Industrial Energy Management Gap Analysis

Received: 29-Apr-2015 / Accepted Date: 20-Sep-2015 / Published Date: 22-Sep-2015

Abstract

Improved energy efficiency (EE) is recognized as an essential strategy in energy and climate change mitigation policies (IPCC, 2014). Greater competition, unpredictable energy markets and control on greenhouse gas emissions, drives manufacturing industries to manage their energy demand carefully and use it efficiently. Energy management (EnM) as a cost reduction and risk protection strategy against the unpredictable energy market is a robust tool and support function which helps industries to improve their EE level. However, since energy cost in comparison with total production costs in manufacturing companies has the small portion consequently it receives little attention.

Keywords: Energy management; Practices; Industry; Energy efficiency

17923Introduction

Improved energy efficiency (EE) is recognized as an essential strategy in energy and climate change mitigation policies (IPCC, 2014). Greater competition, unpredictable energy markets and control on greenhouse gas emissions, drives manufacturing industries to manage their energy demand carefully and use it efficiently. Energy management (EnM) as a cost reduction and risk protection strategy against the unpredictable energy market is a robust tool and support function which helps industries to improve their EE level. However, since energy cost in comparison with total production costs in manufacturing companies has the small portion it receives little attention. Previous studies of improving industrial EE through EnM have been conducted in energy auditing [1] optimizing industrial energy systems [2], manufacturing simulation Solding et al [3], energy system modeling, Kissock et al [4], energy efficienct technologies [5-7] and barriers to EE in energyintensive companies and non-energy-intensive companies [8,9]. One of the foremost means of improving industrial energy efficiency in industry is through the use of Voluntary Programs or Long-Term Agreements have an energy management standard played a key role [10]. However, still there is no single accepted definition for energy management practices (EnMPs) [11]. Also, research concerning EnMPs has so far been scarce. Moreover, studies concerning energy services in the industry have not been extensively exploited. There is no study on classification and/or characterization of EnMPs. Notably, energy policy measures for improved EE in industry is in need of clarifications in these regards, as policies involving EnM components forms the backbone of successful industrial energy policies, e.g. Voluntary Agreements, see, e.g. [12-14]. Therefore, the current paper intends to deliver how important is to focus on mentioned four gaps in industrial EnM related literature and policy.

Analysis

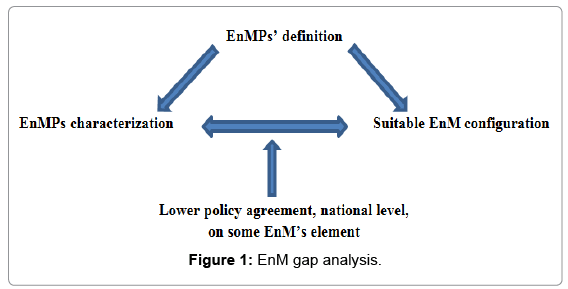

EnMPs are to be seen as more managerial actions, while others can be defined as technical and operational practices. The lack of single accepted definition for EnMPs causes imprecise understanding about EnMPs. As another result, no characterization which could characterize EnMPs’ based on their target exists in EnM literature. It also causes failure in choosing proper EnM configuration through single industry’s characteristics. In other word, the lack of a precise definition about EnMPs causes both technical and managerial failure towards improving companies’ EE. If major improvements in EE are the target for a single industry, many different policy instruments and pre-steps can and must be used. As for effective EnM it is pillar to work continuously, for better result it is necessary to establish policies which could support EnM programs properly and continuously. Even though an EnM system as such cannot be seen as national policy, EnM standards often comprise the backbone of Voluntary Agreements. According to Jelic´ et al [15] comparison of national EnM standards, there is lower agreement on some elements. Management commitment, strategic planning, purchasing and design are all those listed with low agreement level. Policy makers, engineers and scholars are in a position to think about not only what to install to improve EnM programs, but also to how to implement these measures. Thus to converge an unanimously accepted strategy, close contact between practitioners, policy makers and scholars is the mainstay. Simultaneously, it causes not only to avoid any possible confusion in existing program when policy makers and scholars get in touch with the realness of the industry through the practitioners, but also to establish policies which support EnM program properly. Thus, regardless of any discipline which laws are relevant to, they constantly need to be revised by policy makers to innovate and inject new, necessary, and value added items to the existing program. In Figure 1 a presentation on how these four elements affect each other’s failure and/or success is seen.

Different definitions of a single concept not only cause inaccurate understanding about it, but also cause improper proceedings to obtain the desired results. The perspectives of management only or merely technical to the EnM concept has caused both mentioned problems in industries. However, EnMPs could be defined as total continuous or frequent managerial and technical actions in a company which aim primarily to reduce energy costs or secure energy supply and secondary to reduce pollution [16]. Some authors believe that there is overlap between EnMPs and EE measures. But apart from the existence of some overlaps it is possible to differentiate EnMPs from EE measure [17]. It is useful to list all EnMPs and group them based on where and how they improve the EE. Characterization of EnMP through the EnM definition can be a light to better understanding of what EnM is.

