Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

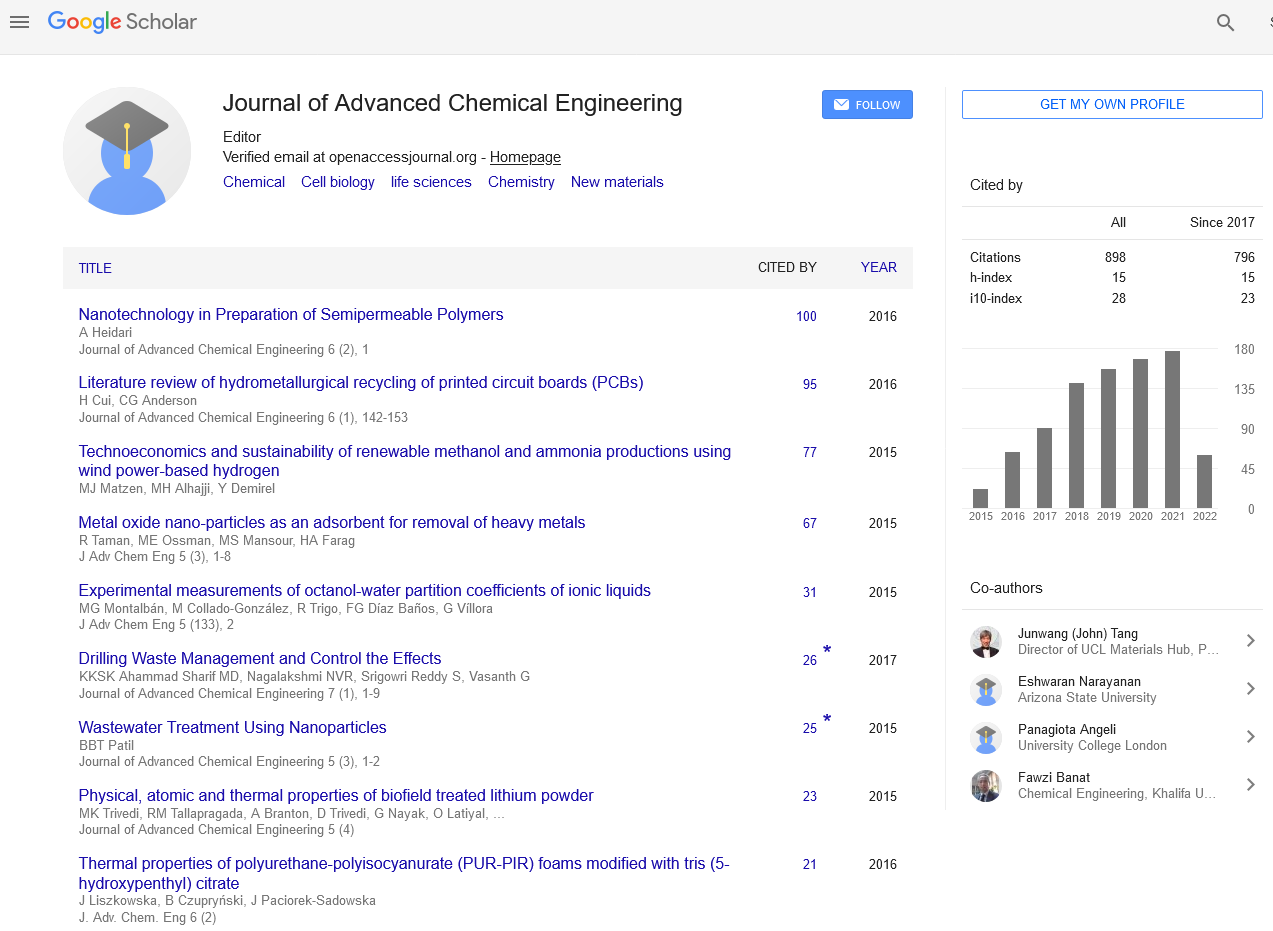

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

An overview of renewable fuels ethanol from cellulose and bio-diesel from conventional/algae feed status and economic options for ETBE

2nd International Conference on Advances in Chemical Engineering and Technology

November 16-17, 2017 | Paris, France

Amarjit Bakshi

Refining Hydrocarbon Technologies LLC, USA

Scientific Tracks Abstracts: J Adv Chem Eng

Abstract:

Advances in Biofuel technology: RHT-ETBE and RHT-TAEE are the Smart configuration technologies to enhance the conversion to over 97 to 90 percent respectively by having multiple side draws from the columns, and one can much better quality also than competitive technologies. The major advantage in these processes is that it allows wet ethanol to be use in the process and still meeting TBA and TAA specifications in the product. Essentially process is rejecting the water from wet ethanol and makes high quality Ethers at low Capex and Opex to the competitive processes. RHT- Biodiesel process is optimized to produce biodiesel from palm oil, Rape seed oil, vegetable and animal product that are all fatty acids with even number of carbon atom typically 12 to 22 atoms. This biodiesel is comparable to hydrocarbon diesel. The triglycerides are reacted with methanol/ ethanol or higher alcohol which all produce biodiesel in the acceptable boiling range. Methanol is most commonly used for the biodiesel production as being the cheapest alcohol, hence provides better economics. After the transesterfication reaction the product, methyl esters of those oils /fats as product and glycerine is produced as a byproduct. Glycerine is separated from the methyl esters of vegetable oils that are the biodiesel by phase separation by gravity settling due to density differences. The methyl esters and glycerine are purified to meet the product specifications. The technology is able to provide that reaction also to meet high overall conversions and selectivity at low Capex and Opex without producing any liquid waste.

Biography :

Over 40 years’ experience in Engineering/ Consulting Management at senior level in Process Engineering, Technology, Business Development, Licensing, Acquisitions, Alliances and Project Management and Engineering, Operations Management and Process Engineering. Provided proven leadership and vision with broader perspectives and able to manage multiple tasks and personnel on mega projects. Patents provide refiners and petrochemical plants innovations to enhance the performance of the units. Worked in all EU countries including UK, Germany, The Netherland. Major developments in Oil and gas business, downstream and petrochemicals technology, Catalysts, international alliance, licensing & contract negotiation, technology marketing, new technology commercial launch, partner relations.Dr Amarjit Bakshi has a Ph.D and also undergraduate degree both in Chemical Engineering from University of Surrey, Guildford, UK.