Effects of Polyvinyl Pyrrolidone and Activated Charcoal to Control Effect of Phenolic Oxidation on In Vitro Culture Establishment Stage of Micropropagation of Sugarcane (Saccharum Officinarum L.)

Received: 29-Nov-2014 / Accepted Date: 10-Aug-2015 / Published Date: 17-Aug-2015 DOI: 10.4172/2329-8863.1000184

Abstract

Sugarcane isgrown in Ethiopia as both cash and industrial crop. Although it plays a great role in the economy of the country, there are no enough sugarcane varieties under production and it is not an ideal crop for conventional breeding. Hence, it takes around ten years for its breeding and extra years to scale up the planting material for commercial by vegetative propagation. To circumvent these limitations, biotechnological tool (Plant tissue culture) was born as best alternative. Though the tissue culture (micro propagation) plays a reliable role, culture establishment stage of sugarcane micro propagation has a serious phenolic oxidation problem which can kill the whole culture. Hence, these experiments were conducted to optimize the appropriate concentration of Polyvinylpyrrolidone (0.0, 0.1, 0.2, 0.3, 0.4 and 0.5 gL-1) and Activated charcoal (0.0, 0.1, 0.2, 0.3, 0.4 and 0.5 gL-1) on (C86-12, C86-56) genotypes in completely randomized design with 2 × 5 factorial treatment combinations arrangements to control the effect of phenolic oxidation. Analysis of variance showed that interaction effect of Polyvinylpyrrolidone and genotypes. Activated charcoal and genotypes on percentage of survived and dead explants due to phenolic oxidation were highly significant at (P=0.001). Murashige and Skoog medium supplemented with 0.2 gL-1 and 0.3 gL-1 of Polyvinylpyrrolidone has gave 100% and 80% survived explants of C86-56 and C86-12genotypes respectively while 0.4 gL-1 and 0.3 gLl-1of activated charcoal resulted in 46% and 40% of survived explants of C86-56 and C86-12 genotypes respectively, after 30 days of culturing. Thus, these optimized concentrations of Polyvinylpyrrolidone and activated charcoal are useful to control the effect of phenolic oxidation on culture establishment of micro propagation, which helps to have enough starter culture for further multiplication stage of micro propagation.

Keywords: Sugarcane; Phenolic oxidation; Polyvinylpyrrolidone; Activated charcoal; Survived explant

403986Introduction

Sugarcane (Saccharum officinarum L.) belongs to the Saccharumgenus of the Andropogoneae tribe of the Poaceae (Gramineae/grass) family with an octaploid 2n=8 × =80 number of chromosomes [1]. It is a perennial cash cropgrown in tropical and subtropical regions of the world, which accounts about 75% of the sugar in the world [2]. The commercially cultivated crops of sugarcane have two geographic centers of origin; in Newguinea and Northern India [3]. It is an important cash crop and the main source of raw material for the production of sugar [4]. It is cultivated as a commercial crop in nearly around 60 countries [5]. In Ethiopia sugarcane isgrown both as cash and industrial crop but there is no well documented reference on how, where and when it was introduced, although some records claim its introduction during the early 18th century [6]. Its properties such as efficient photosynthesis and biomass production make it an excellent target for industrial processing, valuable alternative for animal feed and production of bi-products such as ethanol production from molasses [7]. In Ethiopia the annual yield of sugar was around 300,000 tons from three established sugar factories but the annual domestic demand close to 450,000 tons [8]. However, the country has abundant water resource coupled with a vast fertile land favorable for sugarcane cultivation, suitable agro-ecological conditions, cheap labour and huge domestic and foreign demand for sugar and its by-products. So, by realizing these potentials and opportunities, the Ethiopian government has planned to establish ten sugar factories with 370,000 ha of plantation area.

Though, the edaphic and climatic factors are suitable for sugarcane cultivation, there are limited varieties under production and the country has no breeding facilities to release new high yielding and disease resistance varieties. Furthermore sugarcane is not an ideal candidate crop for conventional plant breeding; because its flowering is notsynchronised, it has low sexual seed viability and it is a perennial crop [9]. Hence, its improvement takes up to ten years from initial crosses to final agronomic assessment of elite varieties [10,3]. In addition it’s vegetative propagation by cutting for commercial production takes extra years and favors dissemination of disease and pest from generation to generation [11,12]. To circumvent these limitations of conventional breeding and vegetative propagation of sugarcane, biotechnological tool (plant tissue culture) was born as best alternative.

