Water Desalination using Solar Energy: Humidification and Dehumidification Principle

Received: 17-Aug-2015 / Accepted Date: 09-Sep-2015 / Published Date: 11-Sep-2015

Abstract

The objective of this paper is to demonstrate an experimental investigation of a water desalination system using solar energy that applies the humidification and dehumidification principle. A prototype/test rig was designed, fabricated and assembled in order to study the effect of water flow rate and the humidifier inlet water temperature against desalinated water productivity. The system consists of a spray type with no packing bed humidifier, a copper coiled Dehumidifier, a flat plate solar water heater, an air blower, a water pump, a water flow meter, a water tank, three thermocouples and four gate water valves. The system is based on an open waterclosed air cycle. A new approach is used such that the humidifier, dehumidifier and the connecting duct between them are made of Poly Vinyl Chloride (PVC) pipes; which makes the system lighter in weight, doesn’t need insulation unlike metal sheets and anti-rust. The effect of operating parameters on the system characteristics has been controlled, measured and investigated. It was found that the hot inlet water temperature to the humidifier has a significant impact on the water productivity; they are relatively proportional, thus, the more the hot inlet water temperature increases, the more the water productivity increases. It was also found that Saline water flow rate has an impact on the water productivity but inversely proportional.

Keywords: Solar energy; Humidification; Dehumidification; Water; Desalination

17873Introduction

Water scarcity has become a fast growing major global challenge, which is mainly linked to climate change. One third of the world’s population already live in areas of moderate to high water crisis; that is, around 1.5 billion people suffer from the lack of ready access to drinking water, with 80 countries suffering from water scarcity. Water use has yet to adapt to the realities of scarcity, with much action that could be taken in water conservation and water re-use. The health of river systems is threatened by overuse and pollution. Rivers are often no longer able to provide the volumes of purified water needed with the increasing impact of pests and diseases. With the introduction of powerful pumping (from deep underground) and piping (across long distances), groundwater aquifers are increasingly being depleted well beyond sustainable recovery levels; this also has lead in many cases to brackish water with high concentrations of dangerous minerals and resulting in health problems as well. Desalination has become a major new source of fresh water, tapping into the vast reserves of seawater and brackish water. It is especially useful where water conservation and water re-use either have limited potential or face major problems of implementation [1].

Desalination processes

Desalination of seawater or brackish water is generally performed by either of two main processes; by evaporation of water or by use of a membrane to separate fresh water from a concentrate. In the phasechange or thermal processes, the distillation of seawater is achieved by utilizing a thermal energy source. The thermal energy source might be obtained from a conventional fossil-fuel, nuclear, or from a renewable resource, like solar energy or geothermal energy. In the membrane processes, electricity is used either for driving high pressure pumps or for establishing electric fields to separate the ions. The most important commercial desalination processes based on thermal energy are multistage flash (MSF) distillation, multiple effect distillation (MED) and vapor compression (VC), in which compression may be accomplished thermally (TVC) or mechanically (MVC) [2].

Fortunately, there are many parts of the world that have exploitable renewable sources of energy that could be used to drive desalination processes. Thus, desalination processes by using solar radiation; solar desalination processes are promising alternatives that can partially support human needs for fresh water, using an environmentally friendly energy source. This would be especially important for tribes or small groups inhabiting remote areas.

Solar desalination requires an efficient method of evaporation and condensation at relatively low temperatures. Therefore, the most promising development in solar desalination to enhance productivity efficiency is the use of the humidification and dehumidification principle. Combining the principle of humidification-dehumidification with solar desalination appears to be the best method of water desalination with solar energy.

Hence, solar desalination offers is considered to be an ecological solution that uses renewable energy efficiently.

Humidification dehumidification principle

The Humidification Dehumidification (HDH) process is similar to the natural hydrological process where the sun heats the ocean, and then the water in the ocean evaporates to form clouds. Finally, the clouds are condensed and water is obtained as rainfall. The HDH process tends to replicate this natural hydrological cycle.

In the HDH process, evaporation takes place by the mixing of hot water with dry air in the humidification chamber, and then passed to the dehumidification chamber, where a condenser is used to obtain fresh water.

