Review Article Open Access

Competitive Advantages of Occupational Health and Safety Management Systems for Ports

Mohammad Ali Hassanzadeh*Ports and Maritime Organization (PMO), Tehran, Iran

- *Corresponding Author:

- Mohammad Ali Hassanzadeh

Ports and Maritime Organization (PMO)

Tehran, Iran

E-mail: info@mtect.info, mahasanzadeh@yahoo.com

Received date: January 27, 2013; Accepted date: February 15, 2013; Published date: February 17, 2013

Citation: Hassanzadeh MA (2013) Competitive Advantages of Occupational Health and Safety Management Systems for Ports. Occup Med Health Aff 1:103. doi: 10.4172/2329-6879.1000103

Copyright: © 2013 Hassanzadeh MA. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Occupational Medicine & Health Affairs

Abstract

Globalization put ports in a dominant position in intercontinental trade and transport that resulted to handling more than 8.7 billion tons of diverse cargoes in 2011. In fierce business environment, being port of call for shipping lines and distribution center for cargo owners, require ports to be as competitive and efficient as possible. Less efficient ports with higher service costs lose their market shares and customers to their competitors and will fade out from business accordingly. Port authorities do their best to cut costs and rise availability, flexibility and marketability of port services for their customers consequently. Such objectives accomplished through optimizing operational performance indicators in ports such as increasing equipment utilization factors and decreasing waiting time, idle time and service time. But the main question is how to improve such indicators to control and even reduce the service costs? Applying know how import management and operation, using modern equipment, increasing public private partnership and last but not least, creating port community systems integrated with information technologies are the most widely used strategies to create service competitiveness. Are such practices the ultimate critical success factors to be used by port authorities in the business environment? International Labor Organization has tried to prevent and reduce accidents and ill health in ports since the 1920s, when the first Convention on accident prevention in ports was adopted. Hopefully in recent decades attention toward individuals who work in ports has changed from simple dock workers to human capitals. Subsequently variety of occupational health and safety management systems (OHSMS) are nowadays in place. But these systems generally focused on protection of people, properties and environment while this research tries to elaborate advantages of OHSMS on optimizing ports’ operational performance indicators and explain their final impacts on creating competitive advantages that should be met by world class ports.

Keywords

Maritime transport; Port, Safety; Operational hazards; Indicators

Introduction

In a global economy, no nation is self-sufficient. Each is involved at different levels in trade to sell what it produces, to acquire what it lacks and also to produce more efficiently in some economic sectors than its trade partners [1]. As Massey (1984) mentioned the new international trade regime allowed manufacturers to re-locate their production and assembly plants to more cost-efficient locations in developing economies, in turn generating a new spatial division of labor [2]. Development in global production and international trade not only has relocated production centers but also has redesigned the whole transport and logistics chain, calling for more market alliance, vertical and horizontal integrations and cooperation amid different players. This new emerging system, in which raw materials, components, and final products are sourced, manufactured, distributed, and shipped globally, has required a profound restructuring of the transportation industry, with shipping and port services being at the forefront of these changes and mutations [3]. Maritime transport is considered as the backbone of international trade and a key engine driving globalization. According to United Nations’ Conference on Trade and Development, around 80 per cent of global trade by volume and over 70 per cent by value is carried by sea and is handled by ports worldwide; these shares are even higher in the case of most developing countries [4].

The port role today exceeds the simple function of services to ships and cargo. Apart from their role as the traditional sea/land interface, ports are a good location for value-added logistics but also for other related services including industrial, trade, financial, and even leisure and property development activities [3]. To increase their market shares, most ports today are competing with one another on a global scale and, with the tremendous gains in productivity in ocean transport achieved over the past several decades, ports are now perceived to be the remaining controllable component in improving the efficiency of ocean transport logistics. This has generated the drive today to improve port efficiency, lower cargo handling costs and integrate port services with other components of the global distribution network [5]. But what are the mechanisms in which ports should initiate to improve efficiency and minimize their service costs for the port customers? Calling for knowledge and experience of global terminal operators to manage and operate port facilities, using state-of-the-art equipment, increasing public private partnership to offer efficient services and/or utilize ports’ resources are the well-known practices to improve port efficiency. Launching port community systems integrated with information technologies such as electronic data interchange and practicing customer relationship management are amid fresh styles in use to create service competitiveness. Are such practices the ultimate critical success factors to be used by port authorities to create competitiveness in the cut throat business environment?

