Research Article Open Access

Selection of Coals for Making High Quality Metallurgical Coke at Ajaokuta Steel Company Limited

Ocheri C*

Department of Metallurgical and Materials Engineering, University of Nigeria, Nsukka, Nigeria

- *Corresponding Author:

- Ocheri C

Department of Metallurgical and Materials Engineering

University of Nigeria, Nsukka, Nigeria

Tel: +2348068433419

E-mail: cyril.ocheri@unn.edu.ng

Received date: December 10, 2016; Accepted date: December 30, 2016; Published date: January 25, 2017

Citation: Ocheri C (2017) Selection of Coals for Making High Quality Metallurgical Coke at Ajaokuta Steel Company Limited. J Powder Metall Min 6:150. doi:10.4172/2168-9806.1000150

Copyright: © 2017 Ocheri C. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Abstract

The objective of this paper is to describe the process and the need to select coals for making high quality metallurgical coke for use in the Blast furnace of the Ajaokuta Steel Company Limited. The selection process of these coals for the production of quality iron and steel will apparently reduce the dependence and huge financial burden that might be incurred by Government in the production process. This paper will therefore focus on the various methods of selecting coals for blend, the options of incorporating the locally available non-coking coal in the charge. Some other parameters, classification of coals and their functions were also highlighted

Keywords

High quality; Metallurgical coke; Blends; Blast furnac; Ajaokuta

Introduction

It has been said that no meaningful industrialization can take place in a nation without Iron and Steel. In fact, the Iron and Steel is the bedrock of Nigeria’s industrialization and the ultimate factor in the realization of our industrialization efforts. As we all know, engineering practice involves the following processes viz. conceptualizing, designing, fabricating, constructing, erecting, operating, and maintaining devices that save labour, increase productivity and quality products or technological process. Ajaokuta steel company limited has been constructed and erected. Therefore, it has to go into operation in view of the huge money already sunk into the project and the relative irreversibility of investment. Coking coal is one of the major raw materials required in the Blast Furnace-Basic Oxygen furnace process of Iron and Steel making construction at Ajaokuta. Apparently, this is one of the most expensive raw materials in the process of Iron making [1]. The need for sustained operation of the coke oven and iron making shop calls for a drastic reduction in the imported coals and this paper will therefore focus on the various methods of selecting coals for blending.

Classification of coal

Coal is the general term for a wide variety of solid materials that are high in carbon content. Most coal is burned by electric utility companies to produce steam to turn their generators. Some coal is used in factories to produce heat for buildings and industrial processes. A special, high-quality coal is turned into metallurgical coke for use in making steel. Coal is an energy resources composed of organic materials associated with ash forming inorganic minerals. It may be broadly classified into coking and non-coking coals. All coking coals possess the properties of softening to a plastic mass on carbonization, followed by decomposition, swelling with evolution of gases and finally re-solidifying (accompanied by contraction) to form a coherent porous coke structure. Coal is classified into lignite, sub-bituminous, bituminous and anthracite based on physical or chemical parameter such as volatile matter, calorific valve, fixed carbon, reflectance, moisture content and x-ray diffraction technique. Unfortunately, only a small percentage of the bituminous coal is coking and capable of being converted into high quality metallurgical coke during high temperature carbonization [2].

Functions of metallurgical coke

Metallurgical coke produced by the process of high temperature carbonization in a coke oven (1000°C) is required to provide the following physical and chemical functions in the blast furnace.

• Energy for endothermic chemical reactions,

• Reducing gases to convert iron oxides to metallic iron.

• Porous permeable bed for counter-current flow of liquid (i.e.) molten slag and hot metal and reducing gases.

• Mechanical support for the burden.

