Page 43

conference

series

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

Recent advances in bacterial nanocellulose for different applications

S

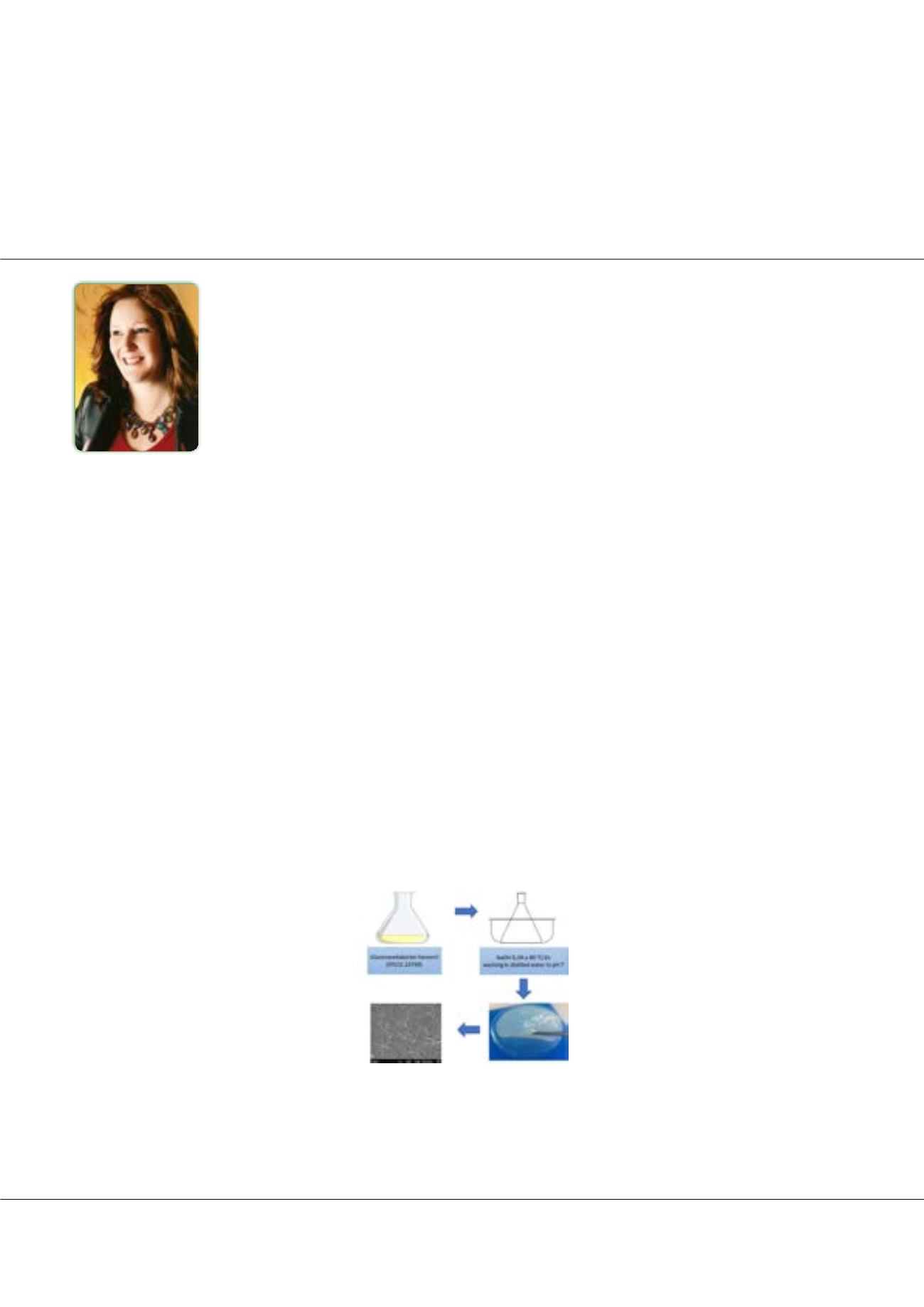

The last years of advances in research have demonstrated the importance and potential of biopolymers for a variety of

applications, particularly for biopolymers produced by microorganisms, including bacterial nanocellulose (BNC). These

polymers can be biosynthesized by bacteria of some genera, but the most efficient producers of cellulose belong to the genus

Gluconacetobacter, that secrets an abundant 3-D network of cellulose fibrils. There are two main methods for producing

BNC: static culture, which results in the accumulation of a thick, leather-like white BNC pellicle at the air-liquid interface,

and stirred culture, in which cellulose is synthesized in a dispersed manner in the culture medium, forming irregular pellets.

BNC can also be synthesized from a variety of substrates such as glucose, sucrose, fructose, glycerol, mannitol, among others.

In this way it is possible to modify and control the physical properties of the cellulose during its biosynthesis. Factors such as

yield, morphology, structure, and physical properties may be affected by the method of production and culture medium used.

The thickness, color and transparency of the membrane can be controlled by means of the culture time of the bacterium. The

BNC appears as a competitive alternative, having as main characteristics: high crystallinity, high tensile strength, elasticity,

durability, hydrophilic potential (retention capacity and water absorption - about 98% to 99% of its volume is composed

of liquids). In the food industry, it is used in the production of coconut cream, ice cream, snacks, sweets, stabilizers for

emulsions and foams. In the cosmetics industry BCN is used as moisturizers and astringents. BNC is also used as an additive

of high quality papers, membranes for high quality audio devices, electronic papers (e-papers), diaphragms for eletroacustic

transducers, liquid crystal displays, OLED support, ultrafiltration membranes (water purification) and membranes for mineral

oil recovery. In the biomedical area BCN is suitable for tissue regeneration, drug delivery systems, vascular grafts, scaffolds for

tissue engineering, artificial blood vessels and microvessels, artificial vascular implant, dental implants, artificial skin, dressing

for wounds and burns, allowing the transfer of medications to the wound while serving as an effective physical barrier against

external infection. In the materials area NCB whiskers can also be used as reinforcement in nanocomposites.

Biography

Ana Paula Testa Pezzin. Graduated in Chemistry, Master in Chemical Engineering and PhD in Mechanical Engineering from the State University of Campinas.

She did postdoctoral studies at the Université Pierre et Marie Curie in Paris / France. She has been a leader in the POLYMERIC MATERIALS GROUP since 2001,

working in research lines: Polymeric biomaterials for medical and dental applications; Composites, biocomposites, nanocomposites and bionanocomposites;

Modification of biopolymers for different applications and synthesis and characterization of biopolymers by microbial culture. Currently, she is a Professor and

Researcher at the University of Joinville Region (UNIVILLE), being a level 2 productivity fellow at CNPq.

anapezzin@yahoo.com.brAna Paula Testa Pezzin

University of Joinville Region (UNIVILLE), Brazil

Ana Paula Testa Pezzin, J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-010