Research Article Open Access

Influence of Repeat Pours of Addition Silicone Impressions on the Dimensional Accuracy of Casts

Mehta R1*, Wadhwa S1, Duggal N1, Kumar A2, Goel M3 and Pande S4

1 Department of Prosthodontics, Government Dental College and Hospital, Patiala-147001, Punjab, India.

2 Department of Pedodontics & Preventive Dentistry, Post Institute of Dental Sciences Rohtak-124001, Haryana, India.

3 Department of Oral and Maxillofacial Surgery, Post Institute of Dental Sciences Rohtak-124001 (Haryana) India.

4 Department of Prosthodontics, Baba Banarsi Das college of Dental Sciences, Lucknow, India.

- Corresponding Author:

- Dr. Richa Mehta, MDS

Department of Prosthodontics

Government Dental College and Hospital

Patiala-1 47001, Punjab, India

Tel: +919671487063

E-mail: richaips@gmail.com

Received Date: November 26, 2013; Accepted Date: January 10, 2014; Published Date: January 15, 2014

Citation: Mehta R, Wadhwa S, Duggal N, Kumar A, Goel M, et al. (2014) Influence of Repeat Pours of Addition Silicone Impressions on the Dimensional Accuracy of Casts. J Interdiscipl Med Dent Sci 2:108. doi: 10.4172/2376-032X.1000108

Copyright: © 2014 Mehta R, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Visit for more related articles at JBR Journal of Interdisciplinary Medicine and Dental Science

Abstract

Aims and objectives: To evaluate and compare the time dependent dimensional accuracy of polyvinyl siloxane impressions. Materials and methods: A brass master die containing two identical posts simulating two complete crown tapered abutment preparation was served as a standardized master model. Impressions were made with polyvinyl siloxane materials (monophase and regular body) using a brass made custom tray. The impressions were repeatedly poured at 15 min, 75 min, 24 hours, 48 hours and 1 week., Interabutment and intraabutment distance were measured in the recovered stone dies (type iv, kalrock) using a profile projector with an accuracy of 0.001 mm. Results: Results of this study indicated that the casts made were dimensionally accurate and the polyvinyl siloxane silicones are dimensionally stable impressions for one week period. Conclusion: Repeated pouring of the impressions at the five different time periods did not significantly affect the accuracy of the casts produced.

Keywords

Accuracy; Dimensional stability; Elastic recovery; Vinyl polysiloxane; Repeated pouring

Introduction

Making an impression represents a critical step in processing and fitting of a dental prosthesis. The definite impression should be accurate to fabricate restoration with ideal marginal fit, internal fit, interproximal contacts and occlusal contacts [1,2].

The impression materials are used to register or reproduce the form and relations of the teeth and the surrounding oral tissues. Dimensional accuracy and stability are the primary requisites of an impression material. Accuracy of an impression depends on properties of impression materials like thermal contraction, polymerization shrinkage, presence of volatile by products, elastic recovery, bulk of material and impression technique used [3]. Other factors which influence the accuracy of an impression are tray material, space between tray and tooth preparation, storage conditions, relaxation of stresses caused by the use of non-rigid trays, excessive seating pressure, too slow removal from the mouth or an impression removed before the polymerization is complete [4,5].

A variety of impression materials as silicones, polyether, polysulfide and alginate are available for crowns and fixed partial denture impressions. The addition-type silicone impression material i.e. polyvinyl siloxane is the most preferred material in the field of prosthodontics due to its favorable qualities, relative simplicity and reliability. Polyvinyl siloxane impression materials are reported to have precise detail reproduction, dimensional accuracy and stability, low creep, a relatively short setting time, moderate to high tear resistance and elastic recovery from undercuts [2,6]. The disadvantage of hydrophobicity of polyvinyl siloxane impression material has been overcome to some extent by addition of polyether carbosilane surfactants [7,8].

The accuracy and functional efficiency of prosthesis depends on an accurate impression which is reproduced on a gypsum cast. The accuracy of impression with repeat pours is of paramount importance as duplicate casts are usually required for various laboratory procedures as wax the individual retainers, develop the connectors of fixed partial denture and complete the wax pattern etc. These duplicate casts are used as working or refractory casts so that the master cast remains unaltered [4].

