PMC/PubMed Indexed Articles

Indexed In

- Academic Journals Database

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- University Grants Commission

- Geneva Foundation for Medical Education and Research

- Euro Pub

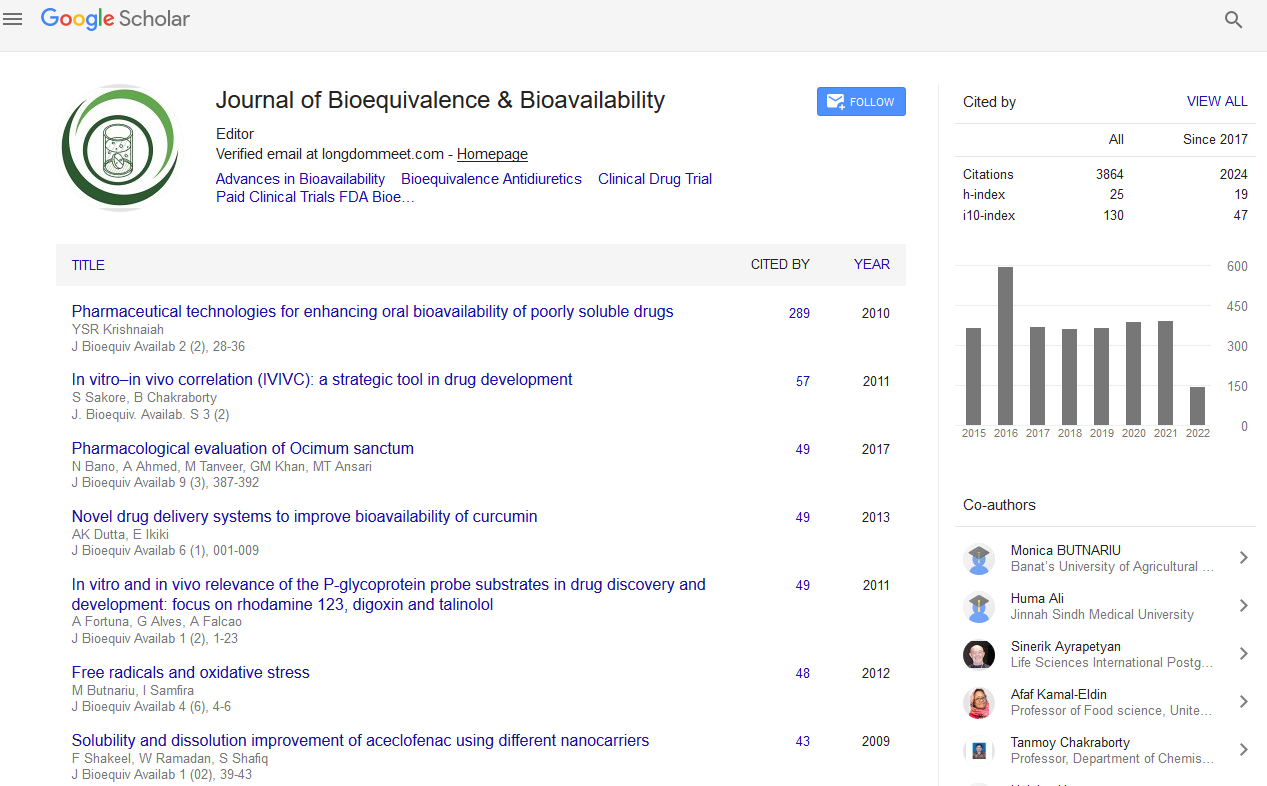

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Product on stopper in a lyophilized biologic drug product: Cosmetic defect or a product quality concern?

Joint Event: 3rd International Conference on Biopharmaceutics and Biologic Drugs & 5th International Pharmacy Conference

August 31-September 01, 2017 Philadelphia, USA

Shyam B Mehta, Cathy Yang and Shouvik Roy

Teva Pharmaceuticals, USA

Scientific Tracks Abstracts: J Bioequiv Availab

Abstract:

Purpose: Despite the popularity and advent of liquid formulations for biological therapeutic products, lyophilized presentations continue to be a robust alternative, especially for products in early stages of development or with in-adequate liquid stability. In this context, there continues to be on-going interest in the pharmaceutical industry about understanding potential failure modes and mitigations for lyophilized products. Here, we present a real life case study of observations of �??product on stopper�?� for a lyophilized product and provide further analysis if this constitutes only a cosmetic/ pharmaceutical elegance issue or can potentially be product quality impacting. The primary failure modes that were the focus of this investigation were potentially improper protein recovery during reconstitution and/or sterility concerns due to container closure integrity compromise. In this context, we also discuss potential mitigations. Methods: Filling of product in vials was carried out using a peristaltic pump filling unit and subsequently the product was lyophilized. Post lyophilization, upon visual inspection, around 40% of vials had cosmetic defect with residual product around stopper of the vial and the remaining 60% vials with no cosmetic defect were called �??acceptable vials�??. Within the product group that had product on stopper, there were different degrees of this event observed. Hence for this evaluation, the lyophilized vials with the worst case product on stopper profiles were evaluated along with �??acceptable vials�?�. Testing performed were protein concentration (UV absorbance at 280), residual moisture (Karl Fischer), sterility (membrane filtration) and container closure integrity (using blue dye ingress). Results & Conclusion: Product quality attributes such as sterility, residual moisture, protein concentration were also similar between the two groups of vials. However, container closure integrity of the �??product on stopper�?? vials was compromised due to the presence of product around stopper of the vial. The results of this study provides two important findings- 1) Defects such as �??product on stopper�?� under certain worst case conditions may pose product quality concerns and not just cosmetic quality concerns, and 2) Container closure integrity test methods may be more sensitive in such cases compared to sterility, which also explains the regulatory agencies preference for this method for assessing sterility assurance. As an outcome of this investigation, the following corrective actions were implemented for this case: use of larger sized vial that can potentially mitigate the product handling issues.

Biography :

Shyam B Mehta is a PhD student in Pharmaceutical Sciences with expertise in areas specific to biologic drugs. His work focuses on drug product development, fill-finish manufacturing of drug product, formulation development including protein stability and biophysical characterization of protein molecules.