A Review of Pollution Prevention Technology in Leather Industry

Received: 28-Aug-2021 / Accepted Date: 29-Oct-2021 / Published Date: 10-Nov-2021 DOI: 10.4172/2573-458X.1000244

Abstract

This is part of the partial fulfillment for the master of science in chemical engineering (food engineering stream) for the course Industrial Ecosystems Engineering-CBEg 6114-. Tannery effluent is among one of the dangerous pollutants of the industry. Beside its benefit industrialization has resulted in the formation of huge amount of waste products, which are released into the environment in the form of wastewater leading to environmental pollution and deterioration. Tanning industries are one of the major manufacturing processes which are responsible for tremendous pollution of water resources. In these industries, animal hides are transformed into leather through many complex stages, consuming high quantities of water and using large amounts of chemicals such as lime, sodium sulfide, ammonium sulfate, sodium chloride, bactericides, vegetable tannins, and chrome salts. Tannery wastewaters are mainly characterized by high salinity, high organic loading, and specific pollutants such as sulfide and chromium. During tanning process there are three types of wastes such as air pollutant, water pollutant and solid pollutant are discharge during various steps namely: beam house operations, tan yard operations, post tanning operations and finishing operations. uncontrolled release of tannery effluents to natural water bodies increases health risks for human beings and environmental pollution. wastes generated from tanning industries, should be managed in an environmentally safe way to reduce the risk of environmental pollution, the paper give an attention to review, major pollutant from the source, and the way to manage in tannery manufacturing process.

Keywords: Tannery; Pollutant; Prevention Mechanisms; Technology

Introduction

Now a day, with the growth of population, the increasing requirement of leather and its products led to the establishment of large commercial tanneries. During the tanning process at least about 300 kg chemicals (lime, salt, etc.) are added per ton of hides [1]. And also, nearly 30 m3 of wastewater is generated during processing of one tone of raw skin/hide [2]. During tanning process there are three types of wastes such as air pollutant, water pollutant and solid pollutant are discharge during various steps namely: beam house operations, tan yard operations, post tanning operations and finishing operations.

As an average of the years 1994 to 1996, globally approximately 5.5 million ton of raw hides on a wet salted basis were processed to yield about 0.46 million ton of heavy leather and about 940 million m2 of light leather, including split leather. At the same time, world-wide 0.62 Million ton of raw skins on a dry basis were converted into almost 385 Million m2 of sheep and goat leather. The light leather production from goat and sheepskins yielded approximately 99 Million m2 in Europe [3]. 80-90% of the world-wide tanneries use Cr (III) salts in their tanning processes. In some parts of the world, the Cr (III) is obtained from Cr (VI) species, which are a hundred times more toxic, but generally tannery effluents are unlikely to contain this form.

In Ethiopia Tanning industry generates large quantities of solid wastes during leather manufacturing process and subsequently during effluent treatment; is source of exports earning and job creation. The Ethiopian leather industry is a relatively older industry with more than 80 years of involvement in processing leather (Proceeding of National Workshop on Enhancing the Ethiopian Leather Industry and Its Market Competitiveness, 2010). And Ethiopia is one of the countries that have the largest livestock populations in the world providing a strong raw material base for the leather industry. About 15.5 million pieces of sheep and goat skins and 1.2 million pieces of cattle hides are supplied to the tanneries per annum (Ethiopian Leather Industries Association, 6th Edition, 2012). The foul odour which emanates from some of these putrescible solid wastes which accounts for much of the smell traditionally associated with tannery wastes.

There are more than 30 tannery industries in operation and have 153,650 sheep and goat skin soaking capacity and 9,725 cowhides soaking capacity per day; together they also employ 4577 persons [4]. The total wastewater discharge estimation from tanneries is about 400 million m3/year. However, most of the leather industries in Ethiopia discharge their effluent partially or without any treatment to the nearby water bodies. This may be due to tanneries do not want to include cost for environmental protection, since it increases their cost of production.

For most of the tanneries the drainage system of the district is not always adequate for the large amount of effluents. Furthermore, the poor environmental standards in the tanning industry encourage the overuse of chemicals, which tend to increase the quality of waste coming from the leather industry. The tanning industry in the Ethiopia sector suffers from complex problems associated with: Poor applied technologies in tanning processes, Lack of environmental awareness, Untrained workers, Huge generated amounts of wastes due to inefficient use of resources, Low export levels due to non-compliance with environmental requirements, Limited investment in the sector. Through the use of large quantities of chemicals and water, the Ethiopian tanning industry has a significant environmental impact, particularly with solid wastes and wastewater. The majority of tanneries, the leather produced in Ethiopia, are located in towns and cities particularly in Mojo town. Poor environmental standards encourage the overuse of chemicals, which in turn increases the quantity of waste produced.

