Solar Still Distillate Productivity Enhancement by Using Reflector and Design Optimization

Received: 28-Jan-2019 / Accepted Date: 11-Feb-2019 / Published Date: 18-Feb-2019

Abstract

Solar still is one of the oldest and simplest techniques for desalination of saline water from the renewable energy i.e. solar energy. The main associated problem with the solar still is the low productivity of fresh water in comparison with the energy input from sun. Different design and operational parameters as well as heat losses are the causes of low performance ratio of this system. This report presents the synopsis of the effect of all design and operational parameters that greatly influence the productivity of still. In doing so, a mathematical model of conventional solar still on engineering equation solver has been developed which predicts the trends of all variables affecting the productivity. The model is solved for the Dhahran KSA on all inputs that are requiring for model.The study of all these effects leads to modification in design of solar still to enhance its productivity. A simple reflector is proposed on top cover of conventional solar still. The effect of all same parameters is then analyzed with this modification. A useful comparison of both cases reveals that the maximum productivity of solar still increased from 0.44 to 0.65 due to reflector. For a given day, the productivity of modified solar still increase by 90 g/h and reaches to maximum value of 230 g/h. Similarly, the presence of reflector enables to conserve energy i.e. the energy loss has been found to reduce by 16%.Other parameters that exhibit the same nature of trend for both cases are glass thickness, its temperature and slope. The model predicts that for a given inputs condition the optimum thickness of glass covering wide range of productivity here is 6 mm. Among three brine pool heights including 1 cm, 2 cm and 3 cm, maximum productivity is obtained at brine pool height of 1 cm. Seasonal effect for both conventional and modified design are widely discussed. It is found that water temperature is higher than glass temperature irrespective of the season of the year. Productivity is found to be higher in summer season than in winter season.

Keywords: Solar still; Reflector; Isotropic diffuse Model; Radiation

Nomenclature

δ=declination; n=Day of the month; ϕ=Latitude; N=Solar hours; Ho=Extraterrestrial solar radiations per day KT=Clearance index; ωs=Sunset hour angle; Gsc=Solar constant; H=Available average solar radiation per day Hd=Monthly average daily diffuse radiations; ρg=Ground Reflectivity; Rb=Geometric factor; β=Slope of glass cover; Ib=Hourly beam radiations; Id=Hourly diffuse radiations; IT=Solar radiation energy received at tilted glass cover; n1=Air refractive index; n2=Refractive index of the glass material; ϴ1=Angle of incidence of radiations; ϴ2=Angle of refraction; τ=Transmittance of the glass; α=Absorptance of the glass; ρ=Reflectance of the glass; QG=Net heat transferred to the glass; QWG=Heat transferred from water to the glass; QR=Heat loss through radiation; QC=Heat loss through convection; QRWG=Radiation energy transferred from water to glass by radiations; QCWG=Energy transferred from water to the glass by convection QS=Energy Stored; TW=Water Temperature; TG=Glass Temperature; TA=Ambient Temperature; mP=mass of plate; mG=Mass of glass; Ap=Area of plate; AG=Area of glass; I=Energy available to top cover

Introduction

Water is the sign of life on this planet earth. All living creatures including human need portable water for their survival. With increasing human population and industrialization, the demand is increasing day by day [1]. Around 96.5% of total water reserves is highly saline or brackish water and cannot be used as portable water. On the worse side, the human activities are polluting existing resources of sweet water and available resources of sweet water are not equally distributed around the globe [2].

Although conventional solar still has meager productivity and performance ratio as compared to the other desalination technologies including multistage flash desalination and multi-effect evaporation but there are many advantages associated with this simplest technology [3]. It is more than a gift for under-privileged areas of globe. It is cheap, easy to maintain, and have almost no running cost [4]. It is also important because of the abundance of solar energy available in the areas facing the scarcity of water. That is why, it is pivotal to improve the distillate productivity of conventional solar still [5].

There are many methods reported in the literature for the improvement of solar still. It includes design modification, addition of porous substances in to the water pool, and use of phase change materials [6].

There are many designs reported in the literature for increased performance of solar still, single slope, double slope, and pyramid type, and inverted conical shape, vertical and horizontal solar still [7]. Use of Sponge cubes, wicks, and charcoal has also been widely reported in the literature. Use of phase change material is also the latest development in the recent past and phase change material make the solar still work around the clock due to their unique physical properties. During solar hour, solar energy is stored while transforming the solid phase material into the liquid state. Opposite happen during the night time in the absence of solar energy [8]. This proved to be a really good idea in near past. Idea of solar reflector is used to boost up the energy available to the solar collector is used in the current study. Solar reflector is receiving solar energy and concentrating it back on the top cover of solar still. This increases the rate of evaporation inside the still body that in turn results in the increase of distillate productivity [9].

Solar still productivity can also be enhanced by improving many variables including slope of top cover angle, wind speed, thickness of the glass, and refractive index of the glass, its transmissivity, reflectivity and absorptivity [10]. Another important factor is the absorptivity of the base plate. Effect of these variables including absorptivity of the base plate has been widely discussed in the recent study and recommendation has been made based on the results of the modeling.

Process Modelling

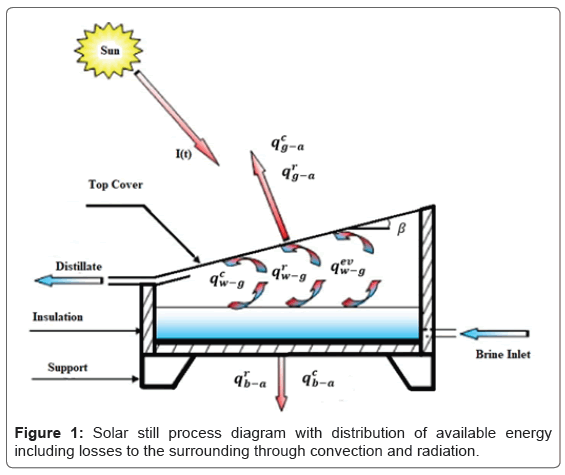

Solar energy is incident on the top cover of solar still. Cover glass optical properties play a pivotal role. Optical properties of glass influence the fraction of the incident energy is transmitted inside the still body [11]. A portion of the incident energy is lost through convection and radiation to the sky. Rest of the energy transmitted by the glass reaches to water and base [12].

Energy reaching the water is further distributed. Part of it is used to evaporate water while rest of the energy is lost to the back to the glass by convection and radiation [13]. A small but considerable part of it is also lost to surrounding through the base plate. Still body is insulated by insulation material to minimize above-mentioned energy. The pictorial view of solar still with associated energies are shown in the Figure 1.

