Study of Appropriateness of Cost-Effective Building Construction Technologies in Housing Sector in India

Received: 12-Sep-2013 / Accepted Date: 02-Dec-2013 / Published Date: 08-Dec-2013 DOI: 10.4172/2168-9717.1000113

Abstract

As housing demand in India is continuously growing, different government schemes are being implemented to cater to the need of mass housing for the poor and lower income group people. Use of appropriate Cost-effective Eco-friendly Construction Technologies (CECT) in housing sector in India has the potential to be the most appropriate in terms of economy and acceptability. The reduced cost of building, enhancement of comfort level and non-compromise on safety may establish appropriateness of CECT, which will also act as a market force and demand for such technologies is expected to grow-up. Previously the appropriateness of CECT in Indian context was never explored. This paper studied the acceptability and adaptability potential of different CECTs through field survey, literature study and technical calculations and tried to find out the most appropriate one among those.

Keywords: Indian housing scenario; Cost-effective eco-friendly construction technology; Safety; Comfort; Acceptability; Adaptability

74053Introduction

Housing shortage in India

In order to meet growing demand of housing, government of India has planned to provide shelter for every shelter-less people and also to build disaster-resistant housing in rural and urban areas. Different government schemes of mass housing are being implemented to cater to the need of housing. In India the buildings constructed under mass housing schemes are all low-energy buildings.

As per the Census reports of India and other reports by different Government Departments, the house types are gradually transforming to Permanent (“Pucca” Houses – in which the walls and roof of which are made of permanent material) and Semi Permanent (“Semi Pucca Houses” – in which either the walls or the roof is made of permanent material) types from Temporary (“Kutcha Houses” - in which both the walls and roof are made of materials that needs to be replaced frequently) in both rural and urban areas. “Report of Technical Group on Urban Housing Shortage (TG-12) (2012-2017)” prepared by the National Building Organisation of India (2012) is the latest document available in this subject which have thoroughly investigated through primary survey, the rural to urban shift of labour resulting in shortage of dwelling houses in urban areas of India – particularly in the Lower Income Group (LIG) and Economically Weaker Section (EWS) segment. Draft prepared in 2012 by the Working Group on Rural Housing for XII Five Year Plan, 2011, Ministry of Rural Development, Govt. of India, has provided a detailed study and analysis on housing shortage in rural areas. Need of introduction and use of eco-friendly and cost-effective housing technologies were included in the document under clause 5.3.1(iii).

Indira Awaas Yojna – one of the flagship rural housing schemes, was launched in 1985-86 and guidelines were revised time-to-time with the latest issued in 2012. In its introduction, the objective of the scheme was stated as “upgradation of unserviceable kutcha houses”. In the same chapter emphasis was given on “use of cost affective, disaster resistant and environment friendly technologies in rural housing”.

The following figures may be taken into consideration to assess housing shortage in India during its 12th Five Year Plan (2012-2017):

(i) Housing shortage in Urban Areas as assessed by Technical Group on Urban Housing Shortage of National Building Organization-18.78 million units of which 95.62% i.e. 17.96 millions belongs to Economically Weaker section and Low Income Group families.

(ii) Housing shortage in Rural Areas as assessed by Working Group on Rural Housing, Ministry of Rural Development, Govt. of India for the 12th Five Year Plan-48.81 million units of which 90% i.e. 43.93 million belongs to Below Poverty Level families.

The trend of conversion from Temporary to Permanent or Semi- Permanent structures is likely to continue in view of economic upliftment of common people and different government schemes on providing durable shelters to people of economically weaker section and lower income group. It is expected that large no. of buildings with durable and easily available conventional materials like brick, sand, cement, steel reinforcement etc. will be constructed in near future and demand of such building materials will shoot up. About 61.89 million units of residential houses for Economically Weaker Section and Low Income Group families will be constructed by 2017 to fulfill the declaration of “Housing for All” by the Government of India under the National Housing and Habitat Policy 1998.

If the said 61.89 million housing units have a minimum area of 25 square meters as per the standards of Indira Awaas Yojna scheme, a total of 1547.25 million square meter of built-up space is likely to be constructed by 2017. As per Indian Standards, the peripheral and main load-bearing masonry walls of any permanent building should be of thickness not less than 230 mm (one brick thickness). Considering the growing concern about safety, quality and comfort, we may consider that that buildings will be built with masonry wall and R.C.C. roof to ensure durability, fulfill peoples’ perception and meet with the provisions in the Indian Standard Codes.

