Page 52

Notes:

conferenceseries

.com

Volume 8, Issue 4 (Suppl)

J Pet Environ Biotechnol, an open access journal

ISSN: 2157-7463

Oil Gas Expo 2017

July 13-14, 2017

Oil and Gas

July 13-14, 2017 Berlin, Germany

3

rd

International Conference and Expo on

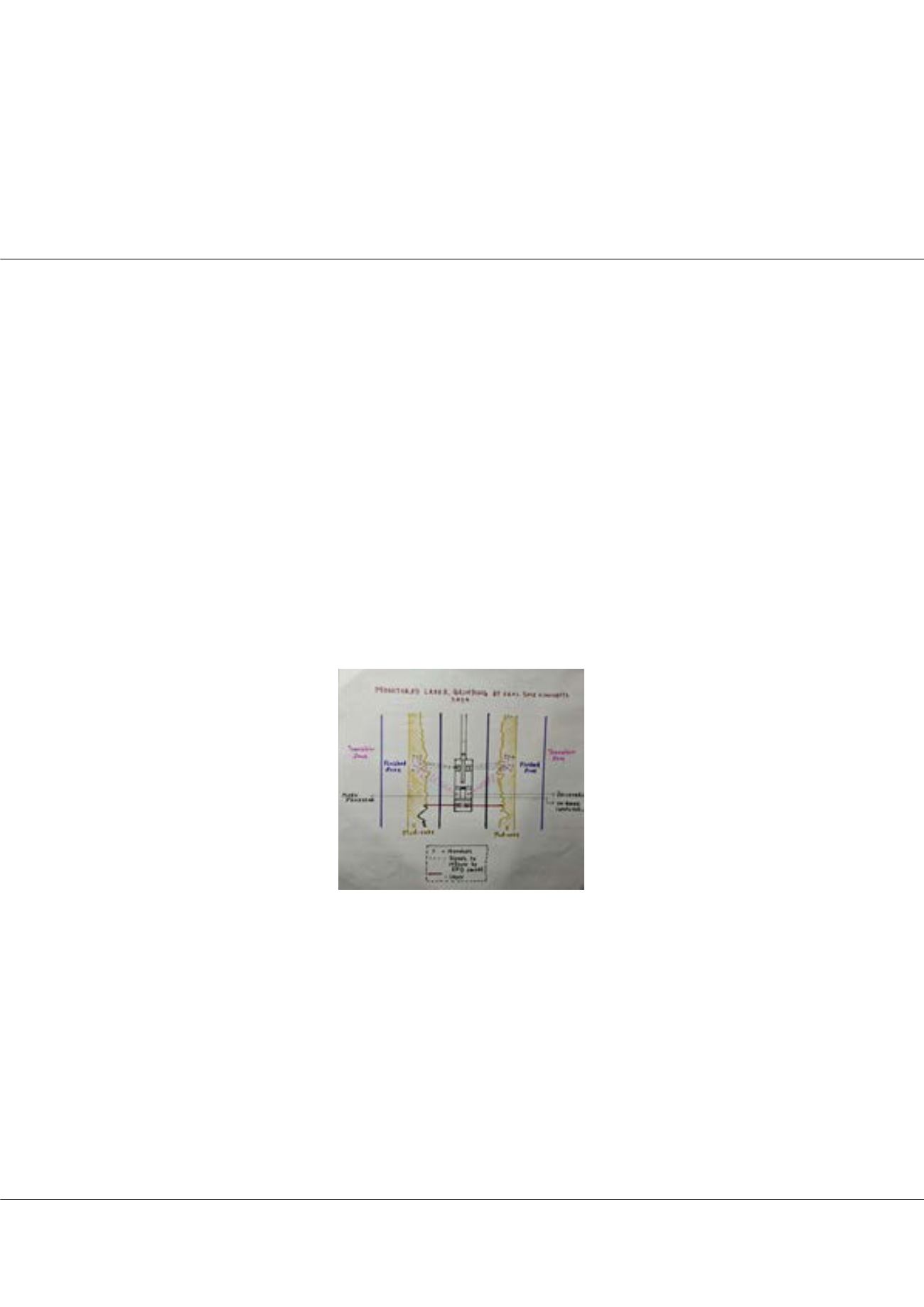

Monitored laser grinding by real time nanobots data: A novel mud cake removal approach

Mohit Jhirwal, Dhruvin Kaneria

and

Tirth Raval

Pandit Deendayal Petroleum University, India

F

or ensuring casing and cementing quality, mud cake removal is essential. Various problems like stuck pipe take place because of

the presence of mud cake. Mechanical methods of water jetting and chemical methods by means of acids, oxidizers, chelating

agents and enzymes are currently employed for mud cake removal. However, water jetting can cause water blockage problems. Also,

mud cakes of different permeability will be removed unevenly by same intensity water jets. Acids and oxidizers are very reactive

but non-specific species, imposing several post perforation problems and formation damage. As an alternative, we propose a new

method/device in this study with the usage of nanobots and laser grinding. The nanobots, placed in carrier, can be sent through

drill string into the drill bit from where they can be deployed in all directions into the targeted zone. These non-adherent and self-

propelled nanobots will move through the vertical permeability of the mud filtrate and would interpret the petro physical properties

of the mud filtrate. The sensors would then send this data to molecular processor and with the help of radio frequency transmitter

and receiver; we could immediately interpret the real time data from every point in the wellbore. This data would be used to change

the intensity of the lasers in accordance with the petro physical properties. Lasers would then vaporize the mud cake according to its

thickness and interpretation obtained and will grind the mud cake by creating popped holes. The precision and control over direction

and power which laser provides could really be beneficial in mud cake removal and the same device could also be used for various

other jobs like perforation and enhancing permeability during production phase. Nanotechnology integrated laser system holds great

potential in removing mud cake efficiently and could significantly be useful in multilateral and horizontal wells.

Biography

Mohit Jhirwal is a Graduate of Petroleum Engineering at Pandit Deendayal Petroleum University, India. He has been working for SPE PDPU Student Chapter for

past 2 years and has received the Outstanding Chapter Award from SPE International.

mohit.jbt15@spt.pdpu.ac.inMohit Jhirwal et al., J Pet Environ Biotechnol 2017, 8:4 (Suppl)

DOI: 10.4172/2157-7463-C1-034

Fig: Monitored Laser grinding by real time nanobots data