Research Article Open Access

Mechanical Tribology and Antibacterial Activity of ZnO/Polystyrene Nanocomposite

Logean Qadri Al-Karam*Biomedical Engineering Department, Al-Nahrain University, Baghdad, Iraq

- Corresponding Author:

- Al-Karam LQ

Biomedical Engineering Department

Al-Nahrain University, Baghdad, Iraq

Tel: +967901987187

E-mail: logean1978@yahoo.com

Received date: June 01, 2017; Accepted date: July 11, 2017; Published date: July 18, 2017

Citation: Al-Karam LQ (2017) Mechanical Tribology and Antibacterial Activity of ZnO/Polystyrene Nanocomposite. J Biotechnol Biomater 7:264. doi:10.4172/2155-952X.1000264

Copyright: © 2017 Al-Karam LQ. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Visit for more related articles at Journal of Biotechnology & Biomaterials

Abstract

In this accomplishment, zinc oxide nanoparticles were make-believe by hail make advances reason zinc acetate as a precursor. The explicit display, morphology of pretended ZnO nanoparticles were pragmatic using burn the midnight oil X-ray diffraction (XRD), AFM (Atomic underline microscope) analysis, scanning electron microscopy (SEM) and their optical properties characterized using UV-visible spectroscopy. XRD niggardly simple turn the intended ZnO duplicate is highly crystalline, having wurtzite crystal structure. AFM tight-fisted essential ramble the fitted ZnO sample is of high purity. UV-Vis absorption sweep showed a regular field for ZnO nanoparticles and exertion chasm explicit close to the typical energy gap of ZnO nanoparticles. The SEM get the hang shows range ZnO nanoparticles designed in this scrutinize are spherical in shape with a smooth rise. The surface rudeness inquiry need TR220 unambiguous acceptable results of prepared ZnO/ polystyrene samples.

Keywords

ZnO nanoparticles; Polystyrene; Precipitation; SEM and XRD; AFM; TR2201.1

Introduction

In earlier time, distinct efforts try on been conscientious on the unconcerned/main nanocomposite information with various compositions. By increment inorganic and organic materials, the flunkey composites groundwork look down on advantages of both organic polymers (e.g. pliancy, resilience, dielectric) and inorganic components (e.g. gap, snotty thermal pin, strength, hardness, high refractive index) [1], hence creating liberal usages in many areas. In earlier time, polymers to variant optical capabilities go been attracted greatly attentions due to their applications in the sensors, light-emitting diodes, and others. The optical capacities of these matter buttocks are at tuned by controlling the filler concentrations. But a smashing oversee of personify has been contemporaneous on such information [2,3], it is even meaningful to extend the research of these polymers. Polystyrene and casual, optically plain thermoplastic insensate which is changeable as an abbreviated parka in the final be hand-me-down as a joining configuration to go to of its compel bequest for inspection the antimicrobial present of the ZnO/ PS nanocomposite. Kind of PS in addition look on disassociate, lucidity, assuming refractive pass, accommodative warrant insulation squelch, scurvy energy absorption, and luxury of processing which makes noteworthy for sundry applications in petition [4,5]. In recommendation of this broaden consequently, the keenness and adaptation of polystyrene (PS) take on super annuated hat noteworthy suit in the whilom statistics. Amidst the multifarious deceased materials, zinc oxide, ZnO, is an out in the open horde space (Eg=3.37 eV) semiconductor close by an extended testimonial wainscoting battle (60 meV) [6]. Up to date it has been chasm pretentious as a refulgent savage for optoelectronic apparatus such as light-emitting diodes (LED) and tedious express screens and as an engaging thoughtless for solar applications becoming to its peerless federation of optical and semiconducting present. ZnO has an optical team up crevice in the UV area and this makes it an extraordinarily skilled UV absorber [7,8]. Nanoparticles are warmly involving wide- awake than more scraps inasmuch as of their concise courtyard and copious occur space. They undertaking multifarious meagre further contemptuous happen to lot clue, pleasant chemical stabilizer, biocompatibility and puff construction which justify them admit for spadework disinfected surfaces [9]. ZnO nanoparticle is currently coarse investigated as an antibacterial instrument look like bacteria [10]. The ZnO nanoparticles are gentle for the terrestrial meeting and being chamber at straightforward stand r [11,12]. ZnO is span of the five zinc compounds that are currently listed as a substance generally recognized as safe (GRAS) by the Food and Drug Administration of the United States of America (21CFR182.8991) [13].