Another important phenomenon occurring through the glass of solar still is condensation of vapor produced by still. Rate of condensation has significant impact on its production. Different factors effecting the rate if condensation are studied in the detail in the following sections [14].

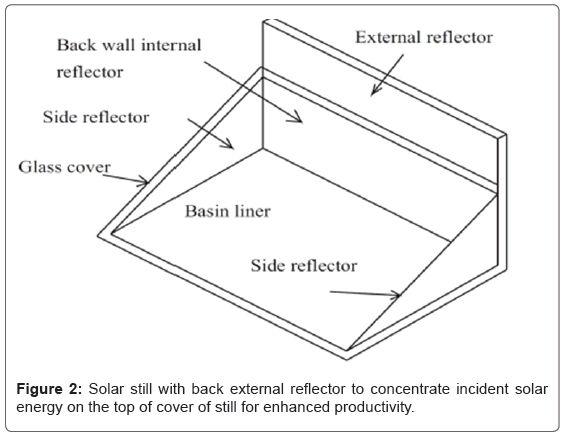

Main theme of this study is to enhance the productivity by putting reflector on the top of the still body as shown in the Figure 2. Reflector reflects the portion of incident energy on the still glass cover. This increases the incident solar radiations on the glass cover which in turn increases the portion of transmitted energy in the still body.

Modeling of Solar still consists of following sequence:

Available energy calculation

The monthly average data for Dhahran, Saudi Arabia (ϕ=26.13) used for calculation of energy reaching the still top cover is summarized in Table 1 [15].

| Month | Day of Month | For Average Day of Month | ||

|---|---|---|---|---|

| Date | n | δ | ||

| January | i | 17 | 17 | -20.9˚ |

| February | 31+i | 16 | 47 | -13˚ |

| March | 59+i | 16 | 75 | -2.4˚ |

| April | 90+i | 15 | 105 | 9.4˚ |

| May | 120+i | 15 | 135 | 18.8˚ |

| June | 151+i | 11 | 162 | 23.1˚ |

| July | 181+i | 17 | 198 | 21.2 |

| August | 212+i | 16 | 228 | 13.5 |

| September | 243+i | 15 | 258 | 2.2 |

| October | 273+i | 15 | 288 | -9.6 |

| November | 304+i | 14 | 318 | -18.9 |

| December | 334+i | 10 | 344 | -23 |

Table 1: Declination and average day of month for calculation of average energy incident on the still top cover.

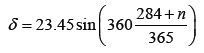

Declination can be calculated based on the average monthly data by using the following relation,

(1)

(1)

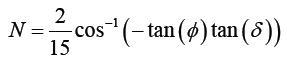

Number of day light hours can be calculated by using equation (2) below.

(2)

(2)

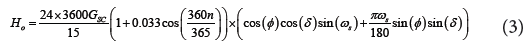

Daily extra-terrestrial radiation for the horizontal surface can be calculated as [6],

Daily clearance index can be defined daily terrestrial radiation to extra-terrestrial radiation as in equation (4) below.

(4)

(4)

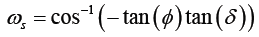

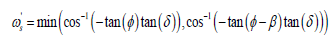

Sun set angle can be defined in term of latitude and declination in term of equation (5) below [16].

(5)

(5)

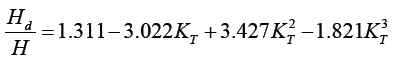

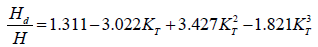

Based on the values of sunset hour angle and clearance index, monthly average daily diffuse radiation can be calculated based on the following two relations depending on the criteria specified before equations (6) and (7).

If ωs ≤ 81.4 and 0.3 ≥ KT ≤ 0.8

(6)

(6)

If ωs ≤ 81.4 and 0.3 ≥ KT ≤ 0.8

(7)

(7)

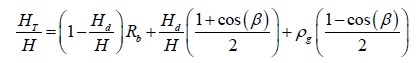

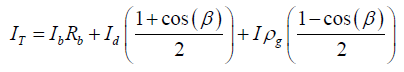

Isotropic diffuse model is used to obtain monthly average daily radiation available to the solar still at different slope values [17].

(8)

(8)

For northern hemisphere,

(9)

(9)

(10)

(10)

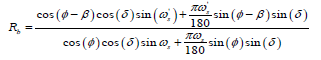

Similarly, isotropic diffuse model proposed by Liu and Jourdan was used to calculate the hourly radiation available to the top cover of solar still. It uses the following relations.

(11)

(11)

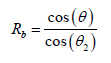

Rb is the ratio of cosine of incidence angle to the cosine of zenith angle as shown in equation (12) below.

(12)

(12)

ϴ and ϴ2 are incidence angle and zenith angle respectively.

Modelling of optical properties of solar still glass

Optical properties of top cover glass play pivotal role and has considerable effect on the distillate productivity in both conventional and modified solar still. Following relations are used for modeling top glass transmittance, reflectance and absorptance in EES code.

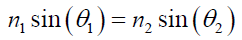

(13)

(13)

n1 and n2 are the refractive indices of the air and glass material used for the top cover of solar still.

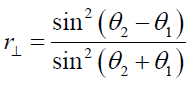

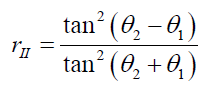

Relation derived by Fresnel has been used to calculate the parallel and perpendicular component of the unpolarized radiations.

(14)

(14)

(15)

(15)

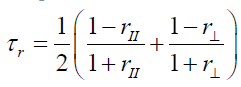

Transmittance of unpolarized radiations is the average of above two components. Therefore, we can write:

(16)

(16)

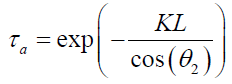

Absorption by glazing was calculated by using Bouguer’law as in equation (17).

K, L and ϴ2 are extinction coefficient specific for the top glass cover of solar still measured in (1/m), thickness of cover and angle of refraction respectively.

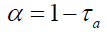

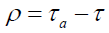

Transmittance, absorptance, and reflectance are calculated based on the method proposed by Siegel and Howell as follows:

(18)

(18)

(19)

(19)

(20)

(20)

Modeling of heat transfer mechanism of solar still

Selective heat transfer relations are used to accommodate heat losses from top cover, edges and from the back of solar still by different modes of heat transfer.

