Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

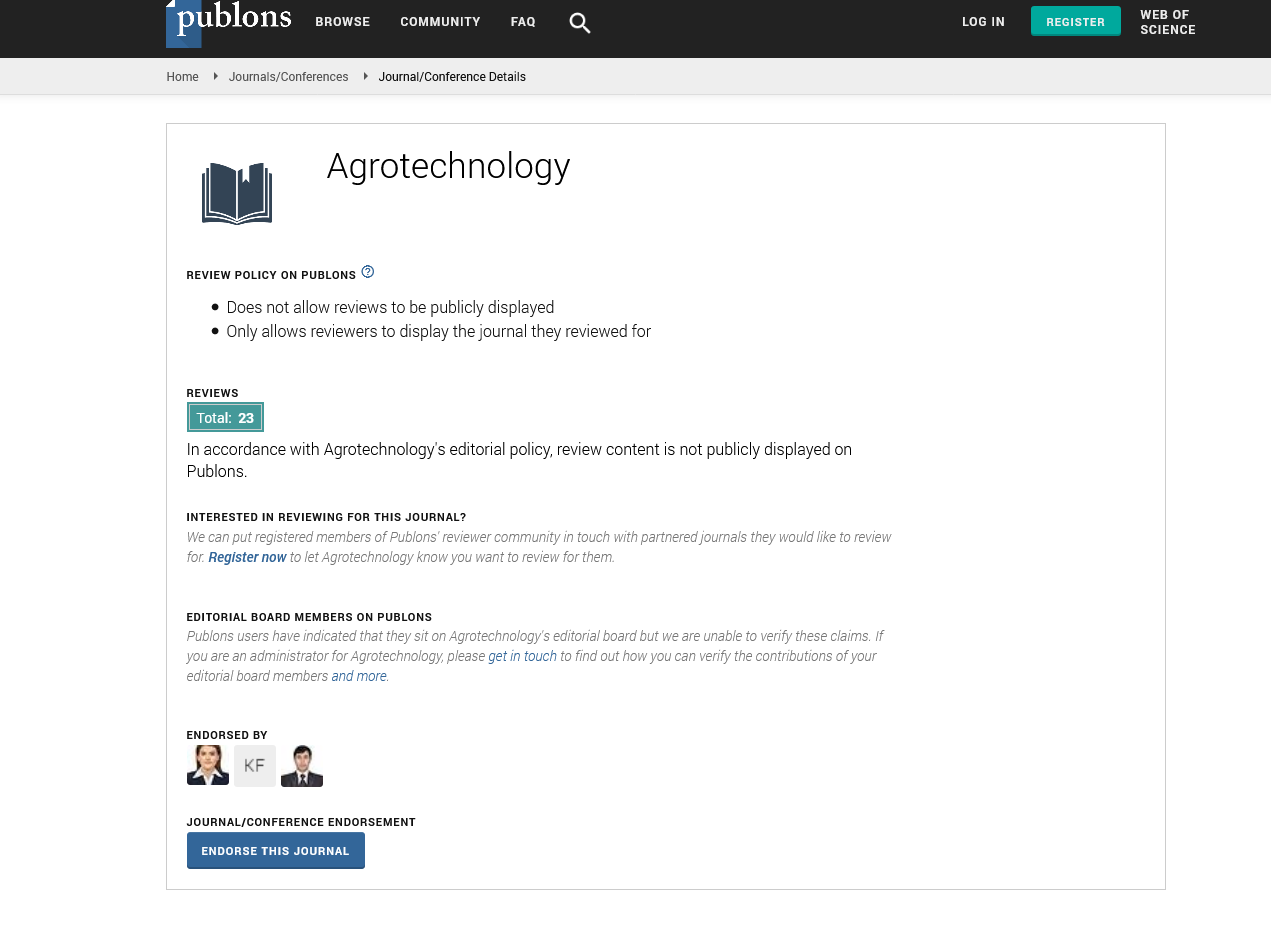

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

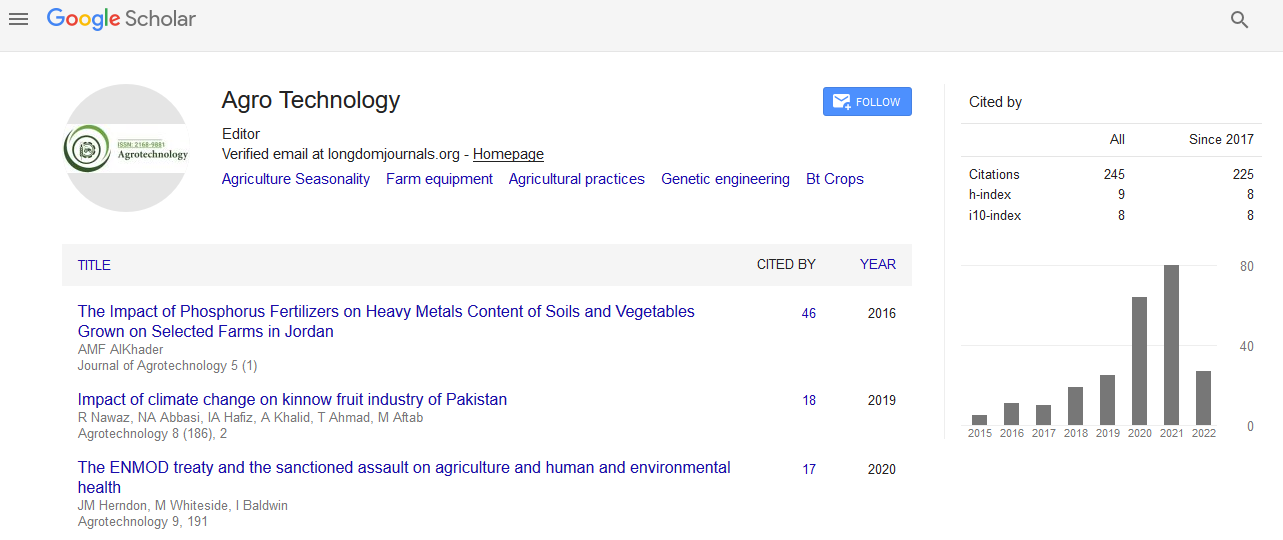

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Studies on papads based on blends of Banana with URD and rice flour

3rd International Conference on Agriculture & Horticulture

October 27-29, 2014 Hyderabad International Convention Centre, India

K Venkata Subbaiah, S L Jagadeesh and R Manjula

Posters: Agrotechnol

Abstract:

Being a climacteric fruit, bananas are kept well for not more than a week after harvest and get deteriorated in one or two days after ripening due to rapid metabolism and it is one of the most nutritious and oldest cultivated tropical fruits and the second important fruit next to mango. Under these circumstances, the crop demands development of shelf stable products. Papad is an important food adjunct among several indigenous traditional savoury preparations are being manufactured and extensively consumed in India. Papads were prepared from steamed pulp of healthy, matured, unripe bananas of three varieties (Grand Naine, Yangambi KM-5 and Monthan) with papad masala (10 g per kg of pulp) and with or without urd flour (25%) or rice flour (25%). The paste prepared after steaming was rolled into balls of