One advantage of the HDH process is that it is seen as the most promising desalination technology compatible with renewable energy systems, especially solar energy. In the HDH system, the humidified air flows in a circuit driven by natural or forced convection between dehumidification chamber and the humidification chamber. The air is distributed on a wetted media and then moves in either co-current or counter-current flow to the hot feed (seawater) through the humidification chamber and becomes saturated. In the dehumidification chamber, water vapor from the humid air condenses on a heat exchanger. The distillate runs down the heat exchanger and collected in a basin. The heat of condensation is mainly transferred to the cold seawater feed flowing through the heat exchanger. Thus, the temperature of the feed in the condenser rises. This feed can be discharged or further heated in a solar collector or by waste heat [2].

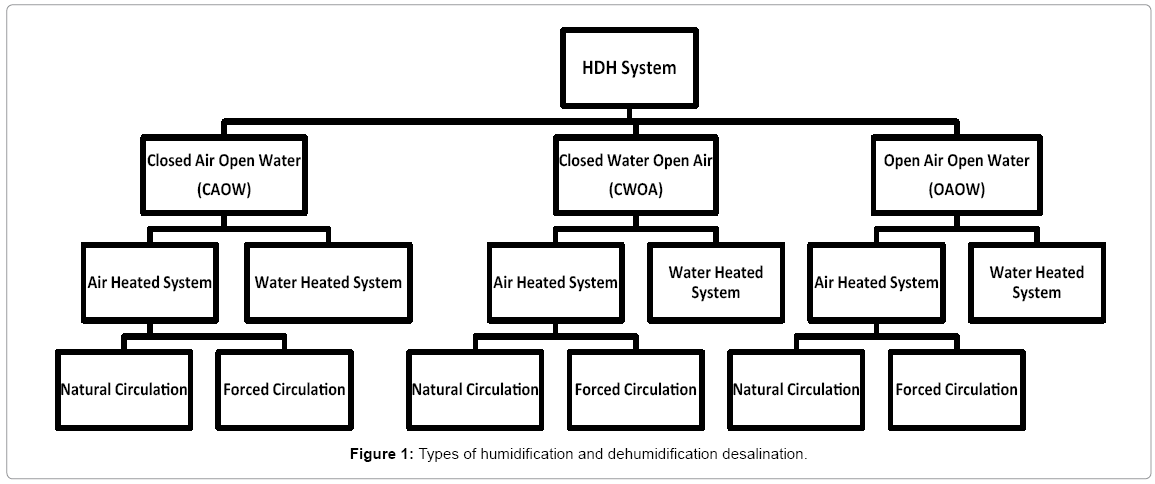

The HDH process can be classified according to cycle configuration, flow mechanism and heat transfer medium (Figure 1). They are generally classified into the closed water open air (CWOA), closed air open water (CAOW) and Open Air Open Water (OAOW) Systems.

In CAOW, the air is circulated between the humidification chamber and the dehumidification chamber in a closed loop while the water is not re-circulated through the dehumidification chamber but rather discharged or partially re-circulated in the humidification chamber to recover heat., this cycle configuration is associated with the need of large amounts of cooling water which at same time serve as the hot feed. Almost in all related research works, the CAOW configuration is adopted [3,4].

In CWOA, the water is circulated in a closed loop and only make up water is added while the air is discharged to the ambient. The water is usually heated is such systems. It is used to emphasize recycling the brine through the system to ensure a high utilization of the salty water for freshwater production. Thus the system requires less cooling water. Very few literature based on this cycle configuration have been reported. One disadvantage of the CWOA is that the temperature of cooling water at the dehumidification chamber rapidly increases. This limits the dehumidification of the humid air resulting in a reduced water production compared to the CAOW system [5].