So far in Ethiopia, new varieties have been imported and propagated vegetatively by cutting for commercial production. But currently, after importing the new varieties, to supplement the vegetative propagation, we have already started in vitro propagation of sugarcane varieties. Though sugarcane tissue culture is the best alternative technology or option, its operation is very difficult; because sugarcane has high content of phenols, especially in the apical meristem and leaf sheaths which poses browning problem during tissue culture process [13]. It is a serious problem associated with the culture establishment stage of micro propagation and the oxidation of phenolic substances leaches out from the explant resulting in browning of the explant, the medium and at last killing the whole culture [14]. Pretreatment of the explants with solutions of ascorbic acid, citric acid, Polyvinylpyrrolidone (PVP) and activated charcoal (AC) or culturing them with these antioxidants could solve the problem [14]. By using 0.3 gL-l PVP [15] Shukla RK et al. found that all their cultures were survived. Around 80% browning free cultures (explants) were obtained by using activated charcoal of 0.2-0.5 gL-1[16]. Hence, this research was conducted to optimize appropriate concentrations of PVP and AC to control the effect of phenolic oxidation on culture establishment stage of micro propagation which helps to have enough starter culture for the subsequent multiplication stage of micro propagation.

Materials And Methods

The experiment was done at Plant tissue culture laboratory of Jimma University College of Agriculture and Veterinary Medicine (JUCAVM), Ethiopia. Two sugarcane genotypes, (C86-12 and C86-56), were used for the study. They were imported from Cuba in 2006. After agronomic performance evaluation; these genotypes were among the selected ones to be commercialized. The sets of these genotypes were prepared, treated with hot water and taken to JUCAVM green house and planted. After two to three months of growing, shoot tip explants were taken from the sugarcane plants. The explants were prepared according to Jalaja NC et al. procedures [12]. The surrounding leaf sheaths of sugarcane tops were carefully removed one by one until the inner white sheaths were exposed. The explants were sized to about 10 cm length by cutting off at the two ends, locating the growing point somewhere near to top. They were washed under running tap water and liquid detergents. They were socked in fungicide solution (0.3% kocid) for 30 minutes under laminar flow cabinet containing three drops of tween-20. After the kocid was properly washed off from the explants, they were rinsed three times with distilled water and disinfected with 70% ethanol for one minute. The ethanol was poured off and the explants were rinsed again with sterile distilled water. Disinfection of explants was done with 0.1% of HgCl2 for 10 minutes [17] followed by 3-4 washing with sterile distilled water. The required amounts of all stock solutions of MS [18] medium, 20 gmL-1 sucrose [19], different concentrations of PVP and AC and 3 mgL-1 of BAP [20] were mixed in a beaker and the pH was adjusted to be 5.8.This was followed by addition of 0.8% agar for solidifying the media. Then, it was heated to melt the agar and then 30 ml media was dispensed in to culture jars. Finally, it was autoclaved at temperature of 121°C for 20 minutes with 15 psi of pressure.

About 1.5 cm explants were cultured under laminar flow hood aseptically and transferred to the growth room at which growth conditions were adjusted to be 16 hr of light and 8hr of dark with 25 μmolm−2s-1 photosynthetic photon flux intensity and 26 ± 2°C of temperature. The experiments were laid down in complete randomized design with two factor factorial treatment combinations arrangements and each treatment was replicated three times. Data of survival and death of explants due to phenolic oxidation (browning) were collected after 30 days of culturing and subjected to two-way analysis of variance (ANOVA) using SAS statistical software version 9.2 (SAS Inc., 2008). Treatments means were separated by using REGWQ (Ryan-Einot- Gabreil-Welsch Multiple range test) mean separation method.

Results And Discussions

The analysis of variance showed a significant interaction effects of PVP and genotypes (p=0.001) for percent of survived and dead explants due to phenolic oxidation. Data of unchanged (neither survived nor dead) explants was not included in the analysis. Among the different concentrations of PVP, the highest percentages; 100% and 80% of survived explants were obtained at PVP concentration of 0.3 gL-1 for C86-12 and 0.2 gL-1 for C86-56 respectively.

