Investigations of Thermal Damage on the Physical and Mechanical Properties of Gneiss Rock Specimen

Received: 03-Aug-2017 / Accepted Date: 07-Aug-2017 / Published Date: 15-Aug-2017 DOI: 10.4172/2168-9806.1000176

Abstract

The effect of thermal damage on the physical and mechanical properties of gneiss has been experimentally investigated. The cylindrical samples prepared from this rock were gradually heated to a specific temperature level of 100, 200, 300, 400, 500, 700, and 900°C and gradually cooled down to room temperature without causing thermal cracking in order to investigate the effect of thermal treatment on physical properties and mechanical properties. The mechanical tests conducted on the sample were the Brazilian test and the uniaxial compressive test. Microscopic analyses from thin section were done to better understand the reasons for the mechanical behavior observed from the mechanical test results. Our study confirms that the thermal treatment reduces the strength of gneiss and increases its porosity. Moreover, it is found that above 600°C of heating, gneiss rock specimens can loss 80% of its original mechanical performances. This is due to a micro crack network connection and their propagation. However between 300 and 400°C we observe an increase in the strength of gneiss. Microscopic examination shows the abundance of feldspar and pyroxene minerals in the gneiss, which in turn show high mineralogical phase changes at 300-400°C compared to change at temperatures above 400°C.

Keywords: Fneiss rock; Thin section; Porosity; Thermal damage; Tensile strength; Uniaxial compressive strength

Introduction

Many civil engineering structures have been constructed with rock. The life of these structures can be reduced by external agents such as water, mechanical and thermal stresses. One of the main problems raised by the safety tunnels, civil engineering structures, public buildings and house is the behavior of materials subjected to fire. In addition, in underdeveloped countries such as Cameroon, for example, thermo mechanical fragmentation of rocks practiced in quarries and small mines for many years also motivates us to study the influence of high temperatures on hard rocks such as granite, gneiss, marble, basalt, sandstone, etc., generally found and exploited in these quarries. Therefore it becomes important to study the resistance of structural materials (rock, cement, steel wood concrete) submitted to an accidental temperature elevations.

In engineering rocks structures, temperature variation is one of the primary factors influencing the integrity and the mechanical properties of rocks. In fact, sudden changes in temperature induced by the fire can lead to changes in the microstructure of materials, creating microcracks, the transformation of their mineral constituents, and a decrease in their mechanical performance [1]. When temperature increases, the minerals composing the rock undergo thermal expansions and contractions [1]. The thermal expansion is substantially anisotropic. It amplifies the mineralogical heterogeneity of the rocks and then causes expansion of inequalities [2]. The different coefficients of thermal expansion along different crystallographic axes of the material can also cause damage due to high temperature of the rock structure [2]. Studying physical and mechanical properties of rocks under different temperature condition is essential to access the suitability of host rock for the integrity of nuclear waste repository and to ensure the safe insulation of nuclear waste [3]. The other application is thermo mechanical fragmentation of hard rock. Many artisan uses fire to fragment rock and produce granulates for civil engineering.

Many experimental studies have been conducted on different rocks, [1-14] with an objective to observe and explain the behavior of physical and mechanical properties of these rocks under high temperature or after thermal treatment. All these experimental works are focus on sandstone [4-7], granite [1,8-10], carbonates [2] and gabbro [11]. However, few studies are interested on the gneiss rock microscopic analysis of thin section of the heated specimen. In this work we focus on gneiss. Due to the fact that gneiss is largely employed in civil engineering; many rail or road tunnels are made of gneiss rock masses because it is a relatively strong material and has low matrix porosity.

Mechanical behavior of thermally-cracked rocks was mostly studied by destructive mechanical tests [12]. In this paper we focus our mechanical test on the compressive and tensile test. These tests are mostly used to provide directs information on compressive and tensile strength of rock versus temperature. The important preoccupation of our study is to use microscopic analysis of thin section to better understand the reasons for the mechanical behavior observed from the mechanical test results. The paper is organized as follows. The gneiss rock specimen under study is prepared, presented and described in Section 2. Section 3 is devoted to the experimental methods and the influence of high temperature on the physical and mechanical properties of gneiss (total porosity, uniaxial compressive strength, tensile strength). The microscopic analysis of thin section is presented in section 4. Finally, the discussion and conclusion is given in Section 5.

