Research Article Open Access

Characterization of Extra Virgin Olive Oil Obtained from Whole and Destoned Fruits and Optimization of Oil Extraction with a Physical Coadjuvant (Talc) Using Surface Methodology

Zina Guermazi1, Mariem Gharsallaoui2, Enzo Perri3, Slimane Gabsi1 and Cinzia Benincasa3*

1National School of Engineering, University of Sfax, Route de Soukra, 3038 Sfax, Tunisia

2Olive Tree Institute, University of Sfax, 3000 Sfax, Tunisia

3Consiglio per la ricerca in agricoltura e l'analisi dell'economia agraria, Centro di ricerca per l'olivicoltura e l'analisi dell'economia agraria, Italy

- *Corresponding Author:

- Cinzia Benincasa

Consiglio per la ricerca in agricoltura e l'analisi dell'economia agraria,

Centro di ricerca per l'olivicoltura e l'analisi dell'economia agraria, Italy

Tel: +39-0984-49284

E-mail: cinzia.benincasa@entecra.it

Received date: August 13, 2015; Accepted date: September 14, 2015; Published date: September 21, 2015

Citation: Guermazi Z, Gharsallaoui M, Perri E, Gabsi S, Benincasa C (2015) Characterization of Extra Virgin Olive Oil Obtained from Whole and Destoned Fruits and Optimization of Oil Extraction with a Physical Coadjuvant (Talc) Using Surface Methodology. J Anal Bioanal Tech 6:278 doi:10.4172/2155-9872.1000278

Copyright: © 2015 Guermazi Z, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Analytical & Bioanalytical Techniques

Abstract

The separation of the two components pulp-stone has allowed the development of a more scented product that respects the environment. According to a preliminary study, it was noticed that the destoning process produced a paste containing 67% moisture without resorting to the addition of water. The destoning process presents an ecologically sensitive system as the amount of waste watergenerated was reduced to 0.46 m3/ton of olives. Experimental studies indicate that stone removal before crushing affects to a greater extent the quality of the oil. Indeed the use of stoned olives decreases the acidity by 20%. The specific results of extinctions K232 and K270 confirm that using stoned olives improves the stability of oil since less oxidized compounds (K232 and K270 values 1.69 and 0.11 respectively) were detected. This study also shows that stoned olive oil had a better sensory note than the conventional one and consequently a higher commercial value in the market. Enhanced extraction yield of oil from stoned olives was attained using response surface methodology. Different olive oil extractions were investigated considering three variables: temperature of malaxation, time of malaxation and dose of adjuvant using Central Composite Design. Highest extraction yields were obtained when the temperature and the time of malaxation were respectively 37°C and 35 min. For the proportion of coadjuvant, the optimum dose was found at 1.5%.

Keywords

Extra virgin olive oil; Stoned olive oil; Sensorial analysis; Quality; Oxidative stability; Coadjuvant

Introduction

Olive oil constitutes one of the most appreciated and consumed vegetable oils, whose benefits for health have been known for millennia [1-4]. Currently, Tunisia is a country that has experienced a significant evolution in the olive sector through the plantations of 80 million olive trees that account for 20% of the world olive-growing area. Tunisia, according to the magazine Olive Oil Times, is the 2nd largest producer and exporter of the southern Mediterranean. Indeed, the harvest of the 2014/2015 season was quadrupled, rising from 70,000 to 285,000 tons of oil. Olive oil is, according to the Ministry of Agriculture, the main agricultural export, with nearly 40% of total national exports. The increase in olive sales prices pushed growers to minimize the loss of oil in the by-product such as olive pomace and waste water. To minimize this loss, an ironing pomace was performed. This procedure involves subjecting the wet pomace, after pulp/stone separation, to a second centrifugation to remove between 40 and 60% of waste oils. This technique has known a large spread in the Sfax region, a city of 6 million olive feet, where the production of olive oil represents 40% of total national production. The drawback of this action is that it leads to the production of oils that do not achieve the standard requirements established by the COI.

With an aim of preserving olive oil’s best physicochemical and organoleptic characteristics and in order to make the reconciliation between olive-growing industries and the environment, a technological improvement in the industrial production of olive oil seems to be represented by the manufacturing procedure which considers the use of stoned olives [5,6].

The benefits of the destoning process on the phenolic compounds have been shown in some studies [7]. Many enzymes of degradation that are present in the stones, in fact, once removed, do not affect the phenolic heritage of the oil during the process of extraction, preserving the antioxidant profile.

Also, higher amounts of volatile compounds were observed for oil produced from stoned olives [8].

The use of de-stoner produces improved sensory characteristic oil, greater impact and volatile content of phenolic compounds and consequently a high stability and long shelf life but has some disadvantages as is the performance problem: the yield of the olive oil has decreased 15% from the whole fruit [9]. Due to the growing interest stoned olive oil testing is performed to solve this major problem [7,8] as the use of the heat exchanger coupled to the stoner improving olive oil yields and makes the more efficient mixing and design of a specific coring device: the spring pitting apparatus (SPIA) [7]. The use of these techniques remain limited given the large investments that is why we thought was a simpler and less expensive technique that is based on the addition of talc which is a natural coadjutant recognized as a food additive by the European Regulations (E-553B). Talc does not change the oil composition, the positive response is presented by these lipophilic characteristics that can destabilize the oil / water emulsion and increase the rate of oil extraction. On the basis of these observations, the objective of this work was to study the influence of this technology on the quality parameters as well as the optimization of parameters for stoned olive oil extraction.