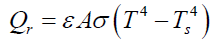

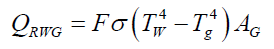

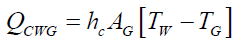

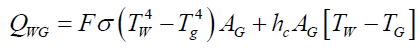

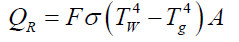

Following relation can be used to calculate heat loss by the radiation mode of heat transfer [18]:

(21)

(21)

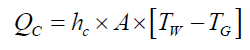

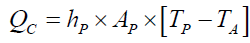

ε and σ are the emissivity of the material and Stefan Boltzmann Constant and its value is  Heat loss through the convection can be estimated by using the following relation.

Heat loss through the convection can be estimated by using the following relation.

(22)

(22)

hc is convection heat transfer coefficient for the surface under consideration.

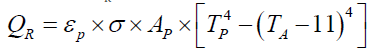

Model of Solar Still

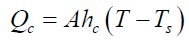

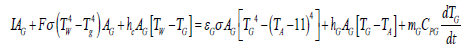

Energy balance for glass cover

Energy received by the glass includes the energy from the sun directly, energy reflected by the reflector plate, energy radiated by the water inside solar still and energy transferred by the convection from water to the glass.

(23)

(23)

(24)

(24)

(25)

(25)

(26)

(26)

(27)

(27)

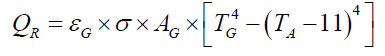

If AG is the area of glass cover than energy radiated from surface to the environment can be calculated as:

(28)

(28)

Where εG emissivity of glass and ‘σ’ is Stefan Boltzmann Coefficient. TG and TA are glass and ambient temperature respectively.

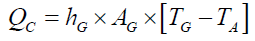

If hG heat transfer coefficient due to natural convection than energy loss due to convection can be written as:

(29)

(29)

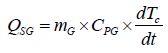

Energy stored can be written as:

(30)

(30)

By plugging in the expression for QG, QT, QR, Qs, and QC in equation (23) we get energy balance for glass cover [19]:

(31)

(31)

Here I is the energy available to top glass of the solar still.

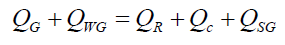

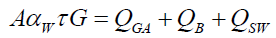

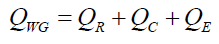

Energy balance for water

Total energy received by the water is summation of energy lost to the air within solar still, energy lost to the absorber surface plate, and energy stored in the water. This can be summarized in following equation [4]:

(32)

(32)

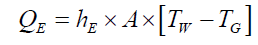

Energy lost to air and glass includes energy lost due to radiation, convection, and evaporation of water[1].

(33)

(33)

(34)

(34)

(35)

(35)

(36)

(36)

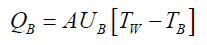

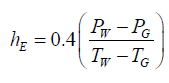

QR, QC, and QE are the energy lost from water due to radiations, convection and evaporation within the solar still body. Energy lost to the absorber plate and energy stored can be written as [20]:

(37)

(37)

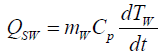

And energy stored in water can written as:

(38)

(38)

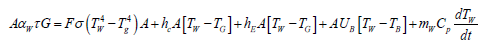

Plug in the expression for QGA,QB, and QSW in equation (32) to get the energy balance for water [21]:

(39)

(39)

Where hE can be determined by the following relation [22]:

(40)

(40)

Energy balance for absorber plate

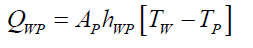

Energy received from the water will be equal to energy stored by absorber plate and energy lost to environment. Energy received from water can be written as:

(41)

(41)

Similarly, energy lost, will include energy lost due to convection(Qc) and radiation (QR)

(42)

(42)

(43)

(43)

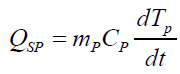

And energy stored can be written in the absorber plate can be written as:

(44)

(44)

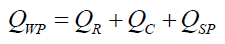

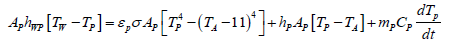

Energy obtained from water is equation to the summation of energy lost due to convection and radiation plus energy stored. Therefore, energy balance for absorber plate can be written as [23]:

(45)

(45)

By plugging in the relations for Qwp, QR, Qc, and QSP in the above equation, we get energy balance for absorber surface plate [4,6,19]:

(46)

(46)

Results and Discussion

Validation of model

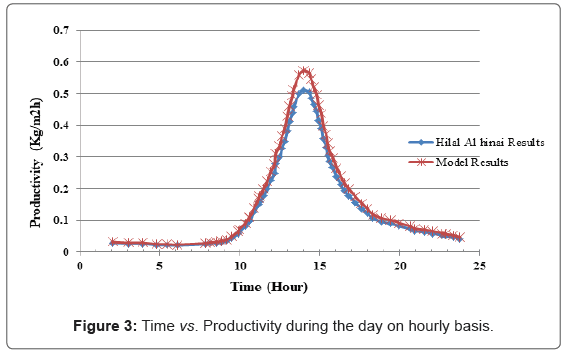

Set of equations developed in section 4 have solved in Engineering Equation Solver (EES) to examine the performance of conventional solar still. The developed model has been validated with the result of Hilal Al-Hinai [24] for confirming the accuracy of the model. This model gives the same results on the input as used by the author. Although there is 2.5%, difference is noted in case of daily productivity at solar noon. This may be due to properties of the sea water and normal water taken in the consideration in the model as all inputs such as location altitude, incident solar energy are same. From all set of data, some are given for the ease of readers (Table 2).

| Location | Oman |

|---|---|

| City | Seeb |

| Slope angle | 23° |

| Considered Month | February |

| Global Insolation | 16.4 MJ/m2 |

Table 2: Location and Time information for validity.

Hourly productivity

The graph plotted above represents the daily productivity for the model presented in this work and the author Hilal Al hinai [24]. A close agreement is found between two works. There is negligible difference in productivity at solar noon (Figure 3).

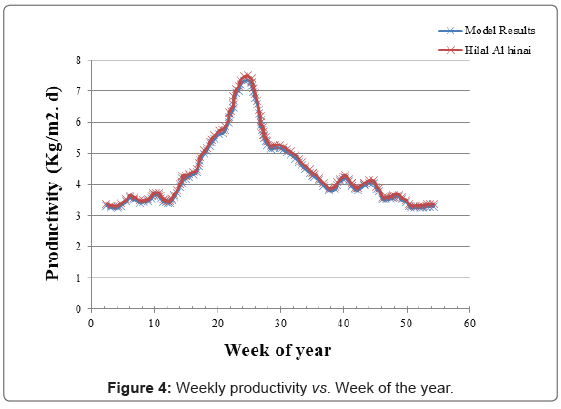

Weekly productivity

The below trend in Figure 4 is for the output of the solar still for all weeks of a year. These results for both model found in closed agreement. The productivity is higher for the months of summer and less in weeks of winter.

