Performance of Wet and Dry Bagasse Combustion in Assalaya Sugar Factory - Sudan

Received: 22-Dec-2017 / Accepted Date: 06-Jan-2018 / Published Date: 12-Jan-2018 DOI: 10.4172/2576-1463.1000179

Abstract

This Paper aims to study performances of dry and wet bagasse combustion to generate 51.58 kg/s of superheated steam in Assalaya Sugar Factory thermal power plant, wherefore, 26 kg/s of bagasse flows with constant rate (proposed design). Boilers efficiencies and evaporation coefficients has been calculated for each type of bagasse. Indirect heat balance method is used for defining amount of heat lost through boilers, which consists of incomplete combustion, unburnt bagasse, surface radiation, heat transferred by convection, and energy lost by ash. Bagasse combustion analysis for heat value and combustion requirements carried out based on chemical reaction method (stoichiometric quantities). There is a great contrast of boiler efficiency when used dry or wet bagasse (50% moisture), resulted as 52% and 84% respectively. The evaporation coefficient of wet bagasse is inversely proportional to bagasse moisture contains.

Keywords: Dry bagasse; Wet bagasse; Combustion; Calorific Value; Flue gases

Nomenclature

h- Specific enthalpy (KJ/kg)

T/H- Ton per Hour

GCV- Gross Calorific Value (KJ/kg)

NCV - Net Calorific Value (KJ/kg)

Cp - Specific heat Capacity (KJ/kg.K)

T - Temperature in C°

Q - Sensible heat lost with flue gases (KJ/Kg)

Ein - Energy inlet (MW)

Eout- Energy outlet (MW)

Elost- Energy lost (MW)

η - Thermal Efficiency

w - moisture per unit bagasse (kg/kg)

m - weight of air used in combustion to theoretical air (kg/kg)

Mv- Heat transferred to the steam (KJ/Kg)

S - Sucrose per unit of bagasse (Kg/Kg)

γ - Coefficient of incomplete combustion

β - Coefficient considering loses by radiation

α - Coefficient considering loses by unburnt bagasse

σ - evaporation coefficient

Introduction

Sudan own 200 million fadden cultivable area, but only 41 million fadden utilized under crop production [1]. Cultivation of sugar cane circumstance concerning climatic requirement and soil type is access. The majority cultivable areas consider as tropical, warm with humid climate, heavy rainfall and the Nile flows from south to north. Sudan is characterized by fertile and flat soil addition to good drainage. Despite of this, concept of sugar cane plantation in Sudan as commercial source started lately, the base foundation of the first sugar production beginning on 1960 at Elguneid. Currently Sudan own six sugar factories, five of them are governmental sector, and one is private sector. The total production of sugar in Sudan about 800,000 tons annually, still 700,000 tons per year deficit that imported from the neighbor countries [2]. Generally, the sugar industry contributes to the gross domestic products as well as it its role in achieving food security and indirectly in its diverse products for connecting industries as raw materials for varies products [1]; currently, it is one of the most important hard currency earners that, contribute substantially to the national economy in terms of investment volume contribution to the total value of the national investment activities [3].

Bagasse is that residuals of sugar cane remaining after the sugar cane containing juice crushed and squeezed, it is considered as fibrous and pithy material. Thermal and electric energy are produced for the own sugar factory production processes, only using sugar cane bagasse as fuel in cogeneration plants. Almost, bagasse specified as one of the important renewable energy source, it is impact in the atmosphere is very limited. The main aim of sugar factories construction in Sudan during a period (1960 -1981), at Al-Gunied, Sennar, Assalaya, Halfa, and Kennana to provides sugar as commodity for local consumption, all effort concentrated in sugar production processes. This situation laid to accumulation of huge quantity of bagasse around factories yards, which causes many environmental problems; usually, accident of bagasse fired frequently occurs. Currently, the sugar factories in Sudan devoted respect efforts to get ultimate utilization of bagasse energy for both, sugar production processes and electricity generation. Assalaya Sugar Factory which located in Rabak locality, White Nile State, about 280 km south Khartoum, has erected recently a new steam unit turbine to increase the electricity generation and to export the surplus to the national grid. This new task, make the bagasse piles accumulation around sugar factory yard for a long period disappeared, often consumption of bagasse in boilers combustion process exceed its flow rate from crushing mill. Assalaya Sugar Factory currently forced to use wet bagasse that received directly from crushing mill in boiler combustion processes, although, there are great variation of heat value for wet and dry bagasse. There are no any technical mechanisms uses in Assalaya Sugar Factory to dry the wet bagasse that flows from crushing mill.