As Tongzon mentioned if a port has a reputation that the handling of cargoes is unsafe, this could drive away potential clients and discourage existing clients [6]. There is increasing and compelling evidence that providing a healthy and safe working environment has the potential to increase labor productivity and in turn increase business profits [7]. When it comes to occupational health and safety at ports, ILO has the leading position since it has tried to prevent and reduce accidents and ill health in ports since the 1920s. At that point the first Convention on accident prevention in ports was adopted [8]. Hopefully in recent decades attention toward individuals who work in ports has changed from simple dock workers to human capitals. Subsequently variety of occupational and health and safety management systems (OHSMS) are nowadays in place. These systems generally focused on protection of people, properties and environment while this research tries to elaborate competitive advantages of OHSMS. In this paper, following literature review, risk of activities in port operation will be discussed. Impact of the OHSMS on optimizing ports’ operational performance indicators and their final outcomes on creating competitive advantages that should be met by world class ports will be reflected later.

Literature Review

As a multidisciplinary subject, occupational health and safety addresses all the risk factors of working environments namely physical, chemical, biological, psychological and ergonomical risks. Leka described Occupational health and safety is a multidisciplinary concept touching on issues relating to subjects such as medicine, law, technology, economics and psychology [9]. Taking into consideration such multidisciplinary subject, seems to be the main reason for different attitudes of governments, employers, workers’ unions and other parties involved in workplace health and safety. Unfortunately considering the multiplicity of disciplines considered in it has been treated as a throw-away subject with all the other disciplines. Thus not only do the various disciplines focus on aspects of the concept but they also make reference to it only during critical situations. For instance, the law discipline makes reference to the concept only when employers are to pay compensations for health and safety failures [10]. In international level, ILO promotes OHSMS and since 1920s, several Conventions, Recommendations and other forms of guidance addressing safety and health in ports have been adopted, the most recent one being a comprehensive code of practice on the subject aimed at protecting people, properties and the environment [8]. While protecting and promoting the health of workers, primary prevention and management of risks for occupational and work-related diseases and injuries are considered as some of the objectives of the WHO Global Strategy on Occupational Health for All [11]. Even though these objectives are not contradictory but complementary to companies interests but as Robin (2003) has mentioned companies and organizations have traditionally evaluated their health in terms of the bottom line [12]. However, with past research uncovering enormous financial and human costs associated with unhealthy organizations, human resource professionals have begun to position healthy workplace programs and activities as a source of competitive advantage [10]. Meantime new attitude toward occupational health and safety at ports started considering the role of port accidents in disruption of global supply chain. Tianjing et al. presented a model for intermodal transportation network that evaluates the impacts of port disruptions, focusing specifically on mitigation strategies of capacity expansion and contingency rerouting [13]. Whereas Thai et al. [14] identified consequences of port accidents on three different levels; port, community and supply chain [15]. Some researchers have used to different criteria as factors to measure the economic effect of OSH on the companies. Roxane et al. assessed the cost of accidents at work, defined the costs and benefits of implementing OSH management systems in enterprises and measured illness absenteeism [16]. It seems that there is a gap in the literature review for implementation of OSH in ports and competitive advantages which it can bring for ports, this paper aimed at valuing business impacts of OSH system through competitive advantages yield by such systems.

Risk Factors of Port Activities

In our time ports are one of the most important logistical systems in a sense of global circulation and trade [17]. In the 21st century, five forces will interact to shape the competitive landscape facing port authorities and port service providers:

• Rivalry among existing competitors

• Threat of new competitors,

• Potential for global substitutes,

• Bargaining power of port users and

• Bargaining power of port service providers.