Use of Cost-effective Eco-friendly Construction Technologies (CECT) to construct safe, durable, comfortable houses can bring down the cost of construction by reducing use of energy-consuming building materials. The cost of building which is expected to be reduced with adoption of CECT may also act as a market force and consequently demand for cost-effective technologies would grow-up. The scope of the study is to examine, through field survey, literature review and computation, an appropriate CECT that will be acceptable by common people of India.

Assessing the guiding criteria for acceptability of construction technologies and building materials

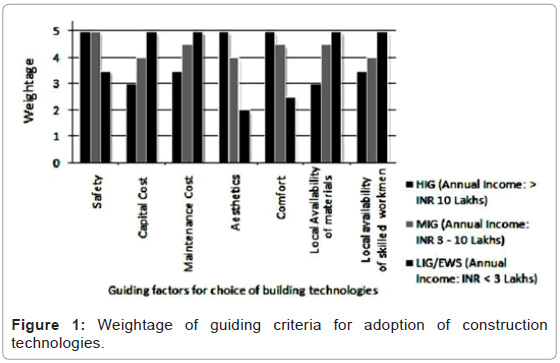

Safety, capital cost (production and construction), comfort, expenditure on maintenance, availability of materials and artisans, aesthetics and to some extent the societal status are guiding criterion of acceptability of building construction technologies in India. A small sample survey was undertaken among people belonging to Higher Income Group (HIG), Middle Income Group (MIG) and Lower Income Group/Economically Weaker Section (LIG/EWS) at six towns and suburbs to get an idea of people’s perception about the above factors. They were requested to assign priority ratings ranging between 0-5 on the guiding criteria. The results are indicated in Figure 1.

The result revealed that safety, construction cost, expenditure on maintenance, availability of materials and artisans decides the options for MIG whereas capital cost, maintenance cost, availability of man and materials are the guiding criteria for LIG/EWS.

Reddy [1] advocated some guiding principles for developing sustainable alternative building technologies. Those are (a) energy conservation, (b) concern for environment, (c) minimisation of transport and maximisation of locally available materials, (d) decentralisation of production and maximum use of local skills. Singh et al. [2] stated that there is an inseparable relationship between energy and architecture and indoor comfort. They have opined that though energy conservation is a necessity, but it should not be achieved at the cost of human thermal comfort. Gut and Ackerknecht [3] have prescribed the following general guidelines for designing of climateresponsive building: (1) Minimisation of heat gains during daytime and maximisation of heat loss at night in hot seasons, and reverse in cold seasons, (2) Minimisation internal heat gain in the hot season, (3) Optimisation of building structure, (4) Control of solar radiation. They mentioned that walls and roof are the two important components of the building envelope that affect the thermal comfort of a building and roof has the strongest thermal impact of heat loss and gain as it receives most of the solar radiation. On choice of building materials and technologies they have cautioned against use of untested materials which may behave adversely under testing conditions like earthquake, flood, cyclone etc. and also which requires frequent maintenance. A combination of traditional knowledge with advanced technology has been preferred and they opined for use of local construction materials and recommended relying on technical ability of local builders.

Based on the primary survey and literature review, it may be concluded that in order to construct 61.89 million houses for of or below Middle Income Group, Capital Cost, Safety, Maintenance Cost, Local Availability of Materials and Workmen can be considered as the guiding criteria. Therefore, study has been limited to those technologies, for mass housing schemes in India, which satisfies the above conditions.

Review of available CECTs in India and their appropriateness based on acceptance criteria

Some of the widely practiced CECTs in India are (i) Compressed Stabilised Earth Block (CSEB), (ii) Bamboo-Reinforced Cement Concrete (BRCC), (iii) Rat-trap bond Wall and Filler Slab. Several other technologies and alternate materials promoted by different research organisations including Central Building Research Institute are also capable to reduce cost in building construction. But their production and use require either special machinery or special craftsman. Those are, therefore, have very much limited use in different showcase projects at small pockets within the country. Society for excellence in Habitat development, Environment protection and Employment generation has compiled the ‘Environment Friendly Indian Building Material Technologies for Cost Effective Housing’. The said document has discussed on 25 such materials/technologies, out of which 15 are for structural part of the building. Among those, except materials like CSEB, Clay Flyash Burnt Bricks, Marble Slurry Bricks, and technology like Rat-trap Bond Brick Masonry Wall, all other requires either special machinery or specially trained manpower for production and construction.

