Case Report Open Access

Beneficiation of Micaceous Iron Oxide from Veldurthi Area, Kurnool, AP,India

Ravi BP*, Venkatesha B, Krishna SJG, Patil MR and Kumar PSMineral Processing Department, VSK University, Nandihalli, Karnataka, India

- *Corresponding Author:

- Ravi BP

Mineral Processing Department

VSK University, Nandihalli-583119

Karnataka, India

Tel: 083922 42873

E-mail: ravibelavadi@gmail.com

Received Date: June 19, 2015 Accepted Date: June 25, 2015 Published Date: July 08, 2015

Citation: Ravi BP, Venkatesha B, Krishna SJG, Patil MR, Kumar PS (2015) Beneficiation of Micaceous Iron Oxide from Veldurthi Area, Kurnool, AP, India. J Powder Metall Min 4:133. doi:10.4172/2168-9806.1000133

Copyright: © 2015 Ravi BP, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Abstract

A micaceous hematite sample from Krishnapuram village, Veldurthi Mandal, Kurnool district, Andhra Pradesh was received for process evolution studies to obtain coating - welding rod - concentrate, assaying Fe>65%, SiO2<2%, Al2O3<2% LOI<1% and 100%<0.1 mm or pellet grade concentrate assaying Fe>63%, SiO2<4%, Al2O3<3% LOI<2% and 100%<0.1 mm. The sample analyzed 52.44% Fe (T), 23.63% SiO2, 0.55% Al2O3 and 0.64% LOI. It contained mainly very fine grained specularite associated with subordinate amounts of fine grained quartz and minor to trace amounts of hematite, magnetite and gibbsite. The process amenability test indicated that the sample is amenable to gravity and magnetic separation. The final test comprises of WHIMS at -200 mesh, >10000 gauss intensity produced a concentrate assaying 65.29% Fe, 4.07% SiO2, 0.42% Al2O3 and 0.32% LOI with 76.8% Fe distribution at wt% yield of 62.1, meeting pellet grade specifications. The above rougher concentrate after one cleaner WHIMS at >8500 gauss, assayed 67.80% Fe, 1.90% SiO2, 0.32% Al2O3, 0.22% LOI and 5 specific gravity with 63.6% Fe distribution at wt% yield of 50.0 meeting the specification of coating and welding rod industry.

Keywords

Specularite; Micaceous Iron oxide; WHIMS

Introduction

Micaceous Hematite/Micaceous Iron Oxide (MIO)/Speculariteis a chemically inert, non-toxic ferric oxide mineral with blocky or platy crustal with a strong micaceous parting. It is mainly used as coatings in pigment industry and as a replacement for iron powder in welding electrodes. The specifications for coating and welding electrode industry is that the concentrate shall analyze Fe>65%, SiO2<2%, Al2O3<2% LOI<1%, Size 100%<0.1 mm, Specific gravity>4.8 and lamellar content >70%. The pellet grade concentrate shall analyze Fe>63%, SiO2<4%, Al2O3<3% LOI<2%, Size 100%<0.1 mm and moisture<8%.

Deposits of quality MIO pigments in the world are limited. MIO is mined in Austria, South Africa, Spain and Morocco in small extends. Austria is the world leader in the production and export of such pigment. In India very limited deposits of micaceous hematite are found inVeldurthy, Kurnool district, Andhra Pradesh, Katni, Jabalpur District, Madhya Pradesh, and Neemkathana, Jaipur district, Rajasthan. Most of them use hand picking, pulverizing and is marketed as coating grade MIO for paint and welding electrode industries on a small scale.

The sample was collected from Krishnapuram village, Veldurthi Mandal Kurnool AP (15oN and 78oE). The ENE trending Ramalkota- Kalva-Gani, fault alignment in Kurnool basin extending into archeans genisses-Proterozoic sediments of Kadppa in the west, houses MIO associated with quartz, due to igneous intrusions near Veldurthi area. The specular hematite quartzite ore assaying 30-60% Fe, 3-18% SiO2 and traces to 0.04%P with 50% mean Fe, is estimated to have indicated reserves of 3.7 million tons in Veldurthi area.

