Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

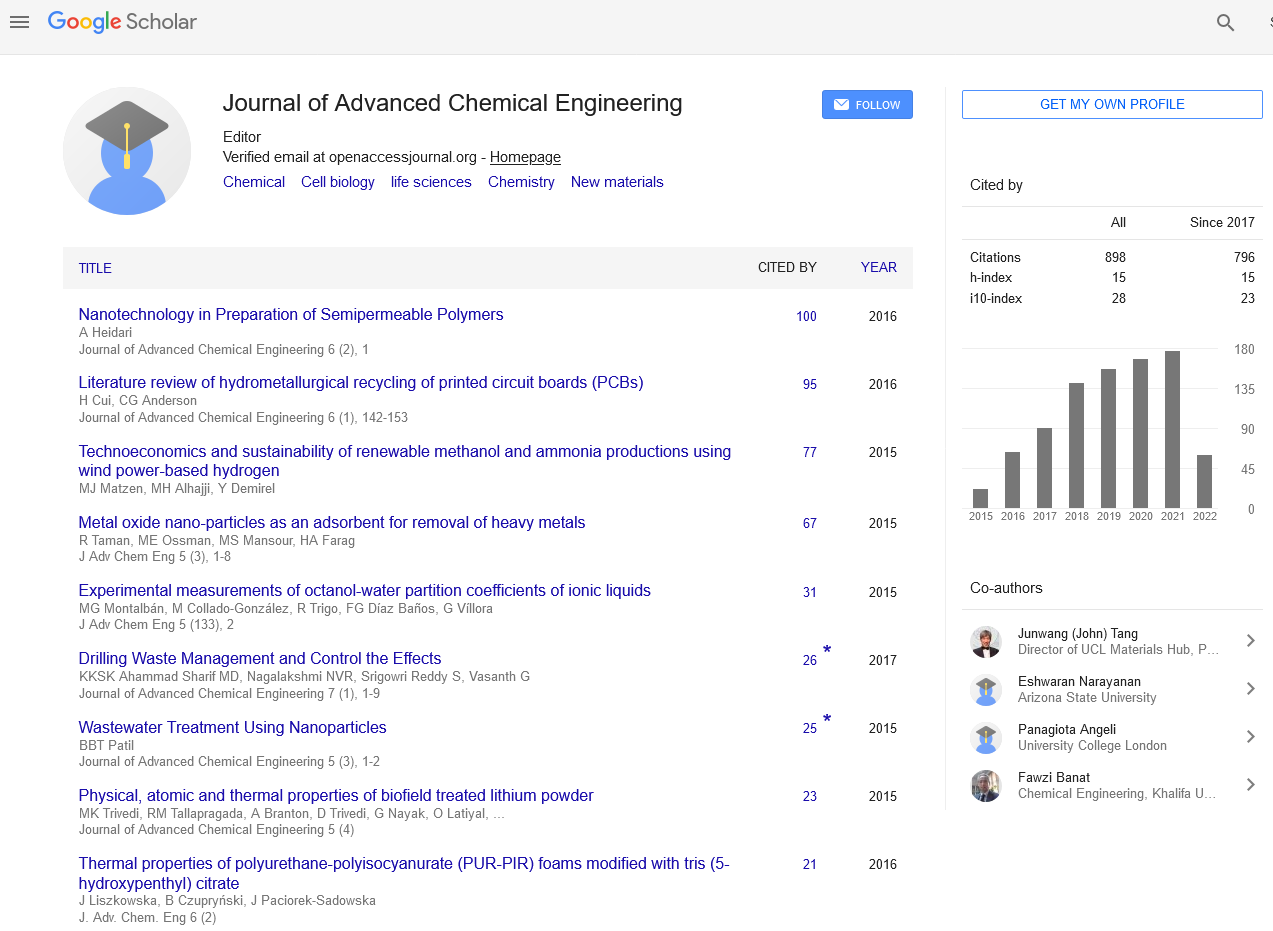

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Foaming in gas sweetening process: Comprehensive experimental efforts lead to better understanding and predication of amine foaming

2nd International Conference on Advances in Chemical Engineering and Technology

November 16-17, 2017 | Paris, France

Emad Alhseinat and Fawzi Banat

Khalifa University, UAE

Petroleum Institute, UAE

Scientific Tracks Abstracts: J Adv Chem Eng

Abstract:

Comprehensive experimental work has been carried out to investigate the foaming behavior of aqueous Methyldiethanolamine (MDEA) in presence of twenty different contaminates including degradation products i.e. N,N,N-tris-(hydroxyethyl) ethylenediamine (THEED), hydroxyethyl ethylenediamine (HEED), N,N/-bis-(hydroxyethyl) piperazine (bHEP), N,Nbis-(2-hydroxyethyl) glycine (bicine), organic acids, and liquid organics. This foaming study was combined with physical characterization of the tested solution to enhance the understanding of the foaming behavior. The foaming tendency of aqueous MDEA solution was reported in terms of foam volume. Foam stability was reported on the basis of the time required for the last bubble to break. The results of this study showed that each contaminate has influenced the foaming behavior either by changing the foam volume or breaking time or both. However, it has been noticed that whatever is the added contaminates to the amine solution it drags the physical properties of the amine to a point where the foaming behavior will be changed. For example, in case of THEED and HEED, the addition of these degradation products increased the foam tendency and stability of the solution as a result of increasing solution viscosity; higher bulk viscosity retards the foam collapse caused by gravity drainage. It is believed that the bottleneck of predicating the foam behavior of any solution would be the predication and monitoring of its physical properties behavior and interaction. We are working now to develop the understating of the interaction between the physical properties and their combined effect on the foaming behavior of the amine solution; this will lead to a breakthrough in foaming monitoring and prediction. Mathematical models on tendency and stability of foaming are presented in this paper to explain the effect of physical properties on foam volume and breaking time of aqueous MDEA solutions.

Biography :

Dr. Alhseinat is currently an Assistant Professor of Chemical Engineering at Khalifa University. Prior to join Khalifa University, Dr. Alhseinat completed his PhD from the University of Edinburgh. Then he worked in Abu Dhabi Petroleum Institute as Research and Teaching Associate; where he was heavily involved in research activity, writing and preparing scientific proposals and presentations, and publishing scientific articles. His current research activities address the development of novel separation processes compatible with renewable energy i.e. Magnetic nanoparticles, Electrical and Magnetic separation technologies, Foaming predication and monitoring, thermodynamics modelling and thermophysical properties characterization, Desalination and Water treatment, and Fouling science.