Agronomic and Physiological Performances of Tomato (Lycopersicum esculentum L.) Under Latent Storage Solar Air Heating Conditions

Received: 13-Jun-2018 / Accepted Date: 27-Jun-2018 / Published Date: 04-Jul-2018 DOI: 10.4172/2576-1463.1000209

Abstract

Greenhouse heating during cold seasons is costly as it is high energy-consuming. The use of latent heat stored during sunny periods for greenhouse heating could be an interesting alternative in several regions worldwide as in Tunisia. Thus, new agronomic/climatic approaches were developed to produce several crops such as tomato (Lycopersicum esculentum L.) in a sustainable way. In this context, the growth, photosynthesis, yield and quality of tomatoes cultivated inside a greenhouse equipped with a new solar air heater with latent storage (IGLHS) were studied in comparison to an unheated greenhouse (IG). Using the solar air heater, the night recovered heat reached 30% of total heating requirements. Consequently, IGLHS microclimatic conditions positively affected plant growth and physiology and led to an early fructification and an increased yield as compared to the unheated greenhouse. Besides, fruit quality evaluation allowed observing significant increases in the lycopene, phenolics, flavonoids and tannins contents (61%, 57%, 63% and 54%, respectively) under IGLHS conditions. The solar air heater collector revealed to be an efficient competitive system enhancing early maturity, leading to increased tomato yields and reducing considerably greenhouse heating costs as it utilizes a highly solicited natural renewable energy.

Keywords: Greenhouse; Growth; Heat; Photosynthesis; Renewable energy; Tomatoes

Introduction

Nowadays, controlled greenhouses designed to provide improved crop yield and quality with reduced phytosanitary problems are the target of a variety of technological innovations. Several important species express their optimal yield when cultivated under controlled greenhouse conditions. Tomato (Lycopersicum esculentum L.) is a world widespread species representing an economically important vegetable crop. It is the seventh most important crop species after maize, rice, wheat, potatoes, soybeans and cassava. With a growing tomato consumption reaching an average of 20.5 kg/capita/year, tomato greenhouse cultivation areas were markedly increased to satisfy such an increased demand [1].

Climate control is one of the major problems encountered in controlled greenhouses. But, the most important constraint is the high energy needs for greenhouse tomato cultivation. Considering that temperature control through heating is favorable for tomato precocity, many heating systems using renewable energy sources were conceived [2,3]. In this context, solar energy represents the most important source used for greenhouse heating. However, solar systems may present some technical problems and are too expensive for commercial use [4]. Nowadays, two solar energy heating systems are available namely the sensible and the latent one. Thus, many concepts of stored excess energy in its sensible state have been developed inside greenhouses such as rock beds and ground storage [5,6]. A solar fat-plate collector was also used to improve the internal greenhouse microclimate and tested it under clear and cloudy day conditions [7]. Further, a capillary polypropylene exchange system was tried for storing excess solar radiation in a greenhouse soil [8]. The latent heat storage was firstly based on the use of phase change materials which are among the most efficient ways to store thermal energy for greenhouse applications, currently in use [9,10]. In the same context, a solar collector with tube heat exchangers was used to study the yield and quality of tomatoes under greenhouse [11].

Several studies considered various heating technologies such as water storage tanks, rock beds storage, earth-to-air heat exchanger systems, ground air collectors and other techniques, used for greenhouses of various sizes and materials. Based on experimental and numerical models, most of the studies focused on the influence of greenhouse building characteristics on the inner thermal environment which markedly affects solar energy absorption, storage and release. Such studies would lead to improved designs that maximize solar energy utilization in future greenhouses [11]. In contrast, few studies investigated the effects of such heating systems on the crop growth and development under greenhouse conditions. In tomato cultivation under greenhouse, night temperature is an important parameter that could affect tomato production. Even though, the mechanism underlying tomato development using a solar air energy collector remains poorly studied. The late flowering stages, in particular, are very sensitive since abortion could occur at low night temperatures and affect future tomato caliber and yield. Since that large-scale greenhouse tomato cultivation relies mainly on fossil fuels as heating energy source, and considering the steady increase of fuel price, it was necessary to explore other heating means within a sustainable agriculture context.