Moreover, uncontrolled release of tannery effluents to natural water bodies increases health risks for human beings and environmental pollution. wastes generated from tanning industries, should be managed in an environmentally safe way to reduce the risk of environmental pollution, the paper give an attention to review, major pollutant from the source, and the way to manage in tannery manufacturing process.

Tannery Production Process

The production processes in a tannery can be split into four main stages of process, hide and skin storage and beam house operations (beam house processes), Tannery process, post-tanning process and finishing process [5].

Pre-Tanning and Beamhouse Operations Process

Cleaning and conditioning hides and skins produce the biggest part of the effluent load.

Soaking: The preserved raw hides regain their normal water contents. Dirt, manure, blood, preservatives (sodiumchloride, bactericides), etc. are removed.

Fleshing and trimming: Extraneous tissue is removed. Unhairing is done by chemical dissolution of the hair and epidermis with an alkaline medium of sulphide and lime. When after skinning at the slaughterhouse the hide appears to contain excessive meat, fleshing usually precedes unhairing and liming. Liming and unhairing produce the effluent stream with the highest COD value.

Deliming and bating: The unhaired, fleshed and alkaline hides are neutralised with acid ammonium salts and treated with enzymes, similar to those found in the digestive system, to remove hair remnants and to degrade proteins. During this process hair roots and pigments are removed. This results in the major part of the ammonium load in the effluents.

Pickling: Pickling increases the acidity of the hide to a pH value of 3 by addition of acid liquor and salts, enabling chromium tannins to enter the hide. Salts are added to prevent the hide from swelling. For preservation purposes, 0.03-2% by weight of fungicides and bactericides are usually applied.

Degreasing: Normally performed together with soaking, pickling or after tanning, degreasing is performed by organic solvents or surfactants, leading to a higher COD value in the effluent.

Tanning Process

The tanning process is applied with various tanning materials (materials able to form stable bonds with collagen) in order to provide the leather with a stable form and high thermal stability. Tanning materials such as vegetable tannins, mineral tanning materials (i.e., chrome tanning) and syntans (synthetic organic tanning materials) are used in tannage. Principally, there are two possible processes, namely: Chrome tanning and Vegetable tanning.

Chrome tanning: After pickling, when the pH value is low, chromium (III) salts are added. To fixate the chromium, the pH is slowly increased through addition of a base. The process of chromium tanning is based on the cross-linkage of chromium ions with free carboxyl groups in the collagen. It makes the hide resistant to bacteria and high temperature. The chromium-tanned hide contains about 2-3% by dry weight of Cr (III). Wet-blue, i.e., the raw hide after the chrome-tanning process, has about 40% of dry matter.

Vegetable tanning: Vegetable tanning is usually accomplished in a series of vats (first the rocker-section vats in which the liquor is agitated and second the lay-away vats without agitation) with increasing concentrations of tanning liquor. Vegetable tannins are polyphenolic compounds of two types: hydrolysable tannins (i.e. chestnut and myrobalan, which are derivatives of pyrogallols (Protrade/GTZ, 1995) and condensed tannins (i.e. hemlock and wattle) which are derivatives from catechol, (UNIDO, 2000). In some cases, as much as 50% by weight of tannin is incorporated into the hide [6]. The vegetable tanning agents used are typically 15-70% of commercial extraxt, often sulphited, then spray dried or concentrated, European Commission, 2001).

Wet Dinishing (Post –Tanning)

The wet finishing processes are sometimes performed in one single float. Chromium tanned hides or Wet-blue are often retanned - during that process the desirable properties of more than one tanning agent are combined - and treated with dye and fat to obtain the proper filling, smoothness and colour. Before actual drying is allowed to take place, the surplus water is removed to make the hides suitable for splitting and shaving. Splitting and shaving is done to obtain the desired thickness of the hide. The composition of pollutants in the wet finishing effluent is complex due to the presence of dyes, fat liquors and combined tanning agents, but the total amounts generated are smaller than in prior steps and often not considered as significant.