Test rig/prototype and expermintal setup

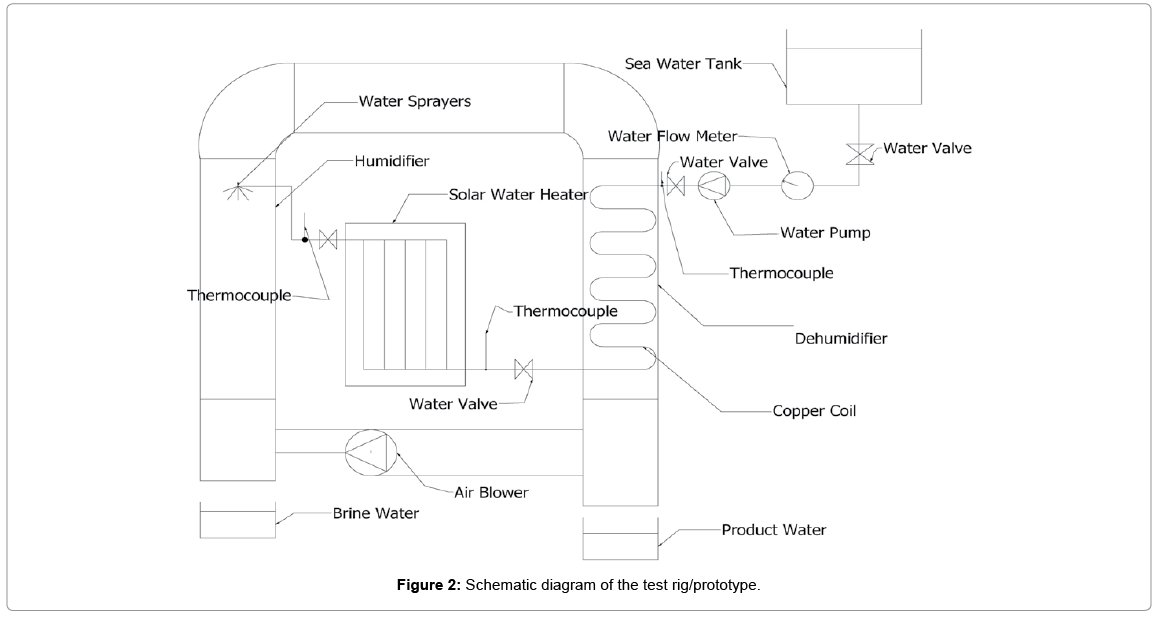

An Open Water Closed Air (OWCA) Humidification and Dehumidification System is used which consists of the following (Figure 2 and Picture 1):

i. A spray type humidifier with no packing bed was fabricated and assembled. It consists of a 160 mm diameter and 1 m long Polyvinyl Chloride (PVC) pipe-as the body-and two locally manufactured sprayers with nozzle diameter of 0.5 mm. The whole made for the sprayers was fixed with thermal silicon to prevent leakage, a PVC elbow at the top of the pipe to connect with the Dehumidifier, a PVC T-Connector at the bottom to connect with the Air Blower and to drain the brine water.

ii. A Dehumidifier which consists of a Copper coil with 140 mm diameter and 650 mm long, tubes of 12.7 mm diameter and total length of 15 m that are added inside a PVC pipe of 160 mm Diameter and 1 m long, with same connection parts as the Humidifier (elbow at the top and T-Connector at the bottom).

iii. An Air Blower of 0.5 Horse-Power and 2850 RPM is used to circulate air in the closed cycle. It is connected to the Humidifier with a 110 mm flexible duct connecter and connected to the Dehumidifier through a 160 mm PVC pipe.

iv. A Water Pump of 0.5 Horse-Power and 2850 RPM is used to circulate the water through the system.

v. A Flat Plate Solar Water Heater was designed and fabricated with frame dimensions 1400 mm×800 mm and copper tubes with 25.4 mm Diameter and 12 m long, adjusted to be put with 30° inclination angel with 155° SE orientation.

vi. A water tank is placed next to the test rig, 1 m diameter and 1.5 m length.

vii. Three thermocouples were placed to measure water temperatures before the copper tubes in the dehumidifier, before the solar water heater, and after the solar water heater (before the Humidifier).

viii. A water flow meter is added before the water pump to measure the water flow rate.

ix. Four gate water valves to control and adjust water flow rate were put between the water tank and the Water flow meter, between the water pump and the Dehumidifier, between the solar water heater and the Dehumidifier, and between solar water heater and the Humidifier.

The humidifier, dehumidifier and the connecting duct between them are made of Poly Vinyl Chloride (PVC) pipes; which makes the system more light in weight, doesn’t need insulation unlike metal sheets and anti-rust.

