A Review of Microbial Enhanced Oil Recovery Applications Projects

Received: 19-May-2018 / Accepted Date: 08-Aug-2018 / Published Date: 16-Aug-2018 DOI: 10.4172/2472-0518.1000152

Keywords: Enhanced oil recovery; Tertiary recovery; Microbial oil recovery; Interfacial tension; Wettability; Water cut; Flooding

Introduction

In the world today, we rely greatly on crude oil as a major source of energy. And a huge percentage of this precious non-renewable resource is inaccessible and therefore left behind in the reservoir after the conventional Oil extraction methods have been applied. However, we really do need to produce more crude oil in order to be able to match up to the ever rising world demand for energy and this explains the importance of having positive improvement in the Enhanced Oil Recovery (EOR) activities. These techniques seek to manoeuvre the major hurdles preventing efficient oil recovery like the high viscosity of crude oil, low permeability of some reservoirs, and high oil-water interfacial tensions that usually results in high capillary force keeping hold of the oil in the reservoir rock.

Microbial Enhanced Oil Recovery (MOER) is one of the many Enhanced Oil Recovery techniques used in the industry and it has to do with bacteria and their by-products being used for mobilization of oil in a reservoir. We can define MEOR as a process that increases oil recovery by inoculating micro-organisms in a reservoir, projecting bacteria and their by-products causes some positive effects such as the formation stable oil-water emulsions, reduced interfacial tension due to the residual oil being mobilized, and diverting of injection fluids through upswept areas of the reservoir by clogging high permeable zones. MEOR activities are getting increasingly accepted around the world because it is cost effective and also environmental friendly in its process to increase the volume of crude oil being produced.

Right Now, the volume of crude oil that have been produced have been witnessing reduction in volume of output in a good number of zones in the world as a result of Oilfield maturity and an example is the Major oilfields in the North Sea [1]. Another concern is the increment in the demand for energy as a result of the global population growth and increasing difficulty in finding new oil fields. There is an irrefutable necessity to discover alternative methods to increase oil recovery from oilfields existing worldwide. Undoubtedly, fossil fuels would continue to be the mainstay energy source supply continuously till the nearest future regardless of the high level of investments in other energy sources like solar energy, biofuels, wind energy, etc. The current global energy production projects this from the fact that fossil fuels which currently stands at 80-90% with oil and gas taking about 60% [2].

In crude oil production, 30-40% of oil productions can account to primary oil recovery, whilst secondary recovery an account for an addition 15-25% with the use of methods like water injection, then a range of 35-55% is left in the reservoirs as residual. Residual oil is usually the primary focus of many EOR, they account for about 2-4 trillion barrels [3] or almost 67% of the entire oil reserves [4]. Being able to produce oil left behind as residual is a major setback for companies in the oil and gas sector as they continue to look for less expensive and more effective means to aid recovery. Improved access to residual Oil would lead to an increment in global oil production whilst adding more years to the producing life span of well around the world.

The Oil industry makes use of EOR methods to optimize total crude oil recovery rate. Tertiary Recovery Methods (another name for Enhanced Oil Recovery) has different examples like Chemical flooding, injection of miscible Carbon di-oxide and Oil recovery through thermal means that uses heat as its major means of addition recovery of oil. Remarkable quantity of residual oil could be harnessed through Enhanced Oil Recovery techniques because the methods applied at the moment still leave roughly two-third as residual oil in wells around the world. Microbial Enhanced Oil Recovery (MEOR) which happens to be the focus of this project. It is the extraction of residual oil from reservoirs with the use of microorganism. This technique has the tendency to be carried out on a low budget planning and can also produce about 50% of the residual oil [5]. According to normal projected oil production decline curve, with the aid of field trials, we can see that the decline could be cancelled off or perhaps reversed with the use of MEOR and it is down to the factor of microbial growth and production of metabolites whose effect could alter physical and chemical properties of crude oil and reservoir rocks [6].

In this project work, consideration of microbial types involved in the process of MEOR and how they affect IFT (Inter facial Tension) between oil and water and the processes leading to the alteration of their wetting properties would be properly done. Although, experimental proof of this on growing bacterial systems is seeming to be notoriously complex.