The main aims of this study to evaluate and compare heat performance of combustion of the wet and dry bagasse that uses in Assalaya Sugar Factory boilers.

Description of Thermal Power Plant

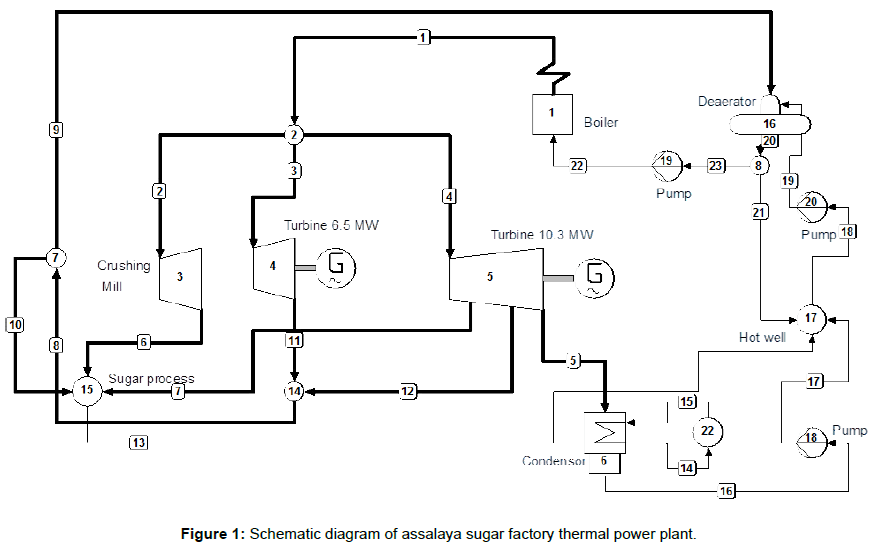

Assalaya Sugar Factory thermal plant consist of five boilers, usually four in working and one is standby, these boilers generates totally 189.45 tons of superheated steam per hour (T/H); 48.35 T/H of superheated steam transfers to six crushing mill unit that produces 485638 tons of bagasse per year. 65.07 T/H of superheated steam converges to buck pressure power turbine that generates 6.5 MW of electricity. 72.28 T/H of superheated steam delivered to 13 MW turbine, which is one of the sugar factory policy to increase the electricity generation and export the surplus to the national net 3.75 TPH of the steam considered as losses.

Specific technical operating condition concerning Assalaya Sugar Factory presented in Table 1, the main compounds and the thermodynamics cycle shown in Figure 1.

| Description | Value | Unit |

|---|---|---|

| Bagasse flow rate to boiler | 26 | Kg/s |

| Bagasse Production | 113.36 | T/CH |

| Bagasse Production per year | 485638 | ton |

| Bagasse to yard | 3.88 | Kg/s |

| Superheated steam flow rate | 51.58 | Kg/s |

| Temperature of Superheated Steam | 380 | CO |

| Pressure of Superheated Steam | 25 | bar |

| Feed water temperature (to boiler) | 105 | CO |

| Feed water flow rate | 53.67 | Kg/s |

| Feed water pressure | 40 | bar |

Table 1: Thermal power plant operating conditions.

Bagasse Specification

Chemical and physical constituents of dry bagasse

The chemical composition of dry bagasse varies slightly according to different authors, since these variations are not large. Essential data concerning the dry bagasse constituent analysis carried out by Elbager [4] used thermogravimetric analyzer. Elbager insured that dry bagasse from Sudan Sugar Factories contained 46.95% Carbon, 6.06% Hydrogen, 42.44% Oxygen, 0.13% Nitrogen, 0.08% Sulfur, and 4% Ash.

Chemical and physical constituents of wet bagasse

Chemical and Physical Constituents of wet bagasse usually determined from its ultimate and proximate analysis. Data concerning Constituent of wet bagasse leaves the crushing mills is very limited, but Magasiner N [5], Gamble GE [6] and Charles Mbohw [7], estimated the main elements of wet bagasse as, 22.5% Carbon, 23% Oxygen, 3% Hydrogen, 50% moisture, and 1.5% Ash. Also, chemical test for wet bagasse in Assalaya factory indicated that it is contained 2% berix.

