Page 47

Notes:

conferenceseries

.com

Volume 8, Issue 5 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN: 2155-6199

Biofuels Congress 2017

September 05-06, 2017

September 05-06, 2017 | London, UK

Biofuels and Bioenergy

6

th

World Congress on

SOFC CCHP – treating biogas for the use in a SOFC-system

Christof Weinlaender

1

, Raphael Neubauer

1

, Martin Hauth

2

and

Christoph Hochenauer

1

1

Insitute of Thermal Engineering, Austria

2

AVL, Austria

A

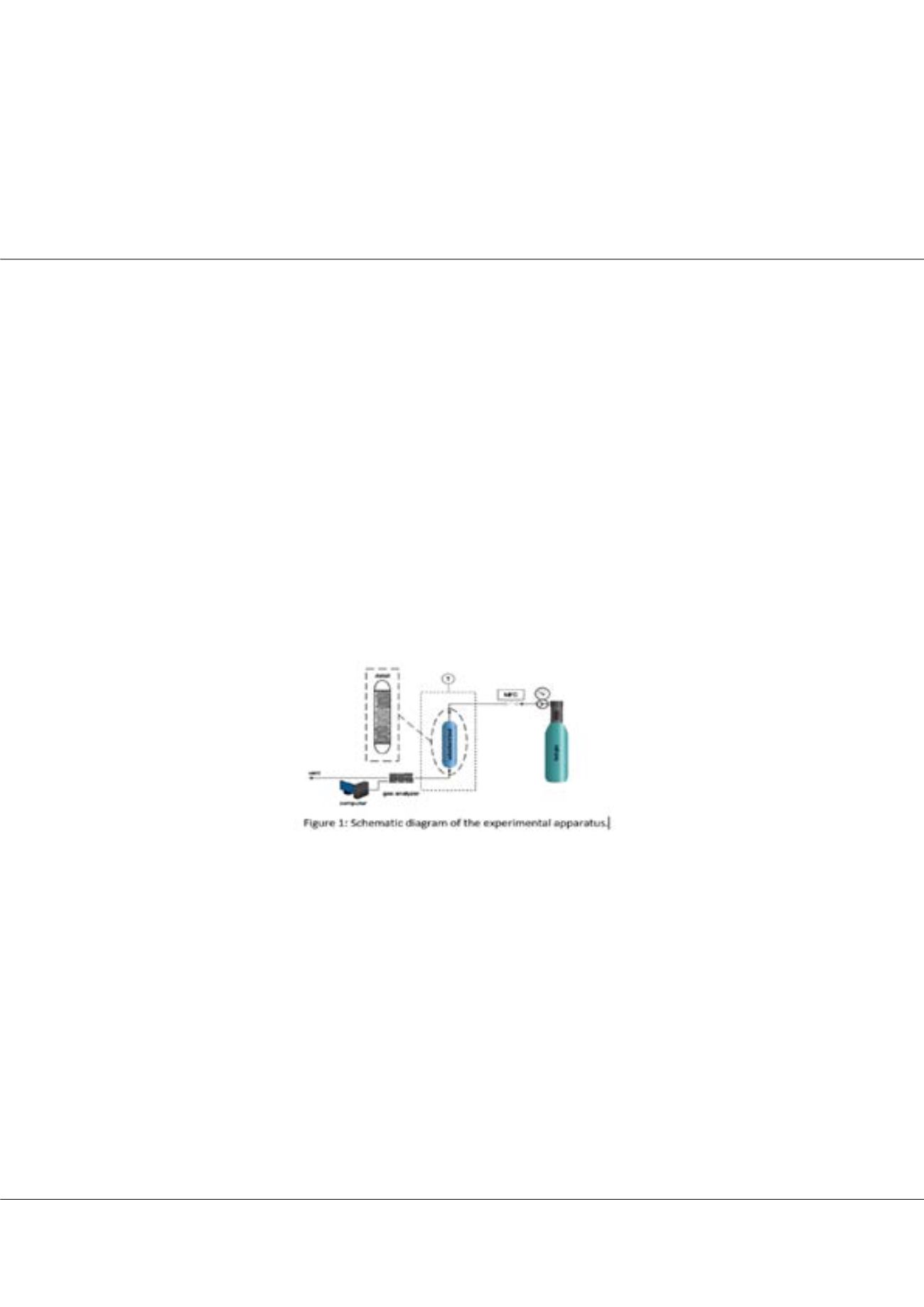

SOFC CCHP system (Combined Cooling, Heat and Power) using renewable energy sources (biogas, sewage gas, landfill gas)

will be developed to achieve high efficiencies. While electrical power will be produced at very high efficiencies using a SOFC

(Solid Oxide Fuel Cell), the energy of the hot exhaust gas will be used to operate an absorption chiller system which provides a low

temperature coolant and its waste heat can be used for heating.The combined system allows the utilization of various renewable energy

sources and a high annual efficiency. Depending on the utilized fuel, which will be converted in the SOFC, different requirements

for the gas cleaning unit have to be taken into account. Due to the planned multi fuel ability of the system, an overall concept for

the gas cleaning and gas processing unit must be developed to achieve a high degree of standardization. The desulfurization of

biogas is essential for the successful operation of SOFCs. H

2

S is one of the main components in biogas. In order to feed a solid oxide

fuel cell, the contaminated gas has to be reduced to a certain degree. In this work, different parameters onto the desulfurization

performance of commercially available desulfurization adsorbents were investigated. H

2

S removal efficiency was monitored under

various operating conditions such as different temperatures, space velocities and inlet concentrations. The experience obtained from

these tests provides fundamental knowledge for further development activities for such systems. This includes the determination of

the useful power range for a product, the real dynamic of the system, the suitability of different fuels and their influence on the system

performance as well as potentials for process simplifications and useful data for adsorption tower design and process optimization.

Biography

Christof Weinlaender studied Chemical Engineering at Graz University of Technology, Austria. In 2014, he finished his Master’s thesis about liquid-liquid extraction

at the Department of Chemical Engineering at Graz University of Technology. Since 2014, he is working at the Department of Thermal Engineering at Graz

University of Technology as Assistant Project Scientist. Key areas of his interest are biofuels, adsorption processes and solid oxide fuel cells.

christof.weinlaender@tugraz.atChristof Weinlaender et al., J Bioremediat Biodegrad 2017, 8:5(Suppl)

DOI: 10.4172/2155-6199-C1-008