Research Article Open Access

Coating Removal Techniques in Aerospace Industries: Study Case

Davarpanah A1*, Hemat AH1 and Larki M21Department of Mechanic Engineering, Young Elite Sponsors Institute, Tehran, Iran

2Department of Mechanic Engineering, University of Applied Science and Technology, Kangan, Iran

- *Corresponding Author:

- Davarpanah A

Department of mechanic Engineering

Young Elite Sponsors Institute

Tehran, Iran

Tel: 989337223427

E-mail: afshindpe@gmail.com

Received Date: January 04, 2017; Accepted Date: February 01, 2017; Published Date: February 15, 2017

Citation: Davarpanah A, Hemat AH, Larki M (2017) Coating Removal Techniques in Aerospace Industries: Study Case. J Powder Metall Min 6: 155. doi:10.4172/2168-9806.1000155

Copyright: © 2017 Davarpanah A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Abstract

In the recent years, aviation industry in terms of corrosion has been undertaken with million pounds. Therefore, by appropriate maintenance and husbandry, these effects could be decreased. Most of the aircrafts could be maintained by long term and short term inspection check. Nowadays, one of the most important and yet most underestimated support activities for corrosion control in aviation industry is protective coating removal like High pressure water, Sodium bicarbonate, Agricultural by-products, Sponge media, Petroleum based plastic media and Engineering bio-based media. Coatings removal techniques can actually degrade the substrate if they are not suited for the surfaces or are not performed correctly. This could have potential catastrophic consequences. However, because of ageing, many of these coatings eventually require removal and reapplication. In this research, the current state-of-the-art coating removal technologies in the aviation industry are discussed. Engineering bio-based media has more advantages than the other and it can be used between 8-15 times. Finally, worker health and safety will be an ever increasing priority when selecting a technique.

Keywords

Coating removal; Aviation industry; Engineering biobased media

Introduction

Corrosion

Material and surrounded environmental situation could cause by these two effects that often occurred simultaneously:

• Chemical (oxidation)

• Electrochemical (galvanic).

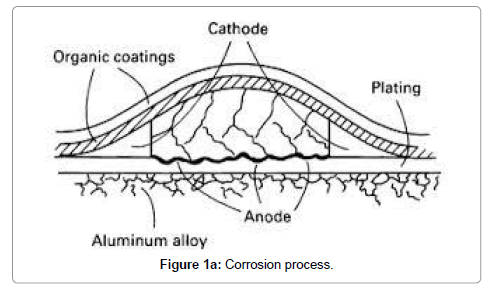

In both cases, metal was altered to the metal compound such as carbonates, hydroxides, oxides and sulphates. Corrosion stages are being contributed with two simultaneous changes. Metals are inveighed against the anodic changes, until it take under a cathodic change [1] (Figure 1a).

Types of corrosion that mostly seen on the aviation industry: There are several types of corrosion. These types are mostly depended on the surrounded metals among the susceptible environment, their applications, weather situation and current corrosion factor. Several types of corrosion that are being seen in the aircraft structures are listed below:

• Surface corrosion,

• Corrosion in the different material substances (with different alloys),

• Intergranular corrosion,

• Exfoliation corrosion,

• Corrosion stress,

• Fretting Corrosion,

• Crevice Corrosion,

• Pitting corrosion,

• Fatigue corrosion,

• Microbial degradation corrosion,

• Steel brittle corrosion.

Factors affecting on corrosion: Several factors effect on the reason, type, corrosion speed and metal extremity corrosion. Even though, some of them are out range of aircraft designers and maintenance engineer, some of them are being controlled. These factors are mentioned below [2]:

• Type and size of the metal,

• Environmental situations,

• Marine environmental (take in the salty water) increase the corrosion rate,

• Humidity,

• High temperature,

• Corrosive factors,

• Dust and soil in the atmosphere,• Type and size of the metal,

• Environmental situations,

• Marine environmental (take in the salty water) increase the corrosion rate,

• Humidity,

• High temperature,

• Corrosive factors,

• Dust and soil in the atmosphere,

• Oil residuals in the engines,

• Remain welding particles.

• Oil residuals in the engines,

• Remain welding particles.