The failure of Microbial Enhanced Oil Recovery (MEOR) technology is associated to a major factor which is the inadequate analysis of the conditions which classify oil reservoirs and the physiology of microbes which thrives under these conditions [7]. The activities of microbes used in MEOR method relies on the physical and chemical circumstances they face in a reservoir. The circumstances are temperature, salinity, pH, redox potential, pressure, etc. nevertheless these circumstances aren’t the same in all reservoir. Physical and Environmental factors usually have an effect on proliferation, growth of bacteria, survival and metabolism and can also reduce microorganism’s capability to formulate the required volume of metabolites desired for EOR [8]. Nevertheless, it’s popularly known that planning sufficiently could help overpower majority of these factors. Limiting factors for successful input of MEOR are as follows;

1. Reduced injectivity as a result of Microbial Plugging of the wellbore; With the aim of preventing plugging of the wellbore, processes like filtration prior to injection has to be taken, biopolymer production also has to be avoided, as well as minimization of adsorption of microbes to the surface of the rock with the use of spores, cell forms, or ultra-micro bacteria.

2. Distribution of necessary parts to target zones.

3. In-situ metabolic activity optimization as a result of factors like pressure, salinity, temperature and pH for all in-situ MEOR activities.

4. Microbial strains removal, lf they can survive in intense conditions at the reservoir.

5. Little in-situ concentration of bacterial metabolites; to solve this, we most likely would require the use of genetic engineering methods.

Methodology

Project evaluation method

Different MEOR case studies would be reviewed, the list of these cases are as follows;

1. The San Andres project

2. Tupungato-Refugio project

3. Xinjaing project.

The history of individual projects before the start of MEOR application and the suitability of the reservoir and operations to MEOR would be evaluated. Next the treatment design and frequency are reviewed. The project results are then evaluated in terms of:

• Production rate increase compared to baseline,

• Decrease in water cut,

• Increase in cumulative recovery,

• Microbe effectiveness as measured by oil compositional changes indicated by viscosity testing.

Field description, treatment and evaluation

San Andres project: This reservoir located in Hockley County, Texas, USA was discovered in 1945, and solution gas drive was used for its production until water-flooding begun in 1967 with 355 barrels per acre foot, at a saturation of 70%. MEOR application begun in 1994 and the oil in place at that time was 239 bbls/ac-ft at an oil saturation of 41%. Line drive pattern was used for the waterflooding with a spacing of 25 acres. The current formation pressure was assessed as 1000 psi. The produced gas-oil ratio is 500 SCF/bbl [9].

The average horizontal permeability of 1.7 md indicates pore throat size that is way smaller than what the microbes can enter. Nonetheless, most of the oil is from the natural fractures that the microbes can easily enter. 115°F is the reservoir temperature and it’s ideal for the growth of microbes. Producing at a water cut of 91%, the average production for each well is 14 BOPD.

Treatment: Treatments comprised of ten barrels of microbe filled water down the annulus. For the first treatment, all wells for this project were shut-in for 3 days, thereafter, during the subsequent treatments, they were shut-in overnight. The wells were treated for every 14 days for the first three months, then after that every 28 days.

Evaluation: The reservoir was stabilized on a consistent 6.5%/ year decline for three years before MEOR was begun. The decline has flattened to 0.6%/year. The production of water on this property is mixed with fresh water and then introduced. Water produced is metered only by carrying out well tests and is not adequately precise to the point where a conclusion concerning water-cut reduction can be drawn. Over the past 19 months 17,000 barrels of incremental oil have been produced which is 7% over the baseline. The on-going oil production rate of 440 BOPD is ten percent over baseline. The cumulative incremental upsurge is projected to stretch to 15% at the time the project ends.

Viscosity for an example well was studied versus shear rate and versus temperature. The baseline sample showed that these microbes can alter the crude to a significant extent. The area under the shear rate curve is reduced by 73% and the oil is more Newtonian. The temperature curve is shifted to the left approximately 10°F. Five samples taken after the start of MEOR indicate that the microbes are indeed effectively altering the crude in the reservoir.

At the end of its life the water flood would have left in place 205 bbls/ac-ft versus 199 with MEOR. The saturation of the residual oil is estimated to drop from 35.0% under water flood to 34.1% with MEOR, a 2.5% improvement.

Tupungato-refugio project

This field located in Tupungato County, Medoza, Argentina was found in 1930. In 1940, 1979 and 1986 the three wells in the project were completed in the Victor Oscuro formation. Production in the reservoir was through a combination of water drive, solution gas drive and water flood. In June 1994, MEOR began in one of the wells and by March 1995 it started in the two other wells. The original oil in place was 625 bbls/ac-ft with an oil saturation of 47% and gas saturation of 10% and average horizontal permeability of 0.8 mD. The wells are about 42 acres spaced and four spot pattern was used for water flooding. Fluid and rock characteristics favour microbe colonization. Completion methods for the wells are by open hole or slotted liner. The average production for each well is within the range of 90 BOPD, with a water cut of about 63%.