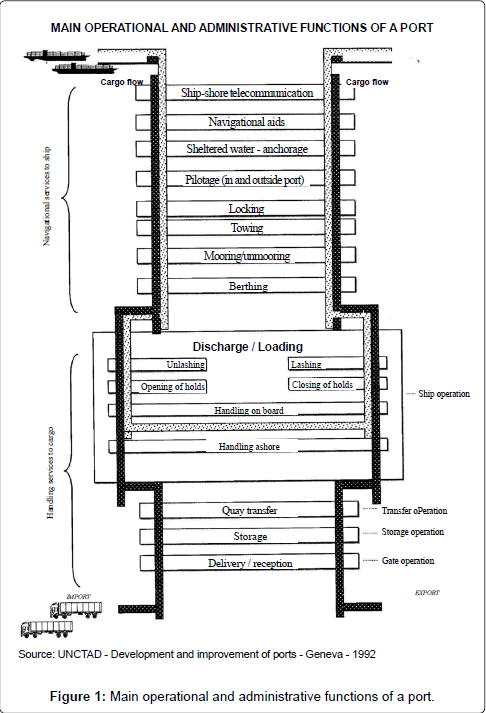

These forces will impact ports of all sizes, driving requirements for port expansion, service improvement, pricing decisions and other management actions. Winners and losers will emerge in the global port sector, largely dependent on how port managers strategically position themselves in the evolving competitive landscape [5]. In order to improve the quality of port service, initially types of services that are offered to the port customers have to be identified. According to UNCTAD navigational services to ships and handling services to cargos are the two main operational and administrative functions of a port which is provided for shipping lines and cargo owners as the main port customers [18] (Figure 1).

However, as Thai et al. and Loh and Thai defined processes and operations in the ports increase in their complexities and range, the integration of ports into supply chain management creates a higher level of uncertainties for downstream planning; product movement as well as information changes [14,15]. To reduce accident and uncertainties in ports, there has to be a proactive plan to identify and manage hazards and risks, otherwise as mentioned by Talley [19] port operator safety plans are often reactive, developed subsequent to worker accidents. At the Port of Hong Kong, for example, worker accidents have occurred from workers falling from high-stacked containers and being involved in object collisions. Hong Kong International Terminals created its safety and health policy to address worker high-risk operations (such as working on high-stacked containers), fire safety, and procedures for handling, storage, and transportation of dangerous cargoes.

Risk management is the core of proactive plans, since risk management provides a sound basis for the improvement of safety. It should cover all work tasks and hazards in the work place and allows hazards to be assessed to see how harmful they are [20]. The following tables show different tasks in providing services to ships and cargos in port as well as examples of their associated occupational health and safety (OHS) risk factors (Tables 1 and 2).

| Tasks during navigational aids to ships | Occupational health risk factors | Safety risk factors |

| •ship-shore telecommunication •navigational aids •anchorage •pilot age •locking •towing •mooring & unmooring •berthing |

•inappropriate working level •shift work •long time sitting position •noise •inappropriate colors of VTS monitors •electromagnetic waves •low light or glow •precise work (high attention) •vibration •movement of heavy items •wrong working posture |

•fall from height •collision with moving objects •smash with mooring ropes •fall to the sea •danger of loose gears1 •dragging of tugboat toward ship •losing tug boat power during maneuvering |

Table 1: Different tasks in navigational services to ships and examples of OHS risk factors.

| Tasks during handling services to cargo | Occupational health risk factors | Safety risk factors |

| •Lashing/unlashing •Opening/closing of holds •Handling on board •Quay transfer •Delivery/reception |

•Inappropriate working posture •Shift work •Long time sitting position •Height •Ultraviolet waves •Cold/ heat •Humidity •Precise work •Movement of heavy tools •Dangerous cargos •High speed operation •Chemicals and gases •Dust from cargoes •Confined space |

•Fall from height •Smash with moving objects •Collision with lifting appliances •Fall of cargos •Fire •Explosion •Fall to the sea •Collision with transfer vehicles •Workers trapped by objects |

Table 2: Different tasks in handling services to cargos and examples of OHS risk factors.

Business Impact of the OHSMS

Felicity Lamm described link between productivity with OHS systems outcomes by four core reasons:

• The need to find more innovative ways to reduce the high rates of workplace injury and illness than has previously been the case.

• The pressure to reduce the social and economic costs of injury and illness, particularly compensation costs.

• The need to improve labor productivity which does not result in employees working longer hours and taking on more work.

• The need to provide good working conditions as a way of recruiting and retaining skilled workers in a tight labor market [7].

If the port provides throughput at a minimum cost (given the unit costs or resource prices to be paid), then it is cost efficient; otherwise it is cost inefficient. In order for a port to be cost efficient, it must be technically efficient, i.e. the latter is a necessary condition for the former. If a port is technically inefficient, it can handle more throughputs with the same resources by becoming technically efficient. Further, given the same resources and thus the same resource costs, the average cost per unit of throughput will decline with the port becoming technically efficient. Alternatively, if the port is technically inefficient, it must follow that it is also cost inefficient [21]. A decrease in port accidents leads to fewer workplace disruptions and ultimately improves the production efficiency of ports [19].