This study aims to investigate the effects of heat supplied by a solar air heater with latent storage collector on the growth, development and quality of tomatoes cultivated under controlled greenhouse conditions.

Materials and Methods

Experimental conditions

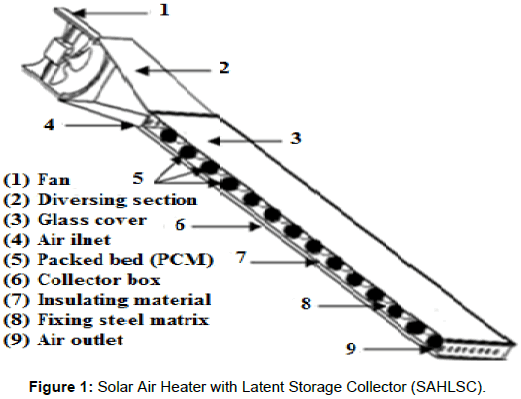

Tomato cultivation was carried out under two small chapel-shaped experimental greenhouses in the Center of Research and Energy Technology of Borj Cedria- Tunisia with an E/W orientation. The greenhouses (14.8 m2 in area and 44.4 m3 in volume) were made of galvanized steel. The walls and roofs were covered with three mm-thick Plexiglas panels, making them thermally isolated. Both greenhouses were equipped with an overhead recirculation fan used to cool down temperature to the desired set point (28°C during the day). The first insulated greenhouse (IG) wasn’t heated while the second insulated greenhouse with latent heating system (IGLHS) was further equipped with a solar air heater with latent storage collector (SAHLSC) which provides heating at night. The solar air heater was composed of blackcoated spherical capsules, fixed with a steel matrix and installed above a packed bed absorber (Figure 1). The collector was 2 m in length, 1 m in width and 0.28 m3 in volume. A 0.004 m thick transparent glass covered the packed bed absorber and a 0.05 m-thick polyurethane, with a heat conductivity of 0.028 Wm was used as an insulation material.

In both greenhouses, CR5000 loggers allowed data acquisition and monitored solar radiation with a Kipp and Zonen pyranometers positioned 1.5 m above ground in the central sector of each greenhouse. White fluorescent tubes (LEUCI S.p.A 36 W T8/6500°K 2500 Im) were fixed on the inside roof of each greenhouse ensure a 16 h photoperiod. Temperature and relative humidity were recorded with temperature and humidity probes (HMP 155, Campbell Scientific Inc). Data were scored at 10 min interval.

Plant material

The experiment took place between January and May 2013. In both greenhouses, tomato plantlets were arranged in four rows at a density of 2 plants m-2. Thus, in each greenhouse 28 tomato plantlets were cultivated on a sandy soil and regularly irrigated using a drip-irrigation system.

Biomass

Fresh shoot and root biomasses were measured under both cultural conditions and dry leaf and shoot weights were measured after oven drying fresh biomass at 75°C until constant weight was obtained. Biomass measurements were done at the beginning and the end of the experiment. Fruit setting period was recorded for 10 plants.

Gas exchange

Gas exchange parameters were determined using a portable Li-Cor system (Li-Cor 6200, Nebraska, USA). Measurements were carried out between 10:00 and 14:00 on seven fully expanded leaves from 10 plants per greenhouse. Net CO2 assimilation rate (A), transpiration rate (E), and stomatal conductance (gs) were measured using the LI-COR software.

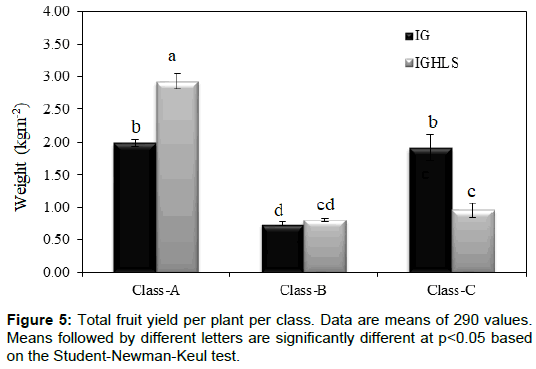

Fruit calibration

At harvest, all tomatoes were weighed and total yield was determined under both climate regimes. The harvested tomatoes were then categorized into different weight classes (Class A>150 g; 70< Class B<150 g; Class C<70 g) to identify tomato yield per class.