General methods for removing corrosion

• Inspect the defections

• Neutralize the residual remains

• Remove each part of corrosion that would be convenient

• Clean the corrosion area from dusts

• Using temporary or constant coatings after painting completely

Coating

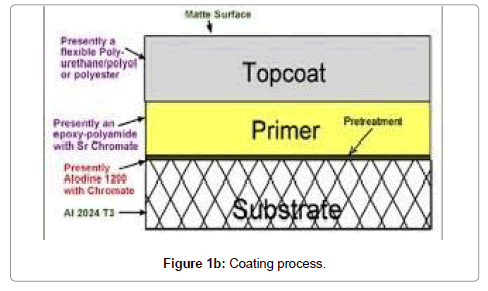

There are several and different types of coatings may be found in the aircraft. Take Aircraft frameworks and large structures have plastic coating for example that is located on the surface followed by a highly cross linked polyurethane top coat. Coatings are mainly consisting of four ingredients: resin, pigment, fillers and solvents. Resin acts as a matrix for pigment and fillers. Primer coats may also have chromium pigments that act as an excellent corrosion barriers. Fillers may include, among other ingredients, talc and calcium carbonate. The solvent liquefies the mixture facilitating delivery to a spray gun. Depending on the chemistry, different properties can be modified as required by the coating system [3] (Figure 1b).

When to remove the coating

Coatings are sometimes completely removed as a part of standard inspection processes. After complete removal of the coating, small corrosion defects such as fill form or exfoliation can detected visually, these defects are not always apparent without removing the coating system. If inspection requirements are not a factor, then the appearance of the aircraft may be a reason for coating removal and reapplication of a new coating system. As mentioned previously, the coating system will age and deteriorate after five to six years in service. On commercial aircraft, after this period of time, the coating will have lost its original gloss, suggesting to the observant passengers an old potentially deteriorating aircraft, in an effort to reduce the scuff sanding technique [4].

Methodology of Work

How to remove coatings

The majority of newly developed coating removal methods use one of the following mechanisms:

• Molecular disassociation,

• Thermal,

• Impact.

Molecular disassociation categories

Which include all chemical strippers, belong to three different groups, depending on the formation of the strippers: acidic (below PH- 7); neutral (PH 7); or alkaline (above PH-7).

Thermal methods

For delicate aerospace components include lasers and heat lamps, both of which usually require some form of robotic application. Lasers are a non-kinetic form of coating removal; whereas heat lamps are usually accompanied by a kinetic CO2 blast stream to loosen heat damaged coating debris [5].

Types of impact coating

• High pressure water,

• Sodium bicarbonate,

• Agricultural by-products,

• Sponge media,

• Petroleum based plastic media,

• Engineering bio-based media.

High pressure water: Developed in the early 1990s, high pressure water is typically projected via special nozzles at pressures of 2000 to 4000 bar. At these pressures even the most tenacious coatings can be removed. The operation is done robotically with such high precision that even every thin aluminum skins (0.4 mm thick) can be processed with little or no effect on the mechanical properties. The process has had success in smaller cabinet size units with a closed cycle water treatment incorporated. This method is now used with much success on naval ships.

Advantages:

• With precise controls, high pressure water can remove coatings from very delicate metallic parts and structures with little or no effect,

• Selective stripping is sometimes feasible,

• Disadvantages:

• Equipment costs, operator skills, and engineering support requirements are considered to be moderate to high,

• Coating removal from delicate composite substrates is often not possible,

• Water must be created to remove coating debris [6].

Sodium bicarbonate: Bicarbonate of soda, also known as sodium bicarbonate, is a type of salt. It is generally manufactured using the Solvay process. As a coating removal method. It is considered a soft friable abrasive with hardness just above 2.0 on Moh, s scale. On the other hand, with a specific density of 2.15 g/cm sodium bicarbonates is much heavier than other dry stripping media types. The media can only be used once. At temperatures over 60°C, sodium bicarbonates start to decompose into sodium carbonate, which is very corrosive [7].

Advantages:

• Low dust production when used in wet mode.

• Water dissolving characteristics reduces the potential impact of ingress on off-aircraft parts with complex interiors.

• Equipment cost operator skills and engineering support: low to moderate.

• Disadvantages:

• Can be aggressive on delicate substrates.

• Corrosion by sodium carbonate is a concern.

• Media can only be used once.

Agricultural by-products: Crushed walnut shell media is also a popular agricultural media. A by-product, it is usually made from English walnut, which has a Moh’s hardness between 3.0 and 4.0 and a specific density of 1.2 to 1.4 g/cm3. This media type is appropriate for aerospace applications as it meets higher quality standards. Normal operating pressures for agricultural media is 2-6 bar [8].