Samples Preparation and Heat Treatment

Before performing the measurement of properties of the rock, observation is done then the selection of the rock specimen to be studied is made. The sample should be as homogenous as possible in terms of lithology.

Description of rocks samples

Macroscopic observations show a fruste foliation and an alternation of light and dark rocks, which let us to conclude that this is ortho gneiss, a metamorphic rock. Carrots examined show the presence of feldspar quartz veins, resulting from the intrusion of quartz-feldspathic which filled cracks developed during metamorphism of endogenous rocks.

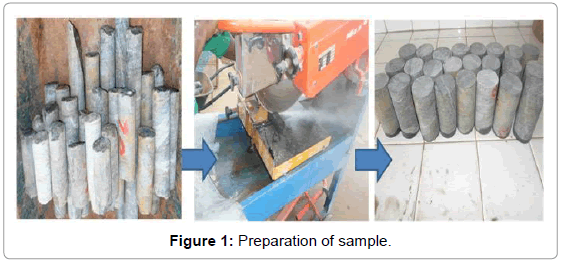

Samples of cylindrical shape were carefully collected by coring non-destructive in situ. Then we used a small machine for cutting and sawing grind carrots, to obtain samples of rocks perfectly machined (parallelism and polishing surfaces) as shown in Figure 1.

The machine is equipped with a block fastener and a watering system that avoids the rising of dust and uncontrolled warming. Particular attention has been paid to the quality of the cutting and grinding. The samples obtained are then listed and numbered.

After these preparatory steps, we obtain the final cylindrical samples 55 mm in diameter and 110 mm length (Figure 1). The choice of 2 slenderness ratio was imposed by ISRM [13]. The samples thus prepared were placed in an oven at a temperature of 60°C to remove the water in the pores of the material (Table 1).

| Gneiss sample | 25°C | |

|---|---|---|

| Mineralogic composition | Feldspar | 20-25% |

| Quartz | 10-12% | |

| Amphibole and pyroxene | 50-60% | |

| Garnet | 2-3% | |

| Oxide | 2-2.5% | |

| Calcite | 1-2% | |

| Biotite | - | |

| Mechanical and physical properties | Uniaxial compressive strength (MPa) | 173 |

| Tensile strength (MPa) | 18.95 | |

| Total porosity % | 0.00101 | |

| Bulk density | 2.823 | |

| Wet density | 3.136 | |

Table 1: Properties of unheated gneiss.

Thermal treatment

Heat treatment of rock samples consist of heating it in an electric furnace at a constant rate of one degree Celsius per minute. Selected treatment temperatures were: 100°C, 200°C, 300°C, 400°C, 500°C, 700°C and 900°C. Before the thermal treatment, initial properties of all samples were measured in order to provide a good analysis basis to study its variation characterizing thermal damages.

For the measurement tests considered, the heating rate should be slow in order to ensure that the cracks induced in the material only result from the effect of high temperature and not the temperature gradient through the sample. For each heat treatment, the sample was heated to this set of temperature and maintained for 6 h. After heating they were allowed to cool gradually to room temperature before either mechanical test were performed or thin sections specimens were obtained for microscopic investigations.

A heating or cooling rate above 2°C/min introduces micro cracks into the sample during heating and cooling [14]. Considering this we have attempted in all our heat treatment to keep the heating and cooling rates of the rock samples below 2°C/min.

Evolution of the Physical Properties of the Gneiss Sample with Temperature

In 2004, Lion et al. [14] noted that the temperature could lead to contradictory phenomena such as densification and cracks in hard rock, and significantly influence their physical properties. In this paper, the physical property considered is total porosity.

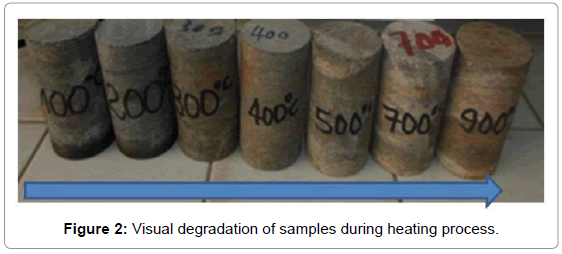

Visual observation

It was clear from observations that the samples had undergone changes in appearance during the thermal treatment process. Figure 2 shows selected images indicating these changes. Samples changed from being dark grey in color to light grey.