Materials and Methods

Preparation of samples

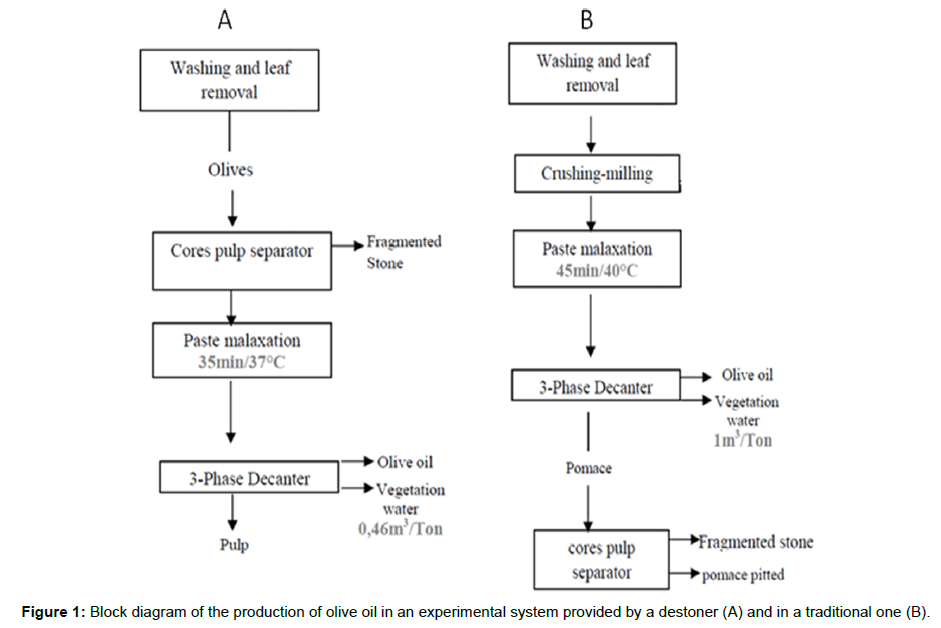

Seventeen pairs of olive oils, obtained from whole and stoned olives, were studied. Each pair was obtained from the same batch of olives. Oil was produced from only one cultivar, Chemlali, collected in February 2014. The traditional extraction of the oil has been conducted by using an oleodosor, while, the destoning procedures has been achieved by a reorganization of the extraction steps of the traditional system (Figure 1). In both extraction system, olives were washed and leaves removed. The olives were crushed in a metal crusher and the paste mixed at different temperatures and times with different doses of coadjuvant (talc). The paste was then centrifuged at a speed of 3500 rpm for 1 min. The oils obtained were stored hermetically in 90 mL glass bottles at 4°C. In particular, in the traditional system the paste was malaxed for 45 min at 40°C and the final products were olive oil, vegetation water and pomace. The pomace was then destoned and treated in order to obtain extra olive oil. In the new experimental system olives were destoned by means of a separating pulp cores directly after been washed and then crushed. The paste was then malaxed for 35 min at 37°C. In this system, instead of pomace, an olive pulp is produced.

Quality indices

Free fatty acidity, peroxide value (PV), conjugated dienes (K232) and trienes (K270) were determined according to the methods reported in the Regulation EEC/2568/91 [10] and subsequent amendments and additions of the European Union Commission.

Phenolic compounds

Quantitative analysis: Folin Ciocolteau Test: Total phenolic compounds were determined as reported in the literature [11]. Briefly, 1 g of olive oil was dissolved in 5 mL of hexane; the solution was loaded on a C18 cartridge (1 g; 6 mL) and washed twice with 5 mL of hexane. Phenols were eluted with 10 mL of MeOH. Final solution (1 mL) was submitted to the Folin Ciocolteau assay.

Quantitative analysis by HPLC/MS/MS: Extraction of phenols: According to the method described by COI (COI, 2009), 2 g of olive oil was added to 6 mL methanol/water (80/20 V/V) and shaken for 1 min in order to homogenize the mixture. The sample was placed in an ultrasonic bath for 15 min and then centrifuged at 5000 rpm for 25 min at 4°C. The supernatant was, finally, injected into the HPLC-MS system.

Preparation of standard solutions: The assay of phenols by LCMS/ MS has been carried out by external standard method. Standard stock solutions were prepared by dissolving reference compounds in methanol. Aliquots of these solutions were further diluted with methanol/water (80/20 V/V) to obtain calibration standards at concentrations between 1-200 μg/mL for oleuropein, hydroxytyrosol, tyrosol, luteolin, apigenin, p- and o-coumaric acids, vanillic acid, vanillin, ferulic and caffeic acids.

Calibration curves were constructed using a least-squares linear regression analysis. For each analyte the calibration curves were linear with correlation coefficients ranging between 0.9993 and 0.9998. Recovery tests were carried out injecting three times two standard solutions at different concentration of the eleven active molecules. Results from recovery experiments at levels of 30 and 80 μg/mL gave mean recoveries ranging from 93-114% with satisfactory precision (relative standard deviation (RSD) from 0.2-0.4%). Limits of quantitation (LOQs) from 1.249-2.848 μg/mL.