Productivity w.r.t slope of still

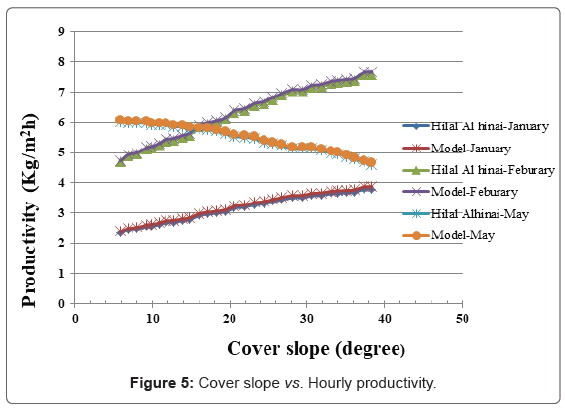

The graphs in Figure 5 represent trend of productivity for the different slopes angles of the cover of still for winter and summer seasons. January and February are selected for the winter season while month of May shows the trend for summer season. The model shows closed results for each case with the author work. The optimum angle as predicted by model for higher productivity in any month is same as that of latitude of Seeb, Oman i.e. 23 degrees.

Available energy for KSA

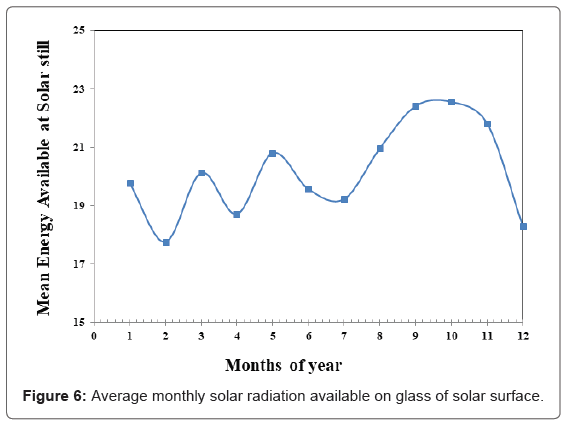

Section 3.1 enables to determine the Energy available for KSA for the whole year. The results from equation (8) for energy have shown in Figure 6. The knowledge of available solar radiations is important as it is the only source of energy for water production especially for the passive solar stills.

The slope of solar still is being selected at 45° for evaluation of energy on the glass. This graph depicts that monthly average solar radiation in (MJ/m2) available on the glass of the solar still varies throughout the year. This means that the evaporation or hence the productivity of distillate water also vary through the year. Therefore, it is predictable that solar still output is limited by the variation of radiations.

Productivity of solar still

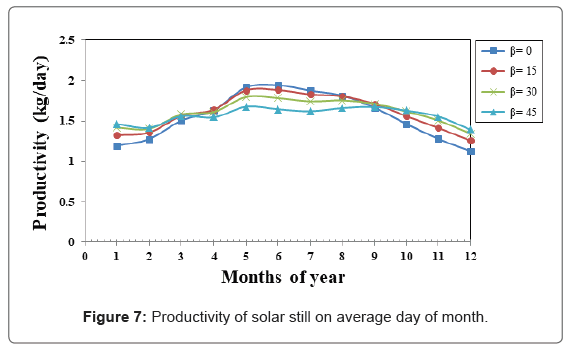

From Section 3 the productivity of solar still at the basis of monthly average radiation throughout the year can be obtained. The results from this section show the productivity of solar still based on each month in Figure 7. It represents the same concept that describes in Figure 6, since the output is directly related to the productivity.

Moreover, the variation of cover slope is also shown in the same figure. The effect of different slope on productivity of conventional solar still analyzed with all other parameters kept constant. As the angle of still increases, the productivity decreases in similar proportion. The maximum productivity is obtained on the horizontal glass i.e. Zero slope of solar still which is theoretically possible only. As there must be some inclination angle to obtain the distillate water on one side of the product by gravity flow. Therefore, the case of zero slope angles is not applicable in practically design aspects. The slope of 15 degree covers the wide range of productivity throughout the year.

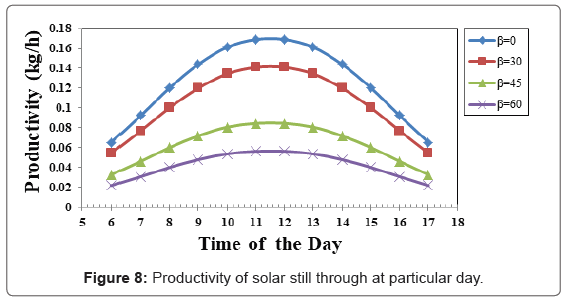

In similar manner Figure 8 summarize the same conclusion but it shows variation over the average month of April for Dhahran KSA. Throughout the day, Productivity increases with solar radiation as it reaches to solar noon and the decrease in correspondence after solar noon. This also highlights the limitation of angle for the design of solar still to obtain the optimum productivity. Note that the angle equal to latitude of Dhahran covers the wide portion of higher productivity as compared to other angles of slope. This analysis of angle depicts the optimum angle selection against the location and available solar radiation.

Parameters affecting the solar still productivity

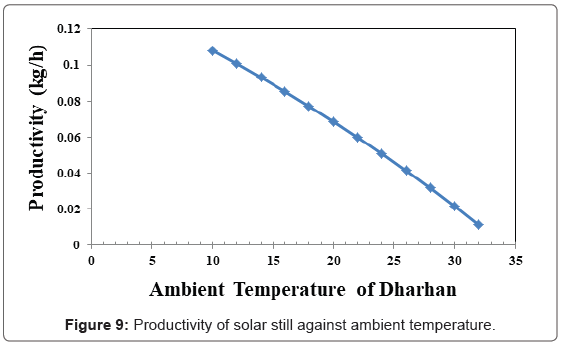

Ambient temperature: The productivity of solar still greatly varies with the ambient temperature of location. For this report, solar still’s productivity is studied against the ambient temperature of Dhahran. Productivity of solar still greatly reduces as the ambient temperature increases. This is because of low cooling or heat loss from glass surface. Increase in ambient temperature leads to higher glass temperature and hence turn into low productivity [11,25]. Cooling of glass surface is the best treatment for reduction in glass temperature that may result from higher ambient temperature. Figure 9 below predicts the performance of solar still based on the ambient average temperature of the Dhahran.

