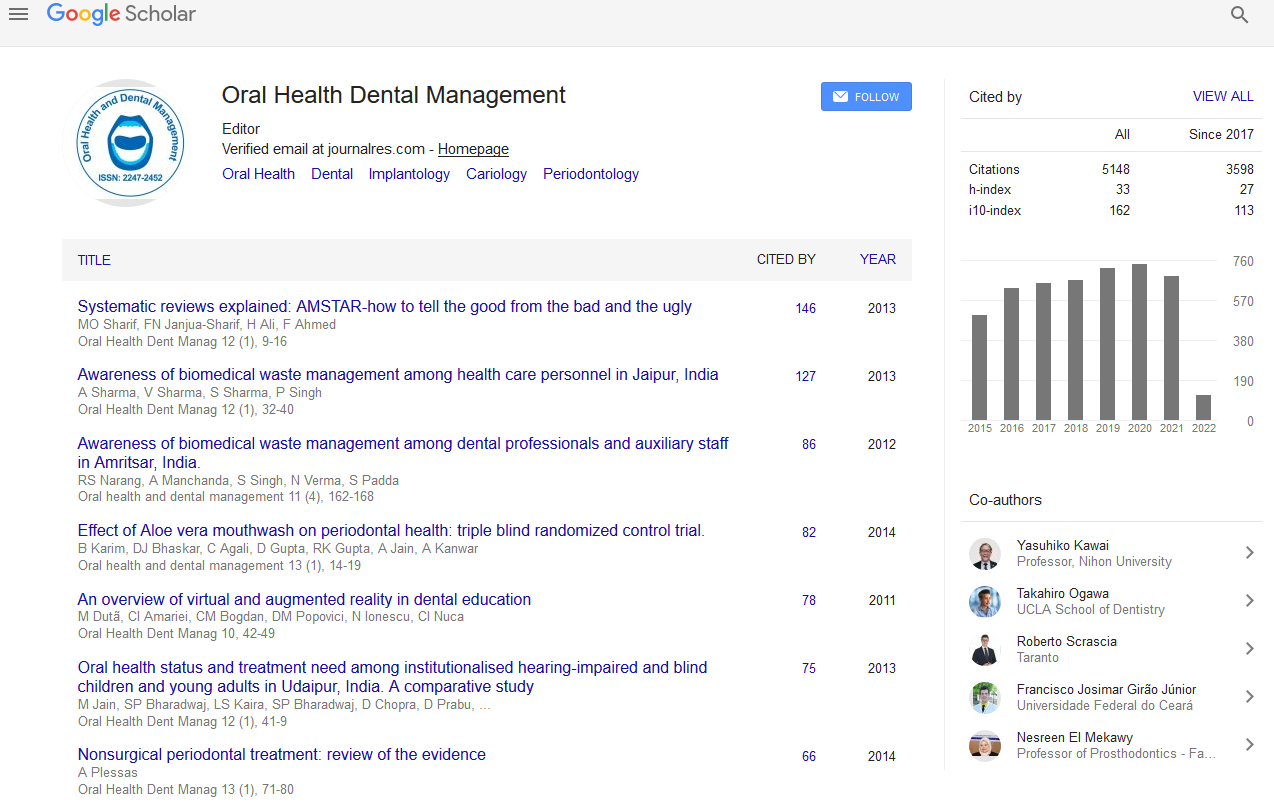

Indexed In

- The Global Impact Factor (GIF)

- CiteFactor

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- Virtual Library of Biology (vifabio)

- International committee of medical journals editors (ICMJE)

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Porous Titanium Implants Fabricated by Powder Metallurgy Technique (Biomechanical and Histological Evaluation)

4th Asia Pacific Congress & Expo on Dental and Oral Health

July 27-29, 2015 Brisbane, Australia

Widad A H Alnakkash and Duha Hussain Mohammed

Baghdad University, Iraq

Posters-Accepted Abstracts: Oral Health Dent Manag

Abstract:

Background: It may be an important prospective clinical use for the manufacturing of porous implants for clinical situations, such as cases of limited available bone height, poor bone quality. The small segment of porous implant allowed an effective osseointegration, due to increased contact area provided by its surface configuration. Objective: Fabrication of porous titanium implants by powder technology, as well as the observation of removal torque values of porous titanium implants compared to smooth titanium implants, and to investigate the biocompatibility of these porous implants. Material and methods: Twenty four porous titanium implants (3.2 mm in diameter and 8 mm in length) were manufactured by powder technology using commercially pure titanium powder of �?�75um particles size, with polyvinyl alcohol powder of 212- 300 um particle size, as a space holder, by volume ratio (70:30)% respectively. The mixed powder was compacted using punch and die set-specially designed for this study�??under 20 bar then sintering at 900�?C by the use of argon gas. Twenty four smooth titanium implants were prepared of (3.2 mm in diameter and 8mm in length) by lathing of commercially pure titanium rod as a control group. The implants were examined by X-ray diffraction (XRD) and also the microstructure was investigated by scanning electron microscope (SEM), as well as estimation of porosity percentage. For each tibia of the 24 white New Zealand rabbits, one implant of each type (one porous in right, and the smooth in left tibia), through surgical procedure was carried under serial condition with antibiotic cover. Mechanical test was performed to evaluate the bone-implant interface, after (2 and 6 weeks) healing periods. The implants were divided as: 40 implants in 20 rabbits (divided into 20 porous and 20 smooth implants) were used for the measurement of torque removal amount required to remove implants from bone. The remaining 4 animals received 8 implants, these four porous and four smooth implants were divided to two groups. 2 rabbits were selected for each histological examination period (2, 6) weeks. Result: Porous implants were obtained successfully by powder technology with 52% porosity and pore size 210±17 um. The porous implant showed significantly higher removal torque values when compared to smooth implants, at two different intervals of examination (2,6 weeks), this proved to be statistically highly significant. Also, a highly significant difference was noticed for the means of the torque removal values in the same group at different implantation period. In addition, histological analysis confirmed new bone formation in contact with implant, as well as improvement of bone in response to porous titanium implants compared to those produced by smooth implants, with no evidence of clinical or histological features of inflammatory reaction with both. Conclusion: Powder technology seemed to be particularly advantageous in fabrication of porous titanium implant with interconnected porous structure with pore size (210±17 um) and 52% porosity. Porous implant shows a biocompatibility and increasing bone ingrowth compared to the smooth type represented by higher removal torque values and supported by histological analysis for both healing periods (2, 6) weeks.

Biography :

Professor Dr. Widad abdul-Hadi Alnakkash is a Prosthodontist, carrying a B.D.S, H.D.D.,M.Sc. Degrees, works as one of the teaching staff at the Prosthodontics Department, College of Dentistry, Baghdad University, Ministry of Higher Education and Scientific Research. Had held the position as the vice head and the Head of the Prosthodontics dept. for several years, participated in more than 80 examining committees for postgraduate students , higher diploma, master, or PhDs as a member or the head of the committee in addition to the supervision of postgraduate students served as an external co-examiner in several universities , had and still a member of the central scientific committee at the college of dentistry in addition to the scientific committee at the prosthodontics dept. ,published many papers in reputed journals with an impact factor, as well as serving as an editorial board member , served as a teaching staff in many other universities in Kurdistan and Yemen.

Email: dr_widdad@yahoo.com