Dry bagasse calorific value

The gross calorific value of dry bagasse: The only methods used for dry bagasse to assess its calorific value available presently are direct laboratory analysis or the uses of calculation formulas derived for specific conditions. Despite of considerable differences in appearance between varieties of cane, the Gross Calorific Value (GCV) of dry bagasse varies only slightly among a different country [8]. Experimental test for Asalaya Sugar Factory dry bagasse carried out in Sudan University of Science and Technology laboratories, to determine its gross calorific values used the bomb calorimeter, under Khartoum climate conditions, where temperature is 35.96°C and pressure is 1.007 bars. The Gross Calorific Value of dry bagasse in Assalya Sugar factory indicated 19 497.61 Kj.Kg-1.

The net calorific value of dry bagasse: The Net (low) Calorific Value (NCV) gives a more accurate indication of heat practically obtainable, but there is no means of determining it directly. It is therefore necessary to calculate this value, the convention adopted of subtracting from G.C.V the weight of hydrogen per unit mass of bagasse [9]. The South African Sugar Technologist’s Association [8] developed equation to predict the net calorific value of bagasse given as:

NCV= GCV-21936 H (KJ.Kg-1) (1)

The NCV dry bagasse in Assalaya Sugar Factory resulted as NCV=18071.77 KJ.Kg-1

H= hydrogen per unit weight of bagasse

Calorific value of wet bagasse

The gross calorific value of wet bagasse depends mainly on the water content of the bagasse. Decrease of bagasse moisture enhance boiler efficiency due to the increasing of the calorific value. Sakalp -Shirivastav et al., [10]. The South African Sugar Technologists Association [8], and E. Hugot [9] summarized the main formulas developed by varies authors conventionally used to calculates the gross calorific value of wet bagasse in sugar industries, Von Pritzelwitz formula is seen to be more accurate.

GCV= [19632-(30.98%brix)-(196.32 × %moisture)-(196.32 × %ash)]KJ.Kg-1 (2)

NCV= [18335-(30.98 × %brix)-(207.6 × %moisture)-(183.35 × %ash)]KJ.kg-1 (3)

The Gross and Net Calorific Value of wet bagasse in Assalaya Sugar Factory computed according to Von Pritzelwitz formulas (equation 2 and 3) and taken as 9361.4 kJ.kg-l and 7526.34 k J.kg-l respectively.

Air required for Dry Bagasse Combustion

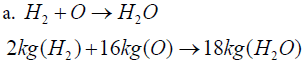

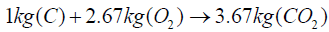

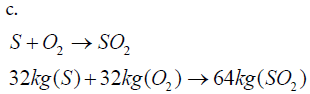

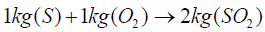

To ensure complete and efficient combustion in a furnace, an adequate supply of oxygen must be brought into contact with the fuel. The simplest way of measuring combustion efficiency is to determine the percentage of carbon dioxide, oxygen and carbon monoxide in the, flue gases. A trace of carbon monoxide indicates incomplete combustion, whilst the carbon dioxide indicates of complete combustion [9]. Generally, combustion of bagasse analysis, for both wet and dry base on chemical reactions method (Stoichiometric quantities). Therefore, according to it is constituents and subsequently masses of air required for complete burning is estimated. To perform complete combustion carbon present in bagasse transforms into carbon dioxide, hydrogen into water, and sulphur into sulphur dioxide that presented by equations a, b, c and d below. Thus, it is obvious that the total mass before combustion and after combustion remains constant; although the elements exist in form of different chemical compounds in reactants and products based on mass.

Or

Or

Or

It is noted from the chemical formulas, 1 kg of hydrogen shall require 8 kg of oxygen, 1 kg of carbon shall require 2.67 kg of oxygen and 1 kg of sulfur shall require 1 kg of oxygen. So, ash and nitrogen assumed not undergo any chemical reaction.