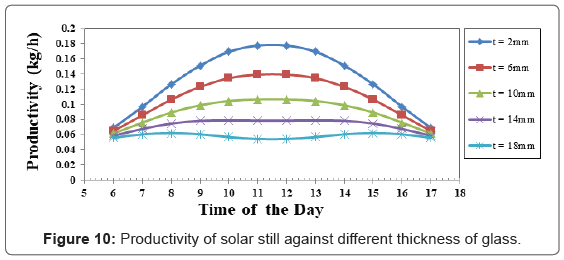

Thickness of solar still glass: Similarly, an interesting parameter that affects the design and productivity of still is the thickness of the glass of solar still. There is wide range of thick glass available of different thickness that may employ in solar still. The model greatly predicts the thickness effect on productivity [1,14]. Figure 10 shows the variation of thickness and its effect on distillation quantity. Higher the value of thickness, less productivity. This is due to mainly two reasons firstly high thickness provides higher conduction resistance and less heat transfer to the water from the incoming radiation. Secondly it is difficult to cold down or lowers the temperature of the still if it has high thickness [26]. So, this reduces the productivity.

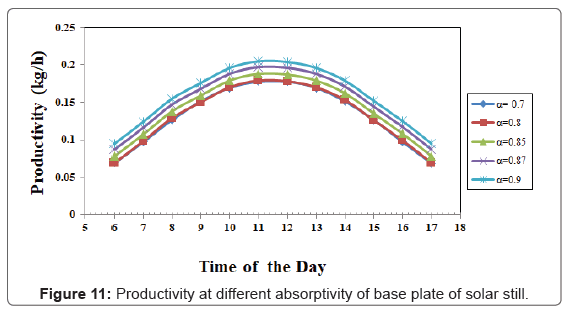

Absorptivity of water inside solar still glass: The model presented in this study can be used to examine the effect of physical design of solar still as well as properties of the saline water in its base. Absorptivity of water present inside the solar still also impacts the distillate productivity. Higher the absorptivity of water inside the solar still increases absorption of incoming solar radiation that result in more evaporation at a given time shown in Figure 11. The higher absorption also minimizes the heat loss from the base to surroundings.

The absorptivity range consider for this case is vary from 0.7 to 0.9. Figure 11 results the model prediction for productivity for these stated values of absorptivity. As the absorptivity increases, the productivity increases. This conclusion leads for the evaluation of different technique that can be employed for the increment of absorptivity of water inside the still. These may include the placement of charcoal, wick and violet dyes inside the single basin of solar still. That absorbs more radiation and enables water to evaporate more quickly. This can be the way to improve the overall performance ratio of the system.

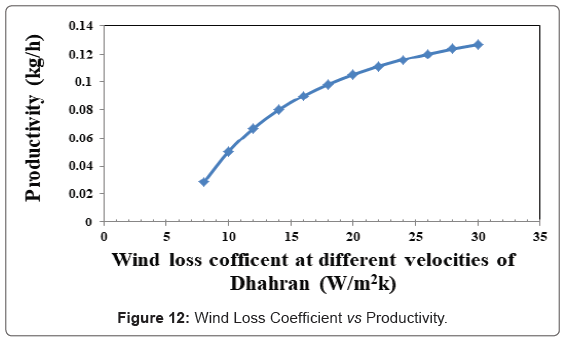

Ambient temperature: Figure 12 represent the subject productivity against the wind speed circulating at Dhahran. The wind speed is taken at average day of January. If the wind speed increases, heat transfer coefficient increases that result in more cooling by the convection from the wind. This greatly influences the productivity. Higher the cooling of solar still impacts the more evaporation due to temperature difference of still water and glass.

Modified solar still with reflector

After the detailed study of conventional solar still, it has observed that some modification is still required for increasing the productivity and decreasing heat losses to the surrounding. Since it is obvious that the productivity or the gain of fresh water from solar still is not much higher as compared to other techniques of desalination so there are two possible options for the modification. Either switches the whole system to active one with the addition of an external energy or modifying it keeping the system as passive. For commercial point of view, the productivity is not much higher so there should be some modification that is least in cost and increase the productivity up to noticeable level.

For keeping the cost of modification as low as possible a simple reflector of glass with some inclination is proposed in this study to examine the effect of this modification and to make comparison with conventional solar still.

Energy comparison

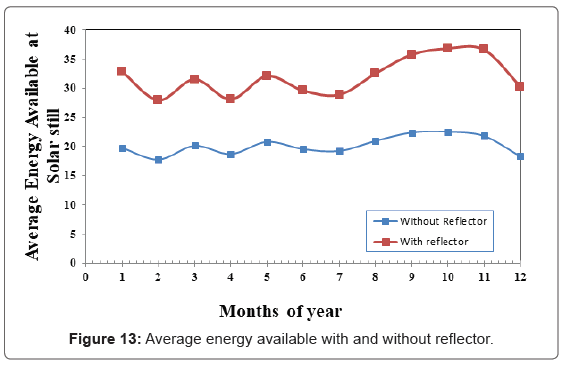

Since the problem associated with solar still is the variation of radiation through the year. It has been tackled by the modification in form of reflector. Due to additional reflector, high energy is available on the solar still and less reflection losses from the glass. The higher the available energy on glass results in more productivity for the same size of still as well as same water quantity of water in its basin.

Figure 13 represent the energy for the whole year. In similar fashion the energy with and without reflector is presented on the Figure 14 for one complete average day of April at Dhahran. Energy radiated on the glass of the still is high in case of reflector. It is also noted that there is no significance difference at the early hours of the day and same goes for the late hours of sun. However, at the peak hours of sun, the radiation is high for the reflector. This ensure that contribution of reflector greatly influence the productivity near solar noon hours.