The following table shows the main outcomes resulting from implementation of occupational health and safety management system (OHSMS) in port. As indicated in the table 3 some of the consequences are exclusively impact of either occupational health or safety whereas the others are driven from both. For instance implementing occupational health can result in reducing accidents and at the same time safety measures will reduce the port accident too. But then work absenteeism happens as a result of psychological and ergonomic risk factors which are categorized in occupational health category. Reducing equipment repair time that happens following an accident labeled in the safety category [22] (Table 3).

| The main outcomes of OHSMS application in ports | as an impact of | |

| OH | Safety | |

| Reducing incidents (ships, trucks, equipment, cargos, environment) | * | * |

| Reducing accidents ( people, ships, trucks, cargos, environment) | * | * |

| Reducing absenteeism of port & service providers staff | * | |

| Decreasing operational cost resulting replacement white or blue collars | * | * |

| Dropping operational cost resulting training of new stevedores | * | * |

| Protecting experienced port people | * | * |

| Proposing continuous services to port customers | * | |

| Reducing wastes | * | |

| Increasing productivity of port equipment | * | * |

| Increasing accessibility and utilization of port equipment | * | * |

| Reducing fatigue at work | * | |

| Protecting workers from work related diseases | * | |

| Reducing idle time and increasing accessibility to experienced staff | * | * |

| Reducing port users’ complaints | * | |

| Increasing accessibility and utilization of port infrastructure | * | |

| Reducing operational cost resulting of damaged equipment, properties | * | |

| Reducing equipment repair cost | * | |

| Reducing claim and court cost | * | * |

| Reducing treatment cost following workers’ injury or illness | * | * |

| Reducing insurance and premium cost | * | |

| Increasing return on investment | * | |

Table 3: The main outcomes of OHSMS application in ports.

Creating Competitive Advantages Using OHSMS

In the highly competitive and rapidly globalizing economy of today, the integration of supply chains is taking place and ports are increasingly competing not as individual firms but rather as firms within supply chains. To be a port of call for shipping lines, cargo base for freight forwarders (FFs)and multimodal transport operators (MTOs) and a place to set up industries taking advantage of port position for investors (port tenants), a port has to be competitive enough to attract such potential port users. The selection criteria may differ from one user to another. Beside service cost as one of the main selection criteria, a broad range of norms that shakes port competitiveness are listed in the table 4; for the sake of simplicity such items may be categorized into service quality, service reliability, flexibility, marketability, safety and security. Particular circumstances are in the interest of all users such as decent customer relationship management, while some criterions may be more relevant for shipping lines for instance minimum deviation from the main route. As the other criterion let’s say frequency of transport service with port hinterland are pertinent and in the interest of FFs or MTOs. Of course, there are some criterions such as using integrated IT system which attract attention of two users at the same time (Table 4).

| The main criterion of competitive ports | Importance for | |||

| line | cargo owner | port tenant | ||

| Safety | No record or least accident rate for ships & trucks | high | high | high |

| Maximum acceptable safety level for port tenants | least | low | high | |

| Environmental friendly | low | low | low | |

| No record or minimum damage or loss of cargo | least | high | high | |

| Service quality | Using integrated IT systems | high | high | least |

| High transport service frequency with port hinterland | low | high | least | |

| Minimum absenteeism for port employees | low | high | least | |

| Minimum waiting and service time for ships and trucks | high | high | least | |

| Good infrastructure and superstructure | high | high | least | |

| Minimum port time for ships and trucks | high | high | least | |

| Excellent hinterland connectivity (infrastructure) | low | high | high | |

| Offering competitive port tariffs | high | high | least | |

| Disseminating required and related information to port users | high | high | least | |

| Efficient custom service (gate operation) | low | high | least | |

| Service reliability | Maximum utilization of port equipment | low | low | least |

| Least breakdown for port equipment | low | high | least | |

| Good spare capacity in berth, transfer and storage operation | high | high | least | |

| Providing port services according to the schedule | high | high | least | |

| Marketability | Least trade imbalance (exploiting capacity of ship & truck) | high | high | high |