Phytonutrient extractions

Three tomatoes per plant (>150 g in weight) were randomly harvested at maturity from different plants in both greenhouses. After lyophilization, 1 g of tomato powder was slurred in 10 ml methanol 80%, stirred for 30 minutes and incubated at 4°C in the dark for 24 hours. The mixture was then filtered and the extracts were finally stored at 4°C in the dark till analysis. The chemical analyses were performed in triplicates.

Phenolic compounds: Total phenolic compounds were extracted as described by [12]. The extracts (125 μl) were dissolved in 500 μl distilled water and 125 μL of Folin-Ciocalteu reagent. After stirring, 1250 μl of Na2CO3 (7%) solution were added and the final volume was adjusted to 3 ml with distilled water. The mixture was allowed to stand for 90 min under darkness. The absorbance was measured at 760 nm. The absorbance of each sample extract was measured at 760 nm in a spectrophotometer (Ultrospec 2000). The results were expressed as milligram gallic acid equivalents per g dry weight (mg GAE g−1 DW).

Flavonoids: Total flavonoids were determined according to [13,12]. After mixing 250 μl of the diluted extracts with 75 μL of NaNO2 (5%) solution for 6 min, 150 μl of aluminum chloride (AlCl3 6H2O, 10%) freshly prepared were added. The mixture was allowed to stand for 5 min, and then 500 μL of NaOH (1M) were added. The final volume was adjusted to 2.5 ml with distilled water. The reaction solution was mixed and kept for 15 min, and the absorbance was determined at 510 nm in a spectrophotometer (Ultrospec 2000). The results of flavonoids concentration were expressed as mg catechin equivalents. g-1 DW (mg CE g-1DW).

Condensed tannins: Proanthocyanidins were measured using the vanillin assay as described by [14]. 50 μL aliquots of extracts were added to 3 ml of methanol vanillin solution and 1.5 ml H2SO4, respectively. The absorption was measured after 15 min using a spectrophotometer (Ultrospec 2000) at 500 nm wavelength. Different catechin concentrations ranging from 50 to 600 mg-l were used as standards. Tannin content was expressed in mg catechin equivalents per g dry weight (1 mg CE.g-lDW).

Lycopene: Lycopene was extracted as described by [15]. Lycopene extraction was carried out in cyclohexane, dichloromethane or ethanol. Tomato powder (0.1 g) was dissolved in 10 ml (hexane-acetone-ethanol (50/50/1). The solution was shaken for 10 minutes, then centrifuged at 5000 rpm for 15 minutes. 1 ml of the organic phase was then extracted and diluted in 10 ml of hexane. The optical density of the supernatants was measured at 472 nm in a spectrophotometer (Ultrospec 2000). Subsequently, lycopene concentrations were expressed as microgram per g dry weight (μg 100 g−1DW).

Statistical analysis

Statistical analyses were performed using STATISTICA release 7 software. Mean comparisons were done using (ANOVA) at (p<0.05) followed by mean comparisons using the Student-Newman-Keuls test.

Results

Climatic conditions

Tomato plants were transplanted on the 23rd of January under both IG and IGLHS conditions. Along the experimental period, many fluctuations in the temperature and relative humidity were recorded under both greenhouses (Table 1). However, all the recorded differences between both greenhouses were due to their specific conception and ventilation system. Thus, IGLHS night temperature was 0.45 to 1.02 higher than that of IG while day temperature was 0 to 1.05 higher than IG. On the other hand, relative humidity differences between greenhouses and outside conditions were around 21% and 23% for IGLHS and IG respectively, with higher air humidity recorded inside IG than IGLHS (Table 1).