Treatment: The reservoir was initially treated with about 150 barrels of microbe-laden water, and then a 48 hour shut-in period was performed on 2 wells and for the other well it was 24 hours. The treatments that followed were 50 barrels every 15 days on two wells and every 30 days for the other well.

Evaluation: The project was on 7.1%/year decline for 29 months before MEOR was begun. For the past 14 months, from the time when MEOR began, the oil production rate has improved at a rate of 7.3%/ year. Also since the start of MEOR, water production has increased, but the water cut decreased from 63.5% to 62%. More data is needed to reach a conclusion regarding the rate of increase versus cumulative production. Over the past 14 months, incremental oil of about 19,000 barrels has been produced which is 19% above the baseline. Oil production is 270 barrels per day, 29% percent over baseline. The projected cumulative incremental increase is about 57% by the end of the life of the project [10].

Viscosity for an example project well was studied versus shear rate and versus temperature. The baseline sample showed microbes could modify the crude significantly. The area under the shear rate curve is reduced by 54% and the oil is more Newtonian. The temperature curve is shifted to the left approximately 10°F. The sample taken after the start of MEOR indicates the microbes are effectively altering the crude down hole. Oil in place at the end of the project life would have been 509 bbls/ac-ft versus 442 with MEOR. Residual oil saturation is estimated to fall from 38.3% under water flood to 33.3% with MEOR, a 13% improvement.

Xinjiang project

This field is located in No.1 Plant, Xinjiang Uygur Autonomous Region, P. R China situated in the Xinjiang Petroleum Administration Bureau. Solution gas drive was the primary drive mechanism here, although most of the wells are in the later stages of water flooding and are dispersed and not in the same reservoir. So production data can be evaluated but the reservoir performance can’t be ascertained for this grouping. MEOR application began in January 1995. Rod pumps were used for the wells and the pumps were set from 200 up to 6,000 feet above perforation for one well. Fluid and reservoir parameters all favour microbial growth.

Treatment: Every well was treated thrice. The initial treatment comprised of 150 barrels of microbe-filled liquid on 7 wells then 80 barrels on 3 wells, after that, 0-150 barrels of displacing water followed. The distance the rod pump was established above the perforations, then the pumping fluid level was used to calculate the displacement. The second and third treatments comprised 50 barrels for 6 wells and then 75 barrels for the further 4 wells with displacement water within the range of 0-70 barrels.

Evaluation: The wells in the project were on a rapid decline for the 24 months before Microbial EOR was begun. For the 6 months after the start of MEOR, the rate of oil production improved and then sustained a rate of about 300 barrels per day. Production of water declined once MEOR began, the water cut decreased from 64% to 54%. And the trend in water cut against cumulative oil production which was growing quickly is now flat. Over the 6 months 14,000 barrels of incremental oil have been produced which is 43% over the baseline. Oil production is 300 barrels per day, 36% percent over baseline.

Viscosity for an example project well was studied versus shear rate and versus temperature. The baseline illustration showed microbes could modify the crude significantly. The area under the shear rate curve is reduced by 49%. The temperature curve is shifted to the left approximately 10°F. Due to the short duration of the microbe treating and the location of the project, viscosity curves are not available for the field treated oil. However, on five of the wells, the operator calculated an average reduction in viscosity at (49%) and an increase in gravity from 28.70 to 29.6 0 API (3.1%). Microbes positively improved the crude oil in is this reservoir.

Comparisons between the projects

Similarities between the MEOR projects

• The crude oil found in these reservoirs had high viscosity within the range of (4.5-50 cp).

• They all had solution gas drive as their primary drive mechanisms although the Tupungato-Refugio case was a combination of water drive and solution gas drive as its primary drive system.

• They all had reservoir depth within the range of (4745-5700) ft.

• They all had reservoir temperature within the range of (110- 160)°F.

• Before MEOR application, they all had a high water-cut percentage.

• All the projects were initially placed on water flooding as a secondary recovery method. MEOR was introduced as a tertiary recovery method.

Differences between the MEOR projects

• The flood patterns were different for all of them, because of the differences in permeability.