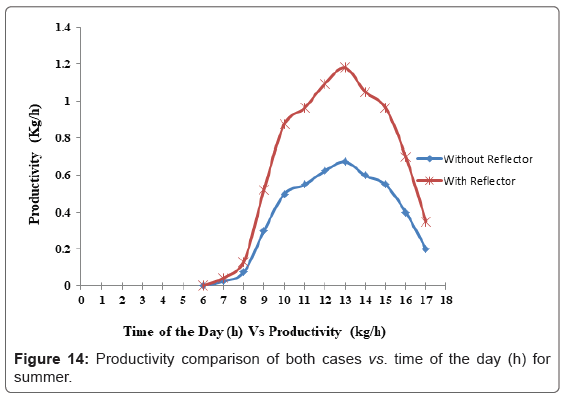

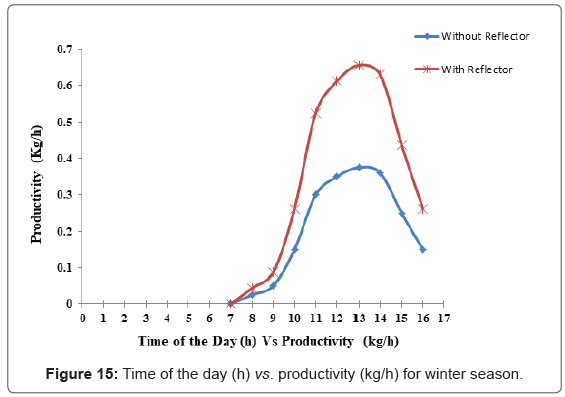

Productivity comparison for summer and winter season for both cases

As stated earlier, the purpose of this study is maximizing the productivity of solar still by making detail design analysis of conventional solar still. Based on the observation optimum set of design constraints are recommended. Season variation is an important parameter that effects the productivity of the still. Summer season is more energy intensive. During summer season, we have more solar hours. This directly implies that there is more energy available to the solar still for evaporation of water. On the other hand, winter season encompasses less solar hours. This results less amount of energy available to the still. Based on all these factors mentioned above, it become a factor of prime importance to study the effect of seasonal variation effects of the productivity of the still. Productivity of the still with reflector and without reflector in the summer season is compared in the Figure 14.

Similarly, solar energy is available for less number of hours. Consequently, we have less energy available for the day in the winter season. Other factors also change during the winter season including air temperature. Although, decreasing temperature causes reduction in glass and water temperature but it also accelerates the process of condensation on the still cover. But seasonal negative effect on the productivity dominates. Consequently, we have less productivity as compared to summer season. This can be seen by comparing Figure 14 and Figure 15.

Water and glass temperature comparison in summer and winter

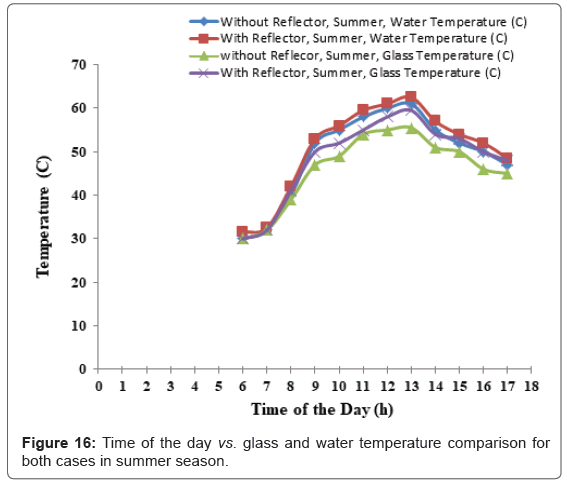

Water and glass temperature are two important factors in determining the productivity of the solar still. Water temperature is driving force for the evaporation of water. Therefore, it is beneficial to have more water temperature for increased productivity. On the other hand, glass temperature is controls the rate of condensation of the vapours for distillate formation. Therefore, less glass temperature means increased rate of condensation. It directly implies more product flow rate. But water temperature can be separately dealt, as it somehow linked the water temperature as glass is the medium that transmit the solar energy to the water to rise.

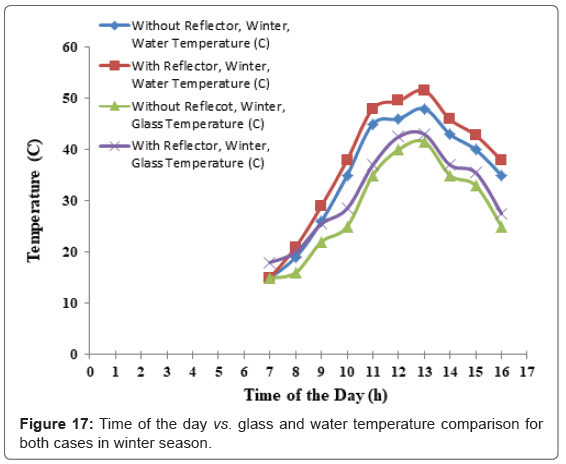

Seasonal variation also impacts the water and glass temperate. As stated earlier, water temperature defines the rate of evaporation and glass temperature defines the rate of condensation of surface of glass cover. Therefore, it is of prime importance to study the impact of seasonal variation on the temperature of the water and glass in both summer and winter seasons. Figure 16 And Figure 17 summarizes the temperature variations in both summer and winter for both cases including the design with reflector and without reflector. More water temperature means more productivity and vice versa. On the other hand, high glass temperature directly implies less condensation rate and consequently less productivity.

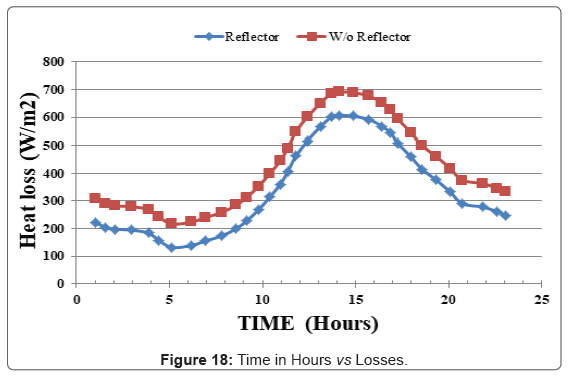

Heat loss comparison

With the modified design of solar still, the energy loss is less from the glass to the air or surrounding. Since it has been studied through given model that the loss of total energy i.e. radiation, convection and evaporation are less in comparison with the conventional one. Figure 18 represent the sum of all three types of energy losses throughout the day for case of reflector and non-reflector. This shows that with the modification of minimum cost, energy can be saved in form of substantial difference. Otherwise, this energy is loss to the surrounding or air from the glass. Although this is based on purely the parametric study and no such results have been reported through experimentally in the previous researched done on this topic.