Finishing

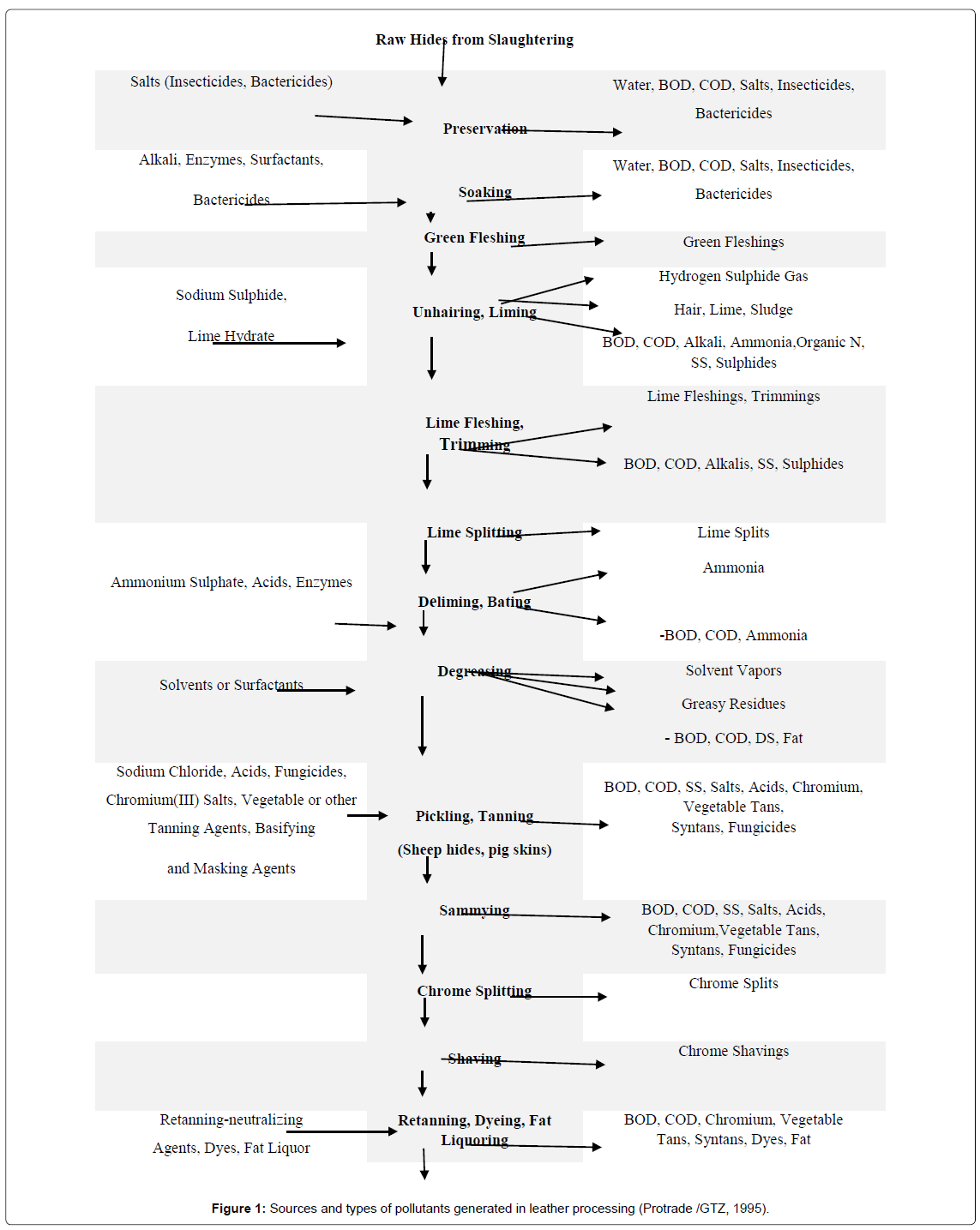

The crust that results after retanning and drying, is subjected to a number of finishing operations. The purpose of these operations is to make the hide softer and to mask small mistakes. The hide is treated with an organic solvent or water-based dye and varnish. The finished end product has between 66 and 85% by weight of dry matter. Environmental aspects are mainly related to the finishing chemicals which can also reach effluent water (Figure 1).