Compressed Stabilised Earth Block (CSEB) or Compressed Mud Block (CMB) is the most economic and energy-efficient building material having heat storage capacity is one of the highest and also has proven capability of control of humidity. Zami and Lee [4] observed that Earth construction is energy saving and economically beneficial requires simple tools and less skilled labour and it improves indoor air humidity and temperature which ensures thermal comfort, and the materials are readily available in large quantities in most regions. From the environmental point of view, emission of greenhouse gas from production of CSEB is about 7.9 times less than that of country-fired bricks. Maini [5] has stated that for production of good quality CSEB, top soil and soil with organic content should be avoided. It requires expertise and knowledge to choose the right soil and stabilizer for production of CSEB as per laid down standards. Hadjri et al. [6] have surveyed users’ perception on different type of constructions in Zambia, Africa and concluded that majority did not prefer buildings made of earth as it is a symbol of low societal status, culturally associated with poverty and there is a chance of decreased durability due to poor design and construction standards.

CSEB has failed to get wider social acceptability in India because (a) people who aims to improve their dwelling prefers ‘pucca’ or permanent construction materials and mud or earth is still considered as a non-durable and poor man’s material, (b) technical and scientific expertise for this technology is not easily available, (c) composition and strength of production of CSEB varies on location, type of available earth and type of stabilisers, thus making it difficult to convince common people and local artisans.

Bamboo-reinforced Cement Concrete (BRCC) has also been considered as a low-cost building material, but its use is very much limited to the bamboo-producing zones of the country and where trained personnel are available for such technology. Zackirson [7] have worked with BRCC as a cheap and energy-efficient building material. Bamboo should be treated immediately when cut at the bamboo grove. There are tendencies to develop crack along cleavage due to low strength along fibres of bamboo and also strength varies from species to species. The alkaline property of concrete may also have adverse effect on bamboos embedded in concrete. However, cost effectiveness, ecofriendliness, light weight, shock absorbing capacity during earthquake advocate the use of bamboo as an alternate building material and an alternative to steel in reinforced cement concrete. Building Materials and Technology Promotion Council of India [8] has promoted bamboo as a material for cost-effective and disaster resistant housing. They said that bamboo is a renewable raw material having a life span of 30–40 years, but the natural durability depends upon the species and type of treatment carried out on that material. In hilly areas and bambooproducing zones these technologies are used by local people, but country-wide acceptability of the same is very poor.

The report of Govt. of India and UNDP Disaster Risk Management Programme [9] has indicated that houses built with mud, unburnt brick and mud mortar become vulnerable due to their loss of strength in submerged condition during flood and houses made from light weight materials like GI or other metal sheets or grass, leaves, bamboo etc. easily float away as soon due to uprooting of their holding down ports by the flowing water. Buildings constructed with lighter materials such as metal sheets and bio-mass materials are not much affected during earthquakes, but can be blown away under the storm winds. But those constructed using heavy materials will be totally destroyed under earthquake conditions endangering life and property. It has been recommended that the plinth should be high enough and must be made of non-erodible material, the superstructure walls must be made stable under earthquake as well as under strong wind conditions, and the wall material should not become soft and dissolve under water. As per the recommendations given by the National Disaster Management Authority of India it is required that the houses in the flood prone areas should be made with flat horizontal roofs which could be used as the shelter by the family during flood. The instant study has been carried out to find out the most appropriate CECT that will conform to all the guiding criteria as perceived by common people as well as will meet the stipulations laid down by the national authorities of India like Bureau of Indian Standards, National Disaster Management Authority etc.

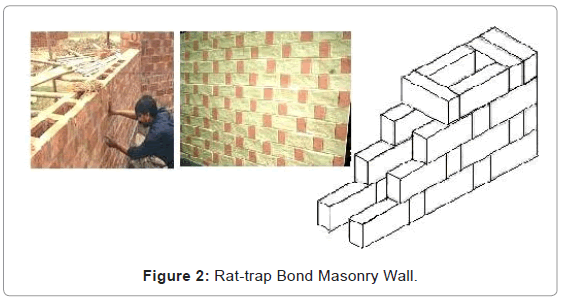

Rat-trap bond is a type of masonry bond of 250 mm (10”) thick brickwork laid by placing the bricks on their sides having a cavity of 100 mm (4”) with alternate course of stretcher and headers (Figure 2). The headers and stretchers are staggered in subsequent layers to give more strength to the walls. The main advantage of this bond is economy in use of bricks, giving a wall of one brick thickness with fewer bricks than a solid bond. Structurally Rat-trap bond wall is an improved form of masonry cavity wall.