High performance liquid chromatography (HPLC): HPLC was performed using an Agilent Technologies 1200 series liquid chromatography system equipped with G1379B degasser, G1312A pump, and G1329A autosampler. The analytes were separated on an Eclipse XDB-C8-A HPLC column [5 μm particle size, 150 mm length and 4.6 mm i.d. (Agilent Technologies, Santa Clara, California)] at a flow rate of 300 μl/min and an injection volume of 10 μL. A binary mobile phase made up of 0.1% aqueous formic acid (A) and methanol (B) was programmed to increase B from 10% to 100% B in 10 min, hold for two min and ramp down to original composition (90% A and 10% B) in eight min and hold for 6 min. The total elution time was 26 min per injection.

Mass spectrometry: The ESI-MS/MS analyses were performed using a MSD Sciex Applied Biosystem API 4000 Q-Trap mass spectrometer in negative ion mode using multiple reactions monitoring (MRM). The experimental conditions were set-up as follow: ionspray voltage (IS) -4500 V; curtain gas 25 psi; temperature 400°C; ion source gas(1) 35 psi; ion source gas(2) 45 psi; collision gas thickness (CAD) medium. Entrance potential (EP), declustering potential (DP), collision energy (CE) and collision exit potential (CXP) were optimized for each transition monitored.

Sensory analysis

Sensorial evaluation of the oils was performed according to the panel test method by a fully trained analytical taste panel recognized by the International Olive Oil Council (IOOC). A panel test was established using the IOOC standard profile sheet method (COI, 2011) [12].

Statistical analyses

The results presented are the averages of the analysis carried out in triple exemplary with the corresponding standard deviations. The threshold of significant difference was fixed at 5% in the Students t-test.

Experimental design: Response surface methodology (RSM) comprises a body of methods for exploring for optimum operating conditions through experimental methods that uses quantitative data from appropriate experimental design to determine optimal conditions. Different levels or values of the operating conditions comprise the factors in each experiment. Some may be categorical (e.g., the supplier of raw material) and others may be quantitative (feed rates, temperatures, and such) [13]. When many factors affect a desired response, it can be an exhausting task to optimize a process. Therefore, RSM can be an effective tool for optimizing the response [14].

The first step of the oil extraction procedure has been optimized using RSM (Tables 1 and 2).

| Objective of study | Study in an experimental field: Surface of Answers |

|---|---|

| Number of variables | 3 |

| Number of experiments | 20 |

| Number of coefficients | 10 |

| Number of answer | 1 |

Table 1: Experimental design: Characteristics of the problem.

| Factor | Unit | Center | |

|---|---|---|---|

| U1 | Temperature | °C | 31.5 |

| U2 | Time | Min | 45.0 |

| U3 | Dose of Talc | % | 1.0 |

Table 2: Experimental design: Experimental field.

A central composite design was chosen to look for the best experimental conditions of three independent factors affecting the extraction process which are: X1, extraction temperature (°C); X2, extraction time (min) and X3, dose of talc (%). For each factor, the experimental range was chosen on the basis of results of preliminary experiments.

In this work, the relationship between the extraction yield and the three selected quantitative variables was approximated by the following polynomial function:

Y=b0 + b1 × X1 + b2 × X2 + b3 × X3 + b11 × (X1 × X1) + b22 × (X2 × X2) + b33 × (X3 × X3) + b12 × (X1 × X2) + b13 × (X1 × X3) + b23 × (X2 × X3)

Where Y is the calculated response function, Xj are the coded variables with no dimension related to the natural variables Uj. The obtained response values were used to estimate the model coefficients bj by the least square method using the experimental design software NEMROD-W [15].

IBM SPSS Statistics 20: The analysis of variance (ANOVA) on SPSS is a bi-varied method of analysis which consists of crossing two different variables, one quantitative and the other one qualitative in order to detect the relation of independence between those two variables.

Results and discussion

Destoning process and its influence on oil quality

Conventional parameters of quality: Table 3 reports the conventional parameters used to characterize the quality of olive oils. Free acidity values remained below the limits reported by Regulation EEC /1989/2003 of the European Union Commission. The destoned olive sample (DO) value was lower than that of the conventional olive sample (CO) (0.6 and 0.8 g of oleic acid per 100 g of oil, respectively). Thus, it has been noticed that the destoning process decreases the acidity by 20%. This is in agreement with the results reported in the literature [16,17]. Also, it has been noticed that acidity increases with the time of malaxation, therefore, it is very important to control this process during all the duration of the oil extraction. The data of specific extinction, K232, showed that oils obtained from stoned olives presented a weakest value (1.8 nm) compared of ordinary oil (2.4 nm). As for K270, the values ranged between 0.11 and 0.16 nm. Another parameter which has an important effect on quality of oil is the time of malaxation; in fact, a positive correlation was noted between this parameter and the state of oxidation, therefore, malaxation time was extended. The stoned samples presented the weakest values of K232 and K270 thus they were less oxidized; this confirmed the assumption of existence of enzymes in stone responsible of degradation of linoleic acid. As regards to the influence of the technology, the difference between WO and DO values of peroxide index was not significant, in agreement with the results of Del Caro [16].

| Sample | Time of malaxationa | Process | Acidityb | K232 | K270 | Peroxide valuec |

|---|---|---|---|---|---|---|

| 1 | 15 | Stoned | 0.52 | 1.72 | 0.11 | 5.67 |

| 2 | 15 | Conventional | 0.71 | 2.03 | 0.16 | 5.56 |

| 3 | 30 | Stoned | 0.58 | 1.81 | 0.13 | 5.70 |

| 4 | 30 | Conventional | 0.78 | 2.11 | 0.17 | 5.43 |

| 5 | 45 | Stoned | 0.61 | 1.91 | 0.15 | 5.64 |

| 6 | 45 | Conventional | 0.82 | 2.21 | 0.18 | 5.87 |

| 7 | 60 | Stoned | 0.69 | 2.11 | 0.17 | 5.42 |

| 8 | 60 | Conventional | 0.91 | 2.46 | 0.19 | 5.53 |

Table 3: Conventional parameters to assess the quality of olive oils.

