Indexed In

- Open J Gate

- Genamics JournalSeek

- Ulrich's Periodicals Directory

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Proquest Summons

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

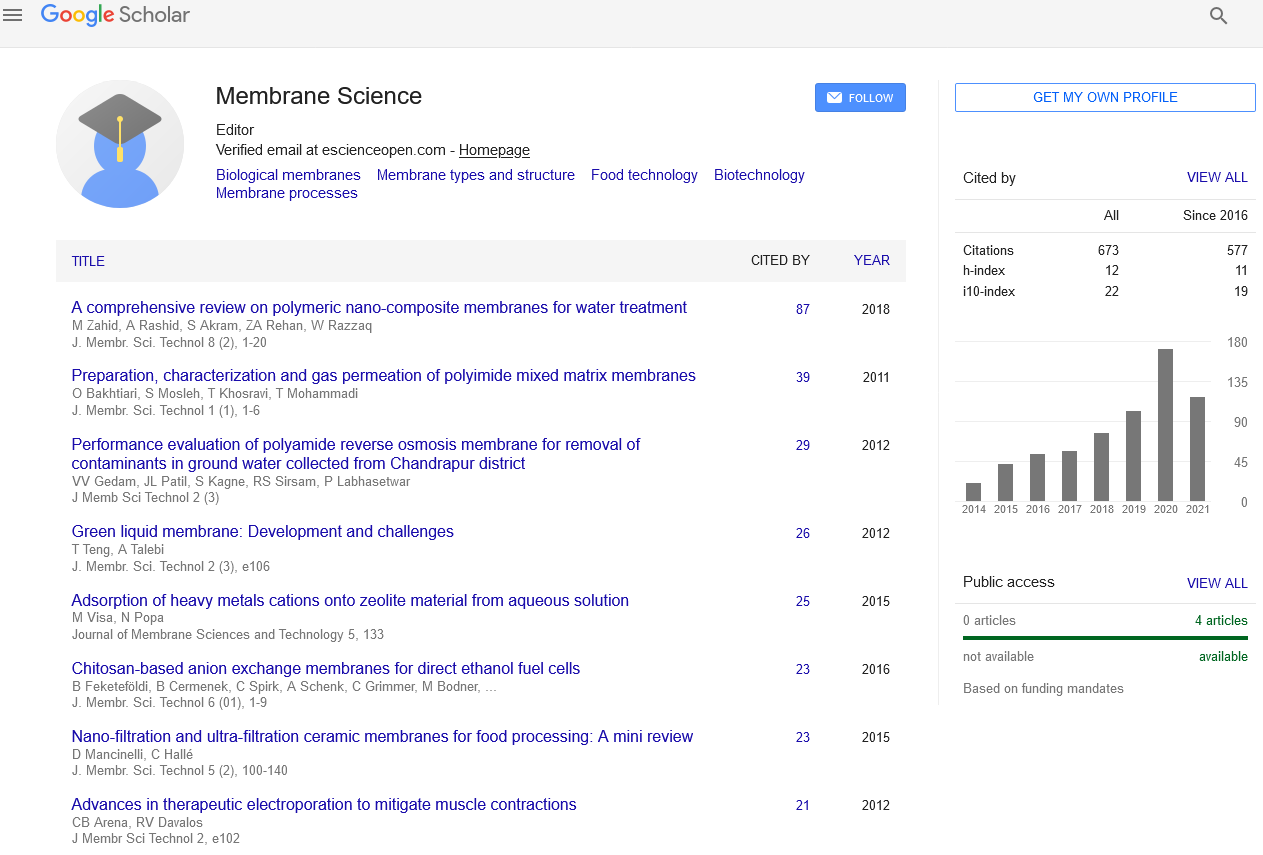

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Preparation and Characterization of Commercial Polyethyleneterephthalate Membrane for Fuel Cell Applications

Abdel-Hady EE, Abdel-Hamed MO and Gomaa MM

Commercial Polyethyleneterephthalate (PET) based proton exchange membrane was prepared by UV-radiation grafting of styrene onto PET films. The effect of irradiation time and different concentrations of the monomer on the degree of grafting (D.G.) has been studied. It was found that the DG increases linearly with increasing the irradiation time and monomer concentration, reaching a maximum at a certain level. The effect of chlorosulfonic acid concentrations on ion exchange capacity (IEC) and tensile strength also studied to find the optimum concentration of chlorosulfonic acid for using in the sulfonation process. The range of IEC, 0.2 to 0.775 m mol/g, resulting from treating styrene grafted and sulfonated PET (PET-g-PSSA) membranes with different chlorosulfonic acid levels showed that chlorosulfonic acid is an effective tool to control IEC. Fourier transform infrared (FTIR) spectroscopic analysis confirmed grafting and sulfonation onto PET Films. In addition, thermogravimetric analysis was used to investigate the behavior of the original PET film and PET-g-PSSA membranes. The methanol permeability and the proton conductivity of PET-g-PSSA film with D.G. 166% were found to be 1.2�10-8 and 58 m S/cm, respectively, better than those of Nafion 212 membrane measured with the same instruments under the same conditions. Since they have lower cost, higher conductivity and lower methanol permeability, PET-g-PSSA could be better used instead of Nafion in direct methanol fuel cells.