There is an apprehension that cavity walls may absorb moisture through the outer surface and the entrapped moisture in the cavity may ultimately harm the structure. But, good quality brick possess very low moisture movement of 0.002% to 0.01% as specified in Section-2, SP- 25-1984 of Bureau of Indian Standards and use of the material does not call for much precaution. In India and abroad, buildings with exposed brickwork in cement sand mortar and joints properly sealed by pointing are being constructed for more than 100 years without any major complaint about moisture absorption from the sides of the walls. However improper construction, impurity in the mortar, use of inferior quality of bricks, faulty damp-proof course may result into moisture absorption and that may occur in any type of masonry construction. Proper precaution and care have to be adopted during selection of materials and supervision of the construction work.

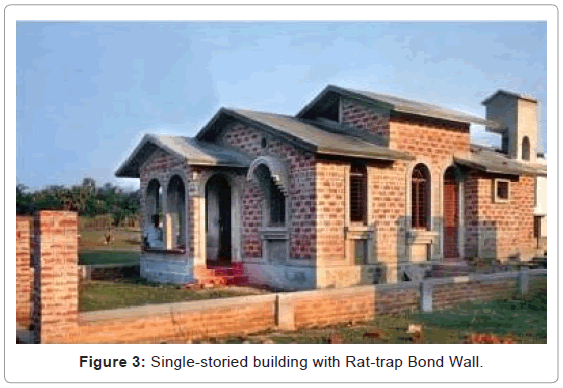

The main features of Rat-trap bond walls are: (a) Strength is equal to standard 250 mm thick brick wall, but savings in consumption of brick, cement and sand are 28%, 37% and 40% respectively (Table 1). The overall saving on cost of materials used for construction compared to the traditional 10” wall is about 20% (b) the air medium created in between the brick layers helps in maintaining a good thermal comfort inside the building. This phenomenon is particularly helpful for tropical climate of India, (d) as the construction is done by aligning the bricks from both sides with the plain surfaces facing outwards, plastering is not necessary except in a few places. The finished surface is aesthetically appealing from both inside and outside (Figure 3), (e) Buildings up to two stories can easily be constructed with this technique (f) In R.C.C. framed structures, the filler walls can easily be made of rat-trap bond, (g) Due to reduced load on the base of the walls, the width of foundation is also decreased, resulting in a saving of about 8%, 8.33% and 7.7% respectively on use of bricks, cement and sand in foundation and plinth for small dwellings.

| Sl. | Item | Conventional Wall (with 1:4 Cement: Sand mortar) | Rat-trap Bond (with 1:4 Cement: Sand mortar) | Savings |

|---|---|---|---|---|

| 1 2 3 |

Brick Cement Sand |

389 119.5 kg. 0.34 cu.m. |

280 75 kg. 0.20 cu.m. |

28% 37% 40% |

Table 1: Material Consumption in Conventional Masonry Wall and Rat-trap Bond Wall (For 1 cu.m. of brickwork).

Earlier work shows that demolition projects in USA have revealed that cavity walls were built in the country 60 or more years ago (Plummer, 1960). From this fact it is evident that cavity walls were in use in United States since early 20th century and the U.S. Army has adopted the technology to build their barracks, officers’ mess etc. since middle of the 20th century. Zackirson Sr. reported that performance of those constructions was reported to be very good in terms of maintenance and thermal insulation [10].

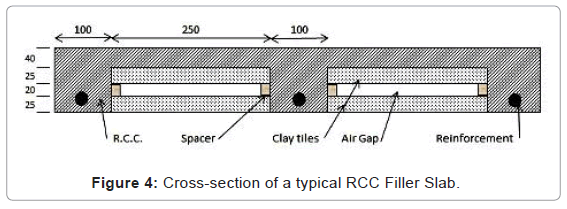

RCC Filler Slab is basically a normal R.C.C. slab where concrete in the tension zone i.e. bottom of the slab, is replaced by light-weight filler materials such as bricks, tiles etc (Figure 4).