uniform size and pressed with the help of papad press. The sun dried papads were packed in 200 guage polyethylene bags and stored in a cool and dry place. The physical, frying, biochemical and sensory quality parameters of papads were studied. Papads of T4 (Sulphur fumigation banana without peel @ 2g/kg of for 30 min + steaming + grinding with papad masala @ 10g/kg pulp + 25% Urd powder + pressing + drying) made from Monthan showed the highest recovery (62.13%) and papads of T3 (Banana with peel + steaming + grinding with papad masala (10g/kg pulp) + 25% Urd powder + pressing + drying) made from Yangambi KM-5 showed the lowest moisture (3.21%). With respect to frying characteristic, papads of T7 (Sulphur fumigation of (2g/kg) of banana without peel for 30 min + steaming + grinding with papad masala (10g/kg pulp) + pressing + drying ) made from Grand Naine showed the lowest oil uptake (9.15%) and highest expansion (30.11%). The highest total sugars (18.76%), reducing sugars (7.79%) and nonreducing sugars (10.43%) were found in papads of T7 made from the variety Grand Naine. With respect to sensory quality, the maximum score for texture, taste, flavour and overall acceptability was recorded in papads of T4 made from Grand Naine, whereas maximum score for colour and appearance was observed in papad of T7 made from Monthan.