| Minimum deviation from maritime routes (position) | high | low | least | |

| 24/ 7 port operation | high | high | low | |

| No lock or long river channel to reach the port (port type) | high | low | least | |

| Flexibility | Customer oriented behavior on contracts & negotiations | high | high | high |

| Decent customer relationship management system in place | high | high | high | |

| Providing logistics services on customer demand | high | high | low | |

| Providing administration services on customer demand | high | high | high | |

| Security | Implementing ISPS Code | high | low | least |

| Maximum invisible surveillance & control | high | high | low | |

| Least record on terrorist acts | high | low | low | |

Table 4: The main criterions of competitive ports and estimation of their importance for shipping lines, cargo owners (FFs, MTOs) and port tenants.

Based on table 3 that listed the main outcomes of OHSMS in port, the following table demonstrates how each of the listed criterions may be influenced either by the occupational health (OH), safety or both of them. For instance, minimizing personnel absenteeism can be done through OH measures, but to increase utilization of equipment and reducing their breakdown, safety measures such as preventive maintenance has to be in place. Of course there are some factors which influenced more from OH than safety measures and vice versa; providing safe workplace for port tenants in depends more on safety measures than OH activities. Deviation from main route or being a river port that may affects users decision, has nothing to do with OH or safety. It is worthy to mention that there are some areas for example, competitive port tariffs. Tariff can be set by port authorities without taking into account the total costs of accidents, but if they decide to include accident costs in their calculation, then OH and safety measures control it (Table 5).

| The main criterion of competitive ports | Influenced by | ||

| OH | Safety | ||

| Safety | No record or least accident rate for ships & trucks | less | more |

| Maximum acceptable safety level for port tenants | less | more | |

| Environmental friendly | more | ||

| No record or minimum damage or loss of cargo | more | ||

| Service quality | Integrated IT systems | ||

| High transport service frequency with foreland and hinterland | |||

| Minimum absenteeism for port employees | more | ||

| Minimum waiting and service time for ships and trucks | equal | equal | |

| Good infrastructure and superstructure | |||

| Minimum port time for ships and trucks | equal | equal | |

| Excellent hinterland connectivity (infrastructure) | |||

| Offering competitive port tariffs | |||

| Disseminating required and related information to port users | |||

| Efficient customs service (gate operation) | |||

| Service reliability | Maximum utilization of port equipment | more | less |

| Least breakdown for port equipment | more | ||

| Good spare capacity in berth, transfer and storage operation | more | ||

| Providing port services according to the schedule | equal | equal | |

| Marketability | Least trade imbalance (exploiting capacity of ship & truck) | ||

| Minimum deviation from maritime routes (position) | |||

| 24/ 7 port operation | equal | equal | |

| No lock or long river channel to reach the port (port type) | |||

| Flexibility | Customer oriented behavior on contracts & negotiations | ||

| Decent customer relationship management system in place | more | less | |

| Providing logistics services on customer demand | equal | equal | |

| Providing administration services on customer demand | more | ||

| Security | Implementing ISPS Code | ||

| Maximum invisible surveillance & control | |||

| Least record on terrorist acts | |||

Table 5: The main criterions of competitive ports and estimation of their susceptibility to occupational health (OH) and safety systems.

The positive impact of introducing occupational safety and health management systems at the organization level, both on the reduction of hazards and risks and on productivity is now recognized by governments, employers and workers [23]. As showed in the table 5 execution of occupational health and safety measures in port directly and indirectly stimulus criterions that are closely monitored by port users, i.e. shipping lines, cargo owners and investors. Having advantage in these criteria, helps ports to position themselves in the cut throat business environment.