• The treatment volume and shut in period for each case were different because they were developed to suit the indigenous reservoirs and were driven by specific models for the individual project.

• Rod pumps (artificial lift methods) were only used in the XINJIANG Project wells, probably due to higher viscosity and water-cut.

• Each MEOR project has different number of wells, and it’s listed below.

1. The San Andreas Project consists of 30 producer and 15 injection wells.

2. The Tupungato-Refugio project consists of 3 producer wells.

3. The Xinjiang project consists of 10 producer wells (Tables 1-3).

| Projects | San Andres | Tupungato-Refugio | Xinjiang |

|---|---|---|---|

| Lithology | Fractured dolomite | Fractured sandstone | Sandstone |

| Depth (ft) | 4745 | 5700 | 4900 |

| Net Thickness (ft) | 46 | 60 | 40 |

| Porosity (fraction) | 0.079 | 0.18 | N/A |

| Effective Permeability [Range] (mD) | 1.7 [0.10-10.0] | 300 [150-1500] | 70 [0.2-440] |

| Reservoir Temperature (°F) | 115 | 160 | 110 |

| Oil Density (oAPI) | 29 | 28 | 29 |

| Dead Oil Viscosity (cp) | 4.5 | 9 | 50 |

| Water salinity (mg/l cl) | 40,000 | 42,000 | 8000 |

| So at MEOR start (%) | 41 | 47 | N/A |

| Water cut (%) | 91 | 63.5 | 64 |

| Drive Mechanism | Solution gas | Solution gas and water drive | Solution gas |

| Flood pattern | Line drive | Four spot | N/A |

Table 1: Comparing some of the characteristics of the three cases. [Source: Dietrich et al. [8]].

| S/N | Subject description | San Andreas project | Tupungato-Refugio project | Xianjiang project |

|---|---|---|---|---|

| 1 | Percentage decline | Was initially on a 6.5%/year decline, but after MEOR began, it flattened to 0.6%/year. | Was initially on a 7.1%/year decline, but for the past 14 months since the start of MEOR, it has inclined at the rate of 7.3%/year. | Was initially on a rapid decline for 24 months before MEOR began, but 6 months after the start of MEOR, oil production rate improved and then sustained a rate of about 300 barrels per day. |

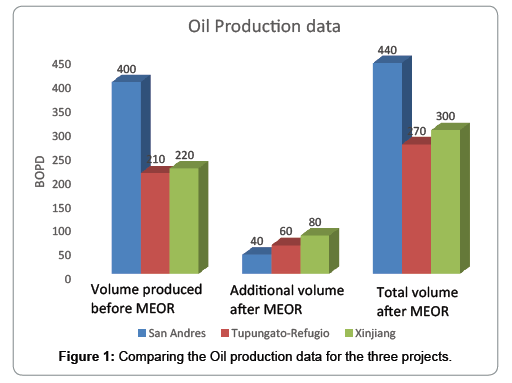

| 2 | Oil Production Rate | Oil production increased by 10% or 40 BOPD after 19 months of microbe treating. | Oil production increased by 29% or 60 BOPD after 14 months of treating. | Oil production increased by 36% or 80 BOPD 6 months after treating. |

| 3 | Baseline Production | Current oil production of 440 BOPD is ten percent over baseline. | Current oil production of 270 BOPD is 29% percent over baseline. | Current oil production of 300 BOPD is 36% percent over baseline. |

| 4 | Incremental Production | Over the past 19 months 17,000 barrels of incremental oil have been produced which is 7% over the baseline | . Over the past 14 months, incremental oil of about 19,000 barrels has been produced which is 19% above the baseline | . Over the 6 months 14,000 barrels of incremental oil have been produced which is 43% over the baseline |

| 5 | Additional Field Wide Production Rate after Waterflooding | At the end of its life the waterflood would have left in place 205 bbls/ac-ft versus 199 with MEOR | Oil in place at the end of the project life would have been 509 bbls/ac-ft after waterflood versus 442 with MEOR | N/A |

| 6 | Effect on Residual Oil Saturation | The saturation of the residual oil is estimated to drop from 35.0% under waterflood to 34.1% with MEOR, a 2.5% improvement. | Residual oil saturation is estimated to fall from 38.3% under waterflood to 33.3% with MEOR, a 13% improvement | N/A |

Table 2: Comparing oil production data between the three MEOR cases.

| S/N | Subject description | San Andres project | Tupungato-Refugio project | Xinjiang project |

|---|---|---|---|---|

| 1 | Decrease in Water Cut | N/A | the water cut decreased from 63.5% to 62% | the water cut decreased from 64% to 54% |

| 2 | Water Production | N/A | Water production increased | Water production decreased |

Table 3: Comparing water-cut and water production data between the projects.

