Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

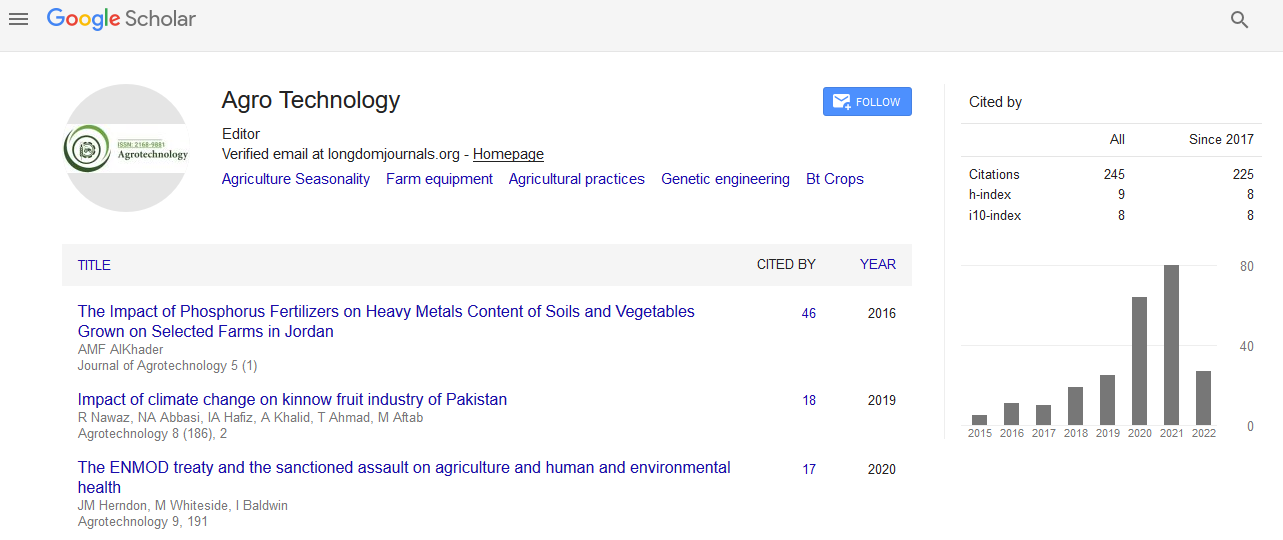

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Evaluation of power operated sugarcane detrasher

2nd International Conference on Agricultural & Horticultural Sciences

Radisson Blu Plaza Hotel, Hyderabad, India February 03-05, 2014

Rahmath Abbas Begum, Kalavani G, Nisha N and Vennila K

Posters: Agrotechnol

Abstract:

Sugarcane ( Saccharium officinarum L.) is the main source of sugar in India and holds a prominent position as a cash crop in the country occupying around 3.8 million hectares of land with an annual cane production of around 270 million tonnes. That is, it occupies about 2.8% of the cultivated land area and contributes about 7.5% to the agricultural production in the country. About 35 million farmers grow and depend on sugarcane for their livelihood. And an equal number of agricultural labourers earn their living by working in sugarcane farms. Detrashing refers to removal of unwanted bottom dry and green leaves at regular intervals. Sugarcane stalk bears large number of leaves (30-35) equal to the number of inter-nodes under good management systems. Detrashing should be taken up after the cane formation around 150 days after planting. There after it could be done at bi-monthly interval depending up on the labour availability. In India and many other developing countries, sugarcane harvesting is done by manual labour. Studies have indicated that the labour requirement for manual cutting and cleaning in India requires 158 and 395 man-h/ha, respectively. When the de-trashing operation is done with help of the tool, the labourers hands are often injured due to the spines and serrated margins of the leaf blade. Considering the above facts and advantages of sugarcane detrashing there is an urgent need to Design a Power Operated Sugarcane Detrasher . Field tests showed that the effective field capacity of the power operated sugarcane detrasher was 0.06 ha/h with 89 per cent field efficiency. Cost of detrashing by the power operated sugarcane detrasher was Rs. 1250 /ha as compared to the Rs. 7500/ ha for manual detrashing. So the conclusion is that, apart from reducing the cost of cultivation, the drudgery, which was faced by the labourers, has also been reduced considerably.

Biography :

Rahmath Abbas Begum has completed BTech (Ag. Engg.) from Agricultural Engineering College and Research Institute, Trichy. Currently she is pursuing MTech (Ag. Engg.) in the Dept. of Farm Power and Machinery from the Tamil Nadu Agricultural University, Coimbatore.