Outcomes on Creating Competitive Advantages

In a research done on the issue of port selection, a list of 11 criterion to assess the most important criteria that are taking into consideration by shipping companies when decide to select amongst the following ports; Felixstowe, Zeebruges, Antwerp, Hamburg or Le Havre. Service cost, quality of hinterland connections, capacity, reliability, port location, cargo base, flexibility, customer service quality, total door-to-door transport time, feeder frequency, risk of loss or damage, and location in port (if locks need to be used) were the identified criterions. Result of this research is showed in the table 6.

| Criterion | Port of Felixstowe | Port of Zeebruges | Port of Antwerp | Port of Hamburg | Port of Le Havre |

| Cost | 3.2 (2-4) | 4.0 (3-5) | 4.4 (3-5) | 3.4 (3-4) | 3.1 (1-4) |

| Hinterland connections | 3.4 (3-4) | 3.3 (2 -4) | 4.5 (4-5) | 4.4 (4-5) | 3.6 (2-4) |

| Port capacity | 2.7 (1-4) | 4.3 (3-5) | 4.6 (4-5) | 3.7 (2-5) | 4.4 (4-5) |

| Reliability | 3.0 (2-4) | 4.3 (4 -5) | 4.5 (4-5) | 4.1 ( 3-5) | 2.4 (2-4) |

| Port location (locks) | 3.2 (2-4) | 3.4 (2-4) | 4.2 (3-5) | 4.4 (3-5) | 3.8 (2-5) |

| Cargo base | 3.4 (1-4) | 3.1 (2-5) | 4.4 (3-5) | 4.2 (3-5) | 3.3 (2-4) |

| Flexibility | 3.0 (2 – 5) | 4.0 (3-5) | 4.5 (4-5) | 3.8 (2-5) | 2.4 (1-3) |

| Customer service | 3.5 (3-5) | 3.8 (3-5) | 4.2 (3-5) | 3,9 ( 3-5) | 3.1 (2-5) |

| Feeder service frequency | 2.7 (1-4) | 2.9 (2-4.5) | 3.4 (2-5) | 4.8 (4-5) | 2.6 (1-4) |

| Risk of loss or damage | 4.0 ( 2-5) | 4.4 ( 4-5) | 4.8 (4-5) | 4.6 (4-5) | 4.3 (2-5) |

| Customs service | 3.6 (2-5) | 3.4 (3-4) | 3.0 (2-4) | 3.9 (3-5) | 2.9 (2-4) |

Table 6: Evaluation of port selection criteria for selected ports (Average (min-max)).

The best scores for most criteria considered are found in Antwerp port. Respondents furthermore commented that the port of Le Havre is scoring low in reliability and flexibility because of the social instability created by trade unions and frequent strikes. The most important criterion turns out to be the cost as can be observed from interview results. But also other criteria like quality of hinterland connections, port capacity and reliability are an area that port authorities can and should consider influencing in order to improve the competitiveness level a port [24]. To judge how occupational health and safety may help competitiveness of Antwerp port, in the following table, criterions used (2010) are tested with the relevant information from tables 4, 5 and 7.

| Competitive advantage criterion for ports | Importance of criterion for shipping line (table 4) | Selected criterion influenced by (table 5) | Situation of criterion in Antwerp port | |

| OH | safety | |||

| Cost | high | * | * | 4.4 (max. 5) |

| Hinterland connections | low | 4.5 (max. 5) | ||

| Port capacity | high | * | 4.6 (max. 5) | |

| Reliability | high | * | * | 4.5 (max. 5) |

| Port location (locks) | high | 4.2 (max. 5) | ||

| Cargo base | high | 4.4 (max. 5) | ||

| Flexibility | high | * | * | 4.5 (max. 5) |

| Customer service | low | * | * | 4.2 (max. 5) |

| Frequency of feeder service | low | 3.4 (max. 5) | ||

| Risk of loss or damage | low | * | 4.8 (max. 5) | |

| Customs service | low | 3.0 (max. 5) | ||

Table 7: Evaluation of port selection criteria for selected ports.