Analysing the Oil Production Result for the Three Projects

From the production data gotten, we can tell that there’s always a sharp increase in production rate immediately after MEOR process has been carried out, this is supposedly as a result of pressure build-up which is a direct effect water flooding, but such level of improvement has never been recorded for any of the project, so undoubtedly, it means the microbes have been at work during the shut-in period. Therefore it is safe to say that the reduction in viscosity of the crude oil by the microbes greatly influenced the record high production rate achieved post MEOR which couldn’t be achieved by mere water flooding.

The Tupungato-Refugio project and the Xinjiang project both had their rapid production rate decline transformed into inclination, the San Andres project couldn’t achieve this feat, although the decline was greatly reduced from 6.5%/year to 0.6%/year (Figure 1).

Comparing the oil production rate amongst the three projects, we can tell that the Xinjiang project had the best inclination rate amongst them, with its production rate increased by 36% or 80 BOPD, 6 months after treatment compared to the San Andres project which had an increase of about 10% or 40 BOPD after 19 months of microbe treating and the Tupungato-Refugio project which had an increase of 29% or 60 BOPD after 14 months of treating.

The San Andres project seems to be the most lucrative project for now with a Current oil production of 440 BOPD which is ten percent over baseline compared to the Tupungato-Refugio Project with a Current oil production of 270 BOPD which is 29% t over baseline and the Xinjiang with a Current oil production of 300 BOPD is 36% over baseline. The Xinjiang still has the best improvement rate though.

We can also see that the Xinjiang project has the best incremental oil production level because, 6 months after treating, 14,000 barrels of incremental oil have been produced which is 43% over the baseline as compared to the San Andres project where Over the past 19 months 17,000 barrels of incremental oil have been produced which is 7% over the baseline and the Tupungato-Refugio project where Over the past 14 months, incremental oil of about 19,000 barrels has been produced which is 19% above the baseline.

The Tupungato-Refugio project has the better reservoir sweep improvement with oil in place at the end of the project life would have been 509 bbls/ac-ft after water flood versus 442 with MEOR versus the San Andres project where at the end of its life the water flood would have left in place 205 bbls/ac-ft versus 199 with MEOR. This data for the Xinjiang project could not be ascertained because, although most of the wells are in the later stages of water flooding and are dispersed and not in the same reservoir, so production data can be evaluated but the reservoir performance can’t be ascertained for this grouping. The reduction in residual oil saturation couldn’t also be ascertained for the Xinjiang for the same reasons, so we have to compare just the other two again, we can tell that the Tupungato-Refugio project has the better reduction in residual oil because the residual oil saturation is estimated to fall from 38.3% under water flood to 33.3% with MEOR, a 13% improvement as compared to the San Andres project which had a drop from 35.0% under water flood to 34.1% with MEOR, a 2.5% improvement.

From the data and results we have, it is obvious that the Xinjiang project was the biggest success story in terms of oil production.

Analysing water-cut and water production data between the projects

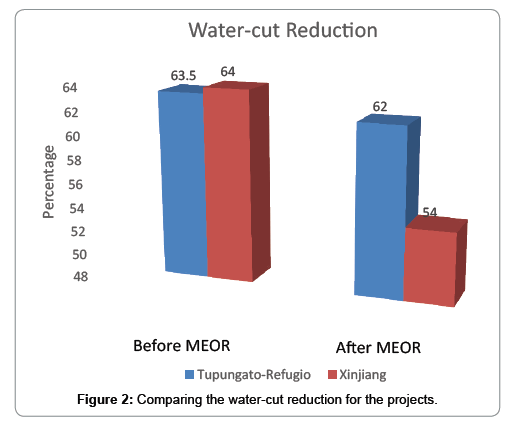

For the San Andres project, the production of water on this property is mixed with fresh water and then introduced, water produced is metered only by carrying out well tests and is not adequately precise to the point where a conclusion concerning water-cut reduction can be drawn. So we would be comparing water cut and water production result from the other two projects whose data is available (Figure 2).