Tanneries Waste and Management Techniques

Tanery Solid Waste

Types, sources and characteristics of tannery solid waste

According to the study made at Ethio-Leather Industry, the physical composition of tannery solid waste generated during leather manufacturing processes was found to be de-dusted salt, hair waste, fleshings, raw skin trimmings, splitting waste, Pickle trimmings, shavings, Crust Trimmings and leather trimmings and it has been observed from literature review that similar types of solid is generated during manufacturing of finished leather from hides and skins. In addition to these, sludge and other solid wastes are also generated during tannery wastewater treatment and the main sources of these solid wastes were found to be un-hairing, trimming, fleshing, splitting, which are all carried out in beamhouse, chrome shaving after chrome tanning operation, crust trimming after re-tanning, finished leather trimming after finishing processes and wastewater treatment plant [7] (Figure-2).

Figure-2: generated of sludge and other solid wastes, pictured from Mojo Tannery Share company, Ethiopia.

The chemical composition of solid wastes generated from beamhouse operations (fleshings, trimmings, splits) depends mainly on a kind and quality of the raw material, treatment type and process conditions. The main components are proteins and fat, up to 10.5% (w/w) for both groups. Water content is high, moisture amounts up to 60%. These wastes contain small amounts of mineral substances, 2-6% (w/w). Chromium compounds are not present in the material, [8].

The tanned leather wastes are mainly useless splits, shavings and trimmings. These waste groups differ mostly in size and shape, the chemical composition is comparable for each. They contain 3-6% (w/w) of fat and about 15% (w/w) of mineral components, including 3.5-4.5% (w/w) of chromium as Cr2O3. Sludge from wastewater treatment plants contains mostly water (up to 65% (w/w)), organic substances (30% (w/w)) and chromium (III) compounds (about 2.5% (w/w)).

Solid Waste Management: Conventional Treatment Methods

To restrain the pollution caused by tannery solid wastes, various effective methods have been taped in the last decades, which chiefly focused on the treatment of solid wastes from the pre-tanning, tanning and post-tanning processes in the leather industry. Despite their diversities of solid wastes, they can be divided into two types: Chromium-free and chromium-containing solid wastes [9].

Treatment of Chromium Containing Solid Wastes

Presently, the use of chromium sulphate is one of the most preferred tanning methods. Thus, large amounts of chromium-tanned solid wastes will be generated during the conversion of hides into wetblue leather. Generally, the tanned solid wastes after this step are the scraps from the wet-blue leather. There are two dominating categories: Direct and indirect treatment of chromium-containing solid wastes. In contrast, the chromium and collagen will be first separated into two or more portions, and then subsequently they undergo further separation [10].

Direct Treatment of the CTSWs

Direct treatment of the CTSWs is a traditional approach and has been a practically used technique in the last decades. The aim of this strategy is to remove the chromium completely and to clean the collagen from the CTSWs. The advantage of this method is that it can be performed in a simple way and easily operated under various conditions. Presently, landfilling and incineration are two dominating methods. Landfilling of CTSWs has been widely used during the last century. However, it was found that this method is not the optimal option and reveals some limitations in its practical application. This is because the chromium from the tanned LSWs was insufficiently removed and will cause secondary pollution [11].

Accordingly, the organic compounds in the CTSWs are burned out completely, producing gaseous emissions, such as SOX, NOX and other burnable gases. Subsequently, they are treated by flue gas cleaning. However, it was also found that the chromium (III) species was easily converted into toxic chromium (VI) at higher temperatures, which will give rise to secondary pollution. This finding demonstrates that ordinary incineration also has some limitations. Improving its operation performances are necessary [12]. To increase the operation performances of incineration, as an improved route, combustion using a fluidized bed technique was proposed.

Indirect Treatment of the CTSWs

To recover some valuable substances from the tannery solid wastes, indirect methods were thus designed. Compared with the direct methods, the operation steps of indirect processes are more complicated and the operation costs are higher. However, the gain of high-valueadded products can compensate such expense. Presently, various techniques, such as oxidation dechroming, hydrolysis dechroming and combination dechroming methods have been developed [13].

Newly Developed Technologies for the Treatment of Chrome Containing Solid Wastes

To solve the problems found in the conventional treatment methods for CTSWs, some innovations have been recently proposed, which mainly focus on the elimination of chromium from the CTSWs and the recovery of byproducts. These newly developed dechroming methods may also be divided into two major types: Direct and indirect techniques. The former primarily includes the high-temperature pyrolysis and biochar dechroming methods [14]. The latter chiefly involves the ionic liquids method, low hydrolysis dechroming and solid-liquid process integration.