But the dimensions of subsequent casts on repeat pouring may be affected by the process of polymerization which involves cross linking of the polymer chains resulting in the reduction of spatial volume [9]. The temperature also alters the dimensions both during the setting phase and after the clinical set. The material used to fabricate the replica or working cast may also be a subject to change in dimensions such as gypsum expansion with setting [10].

Stackhouse observed that the stone dies poured successively from the same elastomeric impressions became increasingly shorter in length and thicker in diameter [11]. However Tjan et al. found that the repouring and delayed pouring of the rubber base impressions did not affect their dimensional accuracy and stability [12].

Ali et al. concluded that repouring of the impression up to seven days did not affect the dimensional accuracy of the resultant casts [3].

As the literature provided conflicting views regarding the time dependent accuracy of elastomeric impression materials, the aim of the study was to evaluate if repeated pouring of addition silicone impression materials would influence the dimensional accuracy of resultant casts.

Materials and Methods

The study was conducted in the Department of Prosthodontics, Govt. dental college, Patiala, Punjab, for comparative evaluation of dimensional accuracy of casts made by repeated pouring of different viscosities of vinyl polysiloxane impressions using custom tray. The materials used were Monophase polyvinyl siloxane impression material (Aquasil, Caulk/Dentsply) and regular/medium bodied polyvinyl siloxane impression material (Reprosil, Caulk/Dentsply).

Master model

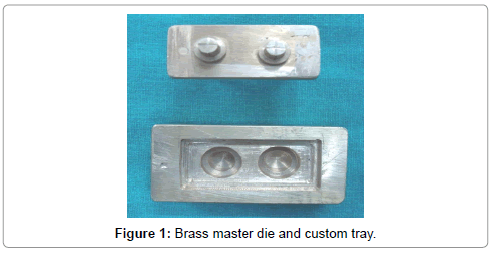

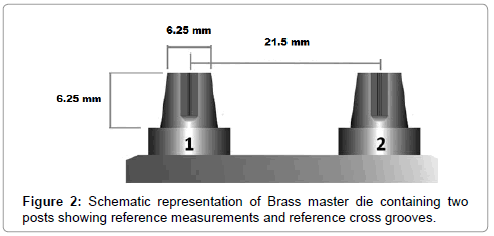

A brass master die of size 52×24 mm containing two identical posts simulating two complete crown tapered abutment preparation was served as a standardized master model. The abutments were prepared with reference cross grooves on occlusal and proximal surfaces for reference measurements. A metal handle was fitted on the opposite side of the base of master die (Figure 1). Reference measurements (made by profile projector with an accuracy of 0.001 mm or 1um) of the standardized master model were as diameter of each post- 6-25 mm. height of each post -6-25 mm, interabutment distance between each post -21-5 mm (Figure 2).

Custom tray and model index fabrication

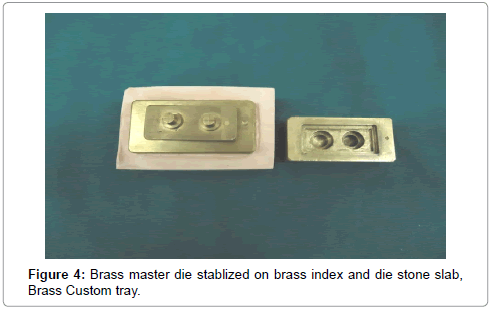

A specially prepared brass custom tray having a uniform space of approximately 2 mm for the addition silicone impression material was fabricated for making the impressions. A rectangular brass plate was fabricated with a slit in the centre which allowed the handle of the master die to pass through. This index was made for precise seating and stabilization of the master die during impression making (Figure 3). The whole assembly was further stabilized on the die stone slab for precise positioning (Figure 4).