Based on EnM literature, there are indications that EnMPs positively link to a top management support and ambitious, productivity, and firm’s climate friendly R&D [18]. Meanwhile companies’ characteristics like energy intensity and size have a direct impact on energy activities. After all, even if there would have existed top management ambitious, in most of the cases two stumbling blocks are exist: 1) there is no energy manager by definition within the company and/or 2) since energy is not considered as a core business and strategic but mostly a secondary issue therefore it receives relatively little attention. Top managements, CEOs, are positioned in a strategic level of any organization. Since top management support is a key to EnM’s program success, energy manager should make EE investments more strategic. The more strategic an investment the more opportunity it has to acquire the contest. While integrating energy and operations approaches erases the line between process energy services and ancillary energy services and spreads out the doors to strategic analysis, linking the operations and energy analyzes could bring better results from the EE improvement point of view. An investment is strategic if it contributes to create, maintain, or develop a sustainable competitive advantages [19]. To build a competitive advantage, making a balance between internal resources and external factors through resource allocation is essential [20].

Turner [21] has a very strategic view towards energy within the industry. Turner determined and clustered five energy related strategies for a single industry, which are: reliability, efficiency, low cost/no cost, funding, and awareness and practices which could maintain the targets are identified. Grouping energy related practices through their targets could make the situation more clear for the top managers to realize by performing which practices they could arrive at what kind of resolutions not only from the EE improvement point of perspective, but also from a strategic point of opinion.

Conclusion

EnM is a robust tool to improve the EE in industries and its main task is to reduce costs for the provision of energy in buildings and facilities without compromising the manufacturing processes. However, it needs some clarifications in regards to definitions, which points towards a direction on how to reach overall sustainability, not just to work in accordance with continuous improvements, this in order to inject into the current and future EnM policy programs for improved impacts. Although the requirements for industrial facilities, in turn, can differ, how EnMPs are defined helps to clear understanding about the in-house EnM program and choosing proper EnM configuration based on industry’s characterization and overall objectives.

References

- Thollander P, Karlsson M, Söderström M, Creutz D (2005) Reducing industrial energy costs through energy efficiency measures in a liberalized European electricity market case study of a Swedish iron foundry.Applied Energy 81: 115-e126.

- Cai YP, Huang GH, Yang ZF, Tan Q (2009) Identification of optimal strategies for energy management, systems planning under multiple uncertainties. Applied Energy 86: 480-e495.

- Solding P, Petku D, Mardan N (2009) “Using simulation for more sustainable production systems - methodologies and case studiesâ€, International Journal of Sustainable Engineering, 2: 111-122.

- Kissock JK, Eger C (2008) Measuring industrial energy savings.Applied Energy 85: 347-e361.

- Anderson ST, Newell RG (2004) Information programs for technology adoption: the case of energy-efficiency audits. Resource and Energy Economics 26: 27-e50.

- Harris J, Anderson J, Shafron W (2000) Investment in energy efficiency: a survey of Australian firms. Energy Policy 28: 867e-876.

- Cagno E, Trianni A (2012) “Analysis of the Most Effective Energy Efficiency Opportunities in Manufacturing Primary Metals, Plastics, and Textiles Small- and Medium-Sized Enterprisesâ€, Journal of Energy Resources Technology, Transactions of the ASME, 134: 1-9.

- Palm J, Thollander P (2010) An interdisciplinary perspective on industrial energy efficiency. Applied Energy, 87: 3255-3261.

- Trianni A, Cagno E (2012) Dealing with barriers to energy efficiency and SMEs: some empirical evidences. Energy 37: 494-504.

- Thollander P, Palm J (2015) Industrial Energy Management Decision Making for Improved Energy Efficiency-Strategic System Perspectives and Situated Action in Combination. Energies, 8: 5694-5703.

- Schulze M, Nehler H, Ottosson M, Thollander P (2015) “Eneregy Management in Industry- a systematic review of previous findings and an integrative conceptual frameworkâ€, International Journal of Cleaner Production In Press. 1-17.

- Rezessy S, Bertoldi P (2011) Voluntary agreements in the field of energy efficiency and emission reduction: Review and analysis of experiences in the European Union. Energy Policy 39: 7121-7129.

- Price L (2005) Voluntary agreements for energy efficiency or ghg emissions reduction in industry: An assessment of programs around the world. Lawrence Berkeley National Laboratory.

- Cagno E, Trianni A, Abeelen C, Worrell E, Miggiano F (2015a) “Barriers and Drivers for Energy Efficiency: Different Perspectives from an Exploratory Study in the Netherlandsâ€, Energy Conversion and Management.

- Jeli? DN, Dušan RG, Milun JB, Davor NK, Vanja MŠ(2010) "Review of existing energy management standards and possibilities for its introduction in Serbia." Thermal Science 14, no. 3: 613-623.

- Sa A, Paramonova S, Thollander P, Cagno E (2015) Classification of Industrial Energy Management Practices: A Case Study of a Swedish Foundry Energy Procedia, 75: 2581-2588.

- Trianni A, Cagno E, Thollander P, Backlund S (2013) Barriers to industrial energy efficiency in foundries: a European comparison. Journal of Cleaner Production, 40: 161-176.

- Cagno E, Ramirez-Portilla A, Trianni A (2015b) “Linking Energy Efficiency and Innovation Practices: Empirical Evidence from the Foundry Sectorâ€.

- Cooremans C (2011) Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4: 473-492.

- Johnson G, Scholes K, Whittington R (1999) Corporate strategy Europe: London Prentice Hall.

- Turner WC, Doty S (2007) Energy management handbook. The Fairmont Press, Inc.

Citation: Aida SA, Patrik T, Enrico C (2015) Industrial Energy Management Practices’ Gap Analysis. Innov Ener Res 4: 122.

Copyright: ©2015 Aida SA, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 16393

- [From(publication date): 12-2015 - Sep 02, 2025]

- Breakdown by view type

- HTML page views: 11537

- PDF downloads: 4856