On the Future of Lignin-Derived Materials, Chemicals and Energy

Received: 01-Aug-2016 / Accepted Date: 02-Aug-2016 / Published Date: 08-Aug-2016

19183Editorial

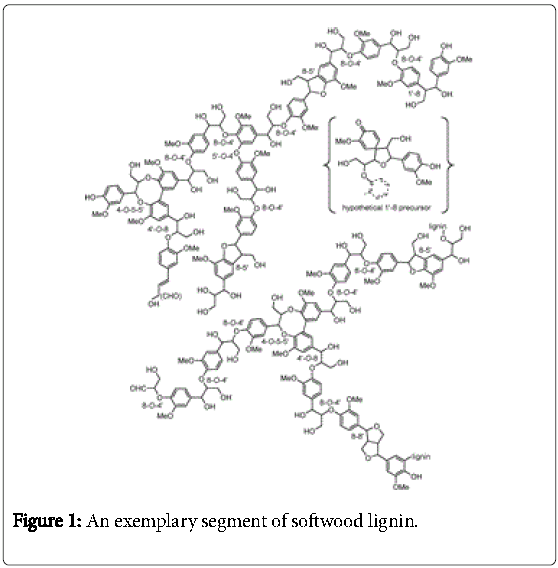

As the global demand for energy, chemicals, and materials continues to increase, so will the need for more sustainable alternatives technologies. Woody biomass, composed of renewable lignocellulose polymers, will be paramount towards developing greener alternative processes and products that will address a growing demand for renewable resources. Lignin [1] (see Figure 1) is a major component of lignocellulose biomass and the second most abundant terrestrial organic polymer on Earth after cellulose, which is as ubiquitous as it is underutilized.

However, this reality is rapidly changing. The production of consistent, relatively pure, streams of industrially isolated lignin coupled with improved spectroscopic understanding of its chemical nature, and novel green application strategies are fundamentally changing the future of lignin for materials, chemicals, and energy.

Lignin As A Resource

Lignin is industrially extracted from wood on the order of 50 millions of tons per year from the global chemical pulping industry and the growing volumes of lignin from cellulosic ethanol plants. The most common delignification process is the sulfate (kraft) pulping process [2]. During kraft pulping, wood is impregnated with cooking liquor containing sodium sulfide and hydroxide in order to cleave lignin-based aryl-ether linkages, which result in the solubilization and separation of lignin fragments from cellulosic fibers. In this solubilized form, nearly 98% of kraft lignin is burned as a less-than-optimal energy resource within pulp mill recovery boilers in order to recover pulping chemical and energy. Notably, the capital costs associated with a recovery furnace and the desire by the pulping industry to obtain higher material yields have spurred increasing research towards repurposing kraft lignin as a value-added byproduct and bioresource for sustainable innovative valorisation research and higher-utility commercial applications [3].

The Challenge

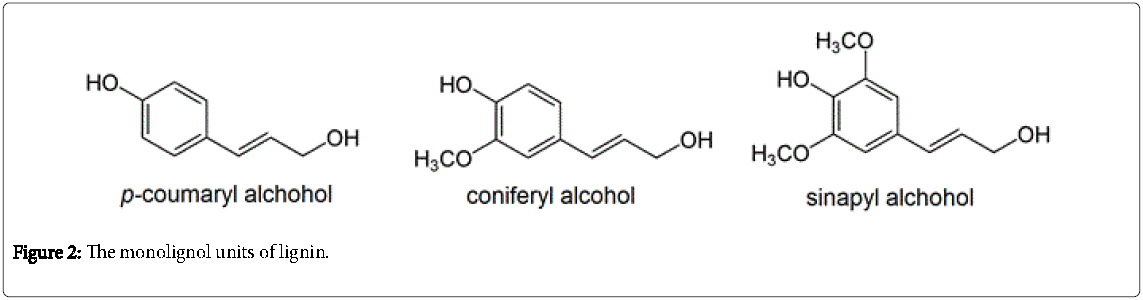

Lignin is a recalcitrant biopolymer composed of varying proportions of cross-linked phenylpropane units based on: p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol (Figure 2) [4,5].

Opportunely, our understanding of lignin structure and chemical nature has advanced alongside efforts to process the compound it into higher-utility compounds. Spectroscopic methods employing nuclear magnetic resonance (NMR) have and continue to be one of the most powerful tools in lignin structure elucidation providing quantitative insight into its structure [6,7]. Today, advancements in lignin characterization with NMR are represented via comprehensive approaches that include quantitative 1H- and 13C-NMR 1D/2D experiments, along with more recent additions such as 2D Whole Cell NMR and phosphitylation followed by 31P-NMR [8,9]. Ultimately, these spectroscopic studies along with FT-IR, wet-chemistry methods serve to inform our understanding of many types, changes to, and effects of lignin in a variety of novel and useful applications [10].