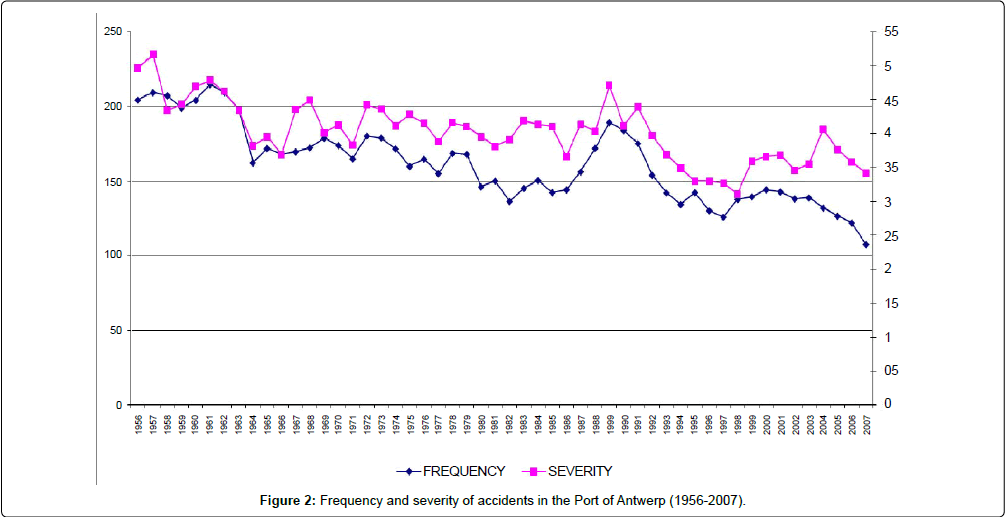

As marked in the above table, in port of Antwerp as the best choice for the shipping companies, almost 50% of the selected criterions are in one way or another influenced by occupational health and safety measures. Search on the level of port safety and health indicates that at the same time, port of Antwerp had the lowest ever record on accidents and their severities. As described by Turnbull to reduce accidents, there is a much stronger emphasis on initial training [25]. Under the Belgian port law of 1972, workers must be recognized as “dockers” before they can work in the “port area”. Re-training and upgrading skills to a different (higher) job classification is also catered for by port training schools called OCHA. The OCHA first opened its doors in 1980 for induction training and has since expanded training provision to engine drivers (in 1984) and then tally clerks, signalmen and lashers, adding courses for warehouse workers in 1994, straddle carrier drivers in 2002 and gantry crane drivers in 2003. Since 1994 the training center has also provided courses in the handling of dangerous goods and offered “back-to-school” training for long-standing dockworkers that need to be brought up to date with new cargoes, new cargo handling methods and new regulations [26]. Over this extended period, the Port of Antwerp has become a much safer place to work, as following clearly illustrates [25]. What is clear from other evidence is that systematic training programs can significantly reduce accidents (Figure 2).

Conclusion

In recent decades globalization has reformed the entire landscape of trade and transport. Maritime transport by reason of its low transport cost reflected to be mainstay of the international trade. In such a new business atmosphere only the top shipping lines and ports can play a note worthy role. All the ports around the world handled about 8.7 billion tons of cargos in 2011 [4]. There is a fierce competition amongst them to gain more market share from such enormous volume. To be a port of call in the transport chain, port authorities do their best to increase their competitive advantages as much as possible. Increasing handling capacity, keep in pace with the megaships requirements, offering tax and customs duty relief, using state-of-the-art equipment, implementing various systems to speed up operation and reduce total time in port are some of the practices to make competitive advantages. Few possibly will consider occupational health and safety management systems at port as a cost reduction element and critical success factor which alongside with the above mentioned factors has the ability in itself to provide competitive advantages. As Tongzon mentioned if a port has a reputation that the handling of cargoes is unsafe, this could drive away potential clients and discourage existing clients [6].

As mentioned in this research, implementing systems based on occupational health and safety measure, not only help to be in line with the national and international rule and regulations, but also help port authorities to identify the elements required to increase their service competitiveness. Examples of port of Antwerp in which had the best training system for equipment operators and the lowest accident record on one side, and being selected by the shipping companies as the best one among 5 European ports clearly shows how occupational health and safety is important for port users. It seems that with further improvement, adding some cost elements in this research, it has the potential to be formed and introduce to port authorities as a model. Talley described port time-related costs in addition to port charges as an important determinant in port selection in a competitive environment. Since port cargo remains in the shipper’s inventory (assuming the shipper retains ownership), the shipper incurs time-related inventory or logistics costs in port; water and inland carriers also incur port timerelated costs, e.g. depreciation and insurance costs on their ships and vehicles while in port. A port can reduce these time-related costs by reducing the time that the cargo of shippers and the ships and vehicles of carriers are in port, i.e. by improving the quality of its service and reducing accidents [21].

To conclude, in spite of the existence of internationally agreed and up-to-date standards, there is still a great need for better practical implementation of these standards. As the 2005 Code of practice observes, port work is still an occupation with very high accident rates [8]. Bringing into surface the positive business outcomes of occupational health and safety, may increase port authorities and other service providers to invest more on safety and provide a safer workplace for stakeholders.

