Page 43

conferenceseries

.com

Volume 8

International Journal of Waste Resources

ISSN: 2252-5211

Recycling Expo 2018

June 25-26, 2018

June 25-26, 2018 | Berlin, Germany

8

th

World Congress and Expo on Recycling

The influence of material flow on ecological cost in the waste paper recycling and manufacturing

process

Tiejun Dai

Beijing University of Technology, China

I

n the background of fact that the problems of the resources and environment are serious day by day, waste paper, as an

important secondary resource, has gradually become the most important raw material for paper making. Now the studies

on environmental impact of waste paper recycling, which always use life cycle assessment, were mainly about comparison

of different recycling strategy. Their results are non-monetary volume, which have difficulties on guiding enterprises to

achieve win-win between economic and environmental. Therefore, in this paper, ecological cost is put forward and defined;

its calculation model based on material flow was set up. Based on the material flow analysis, a standard ecological cost flow

diagram (SECFD) was set up in waste paper recycling system, and the influence of deviating from SECFD on the ecological

cost is analyzed. The rule of the influence of material and energy flow in the waste paper recycling system to the ecological cost

is revealed. Taking the minimum ecological cost of waste paper recycling system as the objective function, the optimal design

is based on the constraint condition of economic benefits, manufacturing process conditions, national policy and industrial

standards. The results show that the ecological cost is reduced to 1385.69 yuan per ton after optimization, which is down by

456.8 yuan/ton compared with that before optimization, and the decrease is 24.79%. At the same time, the economic benefit

is increased to 1326.95 yuan/ton, 13.51% higher than that before the optimization. And it is suggested that the enterprises of

waste paper recycling should be intensive development in the future; properly control the price of waste paper, avoid the high

price of waste paper. The state should give a moderate economic compensation to waste paper recycling enterprise; it will

contribute to the win-win between its economy and ecological environment.

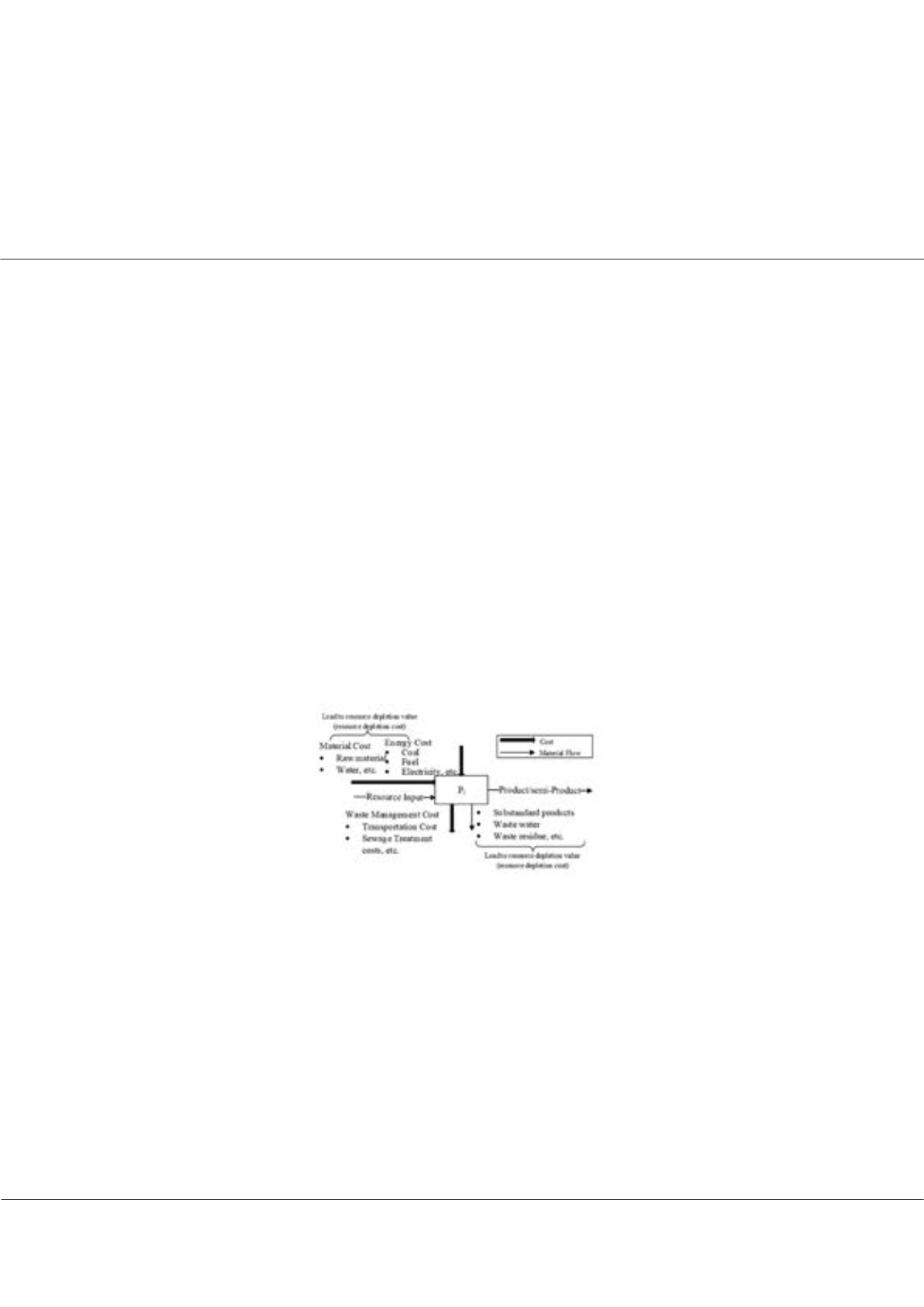

Figure 1:

The cost structure in unit process P

i

.

Recent Publications

1. Dai Tiejun (2015) A study on material metabolism in Hebei iron and steel industry analysis. Resources, Conservation

and Recycling 95(7):183-192.

2. Dai Tiejun (2011) The influence of iron flow on iron resource efficiency in the steel manufacturing process. Resources,

Conservation and Recycling 55(8):760-771.

3. Edens B and Graveland C (2014) Experimental valuation of Dutch water resources according to SNA and SEEA. Water

Resources and Economics 7:66-81.

4. Nakajima M, Kimura A andWagner B (2015) Introduction of material flow cost accounting (MFCA) to the supply chain:

a questionnaire study on the challenges of constructing a low-carbon supply chain to promote resource efficiency. Journal

of Cleaner Production 108(1):1302-1309.

5. Sulong F, Sulaiman M and Norhayati M A (2015) Material flow cost accounting (MFCA) enablers and barriers: the case

of a Malaysian small and medium-sized enterprise (SME). Journal of Cleaner Production 108(1):1365-1374.

Tiejun Dai, Int J Waste Resour 2018, Volume 8

DOI: 10.4172/2252-5211-C1-011