Applications Of Lignin For Biochemical And Biomaterials And Bioenergy

Lignin from chemical pulping operations, as well as increasing quantities of lignin from commercial cellulosic ethanol plants are considered to be promising resources for the production of renewable aromatic chemicals and biofuels via lignin pyrolysis. With the use of catalysis, pyrolysis experiments can be designed to thermally decompose lignin into phenolics and other substituted aromatics [11]. Although the phenolic compounds have valuable commercial markets, the diverse mixture of compounds makes purification difficult and either new pyrolysis process chemistry needs to be developed to narrow the product stream and/or improved deoxygenation and upgrading chemistry must be developed to yield a fungible fuel product. Additionally, pyrolysis of lignin also yields valuable gases as a byproduct that can be captured and used as an energy resource or chemically upgraded to higher molecular weight compounds. The process also generates a bio-char fraction that has applications in air, soil and wastewater treatment [12,13].

Beyond degradative-strategies, lignin also has a number of applications as a "drop-in" material for industrial composites and admixtures [14]. This is particularly valuable as the loading of lignin in strictly synthetic polymers can yield composites with equivalent or improved physical properties with the additional benefit of improving environmental and cost performance issues. Lignin as an admixture also better leverages supplies of limited fossil fuels as a feedstock used to produce synthetic polymeric building blocks [15]. As such, lignin has been implemented as a component in polyethylene, rubber, and thermoplastic composites among many other types [15-18]. Interestingly, lignin also imparts natural antioxidant, rheological or antidegradation properties beneficial for drop-in additives in current products such as an dispersants, cements, paint additives, inks, and dyes [3,19,20].

Future lignin opportunities include the generation of adhesives, resins, and carbon fibers [21,22]. Carbon fibers are essentially graphite fibers that are virtually 500% stronger than steel, yet at only 20-30% of the weight consequence. Moreover, carbon fibers also have a thermal expansion that is lower than most commonly used alloys implemented today and can be spun into a strand thinner a hair of a human beingbut with the tensile strength greater than titanium or shaped into rigid molds are be suitable for many applications in the automotive, aviation and power generation industries. For example, carbon fibers as a replacement for aluminium parts in the manufacturing of cars would reduce the weight of the vehicle without sacrificing strength, thereby improving fuel efficiencies without sacrificing the performance properties of today’s motors or electric/hybrid engine systems that are in use today. Despite these promising mechanical properties, mainstream penetration of carbon fibers is inhibited due to the cost of conventional precursory materials such as petroleum-derived polyacrylonitrile; while lignin has considerable potential as a renewable building block that can reduce the cost of carbon fiber manufacturing, the promise of high-performance lignin-derived carbon fibers remains a research challenge. This specific consequence is due to limited strength profile properties of lignin based carbon-fibers and yet our advancing understanding of the chemical nature of lignin, properties associated with lignin-based carbon fibers, and novel carbonization strategies suggest that these issues will be overcome [3,5,23,24].

Lastly, lignin has been investigated as a feedstock for bioenergy development. This is particularly imperative as the needs for sustainable energy platforms will only increase over the next decades as industrialized and developing nations countries continue to advance and will need increased energy and fuels [25]. While pyrolysis coupled with hydrogenation studies have been demonstrated to yield gasolinelike molecules from lignin, low-energy biological exploits have been reported that make use of oil-producing (oleaginous) microbes with an affinity to degrade plant materials, including lignin [26,27]. The oils, produced by these microbes are intracellularly stored as triacylglycerides, which can be readily transesterified into long-chain fatty acid methyl esters (FAMEs) that have applications as a fungible biodiesel [28]. Recently, a promising organism for biodiesel production is oleaginous Rhodococci which can utilize the aqueous waste streams of a biorefinery waste . These effluents generally contain degraded lignin and carbohydrates, which are simultaneously processed by oleaginous microbes to produce triacylglycerols that can be esterified into FAMEs [29]. Interestingly, the conversion of lignin-contaminated effluents into biodiesel can provide a strategic avenue to better optimize biofuel production and waste stream treatment for a number of industries [30,31]. Moreover, engineered strains of Rhodococci can potentially accumulate high-value metabolic intermediates as opposed to specialty oils for an even broader impact in biotechnological markets [32].

Overall, the future of lignin for advanced materials, chemicals, energy has reached a near unprecedented potential. The avenues for lignin valorization are plentiful, substantial, and feasible. Hence, while our understanding of the biopolymer continues to improve, so will the marketable applications.

References

- Kozlowski R, Batog J, Kubica S, Sytniewski L (2012) Nanolignin as an effective UV blocker for fabrics, nonwoven and polymers foils. Sci Isr Technol Adv 14: 69-73.

- Wells T, Kosa M, Ragauskas AJ (2013) Polymerization of Kraft lignin via ultrasonication for high-molecular-weight applications. Ultrason Sonochem 20: 1463-1469.

- Ko F (2014) Lignin based carbon nanofibers by electro spinning. Bulletin of the American Physical Society.

- Braun JL, Holtman KM, Kadla JF (2005) Lignin-based carbon fibers: oxidative thermostabilization of kraft lignin. Carbon 43: 385-394.