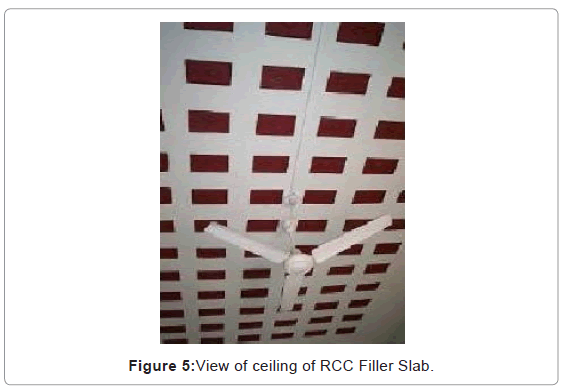

These filler materials are so placed as not to compromise with structural strength. The main features of Filler Slab are: (a) Consumes less concrete and volume of concrete results in reduction of consumption of cement, sand & crushed stonechips by about 49%, whereas use of steel is reduced by about 13% (Table 2), (e) Cost saving of about 23% in comparison with normal RCC slab, (f) produces a good aesthetic if plastering is done only on concrete surface of the ceiling (Figure 5).

| Sl. | Material | Ordinary Slab | Filler Slab | Savings in filler slab |

|---|---|---|---|---|

| 1 | Concrete (M20 grade of standard mix 1:1.5:3) | 3.0 x 3.7 x 0.11 = 1.221 cu.m. | 1.221 – (120 x 0.25 x 0.25 x 0.08) (120 pair of tiles of size 0.25 m x 0.25 m x .025 m with .030 m thick spacer blocks) = 0.621 cu.m. | |

| 1a) | Cement @ 0.286 cu.m./cu.m. of concrete | 0.35 cu.m. | 0.178 cu.m. | 49% |

| 1b) | Sand @ 0.43 cu.m./cu.m. | 0.53 cu.m. | 0.27 cu.m. | 49% |

| 1c) | Stonechips @ 0.86 cu.m./cu.m. | 1.06 cu.m. | 0.54 cu.m. | 49% |

| 2 | Burnt clay tiles of size 250 mm x 250 mm x 25 mm | Nil | 240 nos. | |

| 3. | Steel | 41.4 kg | 36 kg | 13% |

Table 2: Material Consumption in Ordinary R.C.C. Slab and Filler Slab (for a 3.0 m ×3.7 m×0.11 m thick slab).

Computation of strength of the 0.25 m thick rat-trap bond masonry wall on the basis of available Indian Standards has revealed that it is safe to construct walls for two-storied buildings with this technology (Appendix 1). Design of roofs of size 3 m × 3.7 m (Appendix 2), which is a very common size for small residential houses, as filler slab roof has also revealed that it is safe for such houses. However, disaster resistant arrangements like providing RCC bands at sill level and vertical reinforcing bars at centre of masonry columns as suggested by the engineers are to be adopted. This is irrespective of any type of technology or material for construction. From the calculations shown in Appendix 1 and Appendix 2, it may be inferred that both Rat-trap Bond Wall and RCC Filler Slab are safe for construction of small residential buildings up to two floors.

After safety, the next concern for common people is obviously the cost of the building. In a developing country like India, the trend of building technology is inclined towards low-cost locally-available materials and workmen. A balanced approach should be made to construct buildings with minimum cost, maximum safety and moderate level of comfort for users.

Sengupta [11] has compared the cost of the basic structure built with conventional and alternate technologies and concluded that small buildings of size 25 sq.m., which is a standard for mass housing projects under different housing schemes in India, a straightaway reduction of 17% can be achieved in cost of construction of the basic structure without compromising with the safety, durability and aesthetic aspect of the buildings. This aspect will act as an added advantage to the acceptability of these technologies by common people.

Thermal comfort, though not in the top priority of the guiding criteria, may not be ignored also to ascertain acceptability of CECTs among common people.

Parsons [12] has defined thermal comfort as “that condition of mind, which derives satisfaction from the thermal environment. It is rather a psychological phenomenon rather than a physiological state. It is influenced by individual differences in mood, personality, culture and other individual, organizational and social factors. Therefore predicting thermal comfort will never be perfect”.