Tannery Waste Water Production and Characteristics and Management Techniques

Depending on the type of applied technology (conventional or advanced) the water consumption varies extremely. Technologies that can be regarded as advanced in comparison to conventional methods involve processes usually termed low-waste or cleaner technologies (high exhaustion, chrome fixing). Mainly in dry regions, where water supply is limited, this factor plays an important role. The characteristics of tannery wastewater vary considerably from tannery to tannery depending upon the size of the tannery, chemicals used for a specific process, amount of water used and type of final product produced by a tannery. Tannery wastewater is characterized mainly by measurements of Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), suspended solids (SS) and Total Dissolved Solids (TDS), chromium and sulfides etc. In general, tannery wastewaters are basic, have a dark brown color [15].

A significant number of operations within a tannery are wet operations consuming large amounts of water, chemicals and energy and leading to large amounts of polluted water. This, tanneries wastewater effluent is managed or treated in many different ways; this includes: Mechanical treatment; Effluent treatment; and postpurification, sedimentation and sludge handling.

Mechanical Treatment

Usually, the first treatment of the raw effluent is the mechanical treatment that includes screning to remove coarse material. Up to 30- 40% of gross suspended solids in the raw waste stream can be removed by properly designed screens. Mechanical treatment may also include skimming of fats, grease, oils and gravity settling. After mechanical treatment, physio-chemical treatment is usually carried out, which involves the chrome precipitation and sulphide treatment. Coagulation and flocculation are also part of this treatment to remove a substantial percentage of the COD and SS. Effluent from tanneries after mechanical and physico-chemical treatment is generally easily biodegradable in standard aerobic biological treatment plants [16].

Effluent Treatment

In order to carry out effluent treatment in the most effective manner, flow segregation (i.e., keeping wastewater effluents from different process steps separate in order to avoid mixing of different pollutants or dilution of highly polluted streams) is useful to allow preliminary treatment of concentrated wastewater streams, in particular for sulphide and chrome-containing liquors. And although a reduction of water consumption does not reduce the load of many pollutants, concentrated effluents are often easier and more efficient to treat. Where segregation of flows is possible, thorough mixing of chrome-bearing effluents and other effluent streams improves the efficiency of the effluent treatment plant because the chromium tends to precipitate out with the protein during pretreatment.

It is common practice to keep sulphide-containing effluent from the beamhouse separate and at a high pH until the sulphide is treated, because at a pH lower than 9 the formation of toxic hydrogen sulphide (H2S) gas can occur. The sulphides in the deliming and pickle liquors can easily be oxidized in the drum by adding hydrogen per-oxide, sodium metabisulphite or sodium bisulphite. The associated emission level after treatment of sulphide is 2 mg/l in a random sample in the separate effluent. Where segregation of sulphide-bearing liquors is not possible, the sulphides are generally removed by means of precipitation with iron (II) salts and aeration.

A disadvantage of this precipitation is the generation of high volumes of sludge. The levels that can be achieved in treating the mixed effluent are depending on the mixing rate - 2 mg S2-/l and 1 mg Crtotal/l. (e.g., if 50% of the mixed effluent consist of the sulphidebearing effluent, emission levels for the total effluent will be 1 mg S2-/l and 0.5 mg Crtotal/l) [9].

Post-Purification, Sedimentation and Sludge Handling

Post-purification, sedimentation and sludge handling are the last step in wastewater treatment. With sedimentation the sludge in the wastewater treatment plant is separated from the water phase by gravity settlement. After dewatering this sludge by means of filter presses, a sludge cake with up to 40% dry solids can be achieved, whereas belt presses produce a sludge cake with up to 20-25% dry solids. Centrifuges achieve up to 25-45% dry solids and thermal treatment up to 90% dry solids. Energy is an important factor in these processes.

Pollution Prevention Technologies in Tannery

Conventional chrome tanning technology: The basic scheme of conventional chrome tanning process involves pickling, tanning and basifying. The amount of chrome tanning effluents, including washing waters and sammying water, fluctuates in the range of 3-5 m3/t raw hide. Chrome, chlorides and sulphates are the main pollutants [17].