The Xinjiang project had the better reduction in water-cut level because, the water cut decreased from 64% to 54% compared to the Tupungato-Refugio project where the water cut decreased from 63.5% to 62%.

The Xinjiang project also experienced a reduction in water production unlike the Tupungato-Refugio case where the water production level increased instead after MEOR.

From the data we have above, it is obvious to say that the Xinjiang project had the better progress in water-cut and water production reduction after MEOR was carried out.

After the analysis of the results achieved, it is clear that the Xinjiang project is the biggest success story.

Analysing the Xinjiang projects success

Now we have to look at some of the reasons why MEOR was so successful in the Xinjiang Project;

1. It had a significantly higher viscosity (50 cp), compared to the other two projects (4.5 cp and 9 cp respectively), hence, creating room for the microbes to better alter the crude oil, thereby leading to a more gigantic improvement in oil production.

2. Microbes don’t thrive well under high temperature, so having the lowest temperature amongst the three cases apparently favoured the well-being of the microbes in the reservoir.

3. The water salinity for this project was significantly lower than that of the others and without a shred of doubt, we can say this tremendously boosted the effectiveness of microbes in this reservoir compared to the others.

4. The introduction of displacing water after Microbial water flooding seemed to be very effective too.

5. Microbes are known to fare better in sandstone formations.

6. The use of Rod pumps might have also bolstered the production rate.

Conclusion

MEOR considerably improved oil production and also reducedwater cut percentage on the three projects. The only expenses were for the micro-organisms and for carrying out the treatments. No investments or new wells were required for the projects, although they might later be needed as production advances. For each project, the increase in production compensated expenses and lead to ongoing profit. The mean cost for every additional MEOR barrel produced is $3.10 for these projects.

In conclusion, MEOR is a verified technology to improve oil recovery particularly in mature oil wells. MEOR is eco-friendly and cost effective and it is a technique that also indicates various benefits over the other EOR processes. MEOR is also a prospective feasible alternative to the mainstream chemical EOR method.

While MEOR is a very eye-catching technique in the oil recovery field, uncertainties still remain in achieving the engineering design standard required by applying the MEOR method on the a mature field.

References

- Aleklett A, Höök M, Jakobsson K, Lardelli M, Snowden S, et al. (2010) The peak of oil age-analyzing the world oil production scenario in world energy outlook 2008. Energy Policy 38: 1398-1414.

- Graus W, Roglieri M, Jaworski P, Alberio L, Worrell E (2011) The promise of carbon capture and storage: evaluating the capture-readiness of new EU fossil fuel power plants. Climate Policy 11: 798-812.

- Molina-HA, Sato T, Kato C, Gänzle MG, Vogel RF (2003) Effect of pressure on cell morphology and cell division of lactic acid bacteria. Extremophiles 7: 511-516.

- Bryant RS, Stepp AK, Bertus KM, Burchfield TE, Dennis M (1993) Microbial enhanced waterflooding field pilots. Dev Pet Sci 39: 289-306.

- Lazar I, Petrisor IG, Yen TF (2007) Microbial enhanced oil recovery Petroleum Science and Technology. 25: 1353-1366.

- Hitzman DO (1991) Microbial enhanced oil recovery: The time is now. Microbial Enhancement of Oil Recovery-Recent Advances. Development in Petroleum Science, 31, Donaldson EC (ed.) Amsterdam: Elsevier 11-20.

- Sheehy AJ (1991) Microbial physiology and enhancement of oil recovery-recent advances. In: Development in Petroleum Science 31: 37-44.

- Dietrich FL, Brown FG, Zhou ZH, Maure MA (1996) Microbial EOR Technology Advancement: Case Studies of Successful Projects. Society of Petroleum Eng. Richardson. Texas.

- Omoniyi OA, Abdulmalik F (2015) A Review of microbial enhanced oil recovery:current development and future prospects. International Journal of Scientific & Engineering Research.

- Sen R (2008) Biotechnology in petroleum recovery: the microbial EOR. Progress in energy and combustion Science 34: 714-726.

Citation: Nnaemeka O, Franklin N, Stanley O (2018) A Review of Microbial Enhanced Oil Recovery Applications Projects. Oil Gas Res 4: 152. DOI: 10.4172/2472-0518.1000152

Copyright: © 2018 Nnaemeka O, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 5297

- [From(publication date): 0-2018 - Oct 01, 2025]

- Breakdown by view type

- HTML page views: 4318

- PDF downloads: 979