Impression making

All the impressions of the brass master die were made in a custom made brass tray. To simulate oral environment, master die was maintained at 37°C in the oven. A thin even coat of tray adhesive was applied on the custom tray and allowed to dry for 15 minutes according to the manufacturer’s recommendations. The monophase polyvinyl siloxane impression material was mixed using automix cartridge dispensing system. For the regular body polyvinyl siloxane impression material, equal amounts of both base and catalyst pastes were taken on mixing pad. The tray with the impression material was seated gently over the master model while maintaining the finger pressure until the material sets. The impression was allowed to set at room temperature for as recommended by manufacturer. The impression was then removed with straight pull directed along the path of withdrawal of the preparations. The impression was checked for clinical acceptability.

total of 10 impressions were made using two different viscosities of polyvinyl siloxane impression material with 5 impressions of each material. Each impressions was poured repeatedly and sub grouped according to the different storage time intervals 15 minutes, 75 minutes, 24 hours, 48 hours, 1 week. Impression was stored at room temperature. Impressions were poured with type IV dental stone. To standardize the effect of the setting expansion of the improved stone, the water powder ratio was critically matched with manufacturer’s recommendation and a product of similar batch number was used to pour all the impressions. Stone cast was removed from impression after 60 minutes to ensure complete setting of the stone. A total of 50 casts were obtained for both viscosities and different time intervals

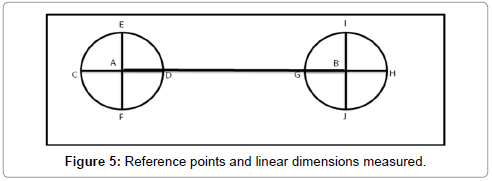

Assessment of accuracy

A profile projector with 15X magnification was utilized for the measurements of the stone casts. The stone dies were placed on a movable table connected to a monitor where movements in the X and Y directions could be displayed and measured with an accuracy of 0.001 mm or 1 um. Interabutment (AB) and intraabutment (CD, EF, GH, IJ) were measured. Each stone cast measurement was repeated three times and means for all distance measurements was calculated (Figures 5 and 6). The interabutment (AB) and intraabutment (CD, EF, GH, and IJ) dimensions on the stone dies were compared to the master model. The data of each measured dimensions were compared and subjected to statistical analysis.

Results

Results of the study are shown in Tables 1-5. Table 1 displays the absolute mean. Values of the interabutment distance AB and corresponding standard deviations. There was slight decrease in interabutment distance (AB) as the time interval increased from 15 min to 1 week. Tables 2 -5 shows the absolute mean Values of the intraabutment distance CD, EF, GH and IJ and their corresponding standard deviations. The intraabutment distances (CD, EF, GH, and IJ) increased slightly as the time interval increased from 15 min to 1 week

| Type of Pour | Group | Subgroups / Time Interval | N | Mean | Std. Deviation | Std. Error | Minimum | Maximum |

|---|---|---|---|---|---|---|---|---|

| Repeat Pour | A (Aquasil) | A1 (15 Minutes) | 5 | 21.4810 | .074196 | .033181 | 21.400 | 21.600 |

| A2(75 Minutes) | 5 | 21.4678 | .060147 | .026899 | 21.403 | 21.565 | ||

| A3 (24 Hours) | 5 | 21.4578 | .138265 | .061834 | 21.290 | 21.612 | ||

| A4(48 Hours) | 5 | 21.4208 | .100306 | .044858 | 21.370 | 21.600 | ||

| A5 (1 Week) | 5 | 21.4053 | .124520 | .055687 | 21.280 | 21.600 | ||

| B (Reprosil) | B1 (15 Minutes) | 5 | 21.4750 | .098489 | .044045 | 21.350 | 21.625 | |

| B2(75Minutes) | 5 | 21.4554 | .086953 | .038887 | 21.300 | 21.500 | ||

| B3(24 Hours) | 5 | 21.4420 | .094247 | .042149 | 21.350 | 21.600 | ||

| B4(48 Hours) | 5 | 21.4119 | .085746 | .038347 | 21.350 | 21.552 | ||

| B5 (1 Week) | 5 | 21.3998 | .135879 | .060767 | 21.300 | 21.582 |

Table 1: Mean and standard deviation values of interabutment distance AB (in mm) for each group at different time intervals.