Porosity

Porosity is one of the basic physical properties of rock (Table 2) [8]. It can be defined by the ratio of void volume to the total volume of the rock. Porosity influences the internal surface area per unit material volume and which, determines the transport properties and strength of the material [2]. A comprehensive study of porosity can provide valuable information in order to determine whether a given type of rock is susceptible to thermal stress or not [14].

| Temperature (°C) | 25 | 100 | 200 | 300 | 400 | 500 | 700 | 900 |

| Dry mass (M1) | 749.17 | 755.61 | 729.24 | 785.46 | 773.08 | 721.56 | 738.16 | 784.52 |

| Satured mass (M2) | 776.69 | 755.95 | 729.66 | 785.91 | 800.71 | 722.88 | 742.72 | 791.11 |

| Satured submerged mass | 506.76 | 514.32 | 478.78 | 524.82 | 506.85 | 473.65 | 491.45 | 540 |

| Total Porosity | 0.1019 | 0.0014 | 0.0016 | 0.0017 | 0.094 | 0.00529 | 0.01814 | 0.0262 |

| Wet Density | 3.136 | 3.097 | 2.879 | 2.98 | 2.865 | 2.871 | 2.924 | 3.119 |

| Bulk Density | 2.873 | 2.898 | 2.797 | 3.012 | 2.965 | 2.767 | 2.831 | 3.009 |

Table 2: Physical properties of gneiss with temperature.

Total porosity is determined by using triple weighing method as recommended by IRSM [13]. It is often used, even if it does not provide access to information on the heterogeneity of the porosity at a microscopic scale.

It is fairly simple to make. It is a technical measurement by immersion, in which we successively perform the weighing of the dry sample, saturation and immerged. The fluid used is water [13]. The method uses Archimedes principle and gives the accurate results. From these tests, total porosity is calculated by the following equation:

(1)

(1)

Where M1 is dry mass, M2 is saturated mass and M3 is saturated submerged mass.

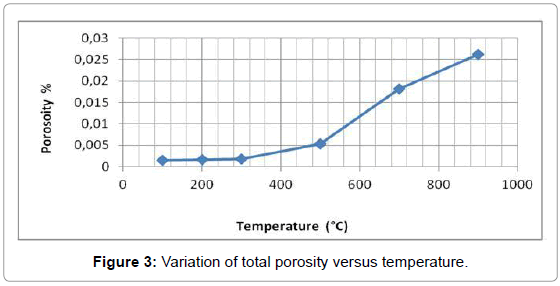

In Figure 3, from 20°C to 400°C, the porosity is very weak. This is explained by a minor modification of the rock structure in this temperature range. This change is primarily due to the creation of new cracks or opening of pre-existing micro cracks with the increasing of temperature. A major change in the rock structure occurs between 400 and 900°C. It induces a drastic increase in porosity. The porosity first increases slowly and then rapidly afterward. This is due to a micro crack network connection, a coalescence of micro cracks and their propagation.

Evolution of Mechanical Properties of the Gneiss Sample with Temperature

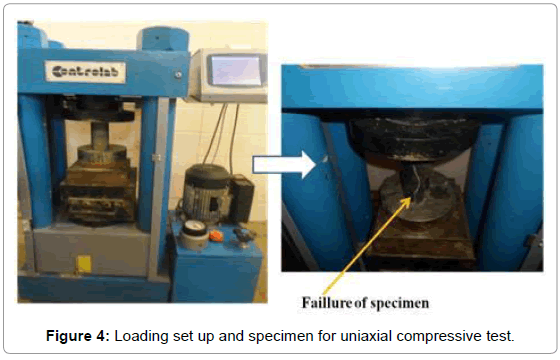

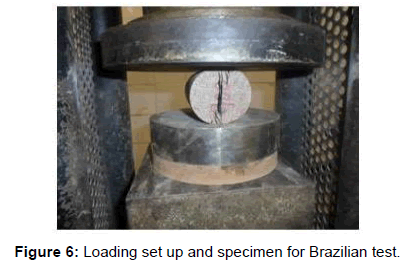

The mechanical tests carried out on samples generally constitute the main tool for determining the laws of materials behavior in general, especially geo materials. In this study, two types of mechanical tests were performed on the samples. Firstly we realized the uniaxial compression test and secondly the indirect tensile test or Brazilian tests (Figure 4).