The operation of the prototype is as follows: The pump circulates water from the saline water tank through the copper pipes in the dehumidifier, and then through the flat plate water solar heater, and then through the sprayers into the humidifier. The water flow rate is measured with the water flow meter. The water temperature is measured through three different points (before the copper coil, after the copper coil and after the solar heater). The air blower circulates the humid air through the cycle. The fresh water is collected in a flask under the dehumidifier. The brine is collected in a flask under the humidifier.

The purpose of the experiment is to produce fresh water out of the saline water by using solar desalination with Humidification and Dehumidification while measuring, controlling and recording some parameters such as the water flow rate and the water temperatures (Figure 2 and Picture 1).

Results And Discussions

The system was tested and operated on several different days within the times between 10:00 am and 2:00 pm, where the solar intensity is most strong and effective. However, those days were in winter/spring season and it was operated in a relatively low range of temperatures. Regardless, saline water flow rate, desalinated water productivity, saline water temperature, temperature before the solar heater and temperature after the solar heater were measured and recorded. Saline water flow rate was controlled by the gate water valves, and the experiment was done with two different flow rates; temperatures and water productivity were measured accordingly.

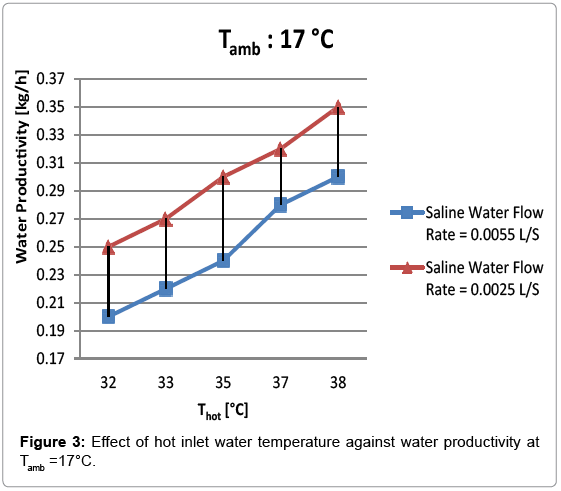

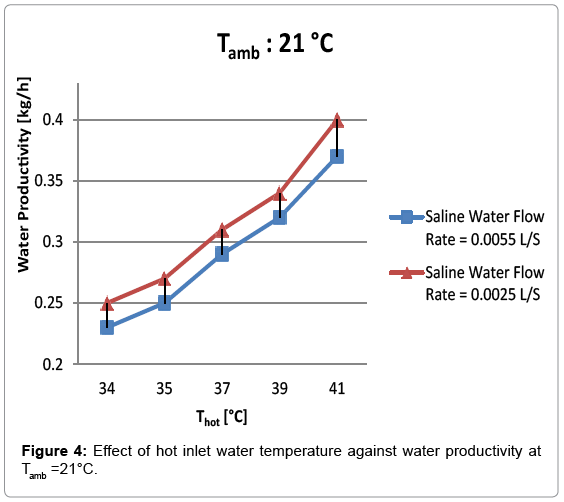

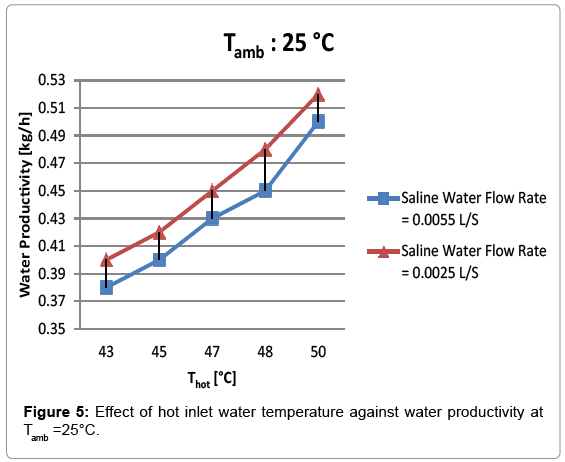

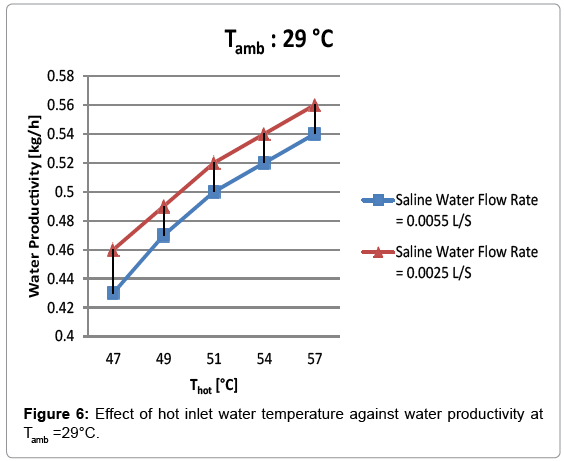

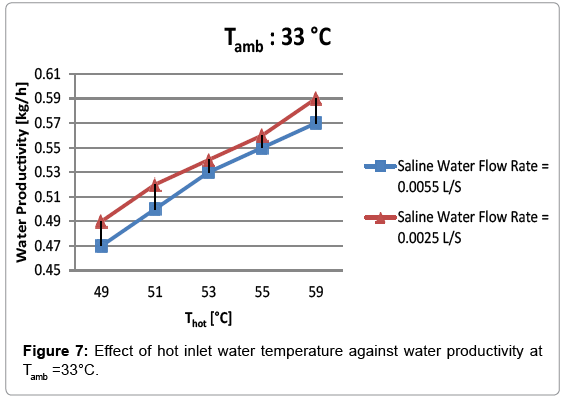