Additionally, the coke should be of such chemical quality so as not to contaminate the hot metal with it’s excessive sulphur, phosphorous and alkali contents. Metallurgical coke strength is determined by the degradation induced during shatter test (ASTM D3038) or by Micum tumbling. A few other strength factors are JIS and Sundgren [3]. Generally, the blast furnace productivity improves with increased coke stability. Few coals can meet the requirements to produce high quality metallurgical coke, and as such two or more coals must be blended to meet the desired specifications. The underlying principle of blending is that the properties of the charge composed must be as close as possible to that of a prime coking coal. Subsequently, during the blending process, careful selections of coals are made so that the deficiency in one technological property of a coal in the coal blend can be offset by an excess of that property in another coal, and as a result, trade-offs can be made to design satisfactory blends

Selection of coals for blending

Coal preparation practice in many steel industries requires selection of suitable coals or materials for blending so as to conform to the designed specifications of the industry. Blending materials includes coking coals, non-coking coal, petroleum pitch, coal tar pitch, and anthracite and coke breeze. The following principles based on chemical and physical properties of coal for selecting coals are discussed.

Coking capacity as a function of volatile matter

Through this method, a coking coal blend is composed from individual coal components such that the resultant coke is of high quality coke in terms of micum strength (M40). An optimum coking coal charge also presupposed a homogeneous distribution of the properties of its components. It has been established that the coking power can be represented by a numerical index, which reflects the behavior of a coal pencil in a dilatometer

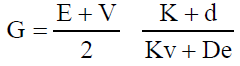

Where G=Coking power

E=Softening temperature

V=Solidification temperature

K v=Contraction

D=dilatation

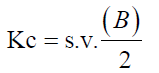

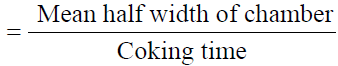

The coking conditions can also be represented by a factor Kc defined below.

Where S=bulk density of charge tons/m³

V=average coking speed

B=Mean width (in cm)

Total dilatation as a function of volatile matter

To obtain high strength coke, individual coal must be blended to produce charge of volatile matter 25-32 (dry ash free) percent. Although low volatile and same high-ranking medium volatile coals produce strong cokes, they exert excessive wall pressure during high temperature carbonization and cannot be carbonized alone in a Byproduct oven because they can cause damage. In addition to those coals do not contract sufficiently during coking and so create pushing problems at the end of carbonization. High volatile coals, on the other hands, possess a lot of contraction property with minimal expansion characteristics. In practice, the two types of coal are blended such that the deficiency in contraction property of low volatile coal is off set by the excess of some property in high volatile coking coal in order to achieve a balanced characteristic through proportioning of the coal components.

Maximum fluidity as a function of mean maximum reflectance

From the studies conducted it was established that coals selected from many countries that have the characteristics of an ideal coal blend required for high quality coke have mean maximum reflectance (in oil) of 1.1 to 1.3 percent and maximum fluidity of or fluidities have to be blended in order to come close to the ideal situation. Gieseler plastomerter (ASTM D2639), which is available at ASCL’s Coke Oven and By-product laboratory, will be used to determine the plastics properties of coal during heating. In selecting coal for compatible blending the components should have overlapping plastics rages to guarantee a homogeneous coke structure.

Composition balance index as a function of strength index

This is based on a petrography approach of correlating coke stability with maceral Composition, and vitrinite reflectance. Coke stability factor predictions curve developed by Ammasov et al. were modified by Schapiro avid Cray of United Steel Corporation to relate to ASTM procedure. This method has provided a good basis for selecting coals for charge preparation at many steel industries. A composition balance index of 1.0 indicates the optimum coke strength for a given coal. Excess or a deficit of inert or reactive will result in a decrease of strength for a particular coal rank. In the process of composing a coking blend, the individual coal would be so proportioned so that the composition balance index come close to ideal value of 1.0 [4].

