Evaluating the Effect of Economizer on Efficiency of the Fire Tube Steam Boiler

Received: 14-Mar-2018 / Accepted Date: 24-Mar-2018 / Published Date: 27-Mar-2018 DOI: 10.4172/2576-1463.1000193

Abstract

In this paper, the effects of using economizer on efficiency of examined fire tube steam boiler is presented. Based on the live tests, the performance indexes of two fire tube 3 passes wet back steam boilers with capacity of 3000 kg/h (one of them with economizer and another without economizer) measured. A MATLAB analysis with the comparison of different results is developed to evaluate the results produced by the live test. The indirect method is the applied method in this study, therefore various types of losses is measured. The results show the effect of using economizer for increase the feed water temperature and improving the efficiency of fire tube steam boiler.

Keywords: Fire tube boiler; Boiler efficiency; Economizer

Introduction

It has always been a goal to increase the energy transfer efficiency, within practical financial limits and operating specifications, of systems, which involve heat transfer [1]. Examples of such systems include: steam boilers which typically burn fossil fuel to convert water to steam for use in heating, cooling, process manufacturing, or the driving of turbines to produce electricity [2-4]; oil refinery furnaces which burn fossil fuel to heat crude oil to produce various petroleum products; and food processing systems which use fossil fuel to heat vegetable oil to produce a variety of products. Many of these systems burn millions of dollars of fuel per year, and thus small changes in efficiency can translate into large monetary savings [2,5,6]. Therefore, it is essential to conduct a thorough investigation on boiler equipment, particularly on its type, characteristics, maintenance and fuel consumption to ensure better boiler efficiency [7]. Boiler efficiency, in general, can be described as the difference between the input and output energy [8,9]. A conventional boiler would require immense initial capital expenditure on fuel usage alone per year. Therefore, slight improvement in boiler efficiency between units could provide significant amount of savings [3,10].

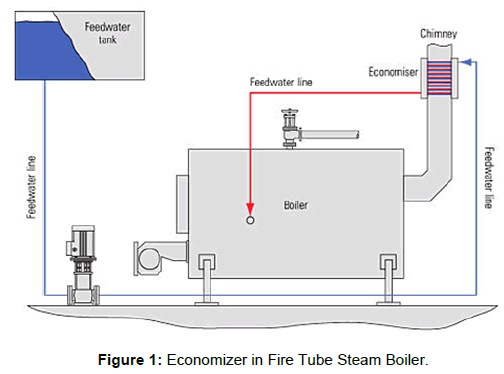

The preheating of feed water in boilers is one of the most effective methods for increasing the efficiency of steam boilers [11]. If the temperature of feed water increase to above 100 degree Celsius, then less firing rate is needed for reaching to a specific horsepower therefore, a significant saving in fuel consumption is achieved and the efficiency be improved [5,12]. The normal temperature of fuel gases in large boilers usually ranged from 230°C to 350°C. The heat produced from preheating of water can be recovered by using Stack economizers that are available in a various sizes [13,14]. Boiler stack economizer in general is a form of heat exchangers that separates between hot fuel gas and water [15-18]. Figure 1 shows the structure of economizer in fire-tube steam that allows the recycle usage of excess heat from exhaust [19].

The present paper focused on the effect of using economizer on the reduction of heat losses and increasing the efficiency of fire tube steam boiler. As well, it is aimed to determine the various types of losses and calculating the exact amount of efficiency before and after using economizer in examined fire tube boilers. The experiments provided the information needed to simulate influences of important parameters that are more effective on efficiency by using MATLAB software. The main purpose of this study is to demonstrate the importance of using an economizer to increase fuel saving during the life time of fire tube steam boiler, which is the most widely used boiler.

Methodology

Efficiency in steam boiler

The efficiency in steam boilers is calculated by two methods, Direct Method (Input-Output method) and Indirect Method (Heat Loss Method) [20]. The Direct Method is assumed by measuring through instrumentation and the calculated data obtained will be utilized to calculate the fuel-to-steam efficiency [21-23]. The Indirect Method can be measured by considering the temporal losses totally. Therefore, the values obtained can be used to calculate the heat balance efficiency [10,24,25]. The main benefit of this method is that the errors in measurement do not make a major change in efficiency.