| Type of Pour | Group | Subgroups / Time Interval | N | Mean | Std. Deviation | Std. Error | Minimum | Maximum |

|---|---|---|---|---|---|---|---|---|

| Repeat Pour | A (Aquasil) | A1 (15 Minutes) | 5 | 6.2735 | .019567 | .008750 | 6.255 | 6.306 |

| A2 (75 Minutes) | 5 | 6.2858 | .059563 | .026637 | 6.209 | 6.368 | ||

| A3 (24 Hours) | 5 | 6.2914 | .107384 | .048024 | 6.210 | 6.463 | ||

| A4 (48 Hours) | 5 | 6.3062 | .130314 | .058278 | 6.138 | 6.453 | ||

| A5 (1 Week) | 5 | 6.3210 | .125921 | .056313 | 6.200 | 6.487 | ||

| B (Reprosil) | B1 (15 Minutes) | 5 | 6.2780 | .121505 | .054339 | 6.156 | 6.443 | |

| B2 (75 Minutes) | 5 | 6.2878 | .047262 | .021136 | 6.210 | 6.321 | ||

| B3 (24 Hours) | 5 | 6.3098 | .059630 | .026667 | 6.261 | 6.409 | ||

| B4 (48 Hours) | 5 | 6.3345 | .099298 | .044407 | 6.256 | 6.455 | ||

| B5 (1 Week) | 5 | 6.3454 | .112811 | .050451 | 6.209 | 6.487 |

Table 2: Mean and standard deviation values of intraabutment distance CD (in mm) for each group at different time intervals.

| Type of Pour | Groups | Subgroups / Time Interval | N | Mean | Std. Deviation | Std. Error | Minimum | Maximum |

|---|---|---|---|---|---|---|---|---|

| Repeat Pour | A (Aquasil) | A1 (15 Minutes) | 5 | 6.2546 | .071423 | .031942 | 6.153 | 6.355 |

| A2 (75 Minutes) | 5 | 6.2916 | .070365 | .031468 | 6.193 | 6.392 | ||

| A3 (24 Hours) | 5 | 6.3156 | .108790 | .048652 | 6.136 | 6.433 | ||

| A4 (48 Hours) | 5 | 6.3348 | .115257 | .051545 | 6.174 | 6.477 | ||

| A5 (1 Week) | 5 | 6.3454 | .112811 | .050451 | 6.209 | 6.487 | ||

| B (Reprosil) | B1 (15 Minutes) | 5 | 6.2824 | .070723 | .031628 | 6.183 | 6.383 | |

| B2 (75 Minutes) | 5 | 6.3136 | .110607 | .049465 | 6.132 | 6.435 | ||

| B3 (24 Hours) | 5 | 6.3256 | .122716 | .054880 | 6.124 | 6.427 | ||

| B4 (48 Hours) | 5 | 6.3530 | .110011 | .049199 | 6.173 | 6.475 | ||

| B5 (1 Week) | 5 | 6.3582 | .139818 | .062529 | 6.152 | 6.464 |

Table 3: Mean and standard deviation values of intraabutment distance EF (in mm) for each group at different time intervals.

| Type of Pour | Groups | Subgroups / Time interval | N | Mean | Std. Deviation | Std. Error | Minimum | Maximum |

|---|---|---|---|---|---|---|---|---|

| Repeat Pour | A (Aquasil) | A1 (15 Minutes) | 5 | 6.2513 | .077424 | .034625 | 6.137 | 6.356 |

| A2 (75 Minutes) | 5 | 6.2718 | .045735 | .020453 | 6.190 | 6.293 | ||

| A3 (24 Hours) | 5 | 6.3150 | .149344 | .066788 | 6.135 | 6.538 | ||

| A4 (48 Hours) | 5 | 6.3328 | .115908 | .051836 | 6.170 | 6.475 | ||

| A5 (1 Week) | 5 | 6.3633 | .139264 | .062281 | 6.135 | 6.455 | ||

| B (Reprosil) | B1 (15 Minutes) | 5 | 6.2798 | .126248 | .056460 | 6.168 | 6.484 | |

| B2 (75 Minutes) | 5 | 6.3108 | .155162 | .069391 | 6.113 | 6.534 | ||

| B3 (24 Hours) | 5 | 6.3338 | .089893 | .040201 | 6.173 | 6.375 | ||

| B4 (48 Hours) | 5 | 6.3486 | .122419 | .054747 | 6.143 | 6.425 | ||

| B5 (1 Week) | 5 | 6.3798 | .117837 | .052698 | 6.169 | 6.440 |

Table 4: Mean and standard deviation values of intraabutment distance GH (in mm) for each group at different time intervals.