The graphs below (Figures 3-7) show the measured values and recordings; they show the relation between the hot inlet water to the humidifier (Thot) in °C against water productivity in kg/h. The graphs were created based on results taken on several different days of experiments that were done during the months of March, April and May 2015 [21-24]. The air ambient temperatures were 17°C, 21°C, 25°C, 29°C and 33°C. The saline water flow rate was controlled and measured to be 0.0055 L/S and 0.0025 L/S.

The effect of operating parameters on the system characteristics has been controlled, measured and investigated.

It was found that the hot inlet water to the humidifier has a significant impact on the water productivity.

- With the increase of hot inlet water temperature from 32°C to 38°C while Tamb was 17°C, the water productivity increased by 50% (from 0.2 kg/h to 0.3 kg/h) while saline water flow rate was 0.0055 L/S. Almost the same ratio was recorded while saline water flow rate was 0.0025 L/S (Figure 3).

- With the increase of hot inlet water temperature from 34°C to 41°C while Tamb was 21°C, the water productivity increased by 60% (from 0.23 kg/h to 0.37 kg/h) while saline water flow rate was 0.0055 L/S. Almost the same ratio was recorded while saline water flow rate was 0.0025 L/S (Figure 4).

- With the increase of hot inlet water temperature from 43°C to 50°C while Tamb was 25°C, the water productivity increased by 31% (from 0.38 kg/h to 0.5 kg/h) while saline water flow rate was 0.0055 L/S. Almost the same ratio was recorded while saline water flow rate was 0.0025 L/S (Figure 5).

- With the increase of hot inlet water temperature from 47°C to 57°C while Tamb was 29°C, the water productivity increased by 25% (from 0.43 kg/h to 0.54 kg/h) while saline water flow rate was 0.0055 L/S. Almost the same ratio was recorded while saline water flow rate was 0.0025 L/S (Figure 6).

- With the increase of hot inlet water temperature from 49°C to 59°C while Tamb was 33°C, the water productivity increased by 21% (from 0.47 kg/h to 0.57 kg/h) while saline water flow rate was 0.0055 L/S. Almost the same ratio was recorded while saline water flow rate was 0.0025 L/S (Figure 7).