Uniaxial compressive strength

It is the most important mechanical property of the rock used for dimensioning, analysis and modeling. Its value is very useful and sometimes gives sufficient information on the mechanical performance expected of a rock.

Standard uniaxial compression tests were carried out on samples once they are returned to room temperature after heating. Specimens used for the test is a cylinder of 110 mm in length and 55 mm in diameter. From these tests, compressive strength is calculated by the following equation:

(2)

(2)

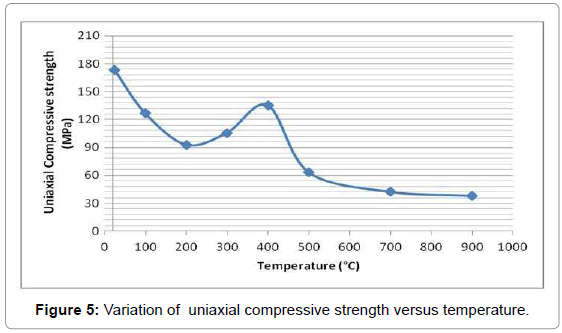

Where PM, S are peak load, area of cross-section of specimen (Table 3). In Figure 5, we observe that the maximum value of uniaxial compressive strength is 173 MPa. This value is obtained at 25°C, the unheated sample.

| Temperature (°C) | 25 | 100 | 200 | 300 | 400 | 500 | 700 | 900 |

| Uni axial compressive strength (GPa) | 17,3 | 12,7 | 9,3 | 10,54 | 13,5 | 6,3 | 4,21 | 3,79 |

Table 3: Uniaxial compressive strength of samples tested.

From 25°C to 300°C, the compressive strength decreases gradually from 173 MPa to 105 MPa. This value represents a decrease of 40%. We can attribute this decrease to the beginning of thermal cracking. However from 300°C to 400°C the uniaxial compressive strength increases to a value 135 MPa. This increase shows that at this plate of temperature the gneiss rock become stronger. This is due to the densification of the fissures network.

Above 400°C, the uniaxial compressive strength begins to decrease rapidly. This decrease shows that thermal effect induces the loss of rigidity of granite at high temperature. Above 600°C of heating, the uniaxial compressive strength tends to a value zero; therefore, gneiss specimen becomes very vulnerable. At this temperature the gneiss rock has loosed 80% of its original strength. A significant loss of mechanical performance of rock is a considerable gain in mechanical energy to spend for the fragmentation of the specimen. This result explains why artisan miners or some engineers use fire to heat rock first before using a mechanical tool to fragment the hard rock in artisanal quarries and in some rock engineering applications (Figure 6).

Tensile strength

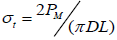

The Brazilian disc test is used to determine for each heated specimen the tensile strength. Specimens used for the test is a cylinder of 110 mm in length and 55 mm in diameter. Under linear pressure in radial direction, each specimen fails in tension. The tensile strength is calculated by the following equation:

(3)

(3)

Where PM, D and L are peak load, diameter and the length of specimen (Table 4).

| Temperature (°C) | 25 | 100 | 200 | 300 | 400 | 500 | 700 | 900 |

| Tensile strength (MPa) | 18,95 | 10,52 | 10,52 | 13,68 | 11,58 | 11,58 | 7,36 | 4,21 |

Table 4: Uniaxial compressive strength of samples tested.

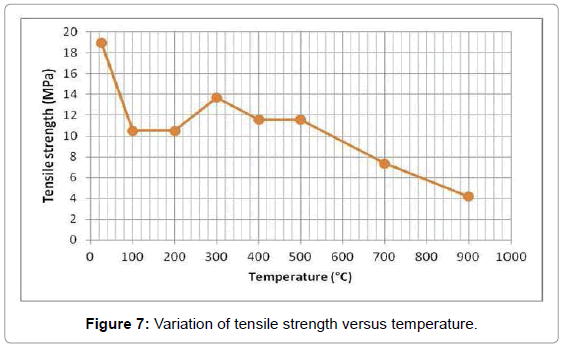

In Figure 7, it is noted that the maximum value of tensile strength is 18.95 MPa, at ambient temperature, 25°C. This value is smaller than the uniaxial compressive strength. We conclude that like in concrete, gneiss resist more in compression than in tensile. From 25°C to 100°C, the tensile strength decreases gradually. We can attribute this decrease to the beginning of thermal cracking. However from 100°C to 300°C the tensile strength increases to 13.6 MPa. Above 300°C, tensile strength begins to decrease rapidly and reaches to a value 4.21 at 900°C. At this temperature the rock has loosed 80% of its tensile strength.