As the concentration of PVP increased (Table 1) from 0.0 gL-1 to 0.3 gL-1, the percentage of survived explants of C86-12 significantly increased from 0% to 100% then declined to 40% as the PVP concentration increased from 0.3 gL-1 to 0.5 gL-1. However, the percentage of dead explants was declined from 80% to 0% then increased to 60%. For C86-56, the percentages of survived explants increased from 6.67% to 80% and then dropped to 40% as the concentration of PVP increased from0.0 gL-1 to 0.2 gL-1 and 0.3 gL-1 to 0.5 gL-1 respectively. Hence, increasing the concentration of PVP beyond 0.2 gL-1 and 0.3 gL-1 is not economical for C86-56 and C86-12 respectively.

| Antioxidant (gL-1) | Genotype | |||

|---|---|---|---|---|

| C86-12 | C86-56 | |||

| Levels of PVP | %Survived ± SD | %Dead(B) ± SD | %Survived ± SD | %Dead(B) ± SD |

| 0 | 0.0f ± 0.00 | 80.00a± 0.00 | 6.67f ± 0.84 | 86.67a± 0.84 |

| 0.1 | 20.0e ± 0.00 | 80.00a± 0.00 | 20.00e± 0.00 | 80.0a± 0.00 |

| 0.2 | 40.0d± 0.017 | 60.00b± 0.00 | 80.00b± 0.00 | 0.0e± 0.00 |

| 0.3 | 100.0a ± 0.00 | 0.00e ± 0.00 | 80.00b± 0.00 | 20.0d± 0.00 |

| 0.4 | 60.0c ± 0.00 | 40.00c± 0.00 | 40.00d± 0.00 | 40.0c± 0.00 |

| 0.5 | 40.0d ± 0.58 | 60.00c± 0.00 | 40.00d± 0.017 | 40.0c± 0.58 |

| CV% | 7.6 | 6.81 | 7.6 | 6.81 |

PVP=Poly vinyl pyrrolidone; B=Browning (phenolic oxidation).

*Values for percent of explants survived and dead given as mean ± SD.

*Numbers within the same column with different letter(s) are significantly different from each other according to REGWQ mean separation method at p < 0.05

Table 1: Effects of PVP in preventing browning.

The best result of this experiment, i.e., PVP at a concentration of 0.3 gL-1 for C86-12 is in agreement with the result obtained by Shukla RK et al. [15] cultured shoot tips explants on MS media containing 0.5 mgL-1 IBA, 2 mgL-1 BAP+0.5 mgL-1 IAA, and 0.5 mgL-1 BAP+0.5 mgL-1gA3 with 0.3 gL-1 of PVP. They indicated that though the cultures showed browning after five days of culturing, most of the explants were survived. In this study, the best results obtained for both genotypes are in contrast to the results reported by Huang CM et al. [16] and Michael PS et al. [21]. Huang CM et al. [16] found 60% and 40% browning free explants for two different genotypes at a PVP concentration of (0.5-1) gL-1. This could be due to genotypic differences among the materials used. MS medium supplemented with 3 mgL-1 of 2,4-D+0.5 gL-1 PVP+0.5 mgL-1 BAP+100 mlL-1 coconut water+8% agar resulted in successful initiation of large embryogenic callus ranging from 80 to 90% which were free of browning [21]. This difference may be happened due to the difference in genotypes and the type of in vitro regeneration path used (Table 2).

| Antioxidant(gL-1) | Genotype | |||

|---|---|---|---|---|

| C86-12 | C86-56 | |||

| LevelsofAC | %Survived ± SD | %Dead(B) ± SD | %Survived ± SD | %Dead(B) ± SD |

| 0.1 | 20.00b± 0.00 | 73.40bc± 0.58 | 0.00c± 0.00 | 86.6ab± 0.58 |

| 0.2 | 20.00b ± 0.00 | 60.00cd± 0.00 | 20.00b± 0.00 | 80.0b± 0.00 |

| 0.3 | 40.00a± 0.00 | 60.00cd± 0.00 | 40.00a± 0.00 | 53.4de± 0.58 |

| 0.4 | 46.60a± 0.58 | 40.00e ± 0.00 | 40.00a± 0.00 | 60.0cd± 0.00 |

| 0.5 | 40.00a± 0.00 | 60.00cd± 0.00 | 20.00b± 0.00 | 60.0cd± 0.00 |

| CV% | 7.53 | 8.51 | 7.53 | 5.81 |

AC=Activated charcoal; B=Browning (phenolic oxidation).

*Values for percent of explants survived and dead given as mean ± SD.

