Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

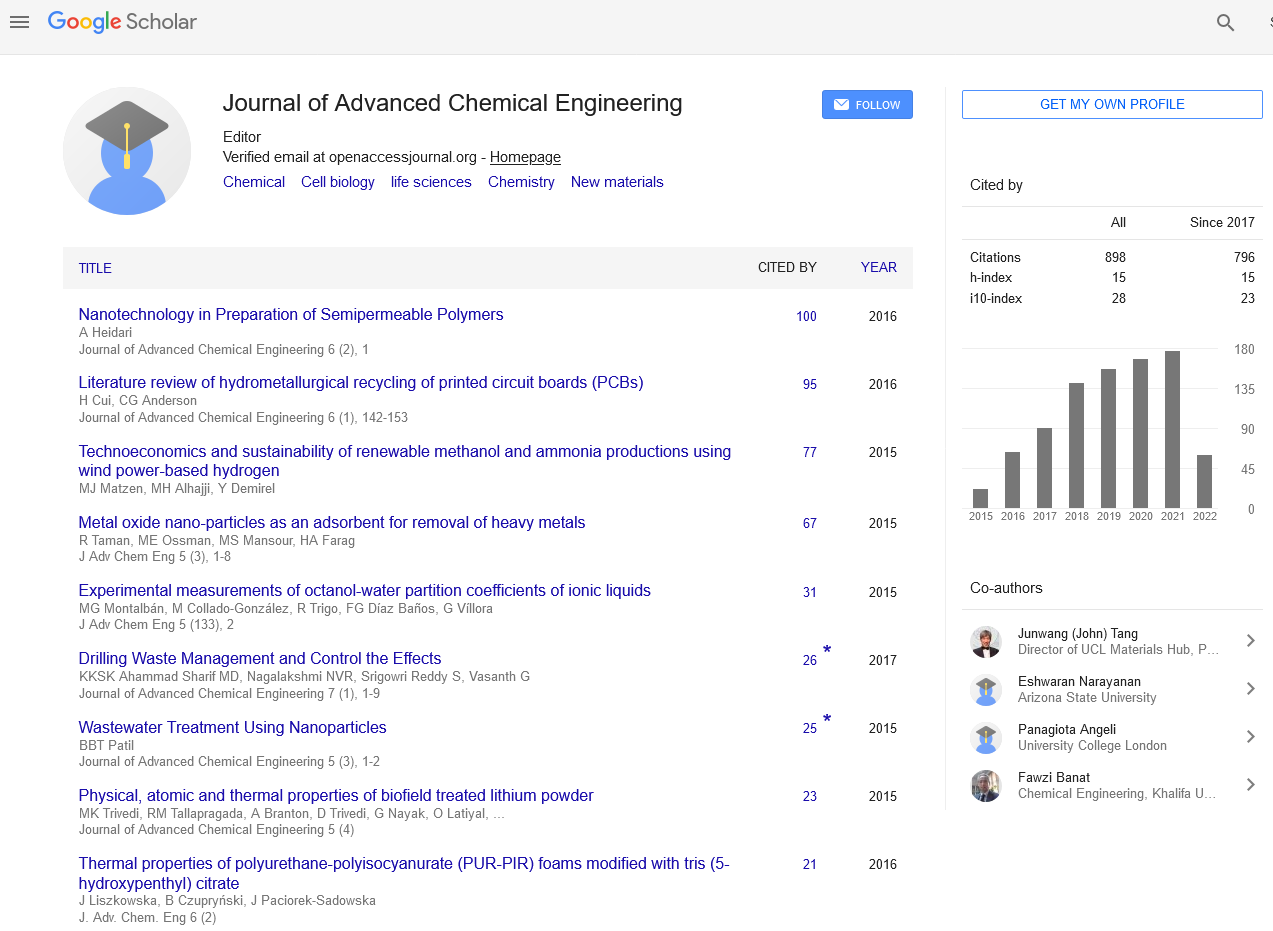

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Understanding the microphase morphology of concentrated cellulose solutions from their rheological behavior

2nd World Congress on Biopolymers

August 04-05, 2016 Manchester, UK

Yumei Zhang, Xiaolin Xia, Yongbo Yao, Hina Saba and Huaping Wang

Donghua University, China

Scientific Tracks Abstracts: J Adv Chem Eng

Abstract:

The rheological behaviors of concentrated cellulose solutions including cellulose/ionic liquid solutions varied with the dissolving process, cellulose/ionic liquid/DMSO solutions and cellulose/protein/ionic liquid solutions have been studied to predict the microphase morphology of different systems. The viscosity, relaxation time and sol-gel temperature of cellulose/ionic liquid solution shift to low value with the effective shearing action of kneading. This indicates significant differences occurring in the structuralization of solutions prepared by different dissolving process. The SEM images of films regenerated from kneading solution exhibited a dense and homogeneous morphology while films prepared by static-state dissolving process were loose with coarse aggregation, which is consistent with the deduce from the rheological results. From the viscoelastic properties of cellulose solutions with 1-butyl-3- methylimidazolium chloride ([BMIM]Cl) and dimthylsulfoxide (DMSO) as solvents, the non-monotonous decrease of viscosity with DMSO content was observed. When the content of DMSO in [BMIM]Cl/DMSO is lower than 5 wt% in [BMIM]Cl/DMSO, the viscosity and gelation temperature (Tgel) decreased with the increase of DMSO. However, the values of viscosity and Tgel showed non-linear change with the further increase of DMSO. It could be understood that DMSO acted as the diluent when the content of DMSO is below 5 wt%. The local micro-aggregation or micro-phase separation of cellulose could have happened when the content of DMSO further increased due to the weak action between cellulose and DMSO. The viscosity of cellulose/protein/ionic liquid solution shows different correlations with blend ratio and shear rate, which is related to multiphase structure of cellulose blend systems.

Biography :

Yumei Zhang has completed her PhD in 1999 from China Textile University and worked as a Visiting Scholar at Sheffield University in 2005. She is Professor of polymer science and engineering in Donghua University. She has published more than 30 papers in reputed journals and has got many patents and achievments on fiber processing in China.

Email: zhangym@dhu.edu.cn