| Type of Pour | Group | Subgroups/ Time Interval | N | Mean | Std. Deviation | Std. Error | Minimum | Maximum |

|---|---|---|---|---|---|---|---|---|

| Repeat Pour | A (Aquasil) | A1 (15 Minutes) | 5 | 6.2546 | .047151 | .021086 | 6.190 | 6.293 |

| A2 (75 Minutes) | 5 | 6.2695 | .060763 | .027174 | 6.169 | 6.330 | ||

| A3 (24 Hours) | 5 | 6.2950 | .114689 | .051290 | 6.135 | 6.438 | ||

| A4 (48 Hours) | 5 | 6.3433 | .169148 | .075645 | 6.138 | 6.562 | ||

| A5 (1 Week) | 5 | 6.3633 | .155239 | .069425 | 6.195 | 6.515 | ||

| B (Reprosil) | B1 (15 Minutes) | 5 | 6.2864 | .070589 | .031568 | 6.209 | 6.399 | |

| B2 (75 Minutes) | 5 | 6.2928 | .104241 | .046618 | 6.132 | 6.411 | ||

| B3 (24 Hours) | 5 | 6.3124 | .132096 | .059075 | 6.210 | 6.482 | ||

| B4 (48 Hours) | 5 | 6.3428 | .184326 | .082433 | 6.162 | 6.593 | ||

| B5 (1 Week) | 5 | 6.3624 | .118604 | .053041 | 6.164 | 6.465 |

Table 5: Mean and standard deviation values of intraabutment distance IJ (in mm) for each group at different time intervals for repeat and delayed pours.

These results were analyzed for statistical comparison and significance by using one-way ANOVA Test. All of the deviations of the stone casts from the master model were within a clinically acceptable range less than 90 um. The dimensions of stone casts made with both viscosities of addition silicone impression material i.e. monophase and regular body showed statiscally insignificant differences from the master model. The addition silicone impression materials were dimensionally stable for 1 week period.

Discussion

An accurate impression is the key to success of any restoration. An impression should reproduce hard and soft tissues around prepared and adjacent teeth in order to obtain biologically, mechanically, functionally and esthetically acceptable restorations. Accuracy of an impression depends on various factors such as impression material, impression technique used, type of impression trays, thickness of impression material, excessive seating pressure, too slow removal of impression from the mouth, storage conditions and stress relaxation.

Addition silicone impression material i.e. polyvinyl siloxane is the most preferred material in the field of prosthodontics due to its favorable qualities as dimensional accuracy and stability, elastic recovery from undercuts, low creep and moderate to high tear resistance. However, repeat pours can affect the dimensions of the impressions due to continuing polymerization of addition silicone impression material. Distortion of the impression material may also occur during the retrieval of stone casts when multiple casts are poured in the same impression.

The results of the present study revealed that repeated pouring of impressions at different time intervals did not statistically significantly affect the dimensional accuracy of the casts produced from both viscosities of addition silicone impression material. The study also exhibited that there was slight decrease in interabutment distance whereas the intraabutment distances increased slightly as the time interval increased. The progressive increase or decrease in dimensions of stone casts as time interval increased was due to contraction of the impression material, but these changes were statistically insignificant. Similar results were obtained by William et al. [13], Lacy et al [14], Eames et al. [15], Ali and Shenoy [3], Marcinak and Draughn [9], Tjan et al. [12], Johnson and Craig [16], Thongthammachat et al. [17]. William et al. [13] found that the addition silicone impression material had exceptionally good dimensional stability at different storage time intervals as compared to other elastomeric impression materials. A statistically insignificant change in the dimensions of die (0.01-0.1 μm) was observed for all storage times.

In the present study the interabutment distance (AB) of the stone casts became continuously smaller when compared to the master model as the pouring time interval increased. The mean difference in interabutment distance for monophase addition silicone impression material ranged from 0.019 mm (0.0884%) at 15 minutes to 0.0946 mm (0.4402%) at I week, whereas for regular body addition silicone impression material the mean difference ranged from 0.025 mm (0.1163%) at 15 minutes to 0.1002 mm (0.4661%) at 1 week, maximum change being at 1 week for both materials.