Preparation of Thin Section and Microscopic Observations

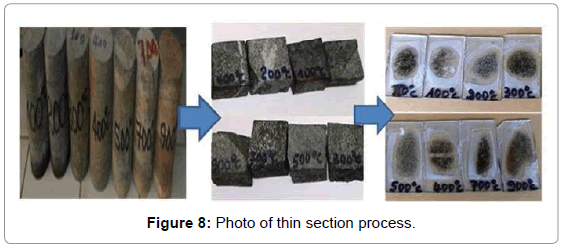

Thin sections were extracted from the heat treated samples for microscopic analyses, which permit us to better understand the effect of temperature on the microstructure and the change in the mineralogy. Therefore it assisted in explaining the reasons for the mechanical behavior observed from the mechanical test results.

Step 1: Cutting a slab

A suitable size slab for mounting on a slide is cut from a piece of rock or drill core with a diamond saw.

Step 2: Initial lapping of the slab

The slab is labeled on one side and the other side is lapped flat and smooth first on a cast iron lap with 400grit carborundum, then finished on a glass plate with 600 grit carborondum.

Step 3: Glass slide is added

After drying on a hot plate, a glass slide is glued to the lapped face of the slab with epoxy.

Step 4: Slab is sectioned

Using a thin section saw, the slab is cut-off close to the slide. The thickness is further reduced on a thin section grinder.

Step 5: Final lapping

A finished thickness of 30 microns is achieved by lapping the section by hand on a glass plate with 600 grit carborundum.