References

- Rodrigue JP (2013) Transportation, Globalization and International Trade, from the Geography of Transport Systems.

- Jacobs W (2011) The Role of Port Infrastructure and Logistics in Global Networks. Utrecht: Utrecht University.

- UNCTAD (2004) Assessment of a seaport land interface: an analytical framework. Geneva: The UNCTAD secretariat.

- UNCTAD (2012) Review of Maritime Transport. Geneva: United Nations Conference on Trade and Development

- The World Bank (2011) The Evolution Of Ports In A Competitive World. Port Reform Toolkit.

- Tongzon J (2002) Port Choice Determinants in a Competitive Environment. National University of Singapore.

- Felicity Lamm CM (2007) Is There A Link between Workplace Health and Safety and Firm Performance and Productivity? The University of Auckland.

- International Labour Organization (2008) The Inspection of Occupational Safety and Health in Ports: a review of existing guidance and practice.

- Leka S (2003) Occupational health and safety practices in small and medium sized enterprises: A comparative study between England and Greece. University of Nottingham.

- Amponsah-Tawiah K, Dartey-Baah K (2007) Occupational Health and Safety: Key Issues and Concerns in Ghana. International Journal of Business and Social Science 2: 119-126.

- World Health Organization (2006) Declaration of workers health. WHO Collaborating Centres of Occupational Health, Stresa, Italy

- Robin R (2003) Healthy, wealthy, and wise. Canadian Business.

- Tianjing LIU, Jasmine Siu Lee LAM (2012) Impact of port disruption on transportation network., Nanyang Technological University, Singapore.

- Thai VV, Chen S, Chen, S (2011) The role of ports in supply chain disruption management. International Conference on Free Port and International Logistics, Taiwan 3: 41-60.

- Loh HS, Thai VV (2011) The Role Of Ports in the Supply Chain Disruption Management. Nanyang Technological University, Singapore.

- Roxane L Gervais, Pawlowska Z (2009) Occupational safety and health and economic performance in small and medium-sized enterprises. D. Elsler European Agency for Safety and Health at Work (EU-OSHA), Spain.

- Transportation Logistics (2008) Different functions of Ports.

- UNCTAD (1992) Development and Improvement of Ports. Geneva: United Nations' Conference on Trade and Development.

- Talley WK (2009) Port Economics. Oxon: Routledge 25: 333-336.

- ILO (2005) Safety and health in ports, ILO code of practice. Geneva: International Labour Organization.

- Talley WK (2006) Chapter 22 Port Performance: An Economics Perspective. Research in Transportation Economics 17: 499-516.

- Hasanzadeh MA (2008) Port Safety Management Tehran, Iran: Ministry of Roads and Transportation, Deputy of Education Research and Technology, The Bureau of Technology and Safety Studies.

- ILO-OSH (2001) Guidelines on occupational safety and health management systems. International Labour Organization, Geneva.

- Aronietis R, Van de Voorde E, Vanelslander T (2010) Port Competitiveness Determinants of Selected European Ports in the Containerized Cargo Market. Antwerp: University of Antwerp.

- Turnbull P (2009) Training and Qualification Systems in the EU Port Sector: Setting the State of Play and Delineating an ETF Vision. Cardiff: European Transport Workers’ Federation.

- WT 100 (2002) The Role of Ports and Longshore Labor in Global Trade.

Relevant Topics

- Child Health Education

- Construction Safety

- Dental Health Education

- Holistic Health Education

- Industrial Hygiene

- Nursing Health Education

- Occupational and Environmental Medicine

- Occupational Dermatitis

- Occupational Disorders

- Occupational Exposures

- Occupational Medicine

- Occupational Physical Therapy

- Occupational Rehabilitation

- Occupational Standards

- Occupational Therapist Practice

- Occupational Therapy

- Occupational Therapy Devices & Market Analysis

- Occupational Toxicology

- Oral Health Education

- Paediatric Occupational Therapy

- Perinatal Mental Health

- Pleural Mesothelioma

- Recreation Therapy

- Sensory Integration Therapy

- Workplace Safety & Stress

- Workplace Safety Culture

Recommended Journals

Article Tools

Article Usage

- Total views: 21781

- [From(publication date):

February-2013 - Aug 30, 2025] - Breakdown by view type

- HTML page views : 16879

- PDF downloads : 4902