From Table 2 the minimum air required theoretically for dry complete combustion is 5.7 kg/kg of bagasse. This air is heated by combustion flue gases temperature is raised from ambient to the undergrate air temperature which is about 250°C.

| N0. | Composition | Percentage (kg/kg) | Oxygen required (kg/kg composition) | Oxygen required (kg/kg bagasse) | Mass of air required for combustion(kg/kg bagasse) (air having 20.3% oxygen) |

|---|---|---|---|---|---|

| 1 | Carbon C | 0.4695 | 2.67 | 1.252 |  |

| 2 | Hydrogen H | 0.0606 | 8 | 0.4848 | |

| 3 | Oxygen O | 0.4244 | - | -0.4244 | |

| 4 | Nitrogen N | 0.0013 | - | - | |

| 5 | Sulfur S | 0.0008 | 1 | 0.0008 | |

| 6 | Ash A | 0.0476 | - | - | - |

| Total | 1.3132 | 5.7 |

Table 2: Air required for dry bagasse combustion.

Air required for Wet Bagasse Combustion

For conditions by supplying only the quantity of air theoretically necessary for wet bagasse; combustion would be poor and incomplete. In order to obtain complete combustion for wet bagasse, without unburned bagasse and all carbon burns to CO2, it is necessary to supply a certain excess of air [9]. Charles [11] explained that wet bagasse which content 50% moisture, practically requires excess air for complete combustion not less than 48% of the theoretical air. By Stoichiometric quantities analysis method (Table 3), the theoretical air required for 1 kg of wet bagasse combustion is 2.65 kg, and the actual air required (after addition of excess air) for wet bagasse complete combustion is 4 kg/kg of bagasse.

| N0. | Composition | Percentage (kg/kg) | Oxygen required(kg/kg composition) | Oxygen required (kg/kg bagasse) | Mass of air required for combustion(kg/kg bagasse)( air having 20.3% oxygen) |

|---|---|---|---|---|---|

| 1 | Carbon (C) | 0.225 | 2.67 | 0.6 | 0.61*100/23 |

| 2 | Hydrogen | 0.03 | 8 | 0.24 | |

| 3 | Oxygen (O) | 0.23 | - | -0.23 | |

| 4 | Moisture | 0.5 | - | - | |

| 5 | Ash(A) | 0.015 | - | - | |

| Total | 0.61 | 2.65 |

Table 3: Air required for wet bagasse combustion.

Dry Bagasse Flue Gases

Flue gases that liberated during dry bagasse combustion determined theoretically from composition of combustion products. In this research assumed all gases formed during combustion process exits through the chimney as flue gases. The main elements of gases that formed during bagasse combustion included carbon dioxide, water vapour, nitrogen, and sulfur dioxide see Table 4.

| N0. | Composition | Percentage (kg/kg) | Products | Mass of flue gases (kg) |

|---|---|---|---|---|

| 1 | Carbon C | 0.4695 | CO2 | 1.72 |

| 2 | Hydrogen H | 0.0606 | H2O | 0.54 |

| 3 | Oxygen O | 0.4244 | - | - |

| 4 | Nitrogen N | 0.0013 | N2 | 5.15 |

| 5 | Sulfur S | 0.0008 | SO2 | 0.0016 |

| 6 | Ash A | 0.0476 | A | - |

| Total | 7.41 |

Table 4: Dry bagasse flue gases.

The Flue gases in Assalya Sugar Factory departure boiler with a temperature of 350°C. The total amount of flue gases that liberated during dry bagasse combustion is 7.41 kg/kg of bagasse.

Wet Bagasse Flue Gases

The flue gases liberate during wet bagasse combustion included all the elements defined in dry bagasse combustion, addition to the oxygen that contained in the excess air, see Table 5. The total amount of flue gases that liberated during wet bagasse combustion is 4.22 kg/kg of bagasse.

| N0. | Composition | Percentage (kg/kg) | Products | Mass of flue gases (kg) |

|---|---|---|---|---|

| 1 | Carbon (C) | 0.225 | CO2 | 0.825 |

| 2 | Hydrogen (H2) | 0.03 | H2O | 0.27 |

| 3 | Oxygen (O2) | 0.23 | O2 | 0.23 |

| 4 | Nitrogen (N2) | - | N2 | 2.4 |

| 5 | Moisture (H2O) | 0.5 | H2O | 0.5 |

| 6 | Ash(A) | 0.015 | A | - |

| 7 | Total | 4.225 |

Table 5: Wet bagasse flue gases.

