Study of the Soil Cutting by Knife Flat Active Rippers â Milling Cutter

Received: 03-Nov-2019 / Accepted Date: 16-Mar-2020 / Published Date: 23-Mar-2020

Abstract

The results of comparative experimental study of combined front plough with an active working body, the front plough with passive working bodies and plough PLN-5-35 in the unit with the tractor T-50K are given. It was found that the use of active working bodies, in addition to performing the function of technological and propulsion, allows improving the quality of work and energy indices of the front of the plough in the processing of soil with low humidity content and plant remains.

Keywords: Plough, Smooth ploughing, High-power wheeled tractor, Active working body, The quality of ploughing

Introduction

Increased productivity of plough sets is possible by increasing the capture width and operating speed. Width of capture of modern serial ploughs has reached 3,15 m, its further increase is connected with overcoming of a number of considerable difficulties. The length of the plough with the number of its housings increases to a greater extent than the width, as distance in the longitudinal direction between the housings 2-3 times greater than their width of capture. When the plough length increases quality of ploughing deteriorates, as the plough worse adapts to field microrelief and so deviations from the desired depth of ploughing width increases his capture, maneuverability of plough set deteriorates, the specific gravity of the plough dramatically increases.

Operating speed of ploughing currently ranges from 7-9 km/h, since further increase leads to the spreading of the soil and a sharp rise in the traction resistance of the plough.

Active working body receiving the drive from the tractor produces Shredders and loosening the topsoil, thereby preventing clogging of the space intercase cameos and blocks the processing of fields with a significant amount of crop residues and improves the quality of treatment. Elements of technology and combined plough with active and passive working bodies are protected by patents [1-4].

Materials and Methods

For loosening and compacted upper soil layers, as well as shredding crop residues on the combined offer frontal plough install active cutter with flat blades. Flat blades at the lowest possible energy costs provide the required crumbling of the soil as the soil after the mill processing is exposed to the ploughing.

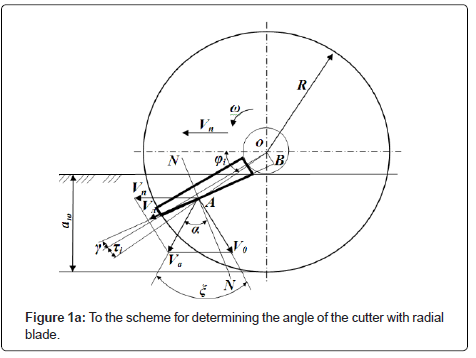

Active flat cutter knives can be set [1-4] radially (Figure 1a) with an inclination of the blade in the rotational direction of radius, or vice versa (Figure 1b). When installing the blades with a slope of the radius of rotation on the go jamming deteriorates of cut plant residues, so this type of interaction cutter knives we have not seen. It is well known that the nature of the interaction of the blade and the force required to cut the material largely depends on the angle α between the absolute speed V0 cutting blade points and the normal NN to it.

For milling with radial blades.

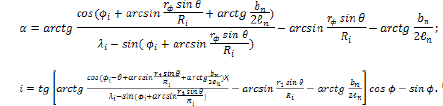

α = ξ – τi – γ (1)

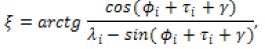

where ξ - the angle between the peripheral speed Va and an absolute velocity V0 cutting point of the knife blade.

τi - the angle between the peripheral velocity V0 of the knife blade point and the normal N - N him.

From Figure 1, a), we have

(2)

(2)

where bn - width of the blade;

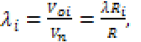

λi - the kinematic parameters for this point of the cutter blade

(3)

(3)

where Ri - the distance from the cutter to the axis of rotation of the point of the knife blade.

