Page 24

Notes:

conferenceseries

.com

Volume 5

Journal of Environmental Analytical Chemistry

Green Chemistry Congress 2018

July 19-20, 2018

July 19-20, 2018 Melbourne, Australia

5

th

World Congress on

Green Chemistry and Green Engineering

Heavy oil-water two-phase flow characteristics in a vertical pipe

Jixiang Guo and Yuqi Yang

Enhanced Oil Recovery Institute, China

O

il-water two-phase flow widely exists in the oil industry with environment of

high temperature and high pressure, such as oil exploitation, transportation

and refining. Despite the great progress about oil-water two-phase flow, it

seems clear that there is room for a great deal for more research on the effect of

temperature and pressure on heavy oil-water two-phase vertical flow pattern. The

goal of this study is to promote a better understanding of flow patterns of heavy

oil-water two-phase pipe flow, particularly, flow patterns under high temperatures

and high pressures. We conducted experimental measurements to examine the

upward oil-water flow patterns in a small diameter vertical pipe (0.01 m ID) under

high temperatures up to 130

o

C and high pressures up to 20 mPa. The viscosity of

the oil sample was 584.24 mPa-s and the density were 1.899 g/cm

3

at 30

o

C. All

the experiments were conducted with an in-house-built high pressure/temperature

flow apparatus. This apparatus is equipped with a view window that allows us to visually observe the upward flow patterns of oil-

water two-phase flow in a 0.01 m ID stainless steel pipe. The effects of pressure, temperature, Input Water Fraction (IWF) and

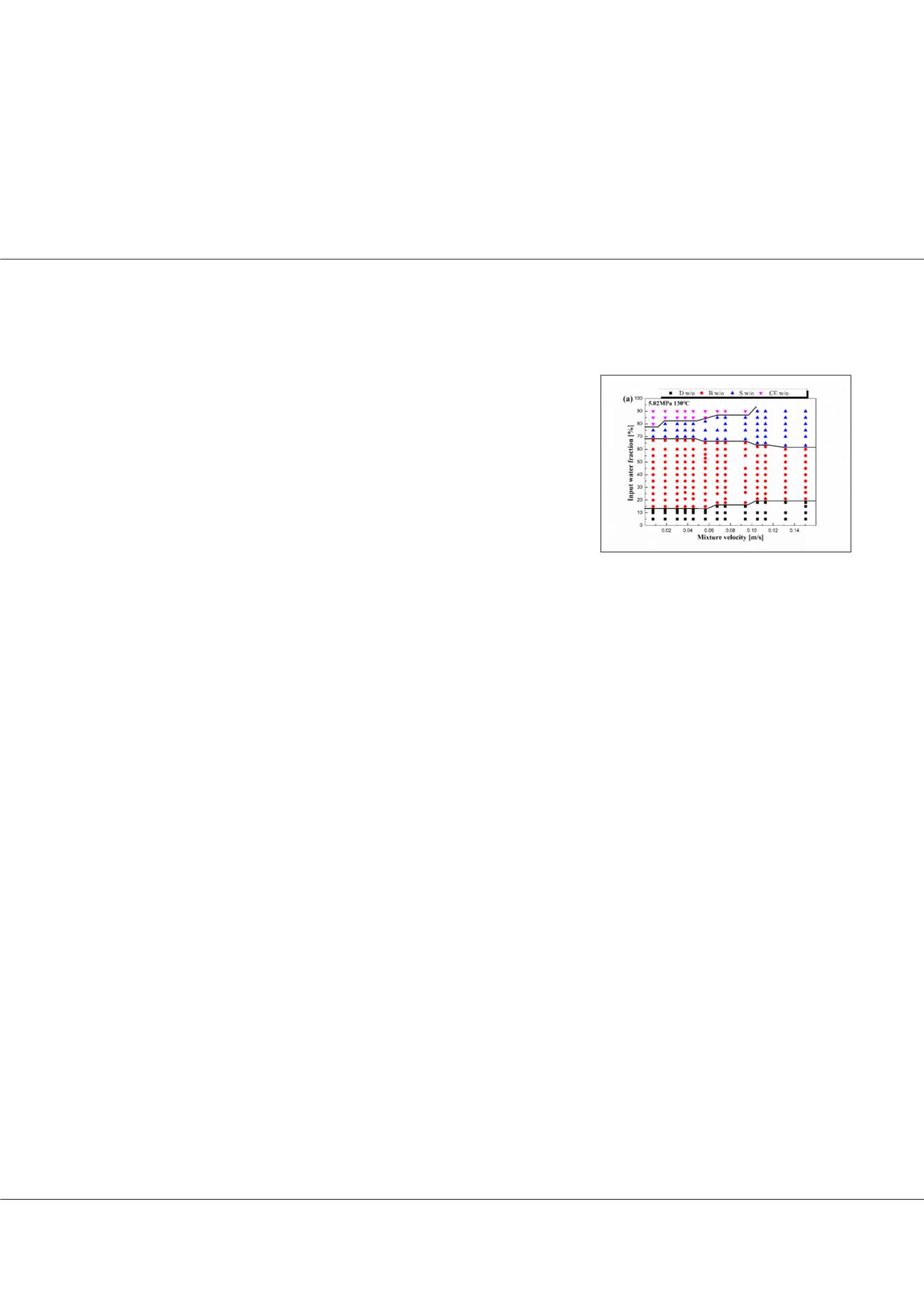

mixture flow velocity on the flow patterns were systematically investigated. We plot the observed flow patterns on a flow pattern

map in which input water fraction was used as the Y-axis and the mixture flow velocity was used as the X-axis. Based on the

measurement results, we can observe the following flow patterns water-in-oil dispersed flow (D w/o), water-in-oil Bubbly flow

(B w/o), water-in-oil Slug flow (S w/o), water-in-oil Creep Flow (CE w/o), churn flow (churn) and core Annual Flow (AF). Phase

inversion was not observed in this work. With an increase in temperature at a given input water fraction, S w/o, CE w/o and

churn flow with large water drops tended to transform into B w/o and D w/o with smaller water drops, the CE w/o disappears

gradually, and the boundaries in the flow pattern maps tend to occur at lower input water fraction values. The effect of pressure

on the flow patterns was found to be opposite to that of temperature. The possible causes leading to the changes in the flow

patterns subjected to pressure/temperature variations were provided in terms of changes in density ratio, interfacial tension and

viscosity ratio between oil and water.

Biography

Jixiang Guo has completed her Doctor degree of Chemistry Engineering and Technology from China University of Petroleum, Beijing. She is a Professor and

Doctoral Supervisor major in enhancing oil recovery. She has presided over several China’s major scientific research projects. She has published more than 40

papers in reputed journals and has been serving as an Editorial Board Member.

guojx002@163.comJixiang Guo et al., J Environ Anal Chem 2018, Volume 5

DOI: 10.4172/2380-2391-C1-002

Figure-1:

Flow pattern map based on input water

fraction and mixture velocity under 5.02 mPa at 130

o

C.