Coal chemical composition (Coal grade)

Coals are selected by grade, which takes cognizance of the chemical quality in respect of ash, sulphur, phosphorus, alkali and chloride contents. In any chemical parameter of a particular coal exceeds limit specified at a coke plant, the coal may still be satisfactory for specific use if it is possible to formulate a blend with other coals or materials such that the final charge lies within the limits specified It should be noted that alkalis cause coke breakdown, scabs and other operating problems in the blast furnace. Consequently, the alkali content in a coal charge for coke making is always kept as low as possible.

It is restricted to a maximum of 1.95% in the case of ASCL. Also chlorides pass into By-product section and require considerable water to remove from the tar recovered in the By-product plant. Because of its corrosive nature, chlorides also cause maintenance problems in the coal handling and coke oven plant.

In April 1993, at Vukhim Pilot Plant Russia, a number of above methods discussed were used to compose coking coal blends for the operation of Ajaokuta Coke Oven plant. Six coals from Australia, United States of America and Great Britain were subjected to a series of tests after which eight charge variants were shortlisted. It was noted that any of variants 1, 2,4,7,8 were good for operation. Sometime in 1993, direct blending test of imported and Enugu coal was carried out on a 250 kg pilot oven at NMDC, Jos [5].

Process of coal handling

The coal handling plant is designed to process the basic raw materials into a homogeneous trouble free coal charge in a number of steps. These steps are: -

• Receiving, storing and averaging of coal in the open coal stockyard.

• Separation of foreign objects.

• Proportioning of various coal components by the dozing apparatus (automatic batch weigher (No. 1-16).

• Crushing with hammer crushers

• Addition of spent solar oil, sludge and acid tar to coal blend.

• Blending of coal components in the mixing machine.

• Storage of coal charge in the coal tower bins.

The process outlined for the coal preparation shop above is purely a physical phenomenon. By the Detailed project Report (DPR) on the coal preparation shop, coals are expected to be transported to the steel plant by rail from Onne port via Oturkpo to Ajaokuta, The Onne port project has been abandoned while the Warri (DSC) port to Ajaokuta rail line has also been abandoned.

Hence coal vendors transported the raw materials by road to the temporary coal storage be-sides Itakpe to Ajaokuta. From this position, they will be re-loaded onto wagons for onward delivery to the off loading facility (unit 08.45) where it will be unloaded into two lines of receiving bins. From the control room the conveyer line is put into operation and with the aid of conveyor belt, C1, C2, C3 and transfer units (Junction towers) Ny1, Ny2 and Ny3, the storage conveyors C4 and C5 which finally discharged the coals to the stockyard through stacking machines The stacking machine discharged at the rate 1,200 tonnes/hr and a stockpile up to a height of 12 meters. There are two of such stacking machines. The averaging operation on the coal is carried out with the reclaiming machine scooping slices of the coal in a vertical direction with its 9 buckets several times and then allowed to fall back to the stockpile. Subsequently, the averaged coals are removed by the recliner machines at the rate of 1,000 tonnes/hr through self-conveyor and hopper and finally unto under-lying conveyors C8, C9, V10, V11 and V12 transfer units Ny5, Ny6; Ny6A, it is transported to foreign object separation screens. At this unit ferrous materials are removed by the electro-magnets while the rotary screens remove objects greater than 100 mm.This operation is compulsory before coals are delivered to the silos so as to prevent the blocking of dozing apparatus and any damage to the hammer head crushers. After the operation at the foreign object unit, the individual coal is transferred by belt conveyors and distributed among the 10 bins of proportioning section

The silos are of 800 tonnes each with capacity 20.5 m high and of diameter 10 meters. For each technological grade of coal, at least two silos bins are allotted based on maximum blending procedure of the coals. Based on the previously discussed principles of selecting individual coals for high quality coke, the blend components in terms of percentage were pre-determined. This is translated to a production programme issued by the superintendent of handling plant on the basis of coal delivered and coal remaining at the storage. The proportioning of the charge components are done by the dozing apparatus (automatic weighing machines) from the operators control room in accordance with the pre-set programme. Through this procedure the pre-set weight of coal component forming the blend is discharged from the silos onto underlying reversible conveyor belt where initial blending is effected.