Performance test

The capacity of examined steam boilers are 6600 pounds (3000 kg of steam production per hour), this boilers were designed according to following standards of British Standard (BS) 2790, and ASME sec VIII and ISIRI 4231 [26-28]. The design pressure is 16 bar, the operation pressure is 10 bar, the pneumatic test pressure is 5 bar, and the hydro static test pressure is 16.5 bar. In first stage the steam boiler without using any equipment for increasing the efficiency (such as economizer) tested, the parameters were measured then the efficiency of the examined steam boiler will be calculated. In this study this boiler is called “Boiler 1”. Another steam boiler has been made with the same specification as “Boiler 1” but this steam boiler is equipped with economizer in the exhaust; in this study this boiler be named “Boiler 2”. The boiler was started and same parameters as before measured, according the results that collected from the experiment the efficiency of this boiler is calculated. Table 1 shows the ultimate analysis and flue gas analysis in “Boiler 1” and “Boiler 2”.

| Ultimate Analysis | Boiler 1 (%) | Boiler 2 (%) |

|---|---|---|

| Carbon | 92 | 92 |

| Hydrogen | 16 | 16 |

| Nitrogen | 0.5 | 0.5 |

| Oxygen | 1.9 | 1.9 |

| Sulphur | 1.8 | 1.8 |

| Moisture | 0.5 | 0.5 |

| GCV of fuel (Diesel) kCal/kg | 10000 | 10000 |

| Fuel firing rate (kg/hr) | 2637.341 | 2637.341 |

| Surface Temperature of boiler (ºC) | 82 | 82 |

| Surface area of boiler (m2) | 90 | 90 |

| Humidity (kg/kg of dry air) | 0.015 | 0.015 |

| Wind speed (m/s) | 3.7 | 3.7 |

| Flue Gas Analysis | ||

| Flue gas temperature (ºC) | 226 | 123 |

| Ambient temperature (ºC) | 30 | 30 |

| CO2 % in flue gas by volume | 11.4 | 10.2 |

| O2 % in flue gas by volume | 7.9 | 7.1 |

Table 1: Ultimate Analysis and Flue Gas Analysis in “Boiler 1” and “Boiler 2”.

Results and Discussion

The calculations for efficiency in these experiments by using indirect method show big differences between two boilers. In this stage the analysis of these discrepancies shows in Table 2 most of the difference in losses between the “Boiler 1” and “Boiler 2” is related to dry flue gas loss that is in “Boiler 1” more than 2 times bigger than “Boiler 2” and the main reason is because of reducing in flue gas temperature that is declined around 103 degree Celsius. The following losses that related to the hydrogen and moisture in fuel do not show big gap between twotested boilers because these losses are mainly related to the specification of fuel and the fuel that used in these boilers is exactly the same (diesel), by using diesel as fuel in these experiments the losses due to fly ash (carbon) and bottom ash (carbon) do not exist that loss due to partial combustion is zero in two examined boilers.

Efficiency and fuel’s GCV

One of the key factors that affect the efficiency is the fuel specification. The exchange of water phases in the combustion process uses energy and having higher water vapor loss during fuel firing

| Input / Output Parameter | % Loss Boiler 1 | % Loss Boiler 2 |

|---|---|---|

| Heat Input | 100 | 100 |

| Losses in boiler : | ||

| 1. Dry flue gas, L1 | 11.7131 | 5.2563 |

| 2. Loss due to hydrogen in fuel, L2 | 9.6797 | 9.0122 |

| 3. Loss due to Moisture in fuel, L3 | 0.0336 | 0.0313 |

| 4. Loss due to Moisture in air, L4 | 0.3443 | 0.154 |

| 5. Partial combustion of C to CO, L5 | 0 | 0 |

| 6. Surface heat losses, L6 | 1 | 1 |

| Boiler 1’s Efficiency = 100 - (L1 + L2 + L3 + L4 + L6) = | 77.2293 | 84.5462 |

Table 2: The Efficiency and Losses in “Boiler 1” and “Boiler 2”.

would result in lower efficiency [29,30]. One of the most important parameters of the fuel is Gross Calorific Value (GCV) that shows the amount of heat made by the inflammation under steady and standard conditions [31,32].

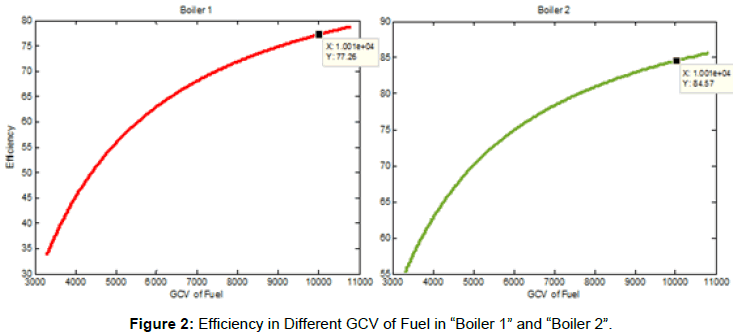

The fuel that used in current experiments is diesel with the gross calorific value (GCV) of 10000 kCal/kg. By placing different fuel’s GCV in the efficiency equations by MATLAB software for the both of boilers, Figure 2 be obtained. The point that mentioned in the curves belong to the current fuel (diesel); as can be seen the type of fuel is more effective on the “Boiler 1” compare to “Boiler 2”; the difference between highest efficiency and lowest efficiency in “Boiler 1”is 45 percent, while this difference in “Boiler 2” is 30 percent, which indicates that the lower efficient boilers are more sensitive to fuel type.