The aim of the work was to evolve a process to produce obtain coating-welding rod-concentrate, assaying Fe>65%, SiO2<2%, Al2O3<2% LOI<1% and 100%<0.1 mm or pellet grade concentrate assaying Fe>63%, SiO2<4%, Al2O3<3% LOI<2% and 100%<0.1 mm by a simple eco-friendly process.

Materials and Methods

50 kgs of as received specular hematite ore sample was mixed thoroughly, the material was crushed to -2 mm size 100% passing by roll crusher and the sample were drawn by coning and quartering. The sample was subjected to characterization studies which include particle size analysis, chemical analysis, density measurement, mineralogical studies. Rest of the sample was used for beneficiation studies for process evolution. The beneficiation studies comprise of stage rod mill grindability, effect of MOG on particle size refining, tabling and WHIMS followed by variation of WHIMS parameters like intensity, matrix type, type of operation (recovery - refining). The products were subjected to characterization tests.

Results and Discussion

The scope of work comprised of Characterization, Comminution, Amenability of sample to size, gravity and magnetic separation processes. The results are discussed below.

Characteristics of the sample

The as received sample was blackish gray lumps with considerable fine. The specific gravity, bulk density and angle of repose of as received sample were 3.3,2.3 t/m3 and 37.6o respectively. The sample analyzed 52.44% Fe (T), 0.43% FeO, 23.63% SiO2, 0.55% Al2O3, 0.08% alkaline earth salt oxides, 0.04% alkalies. 0.01% P, 0.01%S and 0.64% LOI. It contained mainly very fine grained specularite associated with subordinate amounts of fine grained quartz and minor to trace amounts of hematite, magnetite and gibbsite. The iron oxide minerals liberated fairly at size<0.1 mm. The as received sample was ground to -150 mesh size and deslimed. The deslimed product was subjected to sink and float test using Tetra Bromo Ethane [TBE] and hand magnet separation test at 10000 gauss with one re-pass for the magnetic product. The sink and magnet products thus produced met the assay specifications of metallurgical industry, though the yield was low in case of gravity method as compared to magnetic separation similar to the results obtained by Ravi et al. [1] for siliceous iron oxides.

Rodmill stage grindabilitiy tests

250 gms of stock -10 mesh sample was stage ground to -30,- 60,100,-150,-200 and -240 mesh at 67%S with stage grind time of 3 minutes each in lab rod mill [175×350 mm], 5 kg rod charge. The ground products were subjected to wet sieve analysis. MOG results are shown in Figure 1. The grindability data indicated that the sample was medium hard in nature.