- Ralph S, Ralph J, Landucci L (2004) NMR database of lignin and cell wall model compounds.

- Capanema EA, Balakshin MY, Kadla JF (2004) A Comprehensive approach for quantitative lignin characterization by NMR spectroscopy. Journal of agricultural and food chemistry 52: 1850-1860.

- Mansfield SD, Kim H, Lu F, Ralph J (2012) Whole plant cell wall characterization using solution-state 2D NMR. Nature protocols 7: 1579-1589.

- Heitner C, Dimmel D, Schmidt J (2016) Lignin and lignans: advances in chemistry. CRC press, New York.

- Ben H, Ragauskas AJ (2011) Pyrolysis of kraft lignin with additives. Energy Fuels 25: 4662-4668.

- Li X, Su L, Wang Y, Yu Y, Wang C, et al.(2012) Catalytic fast pyrolysis of Kraft lignin with HZSM-5 zeolite for producing aromatic hydrocarbons. Frontiers of Environmental Science & Engineering 6: 295-303.

- Helleur R, Popovic N, Ikura M, Stanciulescu M, Liu D (2001) Characterization and potential applications of pyrolytic char from ablative pyrolysis of used tires. J Anal Appl Pyrolysis 58: 813-824.

- Schorr D, Diouf PN, Stevanovic T (2014) Evaluation of industrial lignins for biocomposites production. Industrial Crops and Products 52: 65-73.

- Samal SK, Fernandes EG, Corti A, Chiellini E (2014) Bio-based polyethylene–lignin composites containing a pro-oxidant/pro-degradant additive: Preparation and characterization. J Polym Environ 22: 58-68.

- Canetti M, Bertini F (2007) Supermolecular structure and thermal properties of poly (ethylene terephthalate)/lignin composites. Composites Science and Technology 67: 3151-3157.

- Hilburg SL, Elder AN, Chung H, Ferebee RL, Bockstaller MR, et al. (2014) A universal route towards thermoplastic lignin composites with improved mechanical properties. Polymer 55: 995-1003.

- Jiang C, He H, Jiang H, Ma L, Jia DM (2013) Nano-lignin filled natural rubber composites: Preparation and characterization. Express Polymer Letters 7.

- Belgacem MN, Blayo A, Gandini A(2003) Organosolv lignin as a filler in inks, varnishes and paints. Industrial Crops and Products 18: 145-153.

- Dilling P, Loeffler VR, Prazak G, Thomas KU (1990) Production of lignosulfonate additives.

- Thanh Binh NT, Luong ND, Kim DO, Lee SH, Kim BJ, et al. (2009) Synthesis of lignin-based thermoplastic copolyester using kraft lignin as a macromonomer. Composite Interfaces 16: 923-935.

- Yang GS, Yoon JH, Nillesh SL, Kim YC (2011) Lignin-based complex precursor for carbon fibres and method for preparing lignin-based carbon fibres using it.

- Baker DA, Gallego NC, Baker FS (2012) On characterization and spinning of organic-purified lignin toward manufacture of low-cost carbon fiber. J Appl Polym Sci 124: 227-234.

- Mainka H, Täger O, Körner E, Hilfert L, Busse S, et al. (2015) Lignin-an alternative precursor for sustainable and cost-effective automotive carbon fiber. J Mater Res Technol 4: 283-296.

- Bergthorson JM, Thomson MJ (2015) A review of the combustion and emissions properties of advanced transportation biofuels and their impact on existing and future engines. Renewable and Sustainable Energy Reviews 42: 1393-1417.

- Ben H, Ragauskas AJ (2012) Pyrolysis of biomass to biofuels. Amer Chemical Soc.

- Kosa M, Ragauskas AJ (2011) Lignin to lipid bioconversion by oleaginous Rhodococci. Amer Chemical Soc.

- Wells T, Ragauskas AJ (2012) Biotechnological opportunities with the ß-ketoadipate pathway. Trends in biotechnology 30: 627-637.

- Wells T, Wei Z, Ragauskas AJ (2015) Bioconversion of lignocellulosic pretreatment effluent via oleaginous Rhodococcus opacus DSM 1069. Biomass and Bioenergy 72: 200-205.

- Beckham GT, Johnson CW, Karp EM, Salvachúa D, Vardon DR (2016) Opportunities and challenges in biological lignin valorization. Current opinion in biotechnology 42: 40-53.

- Ragauskas AJ, Williams CK, Davison BH, Britovsek G, Cairney J, et al. (2006) The path forward for biofuels and biomaterials. Science 311: 484-489.

- Lin L, Cheng Y, Pu Y, Sun S, Li X, et al. (2016) Systems biology-guided biodesign of consolidated lignin conversion. Green Chemistry.

Citation: Wells T, Ragauskas AJ (2016) On the Future of Lignin-Derived Materials, Chemicals and Energy . Innov Ener Res 5: e117.

Copyright: ©2016 Wells T, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 13006

- [From(publication date): 8-2016 - Aug 30, 2025]

- Breakdown by view type

- HTML page views: 11942

- PDF downloads: 1064