one important point about these figures is that these efficiencies are not match with actual conditions because the efficiency by solid fuels (wood wastes with GCV’s from 2500 to 3850) have effected by some other parameters such as fly ash and bottom ash, that resulted different efficiency compare to these figures but this simulation is still beneficial for analysis the effect of GCV’s on the efficiency.

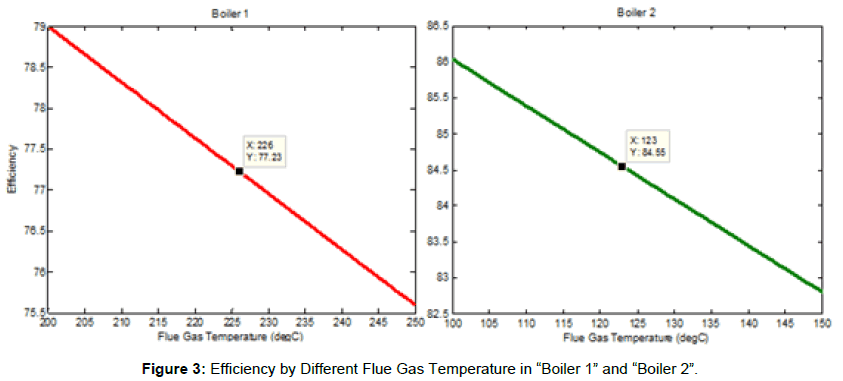

Efficiency and flue gas temperature

Flue gas or stack temperature determined as the combustion gases temperature in the exhaust of the boiler. The flue gas temperature has an important effect on the efficiency [33-35]. Figure 3 shows the effect of different flue gas temperature on efficiency of “Boiler 1” and “Boiler 2”. These figures show that the efficiency and flue gas temperature has a linear relationship. In both the boilers reducing the flue gas temperature has a same effect on efficiency and the slope is same in both the graphs, because this temperature has a fundamental role in all the losses especially on dry flue gas loss.

The difference of flue gas temperature of these boilers is due to the use of additional equipment in “Boiler 2”. The economizer decline the flue gas temperature to about 100°C and has a remarkable effect on improving the efficiency of “Boiler 2” about 7 percent compare to the efficiency of “Boiler 1” that is 77.23.

Conclusion

It has been proven that the initial cost of a boiler is a small part of total cost of boiler during its lifetime. The major costs resulting from the fuel costs. Therefore it is important to use a high efficient steam boiler that consume lower rate of fuel, for this purpose some equipment can be used in steam boilers that one of them used in this project that is economizer. The highest heat losses in boilers is related to dry flue gas that is around 12% of the total heat lost through the exhaust that resulting in efficiency equal to 77.2293% for “Boiler 1”, since the type of fuel and ambient temperature is the same in both boilers; therefore, using economizer concludes in a significant reduction of 103 °C in flue gas temperature. It shows the flue gas temperature of “Boiler 2” equal to 123 °C, and this declining the flue gas temperature declines the dry flue gas loss up to around 6 percent and it increases the efficiency of “Boiler 2” up to 84.5462%, which is a 7.3169% improvement in efficiency. It is found that the method of heat recovery from flue gas by economizer is one of the effective ways to save energy in fire tube boilers.

Acknowledgement

The authors would like to be obliged to Universiti Putra Malaysia and Nirou Boiler Company for providing facilities and financial assistance.

References

- Einstein D, Worrell E, Khrushch M (2001) Steam systems in industry: Energy use and energy efficiency improvement potentials. Lawrence Berkeley National Laboratory.

- Hasanuzzaman M, Rahim N, Saidur R (2011) Analysis of energy, exergy and energy savings of a fire tube boiler. IEEE first conference on Clean Energy and Technology (CET).

- Huang B, Yen R, Shyu W (1988) A steady-state thermal performance model of fire-tube shell boilers. J Eng Gas Turb Power 110: 173-179.

- Ortiz FG (2011) Modeling of fire-tube boilers. Appl Therm Eng 31: 3463-3478.