The decrease in inter abutment distance observed in the present study might be explained on the basis of pattern of polymerization shrinkage of the addition silicone impression material. During polymerization reaction, the impression material shrank towards the center of the mass or bulk of the material. However, the use of tray adhesive redirected the polymerization shrinkage towards the walls of the impression tray. So the impression material contracted towards the walls of the impression tray around each abutment. As there was bulk of impression material in between two abutments and also tray adhesive redirected the polymerization shrinkage towards the tray wall around each abutment, the position of midpoint of both abutments came closer i.e. interabutment distance decreased. Thermal contraction of the impression material, when the temperature was reduced from 37°C to room temperature, could also have resulted in decrease in the interabutment distance.

Clinically, this decrease in interabutment distance can result in potential seating problems when fixed partial denture has to be cast in one piece. ADA specification no. 19 recommends a maximum contraction in dimension of 0.50% after 24 hours [3,18]. The magnitude of decrease in interabutment distance (percentage contraction) in the present study was found to be statistically insignificant.

The present study also indicated that the intraabutment distance (CD, EF, GH, IJ) for all stone casts became continuously larger than the master model. The mean difference in intraabutment distances ranged from -0.0013 mm (-0.0211%) to -0.1133 mm (-1.813%) for monophase addition silicone impression material whereas for regular body addition silicone impression material the mean difference ranged from -0.028 mm (-0.448%) to -0.129 mm (-2.077%), the greatest change being at 1 week for both materials.

The increase in intraabutment distance observed in the present study may be due to the fact that impression material contracted towards the walls of the impression tray coated with tray adhesive. Polymerization shrinkage occurred towards the restrained surface (tray) and away from the unrestrained (tooth) surface. Furthermore, the greater contraction of the impression material towards the walls of the impression tray might have primarily affected the regions with smaller amount of the impression material per wall surface, such as in the areas surrounding the abutments. This might have resulted in increased intraabutment distance or diameter of the abutments on the stone casts as compared to the master die.

From a clinical standpoint, for crown preparations, larger diameters of the working die will tend to facilitate complete seating of the casting on the preparation.

The present study also exhibited that the deviations of the stone casts measurements from the master die were less than 90 um. It indicated that the deviations were within the limits of periodontal ligament space and hence clinically acceptable. The observed changes showed that the immediate pouring of impressions produced the most accurate casts for both the viscosities of addition silicone impression materials studied. The one way ANOVA analysis showed that this decrease in interabutment dimension and increase in intraabutment dimensions with time for each addition silicone impression material was statistically insignificant (p>0.05). This implied that repeat pouring of impressions up to 1 week did not significantly affect the dimensional accuracy of the casts produced from both the viscosities of addition silicone impression materials evaluated. Thus impressions could be poured up to 1 week without undergoing any significant distortion.

Though the present study showed no statistically significant differences in the accuracy of casts obtained at different time intervals but there are various limitations of the study. As the study was carried out in-vitro, it did not take in to account the effect of various intraoral conditions such as the effect of oral fluids, soft tissues, different arch form and the effect of undercuts. Only two viscosities of addition silicone impression material were evaluated which may not represent all the addition silicone and other elastomeric impression materials available in the market. Various factors which may influence the precision of stone casts are correct manipulation of impression material, impression technique used, type of trays, the materials used for making casts.

Conclusion

Within the limitations of this study, following conclusions were drawn:

1. The dimensions of stone casts made with both viscosities of addition silicone impression material i.e. monophase and regular body showed statiscally insignificant differences from the master model for all storage time intervals i.e. 15 minutes, 75 minutes, 24 hours, 48 hours and 1week.

2. The interabutment distance decreased as the pouring time interval increased from 15 minutes to 1 week.

3. The intraabutment distances increased as the pouring time interval increased from 15 minutes to 1 week.

4. All of the deviations of the stone casts from the master model were within a clinically acceptable range (less than 90 um).

5. The dimensional changes observed in the stone casts from the master model were statistically and clinically insignificant.

6. The addition silicone impression materials were dimensionally stable for 1 week period, even though preferable pouring time could be considered as 15 minutes.

