Volume 9

Journal of Bioremediation & Biodegradation

ISSN: 2155-6199

Biofuel Congress 2018 &

Biomass 2018

September 04-06, 2018

Page 40

conference

series

.com

JOINT EVENT

September 04-06, 2018 | Zurich, Switzerland

13

th

Global Summit and Expo on

Biomass and Bioenergy

&

12

th

World Congress on

Biofuels and Bioenergy

Vinay Sharma, J Bioremediat Biodegrad 2018, Volume 9

DOI: 10.4172/2155-6199-C1-013

Development of efficient bioprocesses for improved bioethanol production from a mixture of food

wastes

L

ignocellulosic bioethanol production now-a-days is gaining increasing interest due to global warming, hike in oil price etc.

But there are several technological and other challenges associated with bioethanol production. Technological challenges are

development of efficient pretreatment step which can significantly degrade lignin without altering carbohydrates, efficient hydrolysis

step and development of fermentation step which can utilize both pentose and hexose sugars. The present study has focused on

bioprocess development for bioethanol production from a mixture of food wastes (spinach, cabbage, peels of onion and orange). First

liquid hot water (LHW) pretreatment of food waste was optimized by varying different parameters (temperature, incubation time

and substrate concentration). Maximum reducing sugar yield (525.60 mg/gram dry substrate) was found at substrate concentration

10% (w/v), temperature 160

o

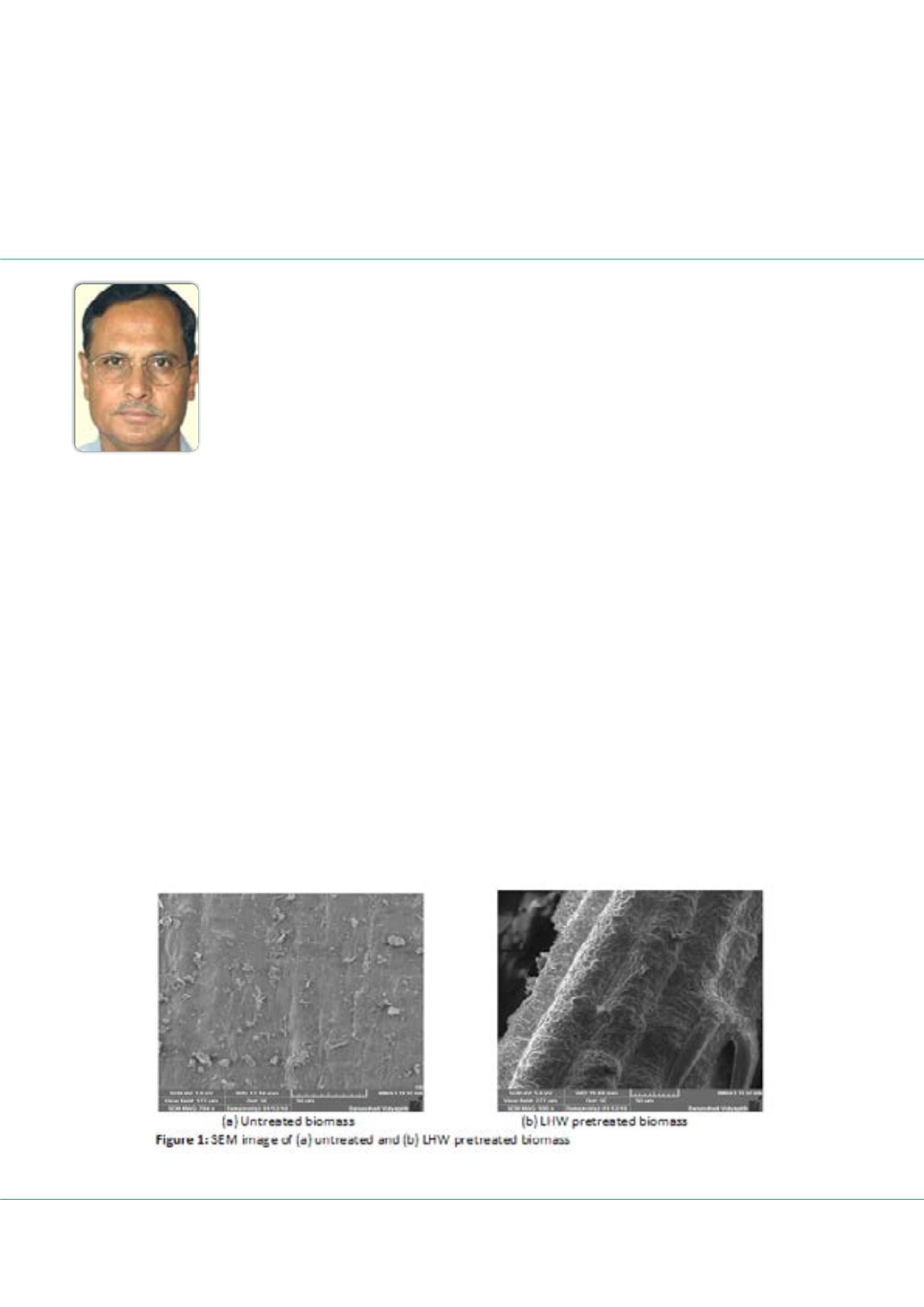

C and incubation time 30 min. After optimization, LHW pretreated biomass was characterized using

Fourier transformed infrared spectroscopy (FTIR), X-ray diffraction (XRD), Scanning electron microscopy (SEM) and biochemical

composition analysis. Further, pretreated biomass was hydrolysed using whole cells of

Fusarium incarnatum

KU377454 (locally

isolated strain) without addition of any enzymes. It showed maximum reducing sugar yield of 580.95 mg/gram dry substrate) within

3 days of incubation at 30

o

C. The produced sugar hydrolysate was further fermented using co-cultures of hexose fermenting strain

(

Sacchromyces cerevisiae

) and pentose fermenting strain (

F. oxysporum

). Maximum ethanol production (3.25%, v/v) was observed

after 48 h of incubation at 35

o

C. The present study, reports development of efficient thermal pretreatment without addition of any

chemicals. Further carbohydrates, part of pretreated biomass were converted into reducing sugars by whole fungal strain without the

use of any costly chemicals. Lastly, fermentation process was optimized using co-culture strategy which yielded maximum ethanol

from both pentose and hexose sugars. This study can be useful for commercial bioethanol production from food waste.

Vinay Sharma

Banasthali University, India