Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

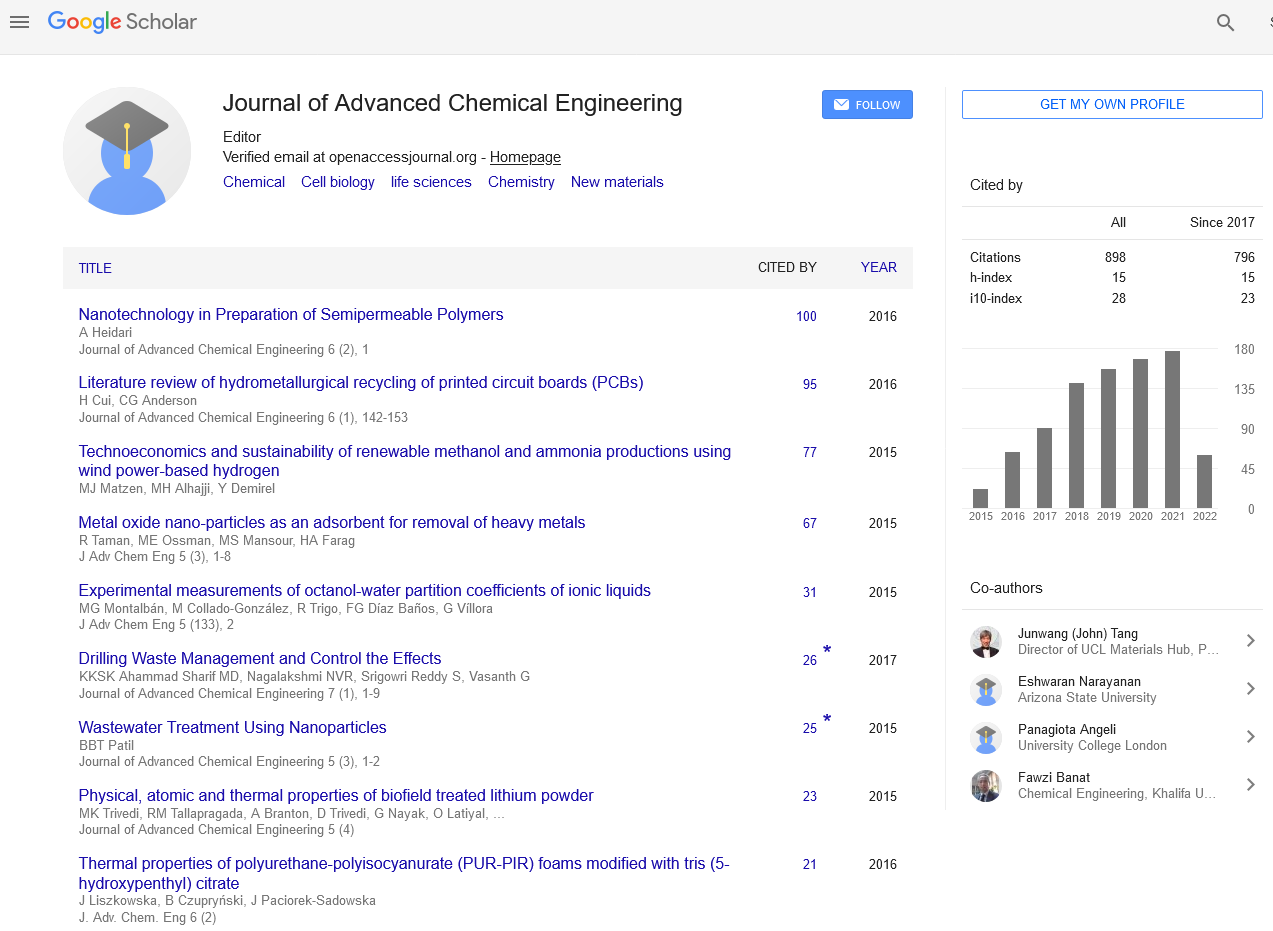

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Lignin phenol formaldehyde resole resin: Synthesis and characteristics

2nd World Congress on Biopolymers

August 04-05, 2016 Manchester, UK

Masoumeh Ghorbani

University of Natural Resources and Life Sciences, Austria

Scientific Tracks Abstracts: J Adv Chem Eng

Abstract:

Lignin has become well-known as a potential substitute for phenol in phenol formaldehyde (PF) adhesives because of their structural similarity. This work reports about a systematic screening of different types of lignin (plant origin and pulping process) for their suitability to replace phenol in phenolic resins. Lignin from different plant sources (softwood, hardwood and grass) were used, as these should differ significantly in their reactivity towards formaldehyde of their reactive phenolic core units. Additionally a possible influence of the pulping process was addressed by using the different types of lignin from soda, kraft, and organosolv process and various lignosulfonates. To determine the influence of lignin on the adhesive performance, beside others, the rate of viscosity development, bond strength development of varying hot pressing time and other thermal properties were investigated. To evaluate the performance of the cured end product, a few selected properties were studied on solid wood-adhesive bond joints, compact panels and plywood. As main results it was found that lignin significantly accelerates the viscosity development in adhesive synthesis. Bonding strength development during curing of adhesives decelerated for all lignin types, whereas this trend was least for pine kraft lignin and spruce sodium lignosulfonate. However, the overall performance of the products prepared with the latter adhesives were able to fulfill main standard requirements, even after exposing the products to harsh environmental conditions. Thus, a potential application can be considered for processes where reactivity is less critical but adhesive cost and product performance is essential.

Biography :

Masoumeh Ghorbani is a PhD student in University of Natural Resources and Life Sciences, Department of Material Sciences and Process Engineering, Vienna, Austria.

Email: marmar.ghorbani@boku.ac.at