Generally, it was found that the hot inlet water temperature to the humidifier has a significant impact on the water productivity; they are relatively proportional, thus, the more the hot inlet water temperature increases, the more the water productivity increases. It was also found that Saline water flow rate has an impact on the water productivity but inversely proportional (Table 1).

| Research name | WaterProductivity | Thot | Saline Water Flow Rate |

|---|---|---|---|

| Nawayseh et al. [8,9] | 0.325 kg/h | 71-78°C | Not given |

| Kabeel A. E. and Emad M. [17] | 1.356 kg/h | Not given | 4.5 kg/s |

| Amer et al. [18] | 5.8 kg/h | 50-85°C | 0.0856-0.2772 kg/s |

| Nafey et al. [6] | 0.43 kg/h | 25.94-36.75°C | 0.005-0.045 kg/s |

| Hermosillo et al. [19] | 1.45 kg/h | 68.9-44.6°C | 0.012-0.023 kg/s |

| Yamali and Solmus[14] | 1.1 kg/h | 35.5-50°C | 0.085-0.115 kg/s |

| Yuan G and Zhang H. [20] | 1.79 kg/h | 38-92°C | Not given |

| Dai Y.J. and Zhang H.F. [21] | 1.8 kg/h | 65-85°C | 0.0378 kg/s |

| Al-Enezi et al. [22] | 0.266 kg/h | 35-45°C | 0.075 kg/s |

| Farid M., Al-Hajaj A. [23] | 0.5 kg/h | 49-63°C | 0.060-0.12 kg/s |

| Eslamimanesh and Hatamipour[24] | 0.178 kg/h | 35-28°C | 3.3 kg/s |

| Farsad S. and Behzadmehr A. [25] | 2.7 kg/hr | 15-25 °C | 0.4-1.4 kg/s |

| Farid et al. [26] | 0.42 kg/h | 60-63°C | Not given |

| Fath H.E.S. and Ghazy A. [7] | 0.45 kg/h | 40-60°C | 0.0001-0.0003 kg/s |

| Orfi et al. [27] | 1.163 kg/h | Not given | 0.08 kg/s |

| Al Sahali M. and Ettouney H. [28] | 2.9 kg/h | 60-90°C | 0.003-0.007 kg/s |

Table 1: Previous Researches Values.

Conclusion

A Solar Water Desalination lab scale experimental system using Humidification and Dehumidification principle was designed, constructed, assembled and tested in the Faculty of Engineering, Ain Shams University, Cairo, Egypt (30° 3’ 54” N, 31° 16’ 47” E); to prove the concept of this desalination technique and to study the effect of inlet water to the Humidifier against desalinated water productivity.

The system consists of a spray type with no packing bed humidifier, a copper coiled shell and tube Dehumidifier, a flat plate solar water heater, an air blower, a water pump, a water flow meter, a water tank, three thermocouples and four gate water valves.

It was found that the desalinated water productivity increased significantly with the increase of the inlet water temperature to the humidifier. A productivity of 0.59 kg/h was achieved with hot inlet water temperature of 59°C and ambient temperature of 33°C which is considered quite good productivity given the size of the prototype, no packing in the humidifier, number of sprayers, operating at low temperatures because of the time of the year.

Some improvements are suggested in a future work in order to develop industrial scale, long term production on fresh water such as but not limited to the following:

• Packing bed to be included in the humidifier to increase the humidity of the carried air out of the humidifier

• More nozzles with smaller diameter to be considered, also to increase humidity of the carried air out of the humidifier.

• Usage of water storage tank between the solar water heater and the humidifier, in order to maintain relatively constant high inlet temperature to the humidifier as time is needed to increase water temperature in the solar water heater.

• Separate cooling cycle can be used through the copper coil in the dehumidifier to increase the condensation rate of the desalinated water. However, this has a disadvantage, that is, the preheating of water to the solar water heater will be lost.

• Air solar heater can be used as well, in order to increase the air capacity of the carrying water. This will consequently increase the humidity.

References

- Müller-Holst H, Engelhardt M, Herve M, Schölkort W (1999) Small-scale thermal seawater desalination simulation and optimization of system design.

- Prakash Narayan G, Mostafa HS (2010) The potential of solar-driven humidification–dehumidification desalination for small-scale decentralized water production. 1187-1201.

- Saadawy MS, Karameldin A, Negeed ER (2008) A Novel super-cooled humidification-dehumidification system driven by thermal vapor compression unit for seawater desalination, 3: 186-214.

- Xiong RH (2005) Experimental investigation of a baffled shell and tube desalination column using the humidification-dehumidification process, 180: 253-261.

- Nafeya AS, Fathb HES, El-Helabya SO, Solimana A (2003) Solardesalinationusing humidification–dehumidificationprocesses. Part II. An experimental investigation, 45: 1263-1277.