| Solar radiation (W.m-2) | Amb. Air T (°C) | Amb RH (%) | Air T (°C) | RH (%) | Air T(°C) | RH (%) | |

|---|---|---|---|---|---|---|---|

| IGLHS | IG | ||||||

| January | |||||||

| Day | 219.90 ± 19.49 | 12.72 ± 2.11 | 65.86 ± 2.16 | 23.68 ± 4.39 | 60.05 ± 10.62 | 22.63 ± 3.15 | 64.19 ± 8.33 |

| Night | _ | 10.05 ± 1.51 | 65.55 ± 2.37 | 12.76 ± 4.33 | 85.48 ± 9.44 | 12.31 ± 4.56 | 87.80 ± 9.45 |

| February | |||||||

| Day | 197.71 ± 84.19 | 12.61 ± 2.71 | 69.05 ± 3.69 | 23.28 ± 4.80 | 60.82 ± 10.8 | 22.86 ± 4.01 | 65.53 ± 7.32 |

| Night | _ | 9.48 ± 2.42 | 68.38 ± 3.65 | 11.51 ± 2.06 | 88.28 ± 3.32 | 10.73 ± 2.01 | 90.50 ± 4.90 |

| March | |||||||

| Day | 202.41 ± 85.13 | 17.07 ± 3.25 | 68.09 ± 4.68 | 26.14 ± 4.91 | 65.30 ± 9.47 | 26.27 ± 5.28 | 68.14 ± 8.32 |

| Night | _ | 13.33 ± 2.6 | 67.12 ± 5.15 | 14.97 ± 2.19 | 88.14 ± 4.97 | 13.9 ± 2.11 | 91.13 ± 5.45 |

| April | |||||||

| Day | 227.90 ± 94.12 | 20.81 ± 4.70 | 68.90 ± 9.13 | 26.47 ± 4.84 | 71.15 ± 11.55 | 26.50 ± 5.34 | 74.64 ± 11.06 |

| Night | _ | 17.06 ± 8.31 | 67.85 ± 3.71 | 17.02 ± 1.44 | 91.51 ± 2.72 | 16.25 ± 1.52 | 93.76 ± 3.07 |

Table 1: Daily mean climatic parameters recorded during the experiment.

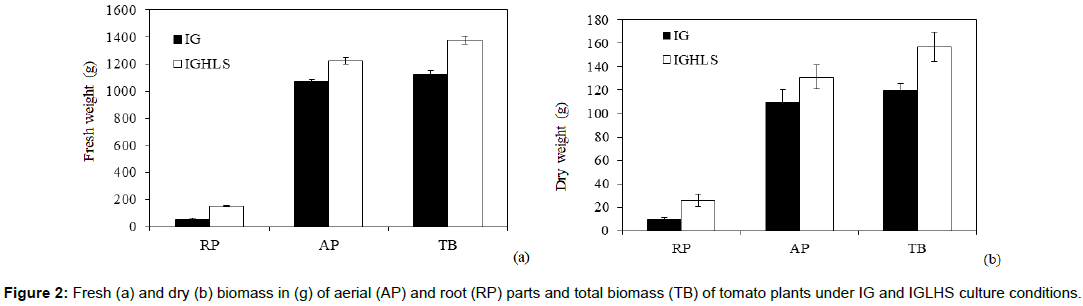

Biomass

Significant differences in the biomass were observed between both cultivation microclimates. Thus, root fresh biomass was slightly decreased under IGLHS conditions (Figure 2) in comparison to IG cultivated plants. However, total fresh biomass was higher under IGLHS (128.2 g increase per plant) than IG conditions (Figure 2a), while the corresponding total dry biomass was decreased by 4.41 g / plant (Figure 2b).

Gas exchange

Under IGLHS conditions, tomato plants presented a significantly higher assimilation rate (17.07 mol CO2 m-2 s-1), transpiration (22.69 mmol H2O m-2 s-1) and stomatal conductance (1.65 mmol H2O m-2 s-1 ) than IG cultivated plants (Table 2).

| E (mmol H2O m-2 s-1) | gs (mmol H2O m-2 s-1) | A (mol CO2 m-2 s-1) | |

|---|---|---|---|

| IG | 17.42 ± 1.26b | 1.25 ± 0.30b | 8.74 ± 1.02 b |

| IGLHS | 22.69 ± 0.64 a | 1.65 ± 0.10 a | 17.07 ± 1.73 a |

Table 2: Gas exchange parameters of tomato plants under IG and IGLHS conditions. Data are means of 14 values. Means followed by different letters are significantly different at p < 0.05 based on the Student-Newman-Keuls test.