References

- Mishra S, Chowdhary R (2010) Linear dimensional accuracy of a polyvinyl siloxane of varying viscosities using different impression techniques. J Investig Clin Dent1: 37-46.

- Nam J, Rajgrodski AJ, Townsend J, Lepe X, Mancl LA (2007) Assessment of preference of mixing techniques and duration of mixing and tray loading for two viscosities of vinyl polysiloxane materials. J Prosthet Dent 97: 12-17.

- Ali KS, Shenoy VK, Rodrigues SJ (2010) Comparative evaluation of dimensional accuracy of casts made by repeated pouring of addition silicone impressions using 1) Two-step putty/light body technique using stock tray and 2) one-step simultaneous dual viscosity technique using custom tray: an in-vitro study. J Nepal Dent Assoc 11: 32-39

- Caputi S, Varvara G (2008) Dimensional accuracy of resultant casts made by a monophase, one-step and two-step, and a novel two-step putty/light-body impression technique: an in vitro study. J Prosthet Dent 99: 274-281.

- Chee WW, Donovan TE (1992) Polyvinyl siloxane impression materials: a review of properties and techniques. J Prosthet Dent 68: 728-732.

- Yeh CL, Powers JM, Craig RG (1980) Properties of addition-type silicone impression materials. J Am Dent Assoc 101: 482-484.

- Johnson GH, Lepe X, Aw TC (2003) The effect of surface moisture on detail reproduction of elastomeric impressions. J Prosthet Dent 90: 354-364.

- Pratten DH, Craig RG (1989) Wettability of a hydrophilic addition silicone impression material. J Prosthet Dent 61: 197-202.

- Marcinak CF, Draughn RA (1982) Linear dimensional changes in addition curing silicone impression materials. J Prosthet Dent 47: 411-413.

- Wadhwani CPK, Johnson GH, Lepe X, Rajgrodski AJ (2005) Accuracy of newly formulated fast setting elastomeric impression materials. J Prosthet Dent 93: 530-539.

- Stackhouse JA Jr (1970) The accuracy of stone dies made from rubber impression materials. J Prosthet Dent 24: 377-386.

- Tjan AH, Whang SB, Tjan AH, Sarkissian R (1986) Clinically oriented evaluation of the accuracy of commonly used impression materials. J Prosthet Dent 56: 4-8.

- Williams PT, Jackson DG, Bergman W (1984) An evaluation of the time-dependent dimensional stability of eleven elastomeric impression materials. J Prosthet Dent 52: 120-125.

- Lacy AM, Fukui H, Bellman T, Jendresen MD (1981) Time dependent accuracy of elastomer impression materials. Part II: Polyether, Polysulfids and polyvinyl siloxanes. J Prosthet Dent 45: 329-333

- Eames WB, Wallace SW, Suway NB, Rogers LB (1979) Accuracy and dimensional stability of elastomeric impression materials. J Prosthet Dent 42: 159-162.

- Johnson GH, Craig RG (1985) Accuracy of four types of rubber impression materials compared with time of pour and a repeat pour of models. J Prosthet Dent 53: 484-490.

- Thongthammachat S, Moore BK, Barco MT 2nd, Hovijitra S, Brown DT, et al. (2002) Dimensional accuracy of dental casts: influence of tray material, impression material, and time. J Prosthodont 11: 98-108.

- [No authors listed] (1977) Revised American Dental Association Specification no. 19 for Non-aqueous, Elastomeric Dental Impression Materials. J Am Dent Assoc 94: 733-741.

Relevant Topics

- Cementogenesis

- Coronal Fractures

- Dental Debonding

- Dental Fear

- Dental Implant

- Dental Malocclusion

- Dental Pulp Capping

- Dental Radiography

- Dental Science

- Dental Surgery

- Dental Trauma

- Dentistry

- Emergency Dental Care

- Forensic Dentistry

- Laser Dentistry

- Leukoplakia

- Occlusion

- Oral Cancer

- Oral Precancer

- Osseointegration

- Pulpotomy

- Tooth Replantation

Recommended Journals

Article Tools

Article Usage

- Total views: 18403

- [From(publication date):

February-2014 - Aug 24, 2025] - Breakdown by view type

- HTML page views : 13578

- PDF downloads : 4825