Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

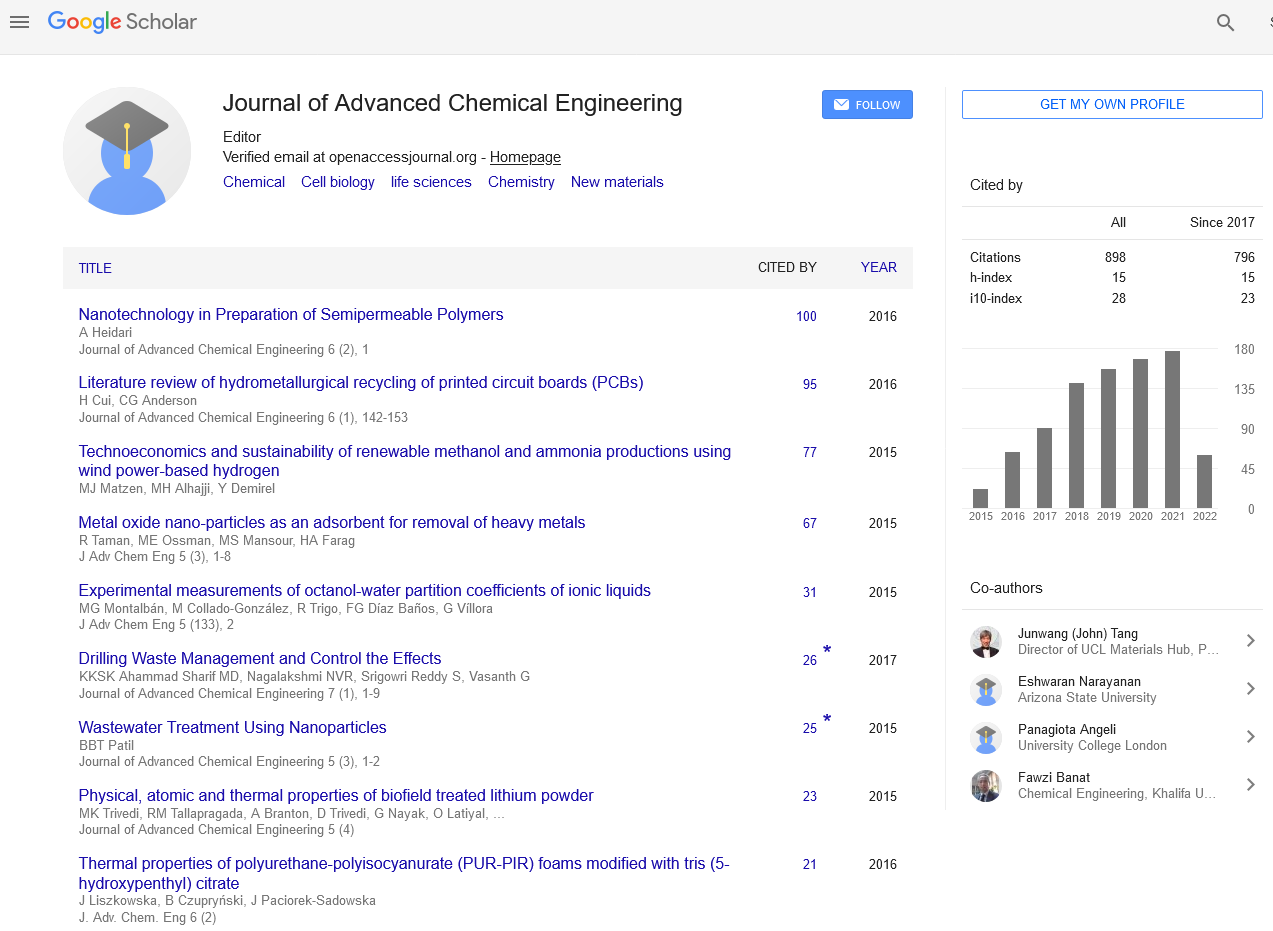

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Radiation processed textile sludge for preparing eco-friendly bricks

2nd World Congress on Biopolymers

August 04-05, 2016 Manchester, UK

Mubarak Ahmad Khan

Bangladesh Atomic Energy Commission, Bangladesh

Keynote: J Adv Chem Eng

Abstract:

Textile mill, the largest revenue earning industry in Bangladesh is facing problem with the disposal of its solid waste (sludge). In this study, textile sludge is detoxified with gamma irradiation (15 kGy) and then used to make environmental friendly bricks for construction purposes. Bricks were graded based on the sludge and clay content ratio. Sludge was mixed with clay and bricks were made in wooden frame. Dried brick samples were then kept at 450°C for 24 hours in furnace. Controlling the temperature allowed us to produce the brick without producing any NOx. Parameters such as density (g/cm³), weight loss (%), firing shrinkage (%), bending strength (MPa), Bending modules (MPa), impact strength (kJ/m²), water uptake (%) and electrical resistivity (Ω-m) were investigated. Density, weight loss, firing shrinkage and electrical resistivity reduced as sludge content (%) in bricks increased whereas bending strength, Bending modules, Impact strength and water uptake (%) increased with the increase of sludge content. The optimum results were found for the 50-50% sludge/clay samples. Further increase in the sludge percentage led to loss of strength and compactness of the brick sample. According to the results, the optimum sample showed higher strength than the sample made by pure clay; but showed slightly lower strength than the commercial brick. The change in density of all bricks was experienced during the aging tests in water, acid, alkali and salt. BS, BM, IS were also tested for water and acid aging. Morphological analysis of the brick samples were done by metallurgical inverted microscope.

Biography :

Mubarak Ahmad Khan is Chief Scientific Officer (CSO) and Director General, Atomic Energy Research Establishment, Bangladesh Atomic Energy Commission. He did his PhD in Radiation and Polymer Chemistry. He is working in several promising areas of radiation chemistry and processing technology, natural fiber reinforced polymer composites, nanotechnology, material science, biomedical science, applied science, etc. He has conducted research works in many countries including America, Germany, Japan, etc. He has worked in Germany (Technical University of Berlin, Fraunhofer Institute of Applied Polymer Research) as DAAD and Alexander von Humboldt (AvH) fellow, in Japan as MIF Fellow, as visiting Scientist in Australia (University of New South Wells) as IAEA fellow. He is trained in Nuclear and Radiation Chemistry through various training course organized by IAEA. He is a part time Professor of Dhaka University, and visiting Professor and Examiner of various universities of Bangladesh. He is author/co-author of about 600 publications including 16 book chapters and a patent. He has served as project director/co-project director of different national and international scientific project on polymer science. He has invented advanced wound dressing material from cow bone, liquid bio-fertilizer from textile effluent, natural plant growth promoter from prawn shell, etc. He is also the inventor of Jutin (Jute Reinforced Polymer Corrugated Sheet) the outstanding housing material from jute plastic composite and food preservative using oligo chitosan (alternative to the formalin). He is awarded several national and international awards including Bangladesh Academy of Science Gold Medal awards 2010 for his remarkable contribution to scientific community. He is also selected as fellow of International Union of Pure and Applied Chemistry (IUPAC). His name was published in Who’s Who in World in 1998. He visited more than 22 countries for participating different seminars, workshops, symposiums, conferences as invited speaker or speaker.

Email: makhan.inst@gmail.com