High-exhaustion tanning process technology: Advanced chrome tanning methods primarily aim at reducing the pollution load of chrome. A range of industrially proven methods for reducing the chrome content in effluents discharged. In this technique the tanning agents used are modified to enhance uptake up to 90%. The method features the characteristics:- Use of considerably shorter floats (20-30% related to pelt weight); Use of higher temperatures (40-42°C or higher); prolongation of tanning time and higher pH value (4.0-4.7); and use of special self-basifying and masked chrome tanning agents.

Cleaner Technologies

By applying industrially proven low-waste advanced methods such as the use of salt-free preserved raw hides and skins, hair-save liming, low-ammonia or ammonia-free deliming and bating, advanced chrome management systems, etc., it is possible to decrease significantly the pollution load, namely: COD and BOD5 by more than 30%, sulphides by 80-90%, ammonia nitrogen by 80%, total (Kjeldahl) nitrogen by 50%, chlorides by 70%, sulphates by 65%, and chromium by up to 90%. Yet, despite all preventive measures, there is still a considerable amount of pollution load to be dealt with by end-of-pipe methods. Very arbitrarily and not quite consistently we speak of the following main phases of treatment [4].

Physical-Chemical Treatment (Primary)

The objective here is the removal of settle able organic and inorganic solids by sedimentation, and the removal of materials that will float (scum) by skimming. Approximately 25-50% of the incoming biochemical oxygen demand (BOD5), 50-70% of total suspended solids (SS), and 65% of the oil and grease are removed during primary treatment. The effluent and sludge from primary sedimentation are referred to as primary effluent and sludge. The wastewater is received in wastewater collection sump having arrangement of screen chamber and grit removal chamber. Screen chamber and grit chamber is provided for the removal of coarse grit, floating matter and any suspended large particles which can damage internal part of pumps and other rotating equipment.

From wastewater collection sump, wastewater is pumped using effluent feed pump to equalization tank. Before equalization tank, effluent is passed through oil and grease trap for the removal of floating and insoluble oil and grease particles. Oil and grease trap is a baffled wall channel where wastewater is subjected to up and down flow for the removal of floating particles at the top surface. Separated oil and grease layer is collected from the top layer by manual skimming operation through collecting troughs and drain pipe. From oil and grease trap effluent is collected in equalization tank. Equalization tank is provided to ensure the complete mixing of varying quality and quantity. Complete mixing is achieved by floating type submerged mixers.

Biological Treatment (Secondary)

In most cases, secondary treatment follows primary treatment, its goal being the removal of biodegradable dissolved and colloidal organic matter using aerobic biological treatment processes. Aerobic biological treatment is carried out in the presence of oxygen by aerobic micro-organisms (principally bacteria) that metabolize the organic matter in the wastewater, thereby producing more micro-organisms and inorganic end products (principally CO2, NH3, and H2O). Several aerobic biological processes are used for secondary treatment and the differences among them have to do primarily with the manner in which oxygen is supplied to the micro-organisms and with the rate at which organisms metabolize the organic matter.

Biological treatment is achieved by providing activated sludge process. In this treatment soluble BOD is stabilized by oxidation of organic matter by microorganisms. Nutrient and food is supplied to microorganisms for enhancing their growth. Oxygen required is provided by air blower through non-clog type membrane diffusers to achieve higher rate of oxygen transfer efficiency. Mixed liquor overflow from aeration tank is taken into secondary clarification process, for the separation of microorganisms under gravity. Bottom sludge from secondary clarifier is re circulated back in the aeration tank. Excess biomass is transferred into bio sludge tank. Clear overflow from secondary clarifier is transferred to the tertiary treatment (Metcalf and Eddy, 2003)

Advanced (Tertiary) Treatment

Tertiary or advanced wastewater treatment is employed to reduce residual COD load and/or when specific wastewater constituents are not removed by previous treatment stages. Tertiary treatment consists of chemical oxidation, pressure sand filter and activated carbon filter. Effluent from biological treatment is passed through chemical oxidation tanks, where Hydrogen Peroxide dosing is done. Mixing in chemical oxidation tank is provided with air agitation using separate air blowers. Effluent from chemical oxidation tank is collected in intermittent storage tank. From where effluent is further subjected to pressure sand filter and activated carbon filter. Suspended solids get removed in pressure sand filter and activated carbon filter provides treatment for removal of color and COD so that final treated wastewater meets the discharge norms. Backwashing of both the filters is done daily for cleaning of filter beds. The backwashed water is diverted back into wastewater collection sump for further treatment.