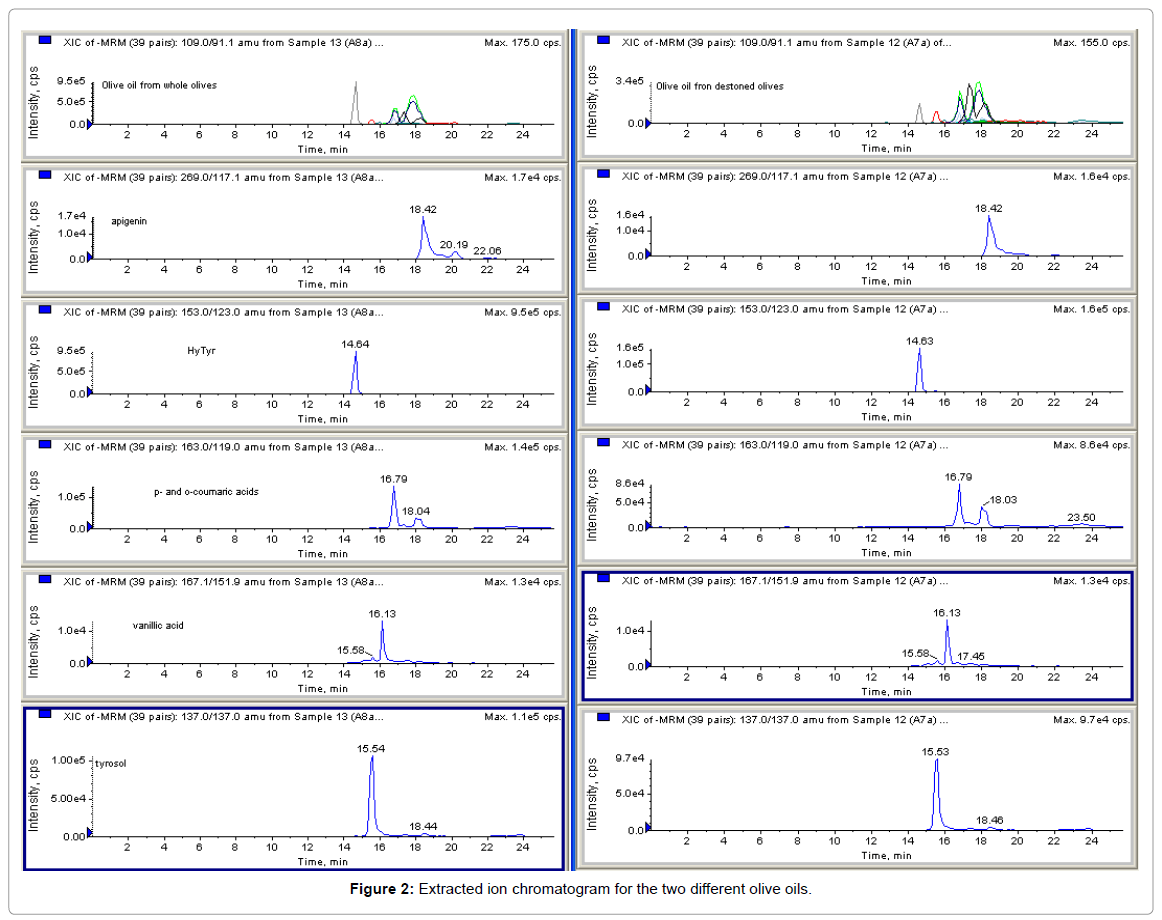

Olive oils are known for their raised capacity of phenolic compounds compared to other refined vegetable oils. These compounds contribute to total flavor complexes in olive oil and provide antioxidant effects [18,19] and are mainly responsible for its shelf life. In agreement with the results found in the literature [7,8], differences in the total phenol content were observed between the oils produced with conventional and the stoned process; two enzymes, polyphenol oxidase (PPO) and peroxidase (POD), are highly concentrated in the destoned olive. PPO and POD can oxidize phenolic compounds resulting in a reduced concentration of phenolic oil. The de-stoning process eliminates a part of peroxidase activity in stone resulting in an increase in the oxidative stability and nutritional value of the olive oil itself [20]. The results of phenolic compounds detected by LC/MS are illustrated in Table 4,while in Figure 2 an extracted ion chromatogram for the two different olive oils is showed.

| Stoned olive oil | Conventional olive oil | Signification | |

|---|---|---|---|

| Tyrosol | 0.46 ± 0.03 | 0.48 ± 0.04 | * |

| Vanillin | 0.26 ± 0.13 | 0.13 ± 0.12 | *** |

| Hydroxytyrosol | 4.65 ± 0.55 | 5.98 ± 0.24 | * |

| P-coumaric acid | 0.35 ± 0.11 | 0.29 ± 0.16 | *** |

| O-coumaric acid | 0.36 ± 0.03 | 0.35 ± 0.05 | n.s. |

| Vanillic acid | 3.90 ± 0.18 | 3.13 ± 0.38 | *** |

| Cafeic acid | 0.03 ± 0.03 | 0.03 ± 0.02 | * |

| Ferrulic acid | 0.33 ± 0.05 | 0.20 ± 0.03 | *** |

| Apigenin | 0.33 ± 0.06 | 0.35 ± 0.05 | n.s. |

| Luteolin | 24.95 ± 0.95 | 27.42 ± 0.77 | *** |

| Oleuropein | 121.22 ± 0.98 | 103.54 ± 0.92 | *** |

Table 4: Result of detection of phenolic compounds by LC/MS and ANOVA test. ****Very significant; ***Fairly significant; *Little significant.