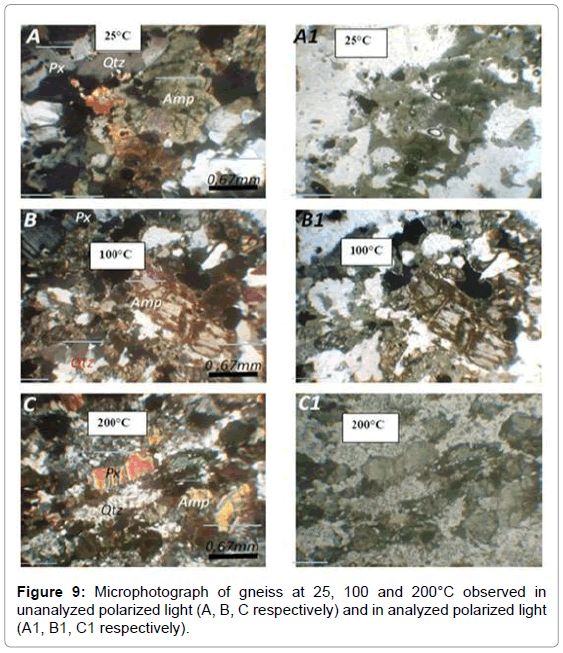

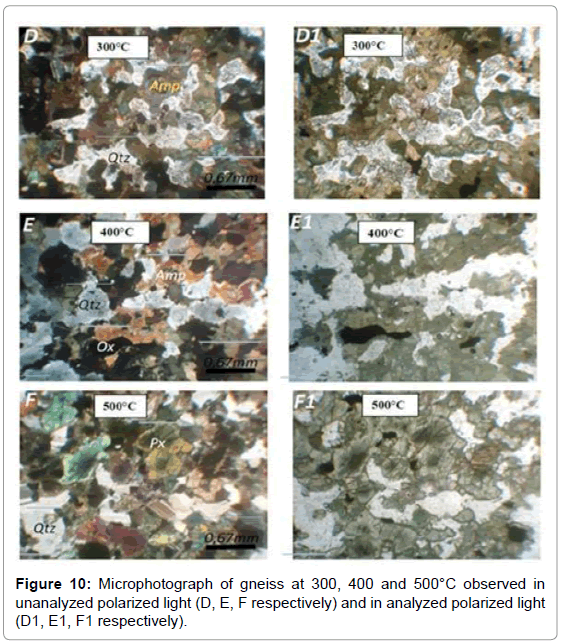

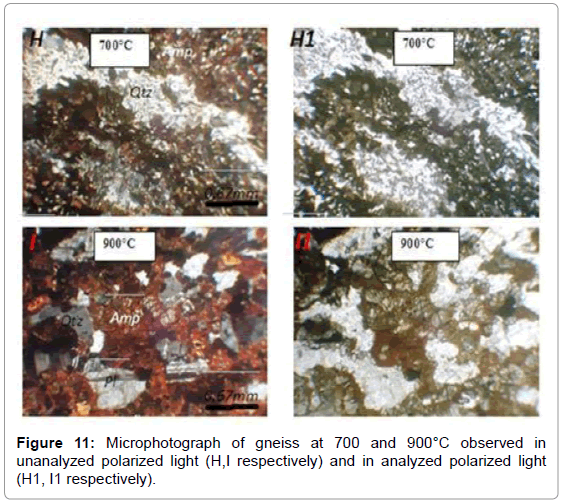

Thin sections were extracted from a sample from each batch after heat treatment and also from unheated specimens. A microscopic examination was performed using polarizing microscopy combined with petrographic digital image analysis technique to identify micro cracks and determine the micro crack intensity within the major minerals and in the rock specimen as a whole (Figures 8-11).

These microscopic observations reveal that from 200°C, quartz and feldspar take a cloudy appearance (presence of numerous cavities) due to the beginning of the melting of mineral (Table 5). Between 300 and 700°C, they form siliceous crowns around the quartz grains. From 500°C pyroxene and amphibole gradually look darker. From 700°C a cloudy appearance, related to a fusion reaction beginning with the formation of crowns around the grain.

| Gneiss sample | unheated | 100°C | 200°C | 300°C | 400°C | 500°C | 700°C | 900°C | |

|---|---|---|---|---|---|---|---|---|---|

| Mineralogical Composition | Feldspar | 22.5% | 17.5% | 17.5% | 17.5% | 22.5% | 25% | 20% | 25% |

| Quartz | 11% | 25% | 25% | 12.5% | 12.5% | 12.5% | 12.5% | 11% | |

| Amphibole and pyroxene | 55% | 32.5.% | 45% | 55% | 57.5.% | 60% | 57.5% | 57.5% | |

| Grenat | 2.5% | 2% | 7.5% | 12.5% | 4% | 3.5% | 1.5% | 2.5% | |

| Oxyde | 2.25% | 11% | 1.5% | 4.5% | 2.5% | 2.5% | 2.5% | 1.5% | |

| Calcite | 1.5% | - | - | - | - | - | - | - | |

| biotite | - | <1% | - | 1.5% | 1.5% | - | - | - |

Table 5: Mineral composition of gneiss with temperature.

From 900°C pyroxene and amphibole take a rusty look (red) due to an accumulation of iron after complete dehydration of the water and their association with quartz crystals and feldspar recrystallized.

From these observations and from this analysis we can conclude that the hard rocks, rich in amphibole or pyroxene (Ferromagnesian), resist to high temperatures due to their high melting temperatures at the beginning. This is the case of basalts.

However the hard rocks rich in quartz and feldspar are not resistant to high temperatures due to their low levels of melting temperature. It is therefore advisable to build with dark hard rocks or aggregates from the dark rocks, such as basalt, gneiss rich in amphibole or pyroxene.

Discussion

Microscopic examination shows the abundance of feldspar and pyroxene minerals which in turn show high mineralogical phase changes at 300-400°C compared to the change in temperature above 400°C. This behavior appears to be the reason for the increase in strength at 400°C, since the minerals undergoing the change phase responded plastically, instead of brittle, thus giving rise to the global strength of specimen [15].

It means that the cracking of these minerals at 400°C was less significant to the strength until 600°C, 700°C and 900°C. Therefore it can be state that the initial mineralogical alterations appear to control the strength at 400°C, while at 600°C, 700°C and 900°C the crack intensity and friability due to the dehydration and the loss of crystal bound water are the cause of rapid decay in strength [15].