Conclusion

Prevent the pollution caused by tannery industry more research needs to be done for optimising the operation parameters, reducing the operation costs and improving the device’s performances.

Cleaner production is an efficient method of preventing or minimizing pollution caused by industrial activities. The primary task of all cleaner technologies is to reduce the amount pollution emissions; and where possible change the nature of pollution emissions to reduce the pressure and costs of end-of-pipe treatment. The expected results primarily include: Lower water consumption, Lower total dissolved solids, Avoidance of use in processing and/or presence in leather of substances from the Restricted Substances Lists (RSL) promulgated by national or regional legislation, leading (multinational) brands and/ or ecolabel due to their proven negative impact on human health and eco-systems, Proportionally higher volume of solid wastes suitable for processing into saleable by-products, Lower levels of BOD, COD and Nitrogen; their respective contents in conformity with local and widely prevailing legislative norms, Low level of chromium in (C) ETP sludge – the scope for land application and/or composting, Lower hazardous and/or unpleasant air emissions, Appropriate occupational health and safety (OSH) standards – better work conditions, fewer accidents.

References

- LAHM Verheijen D, Wiersema LW, Hulshoff Pol, De Wit J (1996) "Livestock and the Environment: Finding a Balance Management of waste from animal product processing" International Agriculture Centre, Wageningen, The Netherlands.

- Suthanthararajan R, Ravindranath E, Chits K, Umamaheswari B, Ramesh T, et al. (2004) Membrane application for recovery and reuse of water from treated tannery wastewater, Desalination 164: 151-6.

- The European Tanning Industry Sustainability Review, Prepared by COTANCE as ancontribution to the World Summit on Sustainable Development, 2002.

- UNIDO (2000) Regional Programme for Pollution Control in the Tanning Industry in South-East Asia Chrome       Management in the Tanyard.

- Ozgunay H (2007) Characterization of Leather Industry Wastes, Polish . J Environ Stud 16: 867-73.

- Environmental Commission of IULTCS: "Typical Pollution Values Related to Conventional Tannery Processes", London, 1997.

- Palanisamy T (2005) Recent Trends in Leather Making: Processes, Problems,nand Pathways, Critical Reviews in Environmental Science and Technology 35: 7-79.

- Kanagraj J, Velappen KC, Chandra Babu NK, Sadulla S, (2006) Solid Wastes Generation in The Leather Industry and Its Utilization For Cleaner Environment-A Review. J Sci Indu Res 65: 541-8.

- Protrade/GTZ "Ecology and Environment in the Leather Industry – Technical Handbook", Eschborn, 1995.

- UNIDO (2012). United Nations Industrial Development Organization Vienna, Technical assistance project for the upgrading of the Ethiopian leather and leather products industry, Independent Evaluation Report Ethiopia, UNIDO project number: TE/ETH/08/008.

- Proceeding of National Workshop On Enhancing The Ethiopian Leather Industry And Its Market Competitiveness, Organized By Leather Industry Development Institute (LIdI) In Collaboration With United Nations Industrial Development (UNIDO), 2010, Adama, Ethiopia.

- Ethiopian Leather J (2012) By Ethiopian Leather Industries Association. 6: 44.

- UNIDO (2000) Regional Programme for Pollution Control in the Tanning Industry in South-East Asia "The Scope for Decreasing Pollution Load in Leather Processing.

- Anita S, Rajesh KS (2010) Risk Assessment of Heavy Metal Toxicity. Through Contaminated Vegetables from Waste Water Irrigated Area of Varanasi, India, Inter Soc Trop Eco 51: 375-87.

- Solid Waste Management Proclamation No. 513/2007, Federal Negarit Gazeta of the Federal Democratic Republic of Ethiopia.

- Rajamani S (2010) World Environmental Update in Leather Sector - Bio-Energy Generation from Tannery Effluent and Solid Wastes, Leather News India, September.

- Palanisamy T (2005) Recent Trends in Leather Making: Processes, Problems,nand Pathways, Crit Rev Environ Scien Tech 35: 37-79.

Citation: Awulachew MT (2021) A Review of Pollution Prevention Technology in Leather Industry. Environ Pollut Climate Change. 5: 244. DOI: 10.4172/2573-458X.1000244

Copyright: © 2021 Awulachew MT. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 5537

- [From(publication date): 0-2021 - Dec 20, 2025]

- Breakdown by view type

- HTML page views: 4622

- PDF downloads: 915