Enthalpy of Dry and Wet Bagasse Flue Gases

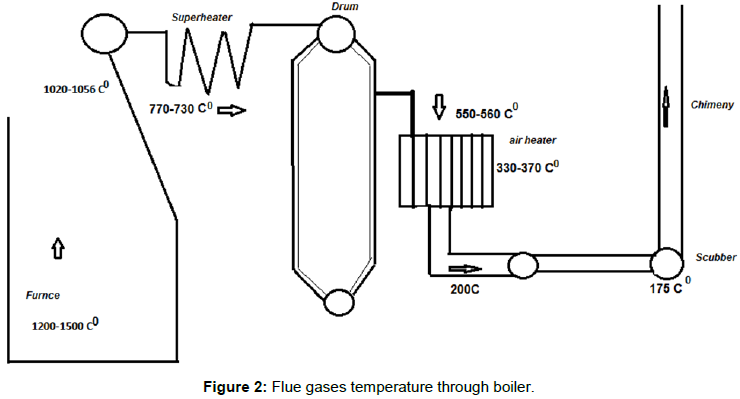

In Assalaya Sugar Factory, the air reheater of the thermal power plant mounted just in the exit of flue gases passage, when leaves boiler. The average temperature of flue gases in air reheater is 350°C, there is no any economizer used in power system, gas temperature flow through boiler presented in Figure 2. Total enthalpy determined according to general form of perfects gas when temperature and specific heat capacity is known; used equation (4), the enthalpy of flue gases liberate during dry and wet bagasse combustion is 5163.1 KJ and 3183 KJ per unit Kg of bagasse respectively.

(4)

(4)

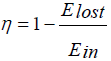

Boilers Efficiencies

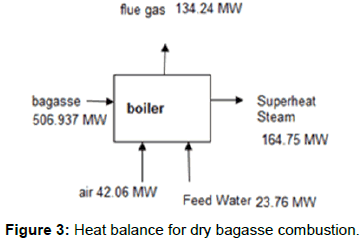

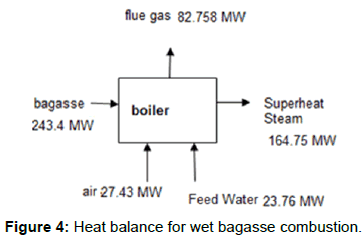

The first law of thermodynamics used to evaluate the total energy lost through boiler body, when dry and wet bagasse uses as a fuel, heat balance equation (5) and thermal efficiency equation (6) used in this application. Energy lost from boiler occurs through varies sources, including, incomplete combustion, unburnt bagasse, surface radiation, convection, and energy lost by ash. Comparison of dry and wet bagasse boiler heat balance presented in Figures 3 and 4 and summarized in Table 6.

| Type of bagasse | Energy in (MW) | Energy out (MW) | Energy Lost (MW) | Boiler Eff. |

|---|---|---|---|---|

| Dry | 572.757 | 298.99 | 273.767 | 52% |

| Wet | 294.59 | 247.51 | 47.08 | 84% |

Table 6: Boilers heat balance.

Ein-Eout= Elost (5)

(6)

(6)

Steam Bagasse Ratio for Dry and Wet Bagasse

Sensible heat of flue gases

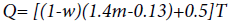

The sensible heat lost with flue gases given by E. Hugot [9] as:

(7)

(7)

For dry bagasse, no moisture and no excess air required for complete combustion [9], therefore, w=0, m=1, equation (7) becomes:

(8)

(8)

Flue gases leave boiler in 350°C

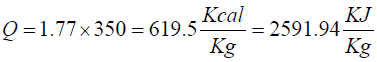

But for wet bagasse w= 0.5, m=1.48, T=350°C,

Heat for steam generation

A general formula derived by E. Hugot [9] used to evaluate quantity of heat required to transferred to the steam, given as:-

Where:

α=0.975, β=0.97, γ=0.95 for spreader –stoker furnaces, where Assalya Sugar Factory Thermal Power Plant one of this type.

Sucrose(S) destroyed by microorganisms and thus disappears in a short time in storage [12], for dry bagasse moisture and sucrose assumed to be equal zero. Therefore, heat for steam generation when used dry bagasse is:-

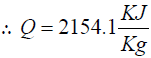

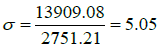

Mv=13909.08 KJ/Kg

Boiler produces superheated stream under pressure 25.01325 bar, and temperature 380°C, enthalpy defined from thermodynamics and transport properties of fluid tables arranged by G.F.C. Rogers and Y.R. Mayhew as 3194 KJ/Kg.

