Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

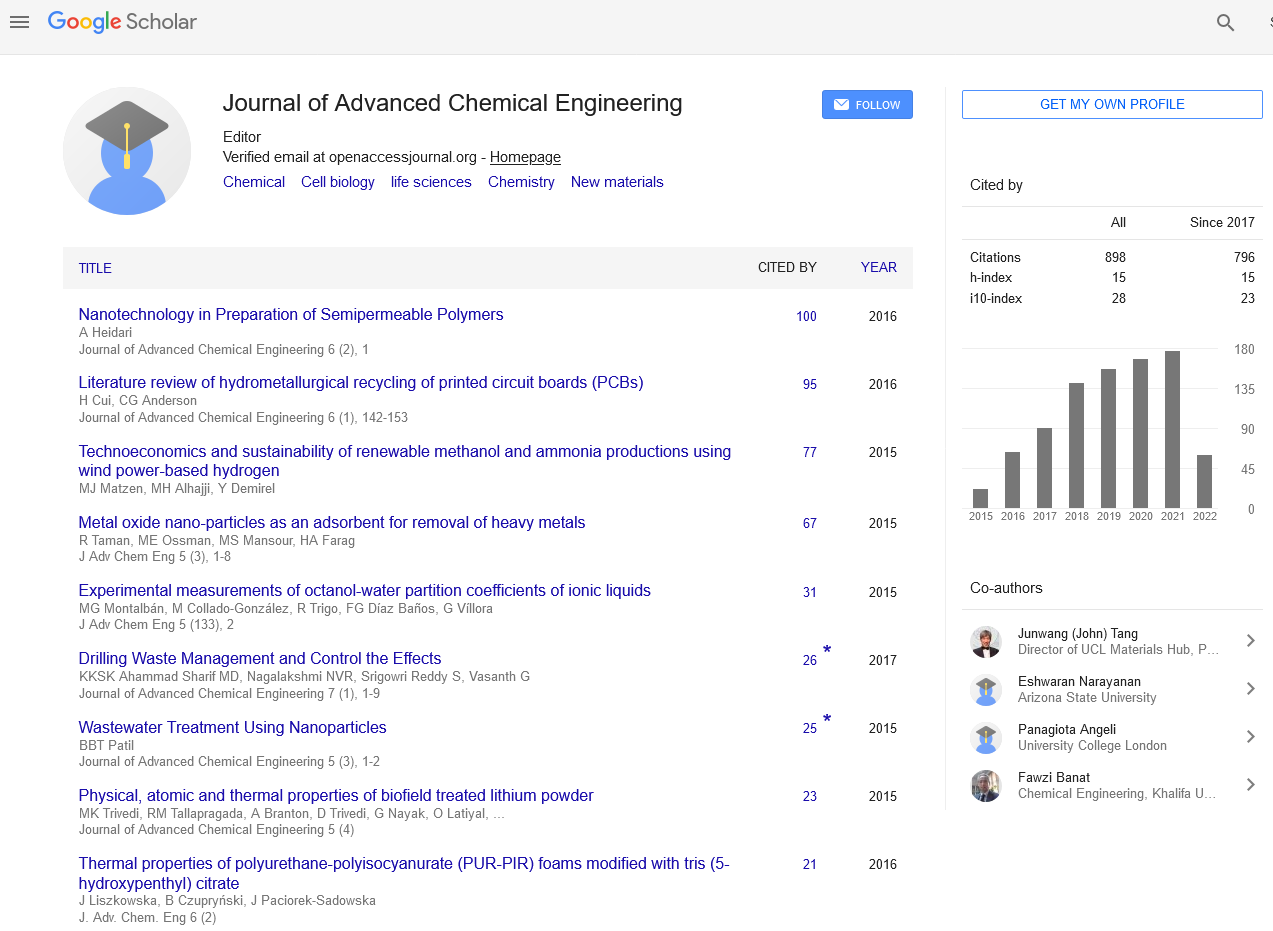

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Pilot scale production of lipopeptide biosurfactant and its application for drilling waste decontamination process

2nd International Conference on Advances in Chemical Engineering and Technology

November 16-17, 2017 | Paris, France

Suwat Soonglerdsongpha, Komkrit Suttiponparnit, Chiratthakan Getwech, Nichakorn Khondee and Ekawan Luepromchai

PTT Research and Technology Institute, Thailand

PTT Exploration and Production Public Company Limited, Thailand

Naresuan University, Thailand

Chulalongkorn University, Thailand

Posters & Accepted Abstracts: J Adv Chem Eng

Abstract:

Lipopeptide is one of the great effective and powerful biosurfactants mostly produced by Bacillus sp. It has been used considerably as alternative to chemical surfactants due to their high surface activity and low toxicity. Both rapid stirring and aeration, are required to supply sufficient quantities of oxygen for Bacillus sp. growth in bioreactor, cause an uncontrollable foaming. The use of chemical anti-foams is not suitable, since they can affect the physiology of the strain and make it difficult to recover the pure products. In our previous work, Bacillus sp. GY19 was immobilized on chitosan to enhance lipopeptide production and prevent foam formation. The aim of this study is to scaling-up the immobilized-cell based lipopeptide production from bench-scale to pilot-scale of 70 and 700 L fermenters. The pilot-scale fermentation results showed a potentially promising bioprocess with high lipopeptide yields of 9.27 g/L without overflow foam problem. Lipopeptide was successfully produced from chitosan-immobilized Bacillus sp. GY19 in pilot-scale fermenters by combining fed-batch fermentation strategy with reducing agitation rate in the larger fermenter. This developed fermentation approach is of great importance for making the process industrially viable in the future. Since oil and gas drilling process produces large amount of solid and hazardous wastes (cutting) which contaminated by high concentration of petroleum hydrocarbon from synthetic based mud, the bio-washing agent was formulated from biosurfactant to remove total petroleum hydrocarbons (TPH) from cutting using bench scale soil washing process as green alternative technology for hazardous waste management.The results showed that total petroleum hydrocarbon (TPH) efficiently removed by formulated biosurfactant up to 70-80%. Moreover, it was found that removal efficiency of TPH was related to the contact time between cutting and biosurfactant in process.

Biography :

Suwat Soonglerdsongpha is a researcher in Environmental Technology Research Department, PTT research and Technology Institute where he has been a member since 2011. He graduated Ph.D. in environmental engineering from The University of Tokyo, Japan in 2010, M.Sc. in environmental management from Chulalongkorn University in 2006, and B.Sc. in environmental resource chemistry from King Mongkut’s Institute of Technology Ladkrabang in 2004. His research interests lie in the area of value added chemicals and materials from petroleum and petrochemical waste utilization and biosensor for environmental and toxicity monitoring. In recent years, he has focused on production and applications of biosurfactant from wastes of biodiesel industries.