- Pattanayak L (2014) The Influence of Operational Parameters on Boiler Performance: An Exergy Analysis. Int J Advan Eng Technol 7: 1489.

- Wulfinghoff DR (1999) Energy efficiency manual. Energy Institute Press Maryland.

- Rusinowski H, Stanek W (2010) Hybrid model of steam boiler. Energy 35: 1107-1113.

- Afgan N, Carvalho M, Coelho P (1996) Concept of expert system for boiler fouling assessment. Appl Therm Eng 16: 835-844.

- Ganapathy V (2002) Industrial boilers and heat recovery steam generators: design, applications, and calculations. CRC Press.

- Mimura T, Satsumi S, Iijima M, Mitsuoka S (1999) Development on energy saving technology for flue gas carbon dioxide recovery by the chemical absorption method and steam system in power plant. Proceedings of the 4th International Conference on Greenhouse Gas Control Technologies, Interlaken, Switzerland.

- Kaag CS (2000) Energy Efficiency Manual. Reference & User Services Quarterly 40: 186-186.

- Huang XY (2008) Practice of low pressure economizer installed in 670 t/h coal-fired boiler to reduce the exhaust gas temperature. J Electric Power 6: 55-58.

- Mimura T, Simayoshi H, Suda T, Iijima M, Mituoka S (1997) Development of energy saving technology for flue gas carbon dioxide recovery in power plant by chemical absorption method and steam system. Energy Convers Manag 38: S57-S62.

- Kuprianov VI (2005) Applications of a cost-based method of excess air optimization for the improvement of thermal efficiency and environmental performance of steam boilers. Renew Sust Energ Rev 9: 474-498.

- Kouprianov V, Tanetsakunvatana V (2003) Optimization of excess air for the improvement of environmental performance of a 150 MW boiler fired with Thai lignite. Appl Energ 74: 445-453.

- Payne R, Chen SL, Wolsky AM, Richter WF (1989) CO2 recovery via coal combustion in mixtures of oxygen and recycled flue gas. Combust Sci Technol 67: 1-16.

- http://cleanboiler.org/learn-about/boiler-efficiency-improvement/efficiency-index/economizers/

- Bujak J (2008) Mathematical modelling of a steam boiler room to research thermal efficiency. Energy 33: 1779-1787.

- Shah S, Adhyaru D (2011) Boiler efficiency analysis using direct method. Nirma University International Conference on Engineering.

- Van De Wal M, De Jager B (2001) A review of methods for input/output selection. Automatica 37: 487-510.

- Wienese A (2001) Boilers, boiler fuel and boiler efficiency. Proc S Afr Sug Technol Ass.

- Barroso J, Barreras F, Amaveda H, Lozano A (2003) On the optimization of boiler efficiency using bagasse as fuel. Fuel 82: 1451-1463.

- Boiler A (2013) ASME Boiler and pressure vessel code: section viii rules for construction of pressure vessels.

- https://www.asme.org/getmedia/1adfc3df-7dab-44bf-a078-8b1c7d60bf0d/asme_bpvc_2013-brochure.aspx

- Kulatilaka N (1993) The value of flexibility: The case of a dual-fuel industrial steam boiler. Financial management 22: 271-280.

- Morgan PA, Robertson SD, Unsworth JF (1986) Combustion studies by thermogravimetric analysis: Coal oxidation. Fuel 65: 1546-1551.

- Aljundi IH (2009) Energy and exergy analysis of a steam power plant in Jordan. Appl Therm Eng 29: 324-328.

- Bhatt MS (2000) Energy audit case studies I- steam systems. Appl Therm Eng 20: 285-296.

- Chao L, Ke L, Yongzhen W, Zhitong M, Yulie G (2017) The Effect Analysis of Thermal Efficiency and Optimal Design for Boiler System. Energy Procedia 105: 3045-3050.

- Che D, Liu Y, Gao C (2004) Evaluation of retrofitting a conventional natural gas fired boiler into a condensing boiler. Energ Convers Manag 45: 3251-3266.

- Zhelev T, Semkov K (2004) Cleaner flue gas and energy recovery through pinch analysis. J Clean Prod 12: 165-170.

Citation: Lahijani AM, Supeni EE (2018) Evaluating the Effect of Economizer on Efficiency of the Fire Tube Steam Boiler. Innov Ener Res 7: 193. DOI: 10.4172/2576-1463.1000193

Copyright: © 2018 Lahijani AM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 11818

- [From(publication date): 0-2018 - Aug 25, 2025]

- Breakdown by view type

- HTML page views: 10626

- PDF downloads: 1192