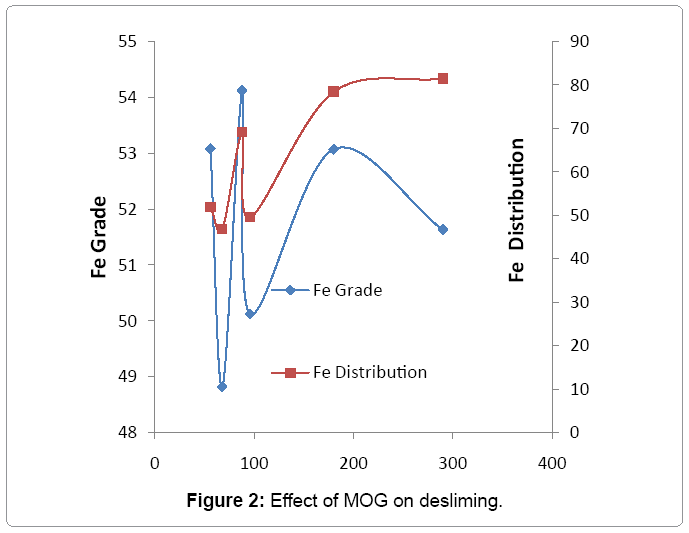

Effect of MOG on desliming

Representative samples were subjected to desliming by wet screening over 400, 500 mesh by varying the mesh of grind from.-30 to -240 mesh. The results are shown in Figure 2. The results indicate that particle size refining at fine size of -0.1 mm yielded a better grade concentrate though not meeting the specifications, probably due to liberation and siliceous non clayey nature of sample. The review of literature [2] on washabilty of sub grade iron ores indicate that scrubbing, desliming used to upgrade the feed by >2% at coarse sizes probably due to washing out the clayey impurities. IBM [2] and Ravi et al. [1] upgraded clayey iron ores by scrubbing and screening.

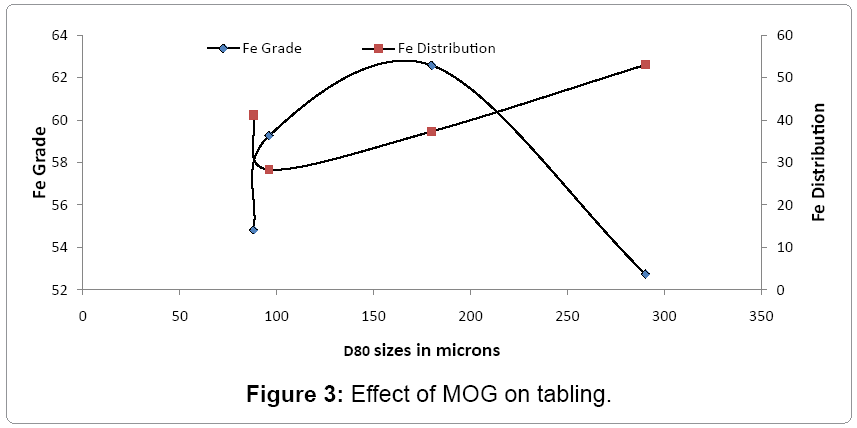

Effect of MOG on tabling

Tabling tests were carried out varying the stage mesh of grind -30#, -60#, -100# and150#. The results are given in Figure 3. Optimum results just marginally failing to meet the specifications were produced at -60 # Mesh of grind, D80 180 microns. The lack of selectivity may be due to flaky nature of hematite which will report in to lighter fraction owing to very high surface area /volume, affecting its settling rate.