Data are means of 14 values. Means followed by different letters are significantly different at p<0.05 based on the Student-Newman-Keuls test.

Fruit set and maturity phases

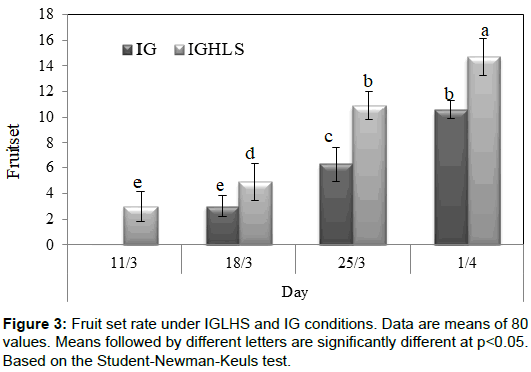

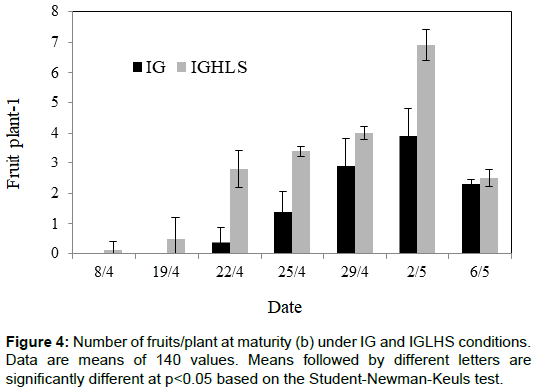

During fruit set (March), the mean night temperature and relative humidity values were 14.97°C and 88.14%, respectively under IGLHS and 13.9°C and 91.13%, respectively under IG (Table 1). The results indicate an increase in the rate of fruit set with night temperature (Figure 3). The highest fruit set rate (14.8%) was observed at the beginning of April when night temperature was the highest under both cultivation conditions. Fruit set rates were significantly higher under IGLHS than IG conditions (Figure 3). On the other hand, tomato plants grown under IGLHS produced mature fruits 6 days prior to those cultivated under IG conditions. The number of mature tomatoes per plant was significantly higher under IGLHS than IG conditions (Figure 4).

Fruit yield and phytonutrients

The highest weight of class A tomatoes/ plant (333 g) was recorded under IGLHS. The yield of class B-fruits was 57 g higher under IGLHS than IG conditions. Generally, significantly higher yields of class A and C fruits were obtained under IGLHS than IG conditions (Figure 5); but, similar class-B fruit yields (1.37 kg.m-2) were measured under both greenhouse conditions (Figure 5). The weight of class A-fruits significantly increased by 8%, under IGLHS conditions while that of class B and C-fruits significantly increased by 3% and 4%, respectively (Table 3).

| Class A | Class B | Class C | |

|---|---|---|---|

| IG | 25.32% | 5.98% | 10.81% |

| IGLHS | 33.64% | 8.83% | 15.41% |

Table 3: Class A. B and C fruits (%) under IG and IGLHS culture conditions.

Regarding phytonutrients, tomato plants had significantly higher contents of phenolic compounds, flavonoids, and tannins under IGLHS conditions as compared to those grown under IG conditions with increases of +61%, +57%, +63% and +54%, respectively (Table 4). Similarly, lycopene contents of tomatoes were significantly higher under IGLHS than IG conditions, with 0.21 μg.g-1 dry weight (Table 4).

| IG | IGLHS | |

|---|---|---|

| Phenolics [mg GAE.g-1 DW] | 11.2 b ± 1.58 | 14.4 ± 1.6a |

| Flavonoïds [mg EC. g-1 DW] | 1.6 b ± 0.05 | 2.15 ± 0.15a |

| Tannins [mg EC. g-1 DW] | 0.85 b ± 0.07 | 1.05 ± 0.1a |

| Lycopene [µg. g-1 DW] | 0.125 ± 0.02 b | 0.21 ± 0.05a |

Table 4: Phytochemical compounds’contents in tomatoes under IGLHS and IG cultivation conditions. Data are means of 24 values. Means followed by different letters are significantly different at p<0.0.

