Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

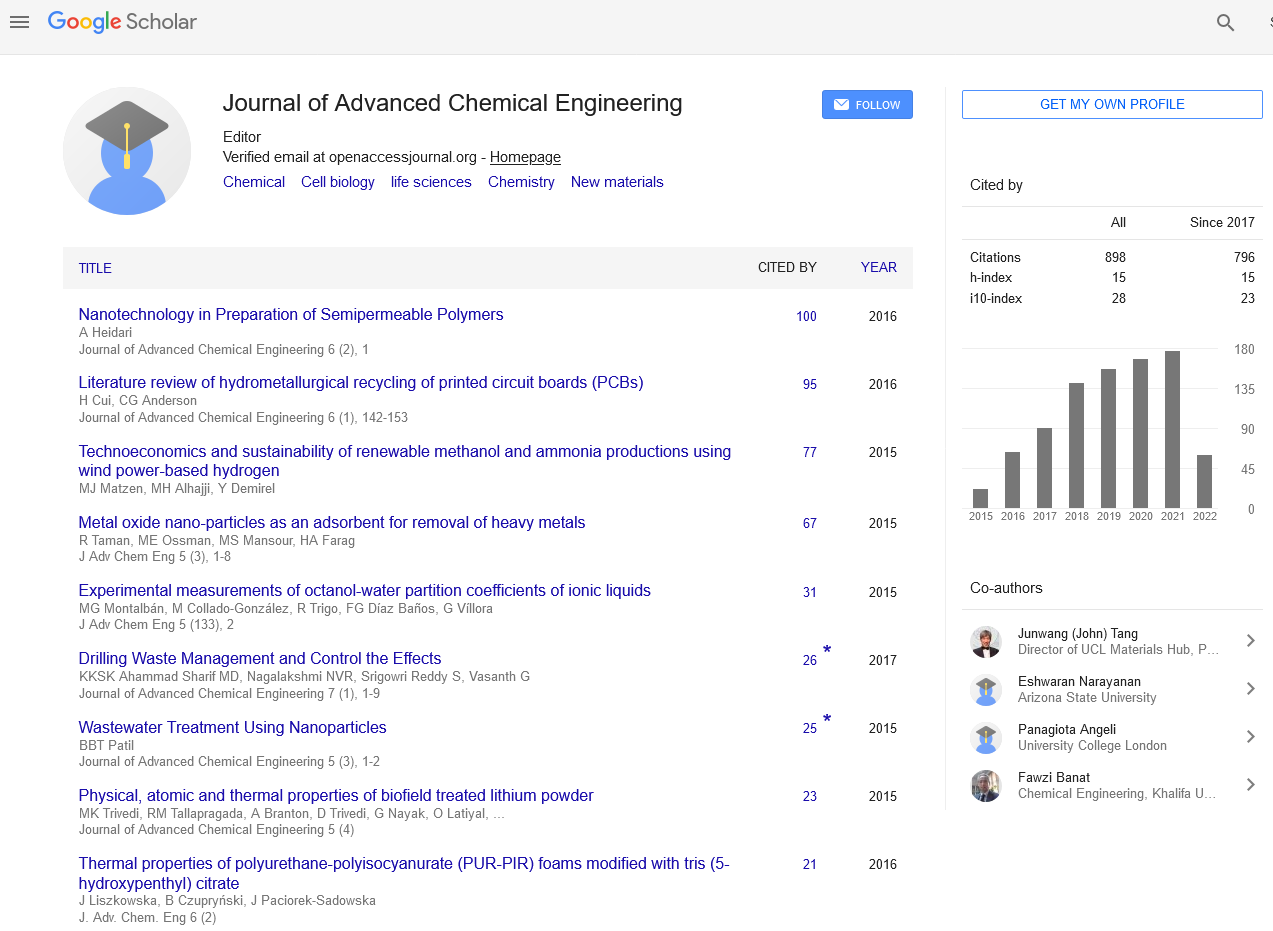

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Amino acids as gas hydrate inhibitors for offshore oil and gas industry

2nd International Conference on Advances in Chemical Engineering and Technology

November 16-17, 2017 | Paris, France

M Fahed Qureshi, Tausif AlTamash, Majeda Khraisheh, Mohammad Ali Saleh and Mert Atilhan

Qatar University, Qatar

Texas A&M University, USA

Scientific Tracks Abstracts: J Adv Chem Eng

Abstract:

Natural gas hydrates are crystalline compounds that are formed under higher pressure and low temperature conditions when small gas molecules like methane and ethane get trapped within the water molecules and form clusters. The formation of these hydrate clusters is a major threat to offshore flow assurance, as they can lead to unwanted blockages in the subsea pipelines and cause safety concerns. So, in order to avoid the risk of hydrate formation, the offshore oil and gas industry heavily relies on the use of thermodynamic hydrate inhibitors (THI) like methanol and mono-ethylene glycol (MEG). These THI does help to mitigate hydrate formation, but they are required in bulk quantity (>30 wt%), are highly flammable and cannot be easily dispose of into the environment. So in order to avoid environmental concerns related to the use of THI, the researchers are looking for hydrate inhibitors that are environmentally friendly, cheap and are required in low dosage. Amino acids are bio molecules containing amine (-NH2) and carboxyl (-COOH) functional groups, that are known to be biodegradable, environmentally friendly, readily available and cheaper than ionic liquids. They are considered to be building blocks of life and are widely used in the manufacturing of pharmaceutical drugs and food products.In this work, the effectiveness of amino acids as the gas hydrate inhibiter has been tested using pure methane gas and the rocking cell assembly (RC-5). The selected amino acids (AA) included: L-Alanine, Glycine, L-Histidine, L-Phenylalanine and L-Asparagine. The experiments were carried out at different AA concentrations (1-5wt %) and within the pressure range of 40-120 bars. The experimental results indicate that the selected AA perform better as a kinetic hydrate inhibitor (KHI) and the addition of synergent compounds like poly-ethylene oxide (PEO) with AA help to improve their kinetic inhibition effectiveness significantly Acknowledgment: Author M Fahed Qureshi would like to acknowledge GSRA. This work was made possible by GSRA # 2-1-0603-14012 from the Qatar National Research Fund (a member of Qatar Foundation). The statements made herein are solely the responsibility of the authors.

Biography :

M Fahed Qureshi.is currently a PhD fellow at Qatar University conducting research on improving effectiveness of low environmental impact gas hydrate inhibitors. He holds MSc degree in Chemical Process Research & Development from University of Leeds UK and has previously worked with Total E& P Qatar in Acid Stimulation project. Currently, he has three publications in the field of gas hydrates and has been awarded Graduate studies research award for his PhD work by Qatar National Research Funds (QNRF). He enjoys writing and is interested in entrepreneurship.