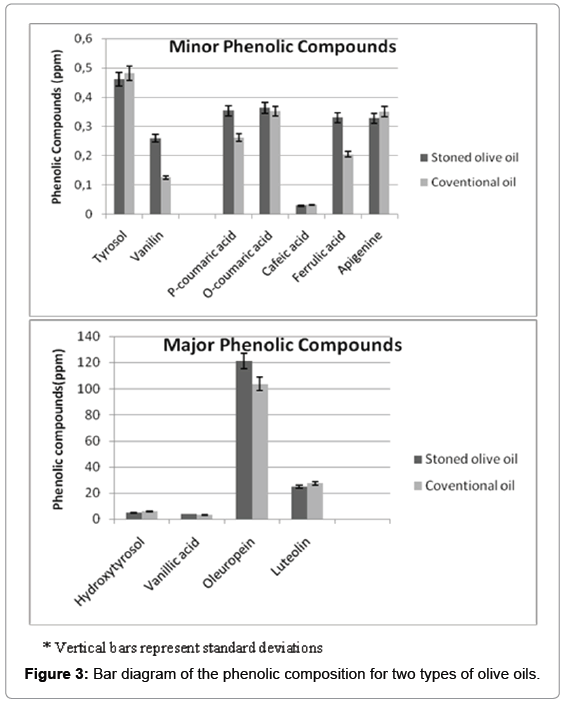

The most important biophenols quantitatively present in the samples analyzed were: tyrosol, vanillin, hydroxytyrosol, p-coumaric and o-coumaric acid, vanillin acid, caffeic acid, ferulic acid, apigenin, luteolin and oleuropein. This detection reveals a similar qualitative composition in individual phenolic compounds, but different from the quantitative stands points that are described in Figure 3.

This is explained by the degradation of some phenolic compounds by existing enzymes in the stone as polyphenol oxidase (PPO); these enzymes can be activated either through H3O+ ions or with fatty acids (linolenic acid). In agreement with recent results [7] increased oleuropein content was observed in the olive oil produced from the same drupes on from classics to stoning procedures; this observation helps to add value to the food. The enzymatic activity of stone is indeed a selective activity affecting some phenolic compounds such as oleuropein so it was found a difference between the two types of oil. Indeed, it can be confidently assumed, that the enzymes of the stone give rise to a process of deglycosylation of the oleuropein [21].

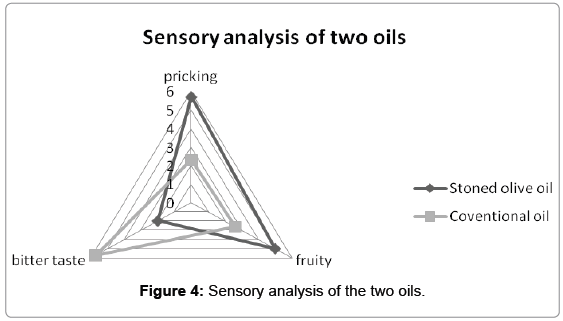

Sensory quality: Phenolic compounds, together with the combined bouquet of volatile compounds, modulate the perceived sensory characteristics of VOO, being phenolic molecules responsible of taste (bitter) and chemesthetic (pungency sensations). Also, jointly with other antioxidants such as tocopherols, carotenes and squalene, the phenolic molecules are directly correlated with the shelf-life of virgin olive oil [22]. The process of the elimination of stone before crushing supports the concentration of total polyphenols which plays a significant role in the oxidative stability and the determination of sensory consistencies. Figure 4 shows that for the fruity aspect, conventional oil presented the weakest values (2.6) but this character is very important for oil obtained from stoned fruits (5.1).

The same observation has been noted for the pricking aspect; the values ranged from 2.3 to 5.7. On the other hand, for the bitter aspect it was observed that the stoned samples presented the lowest values (2.1). The destoning process improves the flavor of olive oil since it increases the fruity aspect and the prickly taste in a significant manner whereas it decreases oil bitterness. These results are in agreement with that found in the literature [7,8,23-25] that showing that the oils obtained from destoned pulp had a higher polyphenol content compared to oils obtained from dough together. De-stoned oils had a larger amount of C 5 and C 6 volatile compounds responsible for positive ratings of the flavor. In fact, the increase is due to the removal of seeds that contain 13-metabolizing enzyme activities other than hydro peroxide lyase hydro peroxides, resulting in a net decrease in grade C 6 unsaturated aldehydes during the extraction process of oil olive. (C 6 aldehydes, C 6 alcohols, C 5 alcohols and C 5 carbonyls).