Discussion

The use of the solar air collector to increase night temperature in winter is of great economic benefit. Heat storage must satisfy the specific greenhouse temperature needs, even though, its performance is closely dependent on outdoor conditions. The performance of the SAHLSC was previously studied and a clear heating effect at night simultaneously with a passive dehumidification process was reported [16]. Thus, under IGLHS, the energy stored in the solar air heater was progressively discharged during 12 hours from 20:00 h to 8:00 h allowing heating at night.

In this study, tomato plants grown under IGLHS microclimatic conditions exhibited marked physiological and organoleptic characteristics as compared to those cultivated under IG conditions. Thus, significantly high fresh biomasses were measured under IGLHS, with an increased root biomass, particularly when both day and night temperatures were increased. Assimilation, stomatal conductance and transpiration were also significantly increased as compared to IG-cultivated plants, which presented a lower gas exchange capacity. It was reported in a similar context that increased night temperature may enhance night respiratory rate and cell metabolism in tomato [17]. IGLHS-cultivated plants have increased transpiration rates under low relative humidity levels due to the latent heat storage system. Such high transpiration rates registered under IGLHS conditions could be neglected since that growth was not disturbed.

Considering tomato fruit set, an increase was observed under IGLHS conditions, at the beginning of April when night temperature was the highest. Even though, Peet and Bartholemew [18] reported that the number of first flower clusters and fruits of tomato decreased at 26°C as compared to 18, 22 and 24°C night temperature, but fruit fresh mass increased with night temperature, reflecting a more rapid development. According to Nuruddin et al. [19] the improvement of tomato yield depends on the period of fruit development. In our study, the low night temperature and high relative humidity conditions prevailing under IG significantly affected fruit set as compared to IGLHS conditions. Dane et al., Adams et al. and Peet et al. [20-22] reported that high day and night temperatures drastically impede tomato flowering, pollination and consequently fruit set, resulting in an increased number of parthenocarpic fruits and hence low marketable yields [23]. Regarding maturation, heat provided at night inside the IGLHS enhanced tomato precocity and allowed to reach maturity one week prior to IG-cultivated plants. In a similar context, Grange and Hurd [24] demonstrated that a decreased heat loss using aluminized polyethylene sheet led to an early tomato production. On the other hand, the enhanced photosynthesis of plants grown under IGLHS conditions led to an increased supply of assimilates inducing an increase in fruit size and total yield. Dannehl et al. [11] reported that microclimatic conditions as well as several physiological processes could explain changes in the volume and weight of different fruit classes. The individual size of fruits per unit area remains the most important quality factor and should be as regular as possible over the whole production period [25]. Even though modern cultivated tomatoes offer a large variation in fruit size, ranging from cherry tomato (less than 20 g) to beef tomato (up to 500 g), the numerous small-caliber fruits obtained under IG conditions and high relative humidity could not be intended for human consumption. Comparable changes in tomato fruit size were also reported under high relative humidity conditions [26]. The effects of IGLHS microclimatic conditions were obvious on fruit yield and quality. In fact, the yield of marketable fruits (A, B classes) significantly increased by 41%. These results are in agreement with Kläring and Krumbein [27] who reported an increased tomato yield following high levels of photosynthetic activities. According to Al Amri [28], the use of a solar water heater enhanced the productivity of tomato by 46.67%. In contrast, flexible solar panels mounted on greenhouse top did not improve total or marketable tomato production. Considering fruit quality, our results indicate significantly increased levels of lycopene, one of the most characteristic phytonutrients in tomato, under IGLHS conditions. This carotenoid, which confers the characteristic red color to the fruit, revealed to be fundamental in the final nutritional quality and the commercial value of tomatoes [29]. Many studies have reported a strong relationship between the nutritional quality of the tomato and its lycopene content [30]. The increased lycopene contents of tomatoes produced under IGLHS cultivation conditions would then certify their nutritional quality. On the other hand, when comparing both greenhouses, our results indicate that phenolics, flavonoid and tannins contents were higher in the IGLHS-produced tomatoes. The increased night temperature seems to be the main factor responsible for the increase in the total contents of phenols, flavonoids, tannins and lycopene. This study demonstrates that greenhouse environmental conditions can affect tomatoes nutritional quality. Rosales et al. [30] reported also higher contents of phenols, flavonoids and anthocyanins in tomatoes cultivated under greenhouse. Consequently, increasing night temperature revealed to be favorable for improving carotenoids and phenolic compounds contents in tomatoes. The accumulation of these substances was associated with a higher photosynthetic activity as described previously. The increased contents of secondary compounds in tomatoes grown under IGLHS would be of great nutritional interest [31].

