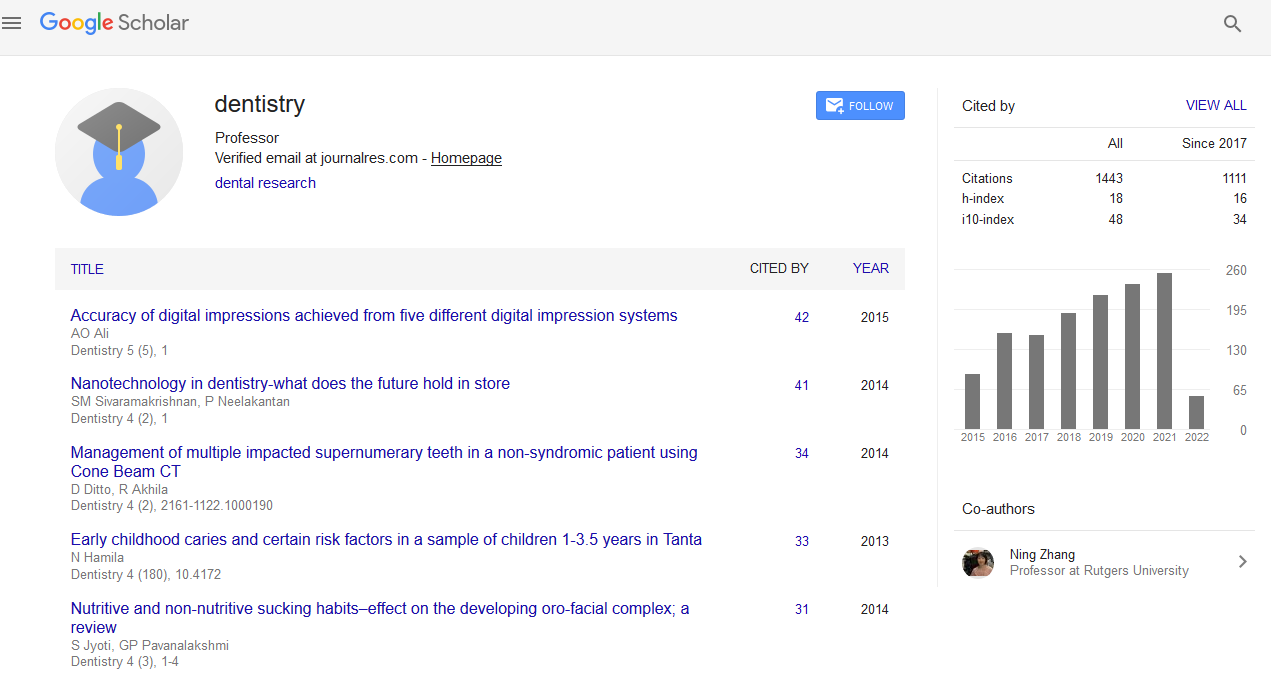

Citations : 1817

Dentistry received 1817 citations as per Google Scholar report

Indexed In

- Genamics JournalSeek

- JournalTOCs

- CiteFactor

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Microwave Sintering of Ceramics for Dentistry: Part 1

R Vaderhobli and S Saha

The objective of this study was to examine the feasibility of sintering dental ceramic (e.g., zirconia) in a microwave oven, and compare the mechanical properties of these with similar materials sintered in a conventional furnace. Zirconia cylinders were heated to 1100°C, 1300°C, 1350°C, 1400 and 1450°C in microwave and conventional furnaces and sintered at varying dwell times. Our results showed that the mechanical and microstructural properties of samples sintered by microwave were comparable to those of the conventionally sintered samples. Indentation hardness and fracture toughness were found to be 1256 ± 7 and 6.4 ± 0.4 Mpa(m)0.5 respectively. The microwave samples were sintered in significantly less time had less voids and more uniform grain structure. Our results suggest that microwave sintering can produce rapid and reliable processing of complex dental ceramics with better microstructural properties and energy savings.