Page 90

conferenceseries

.com

Volume 2

Environment Pollution and Climate Change

ISSN: 2573-458X

Climate Change 2018 &

Global ENVITOX 2018

October 04-06, 2018

October 04-06, 2018

London, UK

16

th

Annual Meeting on

Environmental Toxicology and Biological Systems

&

5

th

World Conference on

Climate Change

JOINT EVENT

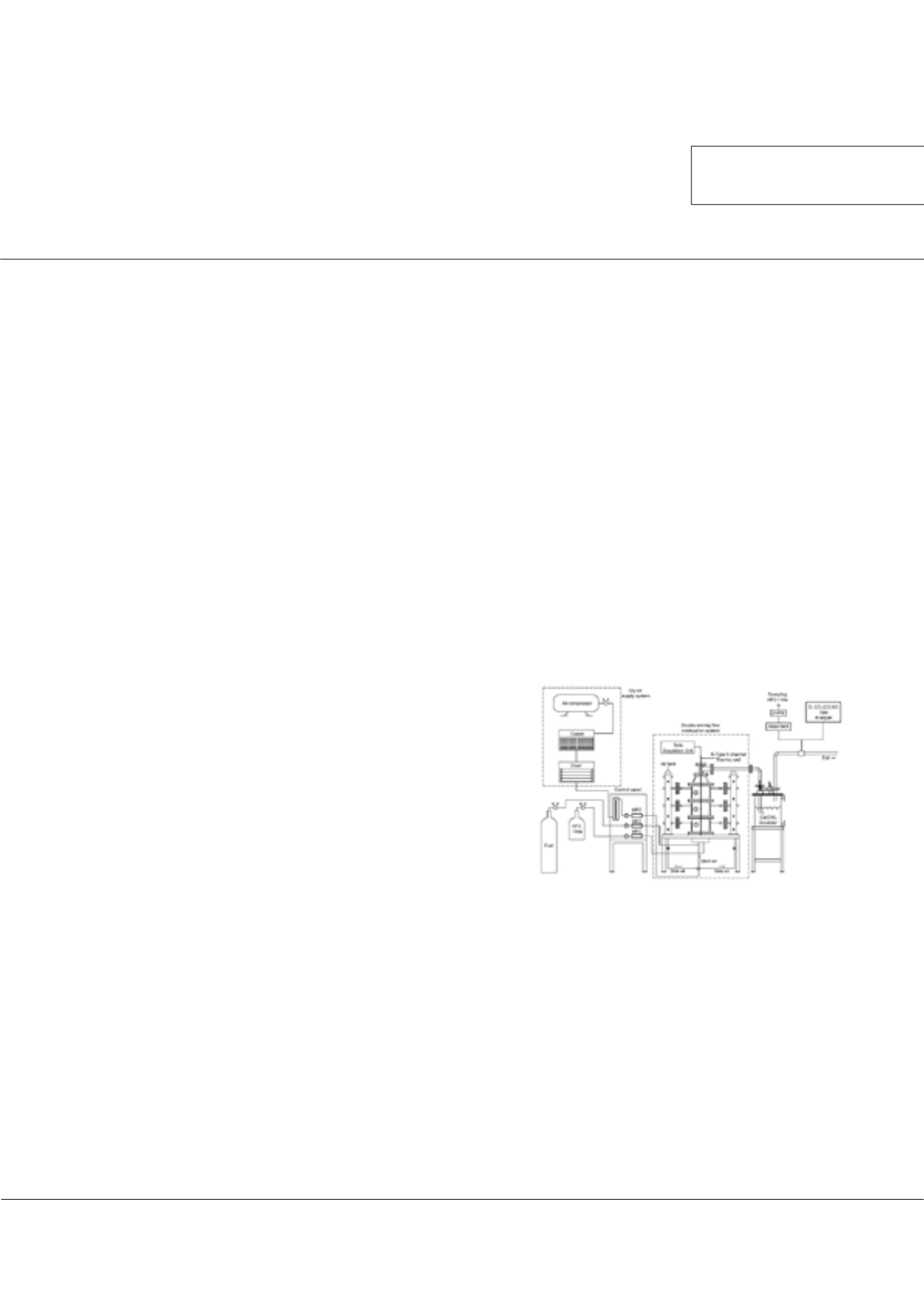

Effect of steam injection into incinerator on thermal destruction of waste refrigerant (HFC-134a)

Tae-in Ohm

1

, Jong-seong Chae

1

and

Seung-hyun Moon

2

1

Hanbat National University, South Korea

2

Korea Institute of Energy Research, South Korea

T

he reuse of hydrofluorocarbons (HFCs) with a global warming potential (GWP) of >150 is prohibited in developed

countries. Decomposition and subsequent neutralization of the produced hydrogen fluorides is currently widely used

for the treatment of high-GWP waste HFCs. However, there is the need to reduce the high auxiliary energy consumption of

the utilized incinerator. For this purpose, we developed two versions of a burner for injecting fuel, oxidizer, refrigerant, and

steam into the incinerator. The simultaneous supply of the waste HFCs and steam into the incinerator was expected to enhance

the destruction of the former, thereby reducing the energy consumption. The following were determined from the results of

experiments that were performed to evaluate the effectiveness of the developed type-1 burner. The simultaneous supply of

steam and waste HFCs into the incinerator increased the internal temperature of the incinerator when using either version of

the type-2 burner. With the simultaneous supply of steam and the HFCs, the internal temperature of the incinerator increases

with increasing steam supply, regardless of the version of the burner used. When using the type-2 burner, by which steam is

supplied to the incinerator in the same direction as the flame, the NO

x

concentration decreases from 71 ppm to 62 ppm with

increasing steam feed rate. In the case of using the type-1 burner, there is no decrease in the NO

x

concentration. The HFCs

decomposition rate is 100% for a HFCs feed rate of up to 2.8 kg/h with no steam supply, while the 100% decomposition is

maintained up toHFCs feed rates of 3.0 and 3.4 kg/hwhen using the types 1 and 2 burners with steamsupply.The decomposition

rate of the HFCs for the two types of burners are the same for steam

feed rates above 0.5 kg/h.

Recent Publications

1. Ohm T I, Myung S Y, Jang W B and Yu S R (2015) A comparison

of refrigerant management policies and suggestions for

improvement in South Korea. J Mater Cycles Waste Manag

19(2):631–644.

2. Jasinski M, Dors M and Mizeraczyk J (2009) Destruction of freon

HFC-134a using a nozzleless microwave plasma source. Plasma

Chem Plasma Process 29(5):363–372.

3. Watanabe T and Tsuru T (2008) Water plasma generation under

atmospheric pressure for HFC destruction. Thin Solid Films

516(13):4391–4396.

4. Hannus I (1999) Adsorption and transformation of halogenated

hydrocarbons over zeolites. Appl Catal. 189:263–276.

5. Wang H P, Liao S H, Lin K S, Huang Y J and Wang H C (1998) Pyrolysis of PU/CFCs wastes. J Hazard Mater 58:221–226.

Biography

Tae-in Ohm has been Professor at the Department of Environmental Engineering, Hanbat National University since 1995. He is interested in designing of incinerator

for wastes, municipal solid waste, waste refrigerant, liquid industrial wastes and RDF. Also, he has experience in drying technology of organic waste with high

water content.

tiohm1@hanbat.ac.krTae-in Ohm et al., Environ Pollut Climate Change 2018, Volume 2

DOI: 10.4172/2573-458X-C1-003

Figure 1:

Schematic diagram for the decomposition system of

the waste refrigerant