Table 2: Effects of AC in preventing browning.

The ANOVA revealed that the interactions between concentrations of AC and genotypes were significantly influenced the percentage of survived and dead explants (p=0.001). Data of unchanged (neither dead nor survived) explants was not included in the analysis. The least percentages of survived explants were observed on MS medium without application of activated charcoal for both genotypes. The highest percentages of survived explants were observed on MS medium supplemented with 0.4 gL-1 and 0.3 gL-1 of AC for C86-12 and C86- 56 respectively. For C86-12, increment of AC concentrations from 0.3 to 0.5 gL-1 showed non-significant effect on percentage of survived explants. However, concentrations of 0.3 gL-1 and 0.gL-1 of AC resulted in 60% death of explants. At 0.4 gL-1 of AC only 40% of explants were died due to the effect of phenolic oxidation which is by far better than that of 0.3 gL-1 and 0.5 gL-1 of AC. Even though the percentage of survived explants is the same with 0.3 gL-1 and 0.4 gL-1 of AC for C86- 56, the percentage of dead explants is 53.4% at 0.3 gL-1 and 60% at 0.4 gL-1 of AC respectively.

As the concentration of AC increased from 0.0 gL-1 to 0.4 gL-1 for C86-12, percentage of survived explants increased from zero to 46.6% whereas for C86-56 the increment was from zero to 40% as the concentration of AC increased from 0.0 gL-1to 0.3 gL-1. Increasing the concentrations of AC beyond 0.4 gL-1 for C86-12 and 0.3 gL-1 for C86- 56 showed a decreasing trend in percentage of survival of explants. This could be due to fact that AC is not only adsorb plant growth inhibitory substances (phenolics) in medium produced by explants, but also adsorb the plant growth regulators and organic substances that are very important for explants to grow [22].

Results obtained at 0.4 gL-1 for C86-12 and 0.3 gL-1 for C86-56 was similar to the result reported by Huang CM et al. [16]. They reported that AC concentrations from 0.2-0.5 gL-1 resulted in 80% browning free (survived) explants. However, our result contradicts with the result reported by Manchanda P et al. [23] found that MS medium supplemented with 2 gL-1 AC controlled the effect of phenolic oxidation on the medium and furthermore it increased percent of somatic embryogenesis and percent of regeneration from 80.21 to 84.88% and 75.15 to 81.22% respectively. This difference could be happened due to genotypic difference and the type of regeneration path followed.

Conclusion

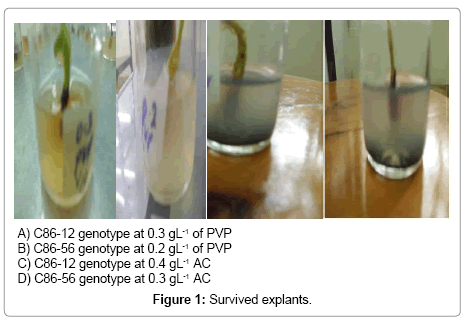

In line with the current findings, it is possible to deduce that the two genotypes may have different concentrations of phenolics and polyphenol oxidase enzyme; that is why we found different concentrations of PVP and AC for both genotypes to control browning effects on culture establishment stage of micropropagation. Hence, MS medium supplemented with 0.3 g-l PVP for C86-12 and 0.2 g-l PVP for C86-56 and 0.4g-l AC for C86-12 and 0.3 g-1 AC for C86-56 were obtained to be the optimum concentrations to control effects of phenolic oxidation. These concentrations can be used to have maximum survival percentage of plantlets during culture establishment stage of micropropagation to have enough starter culture for multiplication stage (Figure1).

Acknowledgements

I would like express my deepest gratitude to Ethiopian Sugar Corporation for funding the research budget and Jimma University College of Agriculture and Veterinary Medicine for facilitating the tissue culture laboratory and its facilities. Finally, I do not want to pass without telling my trust for Mami because she is the reason for my existence like now.

References

- Ather A, Khan S, Rehman A, Nazir M (2009) Optimization of the Protocols for Callus induction, Regeneration and Acclimatization of sugarcane cv. thatta-10.Pak J Bot 41: 815-820.

- PandeyRN, Rastogi J, Sharma ML, Singh K (2011) Technologies for Cost Reduction in Sugarcane Micropropagation. African Journal of Biotechnology 10:7814-7819.