Feed water inter boiler with enthalpy 442.79 KJ.Kg-1. The actual heat added to water to produce superheated steam = 3194 - 442.79 = 2751.21 KJ/Kg

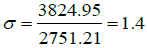

The ratio of bagasse combustion to superheat steam produced (evaporation coefficient) calculated as flowing:

For wet bagasse w = 0.5, m= 1.48, T= 350°C

heat added to water= 2154.1 KJ.Kg-1

Sucrose percentage in wet bagasse, S=0.02 and moisture percentage w=0.5, sensible heat for flue gases from equation (7), Q= 514.85 kJ/ kg. Heat required for steam generation and the evaporation coefficient when wet bagasse used as fuel:-

Mv= 914.2 Kcal.Kg-1= 3824.95 KJ.Kg-1

Conclusion and Recommendations

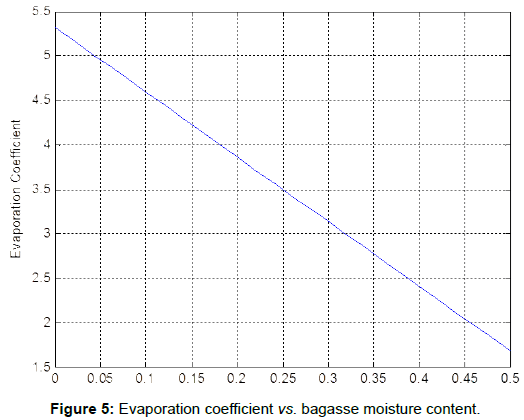

The amount of heat lost through boiler surfaces is 273.767 MW that evaluated from heat balance equation when dry bagasse burned and is very large; therefore, leading to weak efficiency, for suitable efficiency to generate 51 kg/s superheated steam, dry bagasse flow rate decease to moiety. The vapour produced per unit weight of bagasse which known as Evaporation Coefficient lies within the range of 2-2.7 for wet [9]. In Assalaya Sugar Factory thermal power plant, the evaporation coefficient for dry and wet bagasse combustion is 5.05 and 1.4 respectively. The evaporation coefficient for wet bagasse is inversely proportional to bagasse moisture contains, presented in Figure 5.

Wet bagasse contained 50% moisture indicated only 1.4 of evaporation coefficient, this figure less than E. Hugot range (2-2.7). To obtain reasonable evaporation coefficient during wet bagasse burning, bagasse most contains moisture ranges 45% - 37% per unit mass of bagasse.

Acknowledgements

The great support for this work provided by Mohamed Abdalla Osman, The First Engineer of Power Generation in Assalya Sugar Factory is gratefully acknowledged.

References

- Emam AA, Musa MO (2011) The Competitiveness of Sugar Cane Production: A Study of Kenanan Sugar Company, Sudan. J Agricultural Sci 3.

- Hala A (2014) Sugar Market Report Thirty-Second Report, Ministry of Commerce of Sudan.

- Bushara MOA (2016) evaluation of total factor productivity of sudanese sugar company farms a nonparametric analysis-1999-2007. Arabian J Business and Management Review.

- Elbager (2014) Kinetic Study on Co-gasification of Petrolum Coke and Biomas.

- Magasiner N (1966) Boiler Design and Selection in The Cane Sugar Industry Paper-Suoth African Sugar Technologists' Association.

- Wani T (2006) Advances in Engineering and Technology -Proceedings of the First International Conference on Advances in Engineering and Technology.

- Don CE (1977) Calorific values of South African bagasse in mechanical engineering, Natal University.

- Hugot E (1986) Handbook of Cane Sugar Engineering. Book, ELSEVIER: New York.

- Shrivastav S (2013) Design of Bagasse Dryer to Recover Energy of Water Tube Boiler in a Sugar Factory. International J Science and Res (IJSR) India: 2.

- Mwakali JA, Taban-Wani G (2006) Advances in Engineering and Technology Proceedings of the First International Conference on Advances in Engineering and Technology.

- Payne JH (1991) Cogeneration in the Cane Sugar Industry. Elsevier, Academic Press. Sugar Series 12.

Citation: Abdalla AM, Hassan TH, Mansour ME (2018) Performance of Wet and Dry Bagasse Combustion in Assalaya Sugar Factory - Sudan. Innov Ener Res 7: 179. DOI: 10.4172/2576-1463.1000179

Copyright: © 2018 Abdalla AM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 22485

- [From(publication date): 0-2018 - Dec 20, 2025]

- Breakdown by view type

- HTML page views: 20846

- PDF downloads: 1639