In most of the parts of India which are warm and humid, in dwelling houses belonging to middle income group and below i.e. which do not have any provision for artificial cooling, the windows are normally operated in following sequence: (a) In summer, windows are generally closed between 10 A.M. and 5 P.M., when solar incidence is maximum, to reduce inflow of heat from outside into the rooms and those are kept open between 5 P.M. to 10 A.M. to facilitate circulation of air inside the room and dissipation of the accumulated internal heat. (b) In winter windows are generally kept open from 7 A.M to 5 P.M. to get maximum warmth from sunlight and kept closed between 5 P.M. to 7 A.M. to reduce loss of heat from inside of the room and protect the interior from rapid cooling. To coincide with the practice, it would be appropriate to construct the buildings with such materials or technologies which are capable of reducing convection of heat through building envelop [13].

Heat transferred through per square meter of 0.25 m thick rattrap bond masonry walls in still air condition and for a temperature difference of 5 degree is approx. 5.93 W (Appendix 3) compared to that of a solid 0.25 m thick masonry wall as 13.84 W (Appendix 4). In Rattrap bond the air gap between the two wythes of bricks provide the necessary barrier for heat transfer. Similarly it can be calculated that heat transferred through per square meter of 0.11 m thick R.C.C. filler slab in still air condition and for a temperature difference of 5 degree is approximately 16.50 W and that for a solid 0.11 m thick R.C.C. slab is approx. 25.91 W. This is due to the two layers of clay tiles at the bottom of the slab and the air gap between them [14].

These properties of rat-trap bond wall and filler slab result in reduction of heat flow through the wall surface and roof and thus ensure more comfort for the inhabitants and reduction in use of air circulators or air coolers during summer time and heating requirements during winter.

Conclusion

From the above study and analysis it can be concluded that Rattrap bond wall and Filler Slab roof would be the most appropriate and acceptable CECT among people belonging to

Middle Income Group and below in India as they are satisfying all their guiding criteria and capable of providing the following advantages:

(i) Use of locally available traditional materials and can be used by local artisans,

(ii) uch cheaper than presently-followed type of construction of permanent buildings,

(iii) Safe as per Indian Standards,

(iv) Comfortable in all weather, and

(v) Aesthetically pleasant.

References

- Reddy BVV (2004) Sustainable Building Technologies. Current Science 87: 899-907.

- Singh MK, Mahapatra S, Atreya SK (2007) Development of Bio-Climatic Zones in North-East India. Energy and Buildings 39: 1250-1257.

- Gut P, Ackerknecht D (1993) Climate Responsive Building - Appropriate Building Construction in Tropical and Subtropical Regions. SKAT: 324.

- Zami MS, Lee A (2008) Contemporary Earth Construction in Urban Housing – Stabilised or Unstabilised?, The Crescent, Salford, United Kingdom.

- Maini S (2005) Earthen architecture for sustainable habitat and compressed stabilised earth block technology. Paper presented at heritage lecture on clay architecture and building techniques by compressed earth at the meeting of India High Commission, Riyadh City, India.

- Hadjri K, Osmani M, Baiche B, Chifunda C (2007) Attitudes Towards Earth Building for Zambian Housing Provision. Engineering Sustainability 160: 141–149.

- Zackirson HB Sr. Performance Experience with Low-rise Buildings. Insulated Masonry Cavity Walls, A Research Correlation Conference.

- Building Material and Technology Promotion Council, Minister of Housing & Urban Poverty Alleviation, Government of India, India.

- Trilok NS, Reddy DV Natural Disasters. International Journal of Earth Sciences and Engineering, Editorial Note.

- Asamoah AM, Owusu AR (2011) A comparative study of Bamboo reinforced concrete beams using different stirrup materials for rural construction. International Journal of Civil And Structural Engineering 2: 407-423.

- Nilanjan S (2008) Use of cost-effective construction technologies in India to mitigate climate change. Current Science 94: 38-43.

- Parsons K (1995). Standards for Thermal Comfort, 1st Edition. (pp. xiii – xiv), Chapman and Hall, UK.

- Guidelines for Indira Awaas Yojna (IAY) (2012) Ministry of Rural Development, Government of India.

- Estimation of Urban Housing Shortage (2007-2012) Report of The Technical Group, 11th Five Year Plan, India.

Citation: Nilanjan S, Souvanic R (2013) Study of Appropriateness of Cost-Effective Building Construction Technologies in Housing Sector in India. J Archit Eng Tech 2: 113. DOI: 10.4172/2168-9717.1000113

Copyright: ©2013 Nilanjan S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 24909

- [From(publication date): 12-2013 - Aug 24, 2025]

- Breakdown by view type

- HTML page views: 19771

- PDF downloads: 5138