Conclusion

This study revealed the beneficial effects of a greenhouse solar air collector on tomato cultivation under controlled conditions, which particularly concern early production, increased yield and improved fruit quality. Thus, the use of latent solar energy for greenhouse heating during winter seems to be an important issue to vegetable crop cultivation and an alternative to high-energy consuming classical greenhouses. Excess solar heat storage in greenhouses during sunny days and its release during cold periods is of great interest if we consider the increasingly high fossil fuel cost. As pointed out by Bouadila et al. [16] night recovered heat, using this system, reached 30% of total heat requirements. Greenhouse heating based on the use of such a solar air heater with latent storage may be considered as an environmental mean for energy saving and crop production improvement. Yet, it’s worth mentioning that any heating system can be influenced by several interrelated parameters such as heat storage method, greenhouse size and location, cover material structure, cultivated species and climatic conditions.

Acknowledgement

Authors are grateful to the Laboratory of Thermal Processes (LPT) of the Center of Energy Research and Technology (CRTEn) and the Laboratory of Extremophile Plants (LEP) of the Center of Biotechnology of Borj Cedria (CBBC) for financial support.

References

- Bergougnoux V (2014) The history of tomato: From domestication to biopharming. Biotechnol Adv32: 170-189.

- Rousse DR, Martin DY, Theriault R, Leveillee F, Boily R (2000) Heat recovery in greenhouses: a practical solution. Appl Therm Eng20: 687-706.

- Nayak S, Tiwari GN (2009) Theoretical performance assessment of an integrated photovoltaic and earth air heat exchanger greenhouse using energy and exergy analysis methods. Energ Buildings 41: 888-896.

- Garcia JL, Plaza SSL, Navas LM, Benevente RM, Luna L (1998) Evaluation of the feasibility of alternative energy sources for greenhouse heating. J Agric Eng Res 69: 107-114.

- Willits DH, Chandra P, Peet MM (1985) Modeling solar energy collection/storage system for greenhouses. J Agric Eng Res32: 73-93.

- Bouhdjar A, Belhamel M, Belkhiri FE, Boulbina A (1996) Performance of sensible heat storage in a rock bed used in a tunnel greenhouse. Renew Energy9: 724-728.

- Bargach MN, Tadili R, Dahman AS, Boukallouch M (2000) Survey of thermal performances of a solar system used for the heating of agricultural greenhouses in Morocco. Renew Energy 20: 415-433.

- Lazaar M, Kooli S, Hazami M, Farhat A, Belghith A (2004) Use of solar energy for the agricultural greenhouses autonomous conditioning. Desalination168: 169-175.

- Huang BK, Toksoy M, Cengel YA (1986) Transient response of latent heat storage in greenhouse solar system. Sol Energy37: 279-292.

- Vadiee A, Martin V (2013) Thermal energy storage strategies for effective closed greenhouse design. Appl Energy 109: 337-343.

- Dannehl D, Suhl J, Huyskens-Keil S, Ulrichs C, Schmidt U (2014) Effects of a special solar collector greenhouse on water balance. fruit quantity and fruit quality of tomatoes. Agr Water Manage134: 14-23.

- Dewanto V, Wu X, Adom KK, Liu RH (2002) Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J Agric Food Chem 50: 3010-3014.

- Zhishen J, Mengcheng T, Jianning W (1999) The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem64: 555-559.