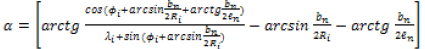

Substituting the values of εi, γ and τi to obtain:

(4)

(4)

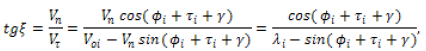

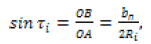

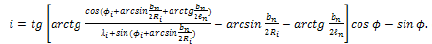

Then the knife slip ratio i on the material being cut is determined by the following formula

(5)

(5)

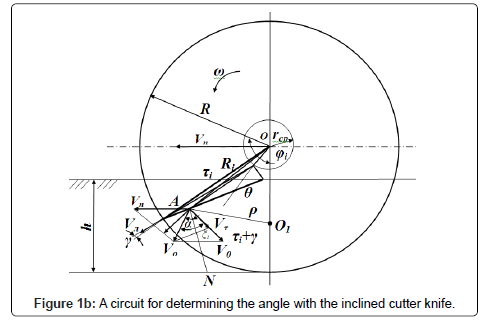

For cutters with blades tilted back at an angle of θ (Figure 1b)

d=ξ–τi (6)

(7)

(7)

where rf-the radius of the blade attachment.

Substituting the values ε and τi (6), we obtain

(8)

(8)

From these expressions (7) and (8) that the slip ratio i of the cut material knife blade has a variable numerical value, which depends on the blade position relative to the soil surface, kinematic parameter λi, the width of the blade b, the distance Ri from the blade point to the axis of rotation milling and friction angle of the cut material. On the value of i for the milling with inclined blade but these factors affect and angle θ.

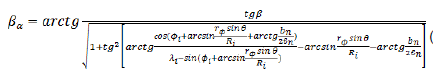

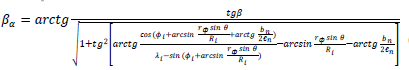

Substituting the values of α in the corresponding dependence define “real” value of the angle of sharpening βα, the transformation ratio of the angle and shape of sharpening Kβ blade

(9)

(9)

(10)

(10)

(11)

(11)

settlement of the obtained expression results at λ = 2,2, θ = 30˚, Ri = 280 mm, β = 20˚ are shown in Table 1.

| Ri Sm | φi =45˚ | φi =85˚ | ||||

|---|---|---|---|---|---|---|

| α | I | Кβ | α | I | Кβ | |

| 10 | 68˚40 | 2,23 | 0,65 | 22˚20 | 0,56 | 1,08 |

| 15 | 37˚10 | 0,87 | 1,04 | 13˚30 | 0,42 | 1,1 |

| 20 | 29˚40 | 0,65 | 1,24 | 6˚10 | 0,09 | 1,13 |

| 25 | 24˚10 | 0,59 | 1,35 | 4˚40 | 0,06 | 1,15 |

Table 1: Variation of the angle α, ε coefficient Kβ and depending on the angle ∅1 (blade position) and the distance Ri from the point of the knife blade rotational axis.

From the Table 1 it is seen that the various blades have different coefficients of terms of longitudinal displacement ε, and accordingly, the angle β and sharpening blades form variously transformed. Ε coefficient with increasing angle of rotation φi of the knife and the kinematic parameter λ decreases along the entire length of the knife blade.

Conclusion

1) Application of active working bodies, in addition to performing the function of technological and propulsion, allows to improve the quality of work and energy indices of the front of the plough in the processing of soil with low moisture content and plant remains.

2) Optimal value of angle position accords with φi and Ri distance from the point of the blade to the blade rotation axis.

References

- Mamatov FM, Ergashev IT, Temirov IG (1991) AS SU 1678220. The two-storey plough-Opubl.

- Panov IM, Kuznetsov YA (1973) Promising directions of creation of the combined tillage and seeding machines. TSNIITEI.

- Mamatov FM, Ergashov GKH, Xoliyarov YB, Mirzaxodjayev SHSH, Kurbanov SHB (2018) Plow for smooth plowing with combined working bodies. Scientific Journal. pp:264-266.

- Mamatov FM, Mirzaxodjayev SHSH (2018) Substantiate the parameters of a combined frontal plug with an active working body. Agro Science 56: 94-95.

Citation: Mirzaxodjaev S (2020) Study of the Soil Cutting by Knife Flat Active Rippers – Milling Cutter. Innov Ener Res 9: 237

Copyright: © 2020 Mirzaxodjaev S. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 2531

- [From(publication date): 0-2020 - Dec 20, 2025]

- Breakdown by view type

- HTML page views: 1706

- PDF downloads: 825