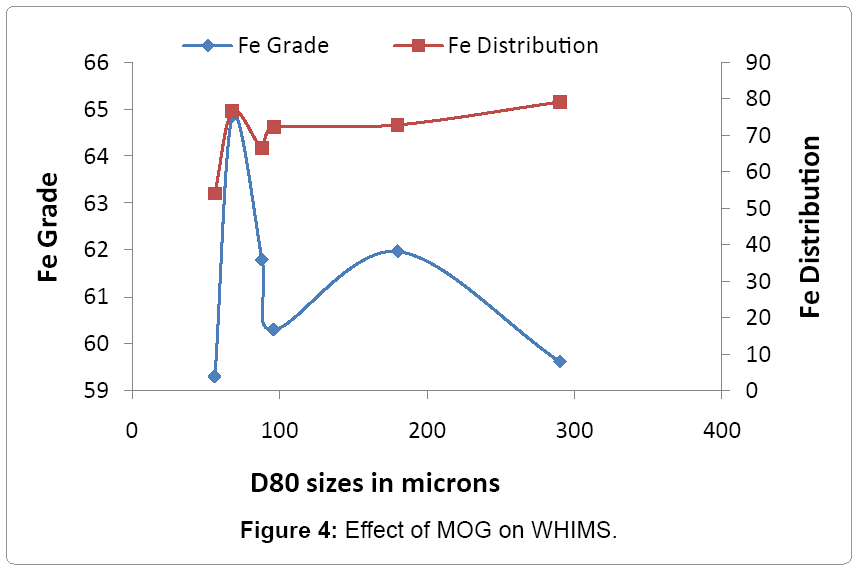

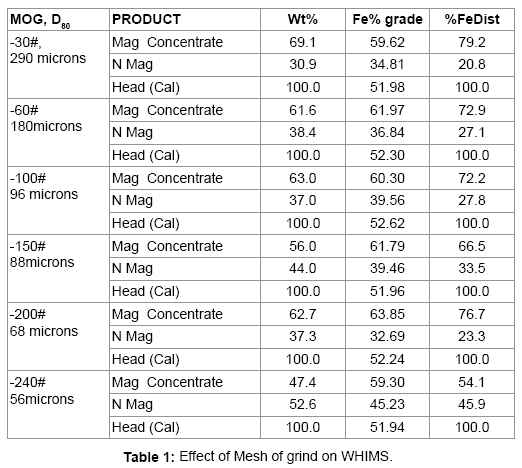

Effect of MOG on WHIMS

Wet High IntensityMagnetic Separation (WHIMS) tests were carried out varying the stage mesh of grind -30#, -60#, -100# -150#.- 200# and -240# the test conditions and results are given (Table 1 and Figure 4). Optimum results just meeting the specifications were produced at -200 # Mesh of grind, D80 68 microns. The lack of selectivity at coarse size may be attributed to concentration of interlocked grains by WHIMS. The lack of selectivity at very fine size may be attributed due to slime coating and necessity of attrition, dispersion of slimes and high gradient. Similar results were obtained by previous workers [3-6].

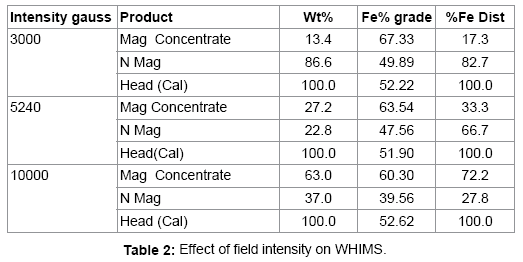

Effect of intensity on WHIMS

WHIMS test were conducted varying the open air intensity by varying the distance between poles in the lab model ferrous wheel separator, at constant matrix, MOG. The test results are given in Table 2 and Figure 5. The results indicate that the concentrate grade increased with decrease in intensity while the % Fe distribution and wt% yield of concentrate increased with maximum intensity of 10000 gauss. Keeping the Fe recovery in view, the maximum intensity of 10000 gauss was chosen, while for attaining the grade, the cleaner intensity was reducedto 8800 gauss.