Influence of destoning at the environmental and economic level: The extraction of olive oil generates huge quantities of wastes that may have a great impact on land and water environments because of their high phytotoxicity. Several studies have proven the negative effects of these wastes on soil microbial populations [26], on aquatic ecosystems [27] and even in air medium [28]. Therefore, there is a need for guidelines to manage these wastes through technologies that minimize their environmental impact and lead to a sustainable use of resources. Indeed, in Tunisia, the majority of oil mills use the three phase system to process about 100 T of olives per day and there is always the need to add water to achieve the separation. Approximately, about each ton of olives produces 1 m3 of waste water. It has been noted that, when the pulp is separated from the stone before the extraction, the moisture of the paste increases up to 67%, the quantity of water added becomes negligible and thus for each Ton only 0,46 m3 is produced.

On the other hand, considering the calorific value of the pomace and the increase in the price of fossil fuels, it seems appropriate to examine the processing and use this by-product for energy in order to reduce disposal costs of residues from oil mills. The humidity of around 50% present in the pomace obtained from continuous systems does not allow the direct upgrading of these by-products in the energy sector. On the contrary, the pomace obtained after destoning is depleted in water and does not require further treatment, making its utilization in the energy path easier and less expensive.

Optimization of parameters of stoned olive oil extraction

The yields were integrated by the NemrodW software in order to estimate the importance of each parameter (Table 5). In the table it is clear that the temperature of malaxation is a determining factor.

| Name | Coefficient | Standard deviation | Significance |

|---|---|---|---|

| b0 | 16.14 | 5.87 | * |

| b1 | 4.45 | 0.27 | **** |

| b2 | 2.06 | 0.11 | * |

| b3 | 1.12 | 1.80 | * |

| b11 | -1.01 | 0.00 | * |

| b22 | -0.00 | 0.00 | |

| b33 | -0.64 | 0.19 | |

| b12 | 3.68 | 0.00 | **** |

| b13 | 2.96 | 0.04 | **** |

| b23 | 0.03 | 0.02 |

Table 5: Estimations and statistics of the coefficients by the NemrodW software. ****Very significant; ***Fairly significant; *Little significant. 1: Temperature (°C); 2: Time of malaxation (min); 3: Percentage of additive (%).

Indeed by increasing the temperature the oil viscosity was decreased and the quantity extracted increased. The time of malaxation and the percentage of additive also have a significant effect. On the other hand, an interaction between the temperature and the time of malaxation improves this phenomenon. An interaction between the temperature and the percentage of talc gives very significant effects. The scale model which connects the yield with the three parameters is presented in the following formula:

Y=16.14 + 4.45 × X1 + 2.06 × X2 + 1.12 × X3 - 1.01 (X1 × X1) + 3.68 × (X1 × X2) + 2.96 × (X1 × X3)

The objective was the optimization of the conditions of olive oil extraction. Table 6 summarizes the levels of the factors which maximize the yield of extraction for each significant interaction. To obtain the best result, the best temperature and time of extraction were found to be at 37°C and 35 min. For the percentage of additive, the optimum was 1.5%.

| Interactions | Factors | Yield (%) | ||

|---|---|---|---|---|

| T° (°C) | Time (min) | Talc (%) |  |

|

| T°-Time | 37 | 35 | 28.7 | |

| T°-% | 37 | 1.5 | 28.9 | |

| %-Time | 35 | 1.5 | 27.9 | |

| Optimum conditions | 37 | 35 | 1.5 | 28.5 |

Table 6: Optimum conditions of temperature, time and dose of adjuvant for best extraction.

Influence of the conditions of extraction on sensory quality

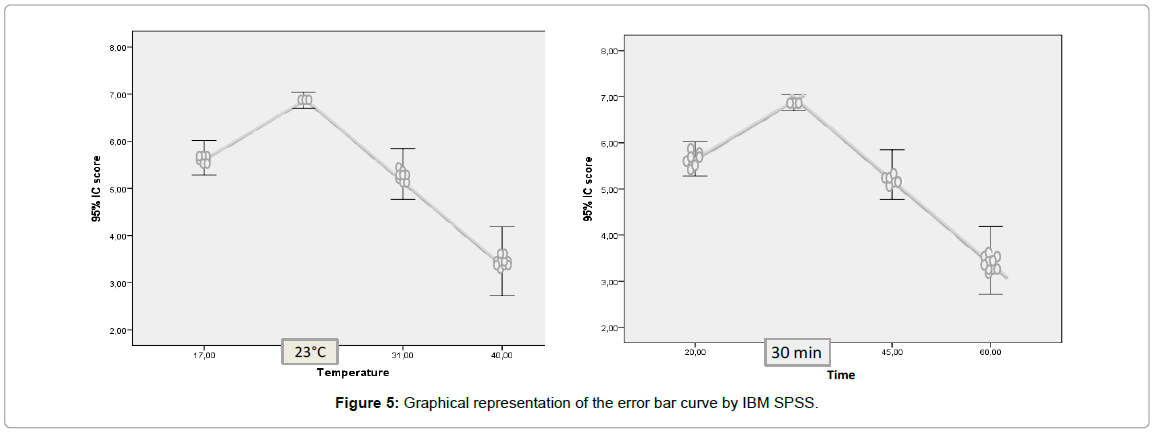

Extraction conditions, in particular the time and temperature of malaxation, produce oils with different flavors [29]. Indeed, these two parameters modify the content of aldehydes and esters which are responsible of positive aroma, and are formed by the action of the lipoxygenase enzyme released when the fruit is crushed and mixed during the stage of malaxation. In this respect, the IBM SPSS software has been used in order to determine the influence of these parameters on the quality. The bar graph of error (Figure 5) shows a reduction in score of the sensory analysis according to temperature and the time of extraction.