Conclusion

This work dealt with the experimental investigation of thermal damage on porosity, tensile strength and compressive strength of gneiss rock specimen. We use Brazilian test and uniaxial compressive test to determine de mechanical strength of this rock. The porosity was inferred from successive mass measurement of dry, water saturated and immersed sample. Microscopic analysis from thin section of sample was also carried out to investigate the reasons for the variation in mechanical and physical properties.

From 25°C to 300°C we observed the decrease of tensile strength and the uniaxial compressive strength. In this range of temperature the variation of porosity is weak.

This is attributed to the creation of new cracks or opening of preexisting micro cracks with increasing temperature.

From 300°C to 400°C, we observed the increase in the strength of the sample. Microscopic analysis from thin section showed the abundance of feldspar and pyroxene minerals which in turn show high mineralogical phase changes at 300-400°C compared to change at temperature above 400°C.

Above 400° the tensile strength and the compressive strength decrease drastically. A major change in the rock structure occurs between 400 and 900°C. It induces a drastic increase in porosity. the porosity increases first slowly and then rapidly afterward. This is due to a micro crack network connection, a coalescence of micro cracks and their propagation. The results clearly show that the mechanical behavior of rock was equally depending on the mineralogical change that occurred at different temperature as they were to micro crack intensity. On the other hand the micro crack intensities were dependent on the mineral types and their thermal properties.

References

- Takarli M, Agbodjan WP (2008) Temperature effects on physical properties and mechanical behavior of Granite: Experimental investigation of material damage. J ASTM Int 5.

- Somerton WH (1992) Thermal properties and temperature-related behavior of rock/fluids system. Elsevier.

- Yavuz H, Demirdag S, Caran S (2010) Thermal effect on the physical properties of carbonate rocks. Int J Rock Mech Min Sci 47: 94-103.

- Torok A, Hajpal M (2005) Effect of temperature changes on the mineralogy and physical properties of Sandstone. A laboratory study. International Journal for Restoration of Buildings and Monuments 11: 211.

- Zhang ZZ, Gao F, Xiao F (2011) Experimental study of temperature effect on mechanical properties of granite. Rock Soil Mech 32: 2346-2352.

- Rao Q, Wang Z, Xie HF, Xie Q (2007) Experimental study of mechanical properties of sandstone at high temperature. J Cent South Univ Technol 14: 478-483.

- Wu G, Wang Y, Swift G, Chen J (2013) Laboratory Investigation of the Effects of Temperature on the Mechanical Properties of Sandstone. Geotech Geol Eng 31: 809-816.

- Chaki S, Takarli M, Agbodjan WP (2008) Influence of thermal damage on physical properties of a granite rock: porosity, permeability and ultrasonic wave evolutions. Construction and Building Materials 22: 1456-1461.

- Xu XL, Gao F (2012) Experimental study on the strength and deformation quality of granite with effect of high temperature. Applied Mechanics and Materials 226: 1275-1278.

- Inserra C, Biwa S, Chen Y (2009) Nonlinear ultrasonic characterization of thermally damaged Westerly granite. Japanese Journal of Applied Physics 48: 7S.

- Keshavarz M, Pellet FL, Loret B (2010) Damage and changes in mechanical properties of a gabbro thermally loaded up to 1,000 C. Pure and Applied Geophysics 167: 1511-1523.

- Houpert R, Homand-Etienne F (1979) Influence of Temperature on the Mechanical Behavior of Rocks. In 4th ISRM Congress. International Society for Rock Mechanics.

- Characterization R (1985) Testing and Monitoring, ISRM Suggested Methods, ed. ET Brown.

- Lion M (2004) Influence de la température sur le comportement poromécanique ou hydraulique d'une roche carbonatée et d'un mortier. Etudes expérimentales (Doctoral dissertation, Université des Sciences et Technologie de Lille-Lille I).

- Saiang C, Miskovsky K (2012) Effect of heat on the mechanical properties of selected rock types – a laboratory study. Harmonising Rock Eng Environment.

Citation: Luc Leroy NM, Joseph NDOP, Bienvenu JM (2017) Investigations of Thermal Damage on the Physical and Mechanical Properties of Gneiss Rock Specimen. J Powder Metall Min 6: 176. DOI: 10.4172/2168-9806.1000176

Copyright: ©2017 Luc Leroy NM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 7266

- [From(publication date): 0-2017 - Dec 20, 2025]

- Breakdown by view type

- HTML page views: 6216

- PDF downloads: 1050