- Hassan ES, Fath AG (2001) Solardesalinationusing humidification-dehumidification technology, 142:119-133.

- Cihan Y, Ismail S olmus (2014) A Parametric Study on Humidification-Dehumidification (HDH) desalination unit powered by solar air and water heaters, 86: 568-575.

- Naser Kh, Mohammed MF, Abdul AO, Ahmad S (1999) Solar desalination based on humidification process. 40: 1441-1461.

- Orfia J, Laplanteb M, Marmoucha H, Galanisb N, Benhamouc B, et al. (2004) Experimental and theoretical study of a humidification–dehumidification water desalination system using solar energy. Desalination. 168: 151–159.

- Said A1-Hallaj MM (1998) Solar desalination with a humidification--dehumidification cycle. 120: 273-280.

- Younis MA, Darwish DM (1993) Experimental and theoretical study of a humidification–dehumidification desalting system. Desalination. 94: 11-24.

- Yamale C, Solmusf I (2008) A solar desalination system using humidification–dehumidification process: experimental study and comparison with the theoretical results. 220: 538–551.

- Chafik E (2003) “A New Seawater Desalination Process Using Solar Energy,†Desalination.153: 25-37.

- AbdElKader M, Aref A, Gamal HM, Yasser E (2014) A Theoretical and Experimental Study for a Humidification-Dehumidification (HD) Solar Desalination Unit. 3: 108-120.

- Kabeel AE, Emad El-Said MS (2012) “A Hybrid Solar Desalination System of Air Humidification Dehumidification and Water Flashing Evaporation Part I. A Numerical Investigation,†Sixteen International Water Technology Conference, IWTC16, Istanbul, 7-10 May.

- Amer EH, Kotb H, MostafaGH, El-Ghalban AR“Theoretical and Experimental Investigation of Humidification-Dehumidification Desalination Unit,†249: 949–959.

- Hermosillo JJ, ArancibiaBulnes CA, Estrada CA (2012) “Water Desalination by Air Humidification: Mathematical Model and Experimental Study,†Solar Energy. 86: 1070–1076.

- Yuan GF, Zhang HF (2007) “Mathematical Modeling of a Closed Circulation Solar Desalination Unit with Humidification-Dehumidification,†Desalination. 205: 156-162.

- Dai YJ, Wang RZ, Zhang HF (2002) “Parametric Analysis to Improve the Performance of a Solar Desalination Unit with Humidification and Dehumidification,†Desalination. 142: 107–118.

- Al-Enezi G, Ettouney H, Fawzy N “Low Tempera-ture Humidification Dehumidification Desalination Process,†Energy Conversion and Management. 47:470-484.

- Farida M, Al-Hajaj AW (2005) “Solar Desalination with Humidification Dehumidification Cycle,†Desalination. 47: 470-484.

- Eslamimanesh A, Hatamipour MS (2009) “Mathematical Modeling of a Direct Contact Humidification-Dehumidification Desalination Process,†Desalination. 237: 296–304.

- Farsad S, Behzadmehr A (2011) “Analysis of a Solar Desalination Unit with Humidification-Dehumidification Cycle Using DOE Method,†Desalination. 278: 70-76.

- Farid MM, Parekh S, Selman JR, Al-Hallaj S (2003) “Solar Desalination with a Humidification-Dehumidification Cycle: Mathematical Modeling of the Unit,†Desalination. 151: 153-164.

- Orfi J, Galanis N, Laplante M (2007) “Air Humidification- Dehumidification for a Water Desalination System Using Solar Energy,†Desalination. 203: 471-481.

- Al-Sahali M, Hisham M (2008) “Humidification Dehumidification Desalination Process: Design and Performance Evaluation,†Chemical Engineering Journal. 143: 257-264.

Citation: Abu ElNasr M, Kamal M, Saad H, Elhelaly M (2015) Water Desalination using Solar Energy: Humidification and Dehumidification Principle. Innov Ener Res 4: 121.

Copyright: ©2015 Abu ElNasr M, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 27833

- [From(publication date): 12-2015 - Aug 16, 2025]

- Breakdown by view type

- HTML page views: 22220

- PDF downloads: 5613