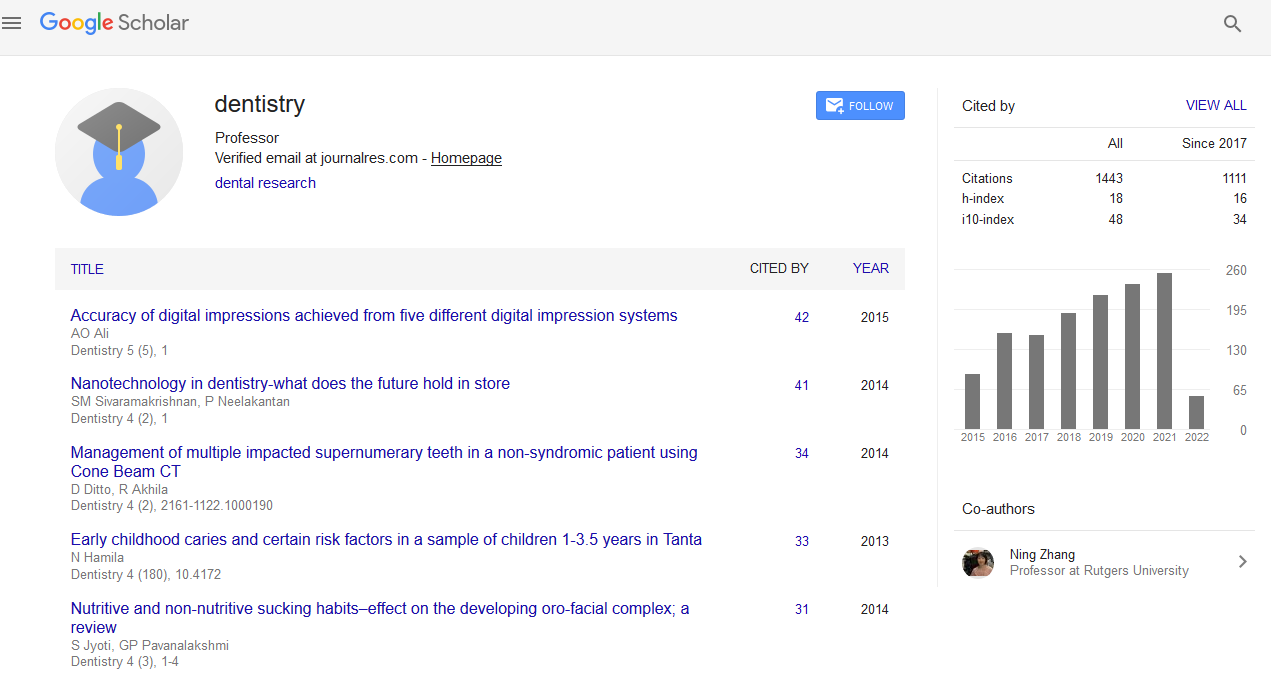

Citations : 1817

Dentistry received 1817 citations as per Google Scholar report

Indexed In

- Genamics JournalSeek

- JournalTOCs

- CiteFactor

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

A Comparative Study On The Marginal Fit Of Zirconia Cores Manufactured By CAD/CAM And Copy Milling Methods

Park JH, Kwon TK, Yang JH, Han JS, Lee JB, Kim SH and Yeo IS

Purpose: The marginal fit of zirconia cores that were produced by CAD/CAM and by copy milling systems was compared and analyzed to confirm the significance of the variation in dental technicians’ skill between the two systems.

Materials and Methods: Using dental resin teeth and individual trays, 30 plaster casts were produced. Fifteen casts were assigned to be used with five different zirconia core manufacturing dental laboratories using the same CAD/ CAM system, which were designated as the CC group. The remaining 15 were assigned to be used with five different zirconia core manufacturing dental laboratories using also the same copy milling system and were designated as the CM group. The zirconia cores were fabricated and were cemented onto the casts. The vertical marginal opening was measured under an optical microscope at 75x magnification. The measured vertical marginal discrepancies were analyzed using an independent sample t-test, and the significance of the vertical marginal gap value for each dental laboratory was analyzed by performing the Kruskal-Wallis test.

Results: The means and standard deviations for the marginal discrepancies of the CC and CM groups were found to be 102.73 ± 29.73 µm and 82.25 ± 22.37 µm, respectively. The independent sample t-test showed a significant difference between the two systems; the CAD/CAM system showed a larger vertical marginal gap than the copy milling system. The Kruskal-Wallis test indicated that no significant distributional differences were found between the dental laboratories in either the CAD/CAM or the copy milling systems.

Conclusions: The copy milling system may produce more accurate zirconia restorations than the CAD/CAM system. The technician’s skill of a copy milling system may not be a determining factor influencing the accuracy of a single zirconia core.