Volume 6, Issue 4 (Suppl)

J Material Sci Eng, an open access journal

ISSN: 2169-0022

Materials Congress 2017

June 12-14, 2017

Page 62

conference

series

.com

June 12-14, 2017 Rome, Italy

Materials Science and Engineering

9

th

World Congress on

Gilbert Daniel Nessim, J Material Sci Eng 2017, 6:4(Suppl)

DOI: 10.4172/2169-0022-C1-066

Gilbert Daniel Nessim

Bar Ilan University, Israel

Towards the growth of 3D forests of carbon nanotubes: Selective height control using reservoirs and overlayers

D

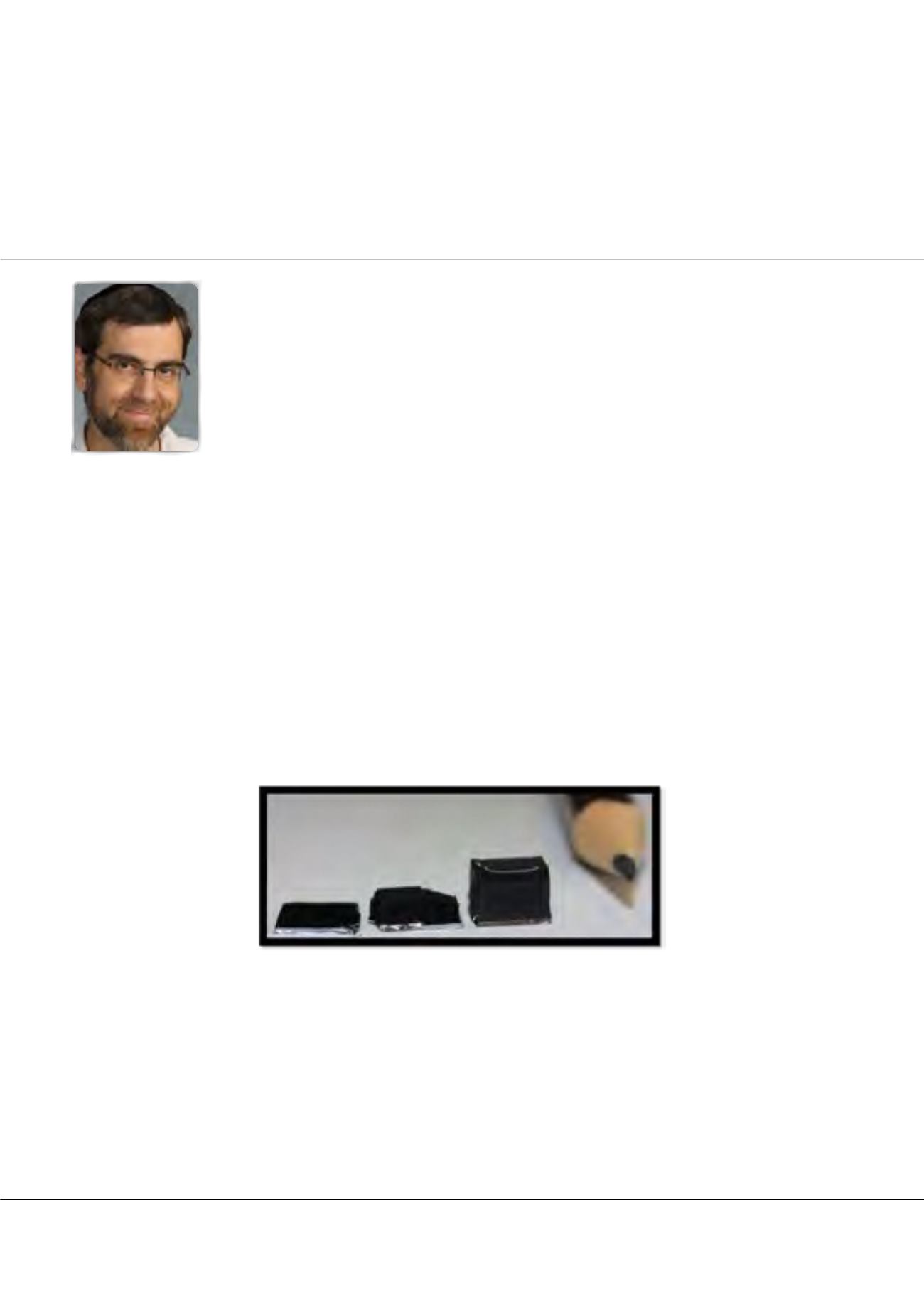

espite the massive progress achieved in the growth of carbon nanotube (CNT) forests on substrate, besides lithographic patterning of

the catalyst, little has been done to selectively (locally) control CNT height. Varying process parameters, gases, catalysts, or overlayer

materials uniformly affects CNT height over the whole substrate surface. We will show here how we can locally control CNT height, from

no CNTs to up to 4X the nominal CNT height from iron catalyst on alumina underlayer by patterning reservoirs or by using overlayers

during annealing or growth. We pioneered the concept of reservoir showing how an iron thin film reservoir placed below the alumina

underlayer almost doubles CNT height and how a copper/silver thin film reservoir deactivates the iron catalyst placed above it. We will also

show how different thin film reservoir materials can enhance CNT growth by a factor of 4X. We also pioneered the concept of overlayer,

where a copper stencil or bridge placed above the catalyst surface during pre-annealing or during CNT growth deactivates the catalyst. We

showed how we could pattern regions with CNTs and without CNTs by simply annealing the sample with a patterned overlayer positioned

above its surface. Using nickel overlayers, we obtained a similar result but with a completely different mechanism. We thus synthesized

patterned CNT forests using a simple process, without the need for lithography. We can now combine the overlayer technique with one of

the above-mentioned reservoirs (no reservoir, Cu/Ag reservoir, or Fe reservoir) to further modulate CNT growth by offsetting some or all

of the growth enhancements achieved using the reservoirs. This modulation of the CNT height is a significant improvement compared to

the "CNTs (one height)/no CNTs" patterning that has been achieved using lithography of the catalyst, and moves us closer to building 3D

architectures of CNTs.

Biography

Gilbert Daniel Nessim heads a laboratory at Bar Ilan University (Israel) that focuses on the synthesis of nanostructures using state-of-the-art chemical vapor deposition

equipment. The scientific focus is to better understand the complex growth mechanisms of these nanostructures, to possibly functionalize them to tune their properties,

and to integrate them into innovative devices. He joined the Faculty of Chemistry at Bar Ilan University in 2010 as a Lecturer and was promoted to a Senior Lecturer in

2014. He holds a PhD in Materials Science and Engineering from the Massachusetts Institute of Technology (MIT), an MBA from INSEAD (France), and Master’s degree

in Electrical Engineering from the Politecnico di Milano and from the Ecole Centrale Paris (ECP, within the Erasmus/TIME program).

gdnessim@biu.ac.il