- Sun B, Ricardo Da Silva JM, Spranger I (1998) Critical factors of vanillin assay for catechins and proanthocyanidins. J Agric Food Chem 46: 4267-4274.

- Benakmoum A, Abbeddou S, Ammouche A, Kef alas P, Gerasopoulos D (2008) Valorisation of low quality edible oil with tomato peel waste. Food Chem110: 684-690.

- Bouadila S, Kooli S, Skouri S, Lazaar M, Farhat A (2014) Improvement of the greenhouse climate using a solar air heater with latent storage energy. Energy64: 663-672.

- Chen J, Kang S, Du T, Guo P, Qiu R, et al. (2014) Modeling relations of tomato yield and fruit quality with water deficit at different growth stages under greenhouse condition. Agr Water Manage146: 131-148.

- Peet MM, Bartholemew M (1996) Effect of night temperature on pollen characteristics. growth and fruit set in tomato. J Amer Soc Hortic Sci121: 514-519.

- Nuruddin MM, Madramootoo CA, Dodds G (2003) Effects of water stress at different growth stages on tomato yield and quality. Hortic Sci 38: 1389-1393.

- Dane F, Hunter AG, Chambliss OL (1991) Fruit set pollen fertility and combining ability of selected tomato genotypes under high temperature field conditions. J Am Soc Hortic Sci 116: 906-910.

- Adams SR, Cockshull KE, Cave CRJ (2001) Effects of temperature on the growth and development of tomato fruits. Ann Bot 88: 869-877.

- Peet MM, Willits DH, Gardner R (1997) Response of ovule development and post-pollen production processes in male-sterile tomatoes to chronic sub acute high temperature stress. J Exp Bot48: 101-111.

- Kleinhenz V, Katroschan K, Schutt F, Stutzel H (2006) Biomass accumulation and partitioning of tomato under protected cultivation in the humid tropics. Eur J Hortic Sci 71: 173-182.

- Grange RI, Hurd RG (1983) Thermal screens- Environmental and plant studies. Sci Hortic19: 201-211.

- Bertin N (1995) Competition for assimilates and fruit position affects fruit set in indeterminate greenhouse tomato. Ann Bot75: 55-65.

- Leonardi C, Guichard S, Bertin N (2000) High vapour pressure deï¬cit influences growth. transpiration and quality of tomato fruits. Sci Hortic (Amst)84: 285-296.

- Klaring P, Krumbein A (2013) The effect of constraining the intensity of solar radiation on the photosynthesis. growth yield and product quality of tomato. J Agron Crop Sci 199: 351-359.

- Al Amri AMS (1997) Solar energy utilization in greenhouse tomato production. J King Saud University Agri Sci9:21-38.

- Georgé S, Tourniaire F, Gautier H, Goupy P, Rock E, Caris-Veyrat C (2011) Changes in the contents of carotenoids phenolic compounds and vitamin C during technical processing and lyophilisation of red and yellow tomatoes. Food Chemistry 124: 1603-1611.

- Rosales MA, Cervilla LM, Sanchez-Rodriguez E, Del Mar Rubio-Wilhelmi M, Blasco B, et al. (2011) The effect of environmental conditions on nutritional quality of cherry tomato fruits: evaluation of two experimental Mediterranean greenhouses. J Sci Food Agric 91: 152-162.

- Bub A, Barth SW, Watzl B, Briviba K, Rechkemmer GP (2005) Paraoxonase 1 Q192R (PON1-192) polymorphism is associated with reduced lipid peroxidation in healthy young men on a low-carotenoid diet supplemented with tomato juice. Br J Nutr93: 291-297.

Citation: Sellami D, Bouadila S, Salem-Fnayou AB, Ghorbel A (2018) Agronomic and Physiological Performances of Tomato (Lycopersicum esculentum L.) Under Latent Storage Solar Air Heating Conditions. Innov Ener Res 7: 209. DOI: 10.4172/2576-1463.1000209

Copyright: © 2018 Sellami D, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 3925

- [From(publication date): 0-2018 - Dec 02, 2025]

- Breakdown by view type

- HTML page views: 3009

- PDF downloads: 916