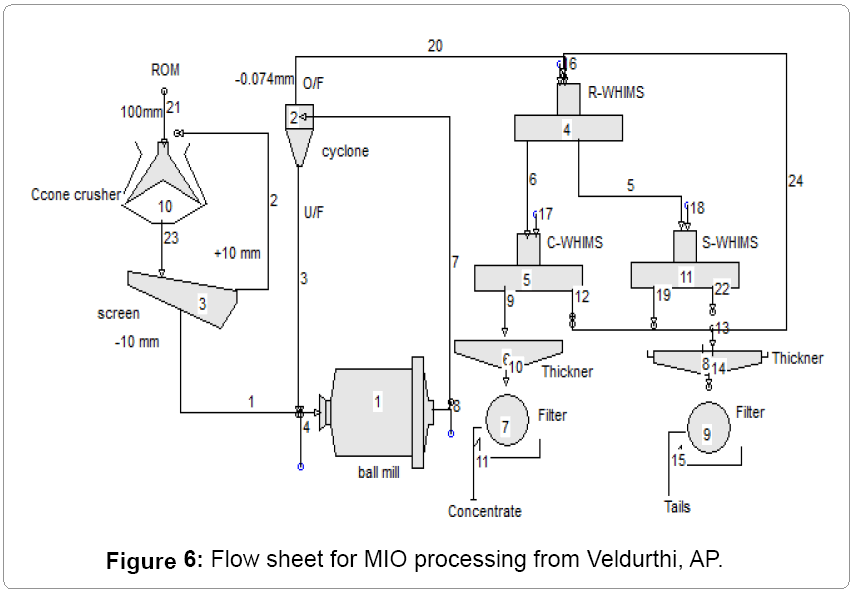

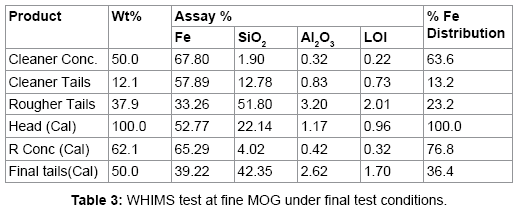

Final test

The recommended process comprises of stage grinding the sample to -200 mesh, D80 68 microns, 33% 20 microns. The ground pulp was subjected to WHIMS at 10000 gauss, 6 mm ball matrix, 20% S pulp. The rougher concentrate is cleaned at 8800 gauss at 15%S. The results are given in Table 3. The WHIMS test -200 mesh yielded cleaner grade concentrates assaying 67.80% Fe, 1.90 % SiO2, 0.32% Al2O3, 0.22% LOI and 5 specific gravity with 63.6% Fe distribution at wt% yield of 50.0 meeting the specification of coating and welding rod industry. On the contrary the rougher concentrate assaying 65.29% Fe, 4.07% SiO2, 0.42% Al2O3 and 0.32% LOI with 76.8% Fe distribution at wt% yield of 62.1 meeting thepellet grade specification The evolved process is simple and meets the objectives laid producing bothcoating-welding rod grade and pellet gradeconcentrates. The flow sheet is given in Figure 6.

Conclusion

A micaceoushematite sample from Krishnapuram village, Veldurthi Mandal, Kurnool district, Andhra Pradesh as saying 52.44% Fe (T), 23.63% SiO2, 0.55% Al2O3 and 0.64% LOI when subjected to WHIMSat-200 mesh, D80 68 microns, 33% 20 micron, 10000 gauss intensity, 20% S pulp, followed by cleaner WHIMS at 8800 gauss yielded acleaner concentrate assaying 67.80% Fe, 1.90% SiO2, 0.32% Al2O3, 0.22% LOI and 4.9 specific gravity with 63.6% Fe distribution at wt% yield of 50.0 meeting the specification of coating and welding rod industry. The sample is amenable to processing. The evolved process is simple and meets the objectives laid, producing bothcoating -welding rod grade and pellet gradeconcentrates.

Acknowledgement

The authors wish to express their thanks to Sri AK Swamy for providing the sample. They are also grateful to S/Sri AK Swamy, MS Hiremath, GM SMIORE, and UM Reddy, GM, JCL, Bellary district for the chemical analysis.

References

- Ravi BP, Kumar GS, Anath BD, Hussain MI, Kristappa MG (2013) Process characterization of some iron ores of India. The Ind.Mineralogist 47: 125-134.

- IBM (2004) Monograph on Iron ore. Mineral facts and problems.

- Dyenforth (1957) Processing of specular hematite of Webush USA. AIMME.

- IBM/OD/BNG/ RI (2011) Beneficiation of Low grade iron ores from Karnataka.

- Ramana Murthy NV, Rao BSS, Chandra S (2007) Process amenability studies of high silica blue dust iron ore.

- Wang WZ, Zhan JR (2011) Beneficiation of specularite by gravity. WHIMS and reverse flotation

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 15387

- [From(publication date):

August-2015 - Aug 20, 2025] - Breakdown by view type

- HTML page views : 10697

- PDF downloads : 4690