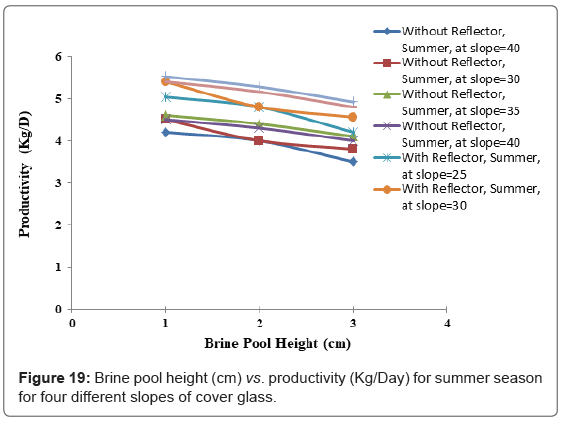

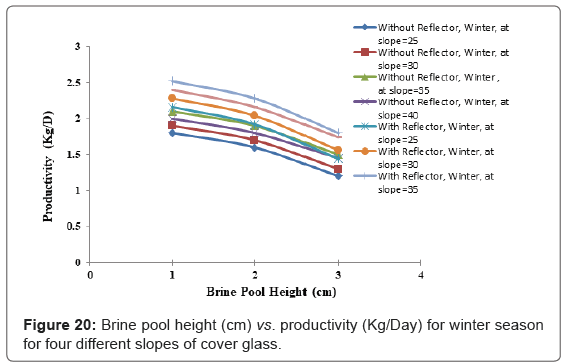

Brine pool height effect comparison for both cases in summer and winter

Brine pool height in the still basin and slope of the cover are really important factors in determining the productivity of the still. Current study reveals that increasing brine pool height decreases the productivity of the still. There different brine pool heights were tested including 1 cm, 2 cm and 3 cm. It was revealed that 1 cm brine pool height gives maximum productivity.

An effort is made to simultaneously study the effect of brine pool height for summer and winter for different glass cover slopes of 25°, 30°, 35° and 40°. It was concluded that 35° gives maximum productivity as compared to rest of three cases under consideration. Figure 19 compares the productivity of still with above three slopes for summer season with reflector and without reflector.

Similarly, productivity of the still for both cases including conventional and modified solar still at different slopes of 25°, 30°, 35° and 40° for winter season have plotted in the Figure 20. Trend is like the previous case as maximum productivity is obtained at slope of 35° and brine pool height of 1 cm. Comparison of the Figure 19 and Figure 20 shows that productivities at all slopes and for both cases in winter is less than the summer productivity due less number of solar hours in the winter. This may be also due to the less water temperature in the basin of still in the winter.

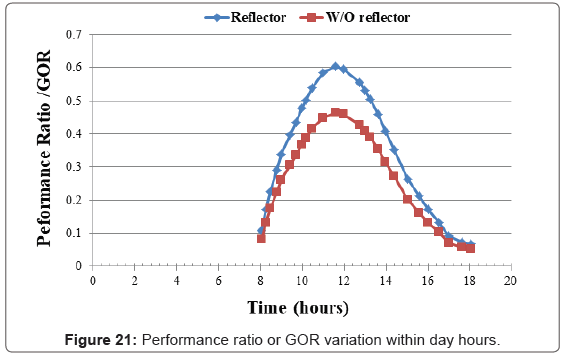

Comparison of gain output ratios or performance ratio

Figure 21 shows the relationship between the performance or GOR of conventional solar still and still that have reflected mirror for concentrated solar radiation. More radiations concentrated on glass results in more evaporation of still and less energy loss to the surrounding. Higher the incoming solar energy has direct relations with the performance ratio. GOR is the ratio of distillate amount produce to the incoming energy. The incoming energy is same for a particular day at a location, so the input energy is same for both the case but reflector enhance the distillate production so the GOR of reflector is high for modified case. Noteworthy the performance is high especially at time of solar noon. This below study is for the month of April based on the average monthly radiation at slope angle of 45 degree in Dhahran.

Conclusion

Conventional solar still has been modeled and results are validated. Sensitivity analysis has performed on the Engineering Equation Solver (EES) to analyze the degree of effect of different design variables and operating condition on performance of solar still. Design parameters includes slope of glass cover, its thickness and temperature, while air temperature, its speed and still’s water absorptance are studied for the optimum productivity from solar still.

Based on the analysis performed of conventional still, a simple design modification that can be made with minimum input of design cost is proposed i.e. a reflector/mirror of high reflectance on top of solar body. Work is extended by incorporating this modification in mathematical model. Comparison for the performance of still is made for both cases referencing the same set of input parameters and operating conditions. Principle conclusions have been drawn for both cases for selection of optimum productivity based on different variables.

The complete work is studied for the case of Dhahran KSA at latitude of 26.231° N. All cases are evaluated at slope of still of 45° for the study where slope is fixed. The average day of month of April is made as reference for the comparison of still. The values of radiations associated ambient temperature and corresponding values of wind velocities have been used.

1. Moreover, for all cases thickness of glass is fixed as 4 mm with water absorptivity 0.7. Based on daily radiation at Dhahran for a specified day, GOR of modified design of still is found to be 16% higher than simple still where as it reaches to 33% at peak hours of solar noon.

2. For radiations based on average day in month of April at Dhahran KSA, the maximum GOR that the modified solar still can provide at ambient temperature of 38°C at its slope of 45 degree is 0.61 when compared with simple design of GOR 0.44.

3. For any solar hour of day, reflector is capable to enhance the fresh water production 90 g/h (minimum) more than simple one. While the average rate of production in modified design is 230 g/h for mentioned day.

4. It is widely studied by all researchers that main drawback of solar still with other methods of desalination technique is the high heat loss to surrounding. The model predicts maximum heat loss for regular design of still 700 W/m2. But the modified design is capable to reduce it to 588 W/m2 at solar noon for same operating conditions.

5. In both design the glass temperature is found to increase along the day. The productivity of simple still is affected by glass temperature and it is reduced upon the increment of glass temperature. Surprisingly this does not happen with the modified design, although the glass temperature increases but the evaporation rates of water surpass its effect and overall result is higher productivity.

Other design parameters and operation conditions such as glass thickness, its slope, absorptivity of still and wind velocity and wind temperature have trend of effect for both cases. The effect of these parameters on performance of still are discussed below

1. Higher the thickness of glass of solar still lowers the productivity of fresh water. The optimum thickness which provides higher productivity for complete day is 6 mm.

2. Slope of glass cover effect the productivity. Model predicts the maximum productivity at zero slopes. This case is not possible from practical aspect for collection of water at one end of still. The optimum slope of cover for wide range of productivity is near around the latitude of location i.e. in b/w 30-45°.

3. Absorptivity of still may be changed by addition of elements such as charcoal and wick. Absorptivity of still water has not much significant impact on the productivity. The trend of productivity against the all-possible values of absorptivity (0.7-0.9) show minimal change in productivity.