The chosen composition of the charge or blend has to be approved by the Head of Coke Oven and By-products plant and is operational for a determined period of time. The coal charge of defined composition above is transferred to the crushing section with the help of belt conveyor Y7, Y8, Y9 and Y10 where grade-wise crushing (of the charge) takes place in the three reversible hammer crusher (2-operating, 1-standby) required by the technology of the process. The capacities of the crushers are 500 tonnes/hr and 300 tonnes/hr for soft and hard coal respectively. The size control for each grade is achieved by adjusting the gap between the rotating hammer and the crusher and also by charging the numbers of hammer rows.

After crushing, acid tar, sludge and spent solar oil are added to the charge at the Acid tar utilization unit to increase the bulk density. From the unit, the charge is transported by conveyor belt Y11 to the final mixing section for thorough blending. The unit is equipped with 2-organised mixing machines (operating, 2nd stand by) of capacity 600-tonnes/hr each. The homogeneous charge is further transported by conveyor Y12, Y13, and Y14 to the upper section of the coal tower ready for charging into the ovens [6].

The specifications of the coal charge for the operation of Coke Oven Battery as per Detailed

Project Report one as listed below:

Total moisture=5-9%

Volatile Matter=27.7-33.3 (daf.)

Number of components=7 (max)

Bulk density=0.69-0.76 T/Nm³

Vertical shrinkage=5-7%

Sulphur content=1% (Max)

Ash content=10% (max)

Provisions are made for automatic technological sampling of the coal and coal charge at junction tower N0 1 and 8 near the stockyard and coal towers respectively for checking ash, moisture and sulphur contents. The plant operates in 3 shifts 4-brigade arrangement while equipment utilization is for 17.5 hours. With this review of the coal handling operations, we proceed to discuss the strategic importance of coal to the company for sustained operation. At the 1.3 million stages, we require about 1.32 million tonnes of coking coal, which is being sourced through 100% importation.

Conclusions and Recommendations

By applying the basic principles based on detailed petrography, chemical and ecological properties of coal a range of coals can be selected to compose a coking blend which when carbonized to high temperature in a non-oxidizing oven, will produce high quality metallurgical coke for Blast Furnace operation. From the foregoing discussions, the following recommendations are made.

• The management of Ajaokuta steel company limited (ASCL) should collaborate with National Metallurgical Development center (NMDC) Jos to test coal sourced locally with imported coals so as to determine the optimum utilization of the coal in the blend for ASCL.

• The incorporation of pre-healing facility must be pursued urgently.

• The possibility of installing a formed coke pilot plant producing at about 200 tonnes/day in the steel plant is worth considering. This will provide a long-term solution to the coking coal problem.

• Partial briquetting plant as an auxiliary facility to the main Coke Oven and by-products plant must be taken up expeditiously. Additionally, the issue of tar distillation plant is pursued in the same manner in order to provide the company with future binder requirements.

• Finally, A COREX plant must be considered, which is an entirely coal based Direct Reduction process leading to the production of hot metal.

References

- Ammosov II, Eremin IV, Sukhenko SI, Osurkov IS (1957) Calculation of coking charges on the basis of petrographic characteristics of coals 12: 9-12.

- Bello AO (1986) Metallurgical coke its production and Quality.

- Goscinski JS (1978) selection of coals for coke making.

- Kapitan JS, Wilson JR(1991) coking selection, coke making practice, and the effects on blast furnace and steel plant operations at inland steel.

- Tiajpromexport V/O (1993) Elaboration of the composition of coking coal blends for Iron and steel works in Ajaokuta, Nigeria.

- Dubroff (1984) IN: coal selection for high quality coke. (at inland steel).

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 6335

- [From(publication date):

April-2017 - Aug 18, 2025] - Breakdown by view type

- HTML page views : 5188

- PDF downloads : 1147