Advantages:

• A non-chemical process, relatively safe for the operations.

• Depending on the parameters, media can be used more than once, 4 to 8 cycles.

• Disadvantages:

• By product nature makes quality control difficult.

• Certain agricultural media may leave only residue on surfaces.

Sponge media: Sponge media is an engineered dry stripping media developed in the mid-1990s. It is propelled with compressed dry air against the surface to be treated. The media is a combination of a soft foam or fibred carrier, which acts as a matrix, and different types of abrasive grits (plastic, mineral, etc.) they are embedded in the matrix. The particle sizes are much larger than typical dry stripping media, ranging from 3 to 6mm in diameter.

Advantages:

• Depending on the abrasive types used, coating removal on delicate parts can be conducted with minimal effects.

• Media can be reused 6-12 times.

• This is a Non-chemical process, relatively safe for the operator.

• Selective stripping is sometimes feasible.

Disadvantages:

• Precise cleaning controls, screening and new media replenishment are critical to prevent extreme performance variations due to abrasive loss from the matrix and loose abrasive in the working mix.

Petroleum based plastic media: The concept of using plastic as a dry stripping media to remove coatings was first patented by DuPont Company in the 1940s. The concept was not considered viable until the health warning about DCM-based chemical strippers started to emerge in the early 1980s.

Advantages:

• Depending on the media type, it can be reused 2-3 times.

• Non-chemical process relatively safe for the operator.

• Selective stripping is feasible under certain circumstances.

Disadvantages:

• Aggressive media types can damage metallic and composite parts.

Engineering bio-based media: The concept of engineering a biobased polymer media for aerospace coating removal applications was the first realized in 1991. The first generation bio-based media was made via a hydrothermal extrusion process with pure native wheat starch. Several aerospace original equipment manufacturers (OEM) found that this soft media type, with an apparent Moh’s hardness of 2.0 and a specific gravity of 1.45 g/cm3, had unique characteristics compared with other plastic media types available at the time [9].

Advantages:

• Depending on media type and parameters they can be reused 5 to 15 times.

• Non-chemical process relatively safe for the operator.

• Selective stripping is feasible under certain circumstances.

Disadvantages:

• Dust produced can contain toxic heavy metals (from coating). Proper protection is required.

• Ingress of media in structures is possible if incorrect masking procedures are used.

Conclusions

Because we have several equipment’s and factors involved, it doesn’t have a simple solution for removing coatings in an aerospace industries. In terms of advantages and disadvantages of any coating in several situations, it must be economically choose a method for removing coatings in aircraft industries. Consequently, labor safety and the economic will be the two critical priorities when selecting the coatings techniques.

References

- Fontana MG (1986) Corrosion Engineering (3rdedn) McGraw Hill, ISBN 0-07-021463-8, p: 556.

- NASA (National Aeronautics and Space Administration), joint EPA/NASA/USAF interagency DE painting study. Report Number. NP-1999-12-152-MSFC, p: 100.

- GRIMES J (2003) Process strips paint off B-1 s, USAF press release.

- GATES J (2005) New 787 goes on diet to keep that svelte look airlines love.

- PAULIR (1995) Alternative processes to methylene chloride chemical strippers, a review of progress to date, 1995 Aerospace/Airline plating and metal finishing forum. American Electroplaters and surface Finishers Society.

- Monetted O (2002) Enhanced type VII plastic media e-strip (MIL-P-85891a) for military aerospace applications, DoD Industry Advanced Coating Removal Conference, p: 11.

- LARSON B (2002) A study of the factors affecting the sensitivity of liquid penetrant inspections: a review of literature from 1970-1998, FAA Technical Report, DOT/FAA/AR 01-95,p: 51.

- HART WGJ (2003) Paint stripping techniques for composite aircraft components, National Aerospace Laboratory Technical Publication, NLR-TP-2003-357, p: 13.

- Meguid SA (1991) Effect of partial-coverage upon the fatigue fracture behavior of peened components, Fatigue Fracture Engineering Material Structures, Fatigue of Engineering materials Ltd. 8756-758X 14: 515-530.

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 3609

- [From(publication date):

April-2017 - Aug 17, 2025] - Breakdown by view type

- HTML page views : 2721

- PDF downloads : 888