- Sengar RS, Sengar K, Garg SK (2011) Role of tissue culture technique in high sugarcane production. Life Sciences 1008-1017.

- Ali A, Naz S, Siddiqui FA, Iqbal J (2008) an Efficient Protocol for Large Scale Production of Sugarcane through Micropropagation. Pak J Bot 40: 139-149.

- Ali A, Naz SH, Iqbal J (2007) Effect of Different Explants and Media Compositions for Efficient Somatic Embryogenesis in Sugarcane (Saccaharum officinarum). Pak J Bot 39: 1961-1977.

- Duri M (1969) Private Foreign Investment in Ethiopia. J Eth Studies 7: 53-73.

- Gallo-Meagher M, English RG, Abouzid A (2000) Thidiazuron Stimulates Shoot Regeneration of Sugarcane Embryogenic Callus. In Vitro Cellular and Developmental Biology Plant 36: 37-40.

- Anonymous (2010) F.O, licht’s International Sugar and Sweetener Report vol.142

- Manickavasagam M, Ganpati A, Anbazhagan VR, Sudhakar B, Selvaraj N et al. (2004) Agrobacterium mediated genetic transformation and development herbicide resistant sugarcane (Saccharum species hybrids) using auxiliary buds. Plant Cell Rep 23: 134-43.

- Cox M, Hogarth M, Smith G (2000) Cane breeding and improvement. Manual of cane growing, Bureau of sugar Experimental Stations, Indooroopilly, Australia.

- Lakshmanan P (2005) Somatic embryogenesis in sugarcane-An addendum to the invited review sugarcane biotechnology: The challenges and opportunities. In vitro cellular & developmental biology 42: 201-205.

- Jalaja NC, Neelamathi D, Sreenivasan TV (2008) Micropropagation for quality seed Production in sugarcane in Asia and the Pacific. Sugarcane pub 13-60.

- Qin TH, Zhou ZL, Wu CW (1997) Study on the phenol pollution in tissue culture of sugarcane. Sugarcane 4:12-14.

- Kumari R, Verma DK (2001) Development of Micropropagation Protocol for sugarcane.

- Shukla RK, Khan AQ (1994) In vitro clonal propagation of sugarcane: optimization of media and hardening of plants. Sugarcane 4: 21-23.

- Huang CM, Li YR, Ye YP (2003) Minimizing Phenol Pollution in Sugarcane Stem Apical Meristem Culture. Short Communication 5:297-300.

- Bisht SS, RoutrayAk, Mishra R (2011) Rapid in vitro propagation techniques for sugarcane variety 018. International journal of pharma and bio science 2:0975-6299.

- Murashige T, Skoog F (1962) A Revised Medium for Rapid Growth and Bioassay with Tobacco Cultures. Physiol. Plant. 15: 473–479.

- Khan SA, Rashid A, Chaudhary MF, Chaudhry Z, Afroz A (2008) Rapid micropropagation of three elite Sugarcane (Saccharum officinarum L.) varieties by shoot tip Culture. African Journal of Biotechnology 7:2174-2180.

- Belay T, Mulugeta D, Derbew B (2014) In vitro Aseptic Culture Establishment of Sugarcane (Saccharum officinarum L.) Varieties Using Shoot Tip Explants. Adv Crop Sci Tech 2: 128.

- Michael PS (2007) Micropropagation of Elite Sugarcane Planting Materials from Callus Culture in Vitro. Journal of the Royal Society 140: 425–426.

- Liu GL, Liang ZH, Zhu J (2001) Effects of activated charcoal on plant tissue cultures. J Jiangsu Forestry Sci Technol 28: 46-48.

- Manchanda P, Gosal SS (2012) Effects of Activated charcoal, Carbon Source and Gelling agents on Diret Somatic Embryogenesis and Regeneration in Sugarcane via Leaf roll segments. Sugar Tech 14: 168–173.

Citation: Shimelis D, Bantte K, Feyissa T (2015) Effects of Polyvinyl Pyrrolidone and Activated Charcoal to Control Effect of Phenolic Oxidation on In Vitro Culture Establishment Stage of Micropropagation of Sugarcane (Saccharum Officinarum L.). Adv Crop Sci Tech 3:184. DOI: 10.4172/2329-8863.1000184

Copyright: © 2015 Shimelis D, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 18314

- [From(publication date): 11-2015 - Aug 29, 2025]

- Breakdown by view type

- HTML page views: 13398

- PDF downloads: 4916