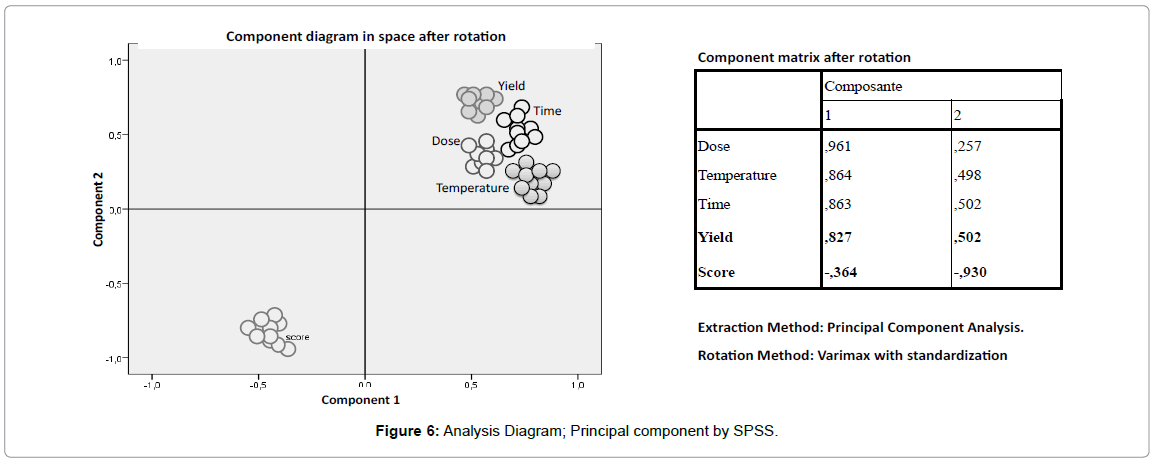

The temperature of 23°C and the time of malaxation of 30 min were the critical points beyond which these two parameters negatively affect the sensory score. Otherwise, it was noted that the length of the error bar was variable, which explains the difference between the variances in these groups. It was shown previously how the positive olive oil attributes are correlated positively to the quantity of polyphenols. Figure 6 confirms these results. Indeed the temperature has a positive correlation with the extraction yield.

However, it is negatively correlated with the oil quality. The same results were found as a function of time: long mixing times were associated to an oil rate increase and a concentration of the volatile compounds responsible for the pleasant taste decrease. In other words, increasing the temperature and the mixing time will result in a reduction in viscosity and an improve of the amount of oil extracted, but it may reduce the quality by promoting the oxidation conditions. In conclusion, the optimum conditions to preserve these aromatic compounds and at the same time having a significant performance is presented in Table 7.

| Interaction | Factors | Content of total polyphenols(mg d’EAG/kg) | Yield of extraction (%) | ||

|---|---|---|---|---|---|

| T°(°C) | Time (min) | Talc(%) | |||

| Temp-Time | 33 | 35 | 2 | 266 | 27 |

| T°-% | 25 | 1 | 280 | 29 | |

| %-Time | 27 | 1 | 281 | 27 | |

| CO | 28 | 31 | 1 | 275 | 29 |

Table 7: Optimum condition to achieve the best yield and total polyphenols. aExpressed as min, bExpressed as % of oleic acid, cExpressed as meq of O2.

Conclusions

In this work we proposed to carry out, before olive oil extraction, the separation of the pulp from the stone. This innovative system brings not only to a reduction of the production cost but also, due to a less water consumption, to a reduction of pollution caused by the exhaust of by-products. In fact, the experimental study has showed how the separation of the stones from the olive reduces the adsorption of water. The absence of the stones in the paste, that are considered water absorbents, preserves the moisture of the mixture and, therefore, the addition of water during mixing is no longer necessary. Furthermore, as the separation takes place at high temperatures, the paste is instantaneously heated and a mixing of 35 min instead of 45 min is sufficient to squeeze out the oil of higher quality. This system also results in a reduction for the storage period of olives before their treatment, thus a better quality of product. In fact, preliminary results have shown that the extraction of oil after destoning made it possible to decrease acidity, to increase the content of polyphenols (natural antioxidant) and to improve the organoleptic quality of oil.

References

- Bedbabis S, Rouina BB, Boukhris M (2010) The effect of waste water irrigation on the extra virgin olive oil quality from the Tunisian cultivar Chemlali. Scientia Horiculturae 125: 556-561.

- Manna C, Migliardi V, Golino P, Scognamiglio A, Galletti P, et al. (2004) Oleuropein prevents oxidative myocardial injury induced by ischemia and reperfusion. J Nutr Biochem 15: 461-466.

- Owen RW, Giacosa A, Hull WE, Haubner R, Spiegelhalder B, et al. (2000) The antioxidant/anticancer potential of phenolic compounds isolated from olive oil. Eur J Cancer 36: 1235-1247.

- Somova LI, Shode FO, Ramnanan P, Nadar A (2003) Antihypertensive, and atherosclerotic and antioxidant activity of triterpenoids isolated from Olea europaea, subspecies africana leaves. J Ethopharmacol 84: 299-305.

- Amirante R, Cini E, Montel GL, Pasqualone A (2001) Influence of mixing and extraction parameters on virgin olive oil quality. Grasas y Aceites 52: 198-201.