4. High ambient temperatures are unfavorable for still productivity. The evaporation rate decreases if the ambient temperature increases. This is because high ambient temperature leads to the high glass temperature that decreases the cooling of the glass and hence less condensation due to less temperature difference between evaporated water and glass.

5. High wind speed results in high air heat transfer coefficient outside the glass so this result in cooling of glass surface and hence more productivity due to increase in temperature difference of water and glass cover. However, productivity is not much affected at very high values of air heat transfer coefficient. The change in productivity is only around 100 g/h for substantial change of heat transfer coefficient from 20 W/m2k to 30 W/m2k. At very high values of wind speed, i.e. greater than 35 W/m2k productivity is nearly constant of about 120 g/h.

6. Three different brine pool heights of 1 cm, 2 cm, and 3 cm are considered in the current simulation. Results show that increasing brine pool height decreases the productivity of the still. Maximum productivity was calculated at brine pool height of 1 cm.

7. Glass and water temperatures are also two important factors in determining the productivity of the both type of stills including with and without reflector. Glass and water temperature rise is higher in summer season than in winter seasons. This directly implies more productivity in the summer as explained earlier in detail.

8. Maximum water temperature obtained in summer at 1 cm brine pool height is reaching maximum up to 48°C without reflector and 51.5oC in the case with reflector. These values for winter seasons are 41.5°C and 43°C for both cases respectively.

9. Simulation also concludes that glass temperature is always lower than water temperature by 1 to 2°C irrespective the season of the year.

References

- Kumar PN, Manokar AM, Madhu B, Kabeel AE, Arunkumar T (2017) Groundwater for Sustainable development experimental investigation on the effect of water mass in triangular pyramid solar still integrated to inclined solar still. Groundw Sustain Dev 5: 229-234.

- Selvaraj K, Natarajan A (2018). Factors influencing the performance and productivity of solar stills - A review. Desalination 435: 181-187.

- Hansen RS, Murugavel KK (2017) Enhancement of integrated solar still using different new absorber configurations : An experimental approach. Desalination 422: 59-67.

- Feilizadeh M, Soltanieh M, Ashrafmansouri S, Estahbanati MRK, Jafarpur K (2017) Optimization of geometrical dimensions of single-slope basin-type solar stills. Desalination 424: 159-168.

- Panchal H, Mohan I (2017) Various methods applied to solar still for enhancement of distillate output. Desalination 415: 76-89.

- Naroei M, Sarhaddi F, Sobhnamayan F (2018) Efficiency of a photovoltaic thermal stepped solar still : Experimental and numerical analysis. Desalination 441: 87-95.

- Pal P, Dev R, Singh D, Ahsan A (2018) Energy matrices, exergoeconomic and enviroeconomic analysis of modified multi – wick basin type double slope solar still. Desalination 447: 55-73.

- Al-harahsheh M, Abu-arabi M, Mousa H, Alzghoul Z (2018) Solar desalination using solar still enhanced by external solar collector and PCM. Appl Therm Eng 128: 1030-1040.

- Abu-arabi M, Al-harahsheh M, Mousa H, Alzghoul Z (2018) Theoretical investigation of solar desalination with solar still having phase change material and connected to a solar collector. Desalination 448: 60-68.

- Bait O (2019) Exergy, environ-economic and economic analyses of a tubular solar water heater assisted solar still. J Clean Prod 121: 630-646.

- Saadi Z, Rahmani A, Lachtar S, Soualmi H (2018) Performance evaluation of a new stepped solar still under the desert climatic conditions. Energy Convers Manag 171: 1749-1760.

- Nayi kh, Modi kv (2018) Pyramid solar still : A comprehensive review. Renew Sust Energ Rev 81: 136-148.

- Modi kv, Modi JG (2018) Performance of single-slope double-basin solar stills with small pile of wick materials. Appl Therm Eng 149: 723-730.

- Arunkumar T, Kabeel AE, Raj K, Denkenberger D, Sathyamurthy R, et al. (2018) Productivity enhancement of solar still by using porous absorber with bubble-wrap insulation. J Clean Prod 195: 1149-1161.

- Manokar M, Winston DP (2017) Comparative study of finned acrylic solar still and galvanised iron solar still. Mater Today Proc 4: 8323-8327.

- Yousef MS, Hassan H (2019) An experimental work on the performance of single slope solar still incorporated with latent heat storage system in hot climate conditions. J Clean Prod 209: 1396-1410.

- Tabrizi FF, Dashtban M, Moghaddam H (2010) Experimental investigation of a weir-type cascade solar still with built-in latent heat thermal energy storage system. Desalination 260: 248-253.

- Nazari S, Safarzadeh H, Bahiraei M (2019) Performance improvement of a single slope solar still by employing thermoelectric cooling channel and copper oxide nano fluid : An experimental study. J Clean Prod 208: 1041-1052.

- Xie G, Xiong J, Liu H, Xu B, Zheng H, et al. (2015) Experimental and numerical investigation on a novel solar still with vertical ripple surface. Energy Convers Manag 98: 151-160.

- Gad HE, El-din SS, Hussien AA, Ramzy K (2015) Thermal analysis of a conical solar still performance: An experimental study. Sol Energy 122: 900-909.

- Deshmukh HS, Thombre SB (2017) Solar distillation with single basin solar still using sensible heat storage materials. Desalination 410: 91-98.

- Ibrahim GM, Elshamarka SE (2015) Performance study of a modified basin type solar still. Sol Energy 118: 397-409.

- Still SS, Al-hinai H, Al-nassri MS, Jubran BA (2002) Parametric investigation of a double-effect solar still in comparison with a single-effect solar still. Desalination 150: 75-83.

- Rahmani A, Boutriaa A (2017) Numerical and experimental study of a passive solar still integrated with an external condenser. Int J Hydrogen Energy 42: 29047-29055.

- Kabeel E, Omara ZM, Essa FA, Abdullah AS, Arunkumar T (2017) Augmentation of a solar still distillate yield via absorber plate coated with black nanoparticles. Alexandria Eng J 56: 433-438.

Citation: Khan M, Mustafa M (2019) Solar Still Distillate Productivity Enhancement by Using Reflector and Design Optimization. Innov Ener Res 8: 222

Copyright: © 2019 Khan M, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 5625

- [From(publication date): 0-2019 - Dec 18, 2025]

- Breakdown by view type

- HTML page views: 4597

- PDF downloads: 1028