- Frega N, Caglioti L, Mozzon M (1999) Oils extracted from olives pitted: Chemical composition and quality parameters. Olivo & Olio 12: 40-44.

- De Nino A, Di Donna L, Mazzotti F, Sajjad A, Sindona G, et al. (2008) Oleuropein expression in olive oils produced from drupes stoned in a spring pitting apparatus (SPIA). Food Chem 106: 677-684.

- Amirante P, Clodoveo ML, Dugo G, Leone A, Tamborrino A (2006) Advance technology in virgin olive oil production from traditional and de-stoned pastes: Influence of the introduction of a heat exchanger on oil quality. Food Chem 98: 797-805.

- Amirante P, Baccioni L, Bellomo F, Di Renzo GC (1987 Facilities for olive oil extraction from olive pastes dènoyantèes. Olivae 17: C.O.I. Madrid.

- EEC (1991) European Union Regulation EEC/2568/91 on the characteristics of olive oil and their analytical methods and later modification. Off J Eur Commun L248: 1-82.

- Gutierrez F, Albi MA, Palma R, Rios JJ, Olìas JM (1989) Bitter taste of virgin olive oil: Correlation of sensory evaluation and instrumental HPLC analysis. J Food Sci 54: 68-70.

- Conseil Oleicole International (2011) Sensory analysis of olive oil: organoleptic evaluation method of virgin olive oil.

- Lenth RV (2009) Response-Surface Methods in R, Using rsm. J Stat Software 32.

- Masmoudi M, Besbes S, Chaabouni M, Robert C, Paquot M, et al. (2008) Optimization of pectin extraction from lemon by-product with acidified date juice using response surface methodology. Carbohydr Polym 74: 185-192.

- Mathieu D, Nony J, Phan-Tan-Luu R (2000) NEMROD-W software. Marseille: LPRAI.

- Caro AD, Vacca V, Poiana M, Fenu P, Piga A (2006) Influence of technology, storage and exposure on components of extra virgin olive oil (Bosana cv) from whole and de-stoned fruits. Food Chem 98: 311-316.

- Saitta M, Lo Turco V, Pollicino D, Dugo G, Bonaccorsi I, et al. (2003) Olive oil pitted pulp obtained from cv Coratina and Paranzana=Olive oils from stoned paste of Coratina and Paranzana varieties. Rivista Italiana Sostanze Grasse 80: 27-34.

- Del Carlo M, Sacchetti G, Di Mattia C, Compagnone D, Mastrocola D, et al. (2004) Contribution of the phenolic fraction to the antioxidant activity and oxidative stability of olive oil. J Agric Food Chem 52: 4072-4079.

- Servili M, Selvaggini R, Taticchi A, Esposto S, Montedoro GF (2003) Volatile compounds and phenolic composition of virgin olive oil: optimization of temperature and time exposure of olive pastes to air contact during the mechanical extraction process. J Agric and Food Chem 51: 7980-7988.

- Amirante P, Clodoveo ML, Leone A, Tamborrino A, Paice A (2010) Influence of the Crushing System: phenol content in virgin olive oil produced from whole and de-stoned pastes. In: Olives and Olive Oil in Health and Disease Prevention, Academic Press Ltd, Elsevier science Ltd, London, England. pp: 69-76.

- Wang W, De-Dios-Alche J, Castro AJ, Rodriguez-Garcia MI (2001) Characterization of seed storage proteins and their synthesis during seed development in Olea europaea. Int J Develop Biology 45: S63-S64.

- Baldioli M, Servili M, Perretti G, Montedoro GF (1996) Antioxidant activity of tocopherols and phenolic compounds of virgin olive oil. J Am Oil Chem Soc 73: 1589-1593.

- Angerosa F, Basti C, Vito R, Lanza B (1999b) Effect of fruit stone removal on the production of virgin olive oil volatile compounds. Food Chem 67: 295-299.

- Luaces P, Pérez AG, Sanz C (2003) Role of olive seed in the biogenesis of virgin olive oil aroma. J Agric Food Chem 51: 4741-4745.

- Runcio A, Sorgona L, Mincione A, Santacaterina S, Poiana M (2008) Volatile, Compounds of virgin olive oil obtained from Italian cultivars grown in Calabria, Effect of processing methods, cultivar, stone removal, and antracnose attack. Food Chem 106: 735-740.

- Paredes MJ, Moreno E, Ramos-Cormenzana A, Martinez J (1987) Characteristics of soil after pollution with wastewaters from olive oil extraction plants. Chemosphere 16: 1557-1564.

- Greca MD, Monaco P, Pinto G, Pollio A, Previtera L, et al. (2001) Phytotoxicity of low-molecular-weight phenols from olive mill wastewaters. Bull Environ Contam Toxicol 67: 352-359.

- Rana G, Rinaldi M, Introna MV (2003) Volatilization of substances after spreading olive oil waste water on the soil in a Mediterranean environment. Agric Ecosystems Envir 96: 49-58.

- Ranalli, Pollastri L, Contento S, lannucci E, Lucera L (2003) Effect of olive paste kneading process time on the overall quality of virgin olive oil. Europ J Lipid Sci Tec 105: 57-67.

Relevant Topics

Recommended Journals

Article Tools

Article Usage

- Total views: 17438

- [From(publication date):

December-2015 - Aug 25, 2025] - Breakdown by view type

- HTML page views : 12740

- PDF downloads : 4698