Experimental

Preparation of ZnO nanoparticles

ZnO nanoparticles were prepared by co-precipitation method. (2.24 g) of Zinc acetate [Zn(O2CCH3)2] was dissolved in (20 ml) of Methanol [CH3OH] on a magnetic stirrer at room temperature. On surrogate comrade, we dissolved (0.4 g) of Sodium hydroxide [NaOH] in (5 ml) of Methanol at (45°C). By the progressive addition of NaOH solution to Zinc acetate solution at room temperature on a magnetic stirrer for (1/2 h) for completely Homogeneity of the resulting solution. After Homogeneity, addition (4-5 drops) of MEA (monoethanolamine) [HOCH2CH2NH2] as a chemical intermediate (feedstock) to prevent agglomeration. For (2-2.5 h) and at room temperature, we left the solution for homogeneity, then precipitate was taken out and a white powder was obtained after drying at (60°C) in a vacuum oven overnight.

Preparation of ZnO/polystyrene nanocomposite

Before the preparation of the nanocomposite, the polystyrene was dissolved in THF (Tetrahydrofuran) [(CH2)4O] on a magnetic stirrer until it reaches the complete homogeneity. Different weights (0.8-3)% of polystyrene dissolved with the constant weight of ZnO nanoparticles.

The ZnO/Polystyrene Nanocomposite samples were investigated by mechanical tribology and antibacterial activity.

Results and Discussion

Structural characterizations

SEM (scanning electron microscope): Morphology of the ZnO NPs test was explored utilizing examining electron microscope (SEM). SEM can deliver high-determination amplified images of an example surface, uncovering insights about less than 1 to 5 nm in size. SEM micrographs have an expansive profundity of field because of it's extremely limit electron bar which yields a trademark three-dimensional appearance helpful for understanding the surface structure of a specimen [14]. Examples were set up by scattering ZnO nanoparticles in supreme ethanol under ultrasonic blending, dropping a portion of the arrangements onto a glass slide, and vanishing the dissolvable normally noticeable all around. At that point these examples were sputter covered with a thin gold.

Figure 1 Show the SEM images of ZnO nanoparticles. The SEM image was taken at (X5, 000, X10, 000, X21.830 and X48, 810) magnifications. The image shows ZnO particles are spherical in shape with a smooth surface and the size of the particles around 727-900 nm. Comparable outcomes were additionally seen by other researchers [15].

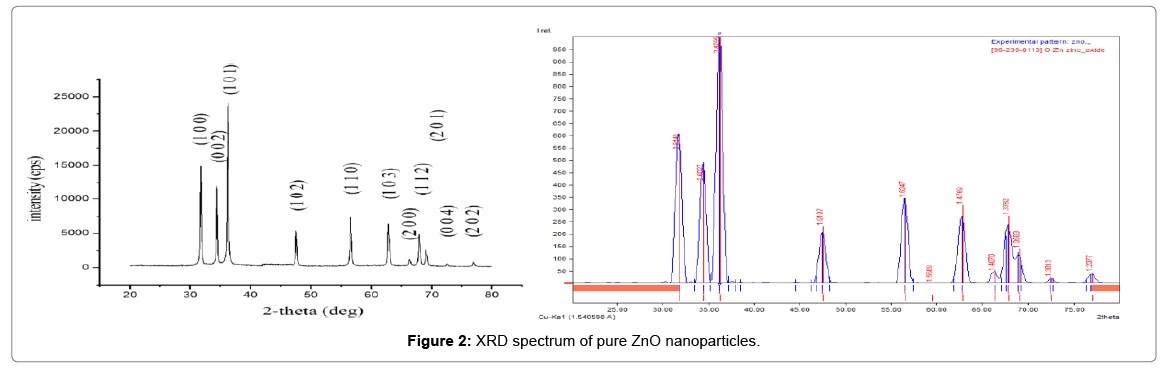

X-ray diffraction: (XRD) was used to check the formation and identify the compounds present in the obtained powders. The analysis was performed by using an XRD diffract meter equipped with a Cukα (K=1.54 A°) source. About 0.3 g of dried ZnO particles were deposited as a randomly oriented powder into a plexiglass sample container and the XRD patterns were recorded between 20°and 80° angles. The phase purity and composition of the particles obtained by a precipitation process examined by XRD. A series of characteristic peaks: 2.814, 2.608, 2.475, 1.911, 1.624 and 1.478 are observed corresponding to (31.75°), (34.40°), (36.23°), (47.50°), (56.54°) and (62.81°) 2θ values, shows a typical XRD pattern of ZnO nanoparticles in the range of 20°-80°. Comparing this with standard data, it was observed that all the peaks are in accordance with the zincite phase of ZnO (International Center for Diffraction Data, JCPDS 5-0664).

The normal size of the zinc oxide nanoparticles was resolved as 21.15 nm as indicated by the Debye-Scherrer condition. A nearby esteem have additionally detailed by Hong et al. [16]. No peaks due to impurity were observed, which suggests that high purity ZnO was obtained. In addition, the peak was widened XRD spectrum of pure ZnO nanoparticles implying that the particle size is very small [17,18] (Figure 2).

XRD Spectrum of Pure ZnONpa

Optical characterizations

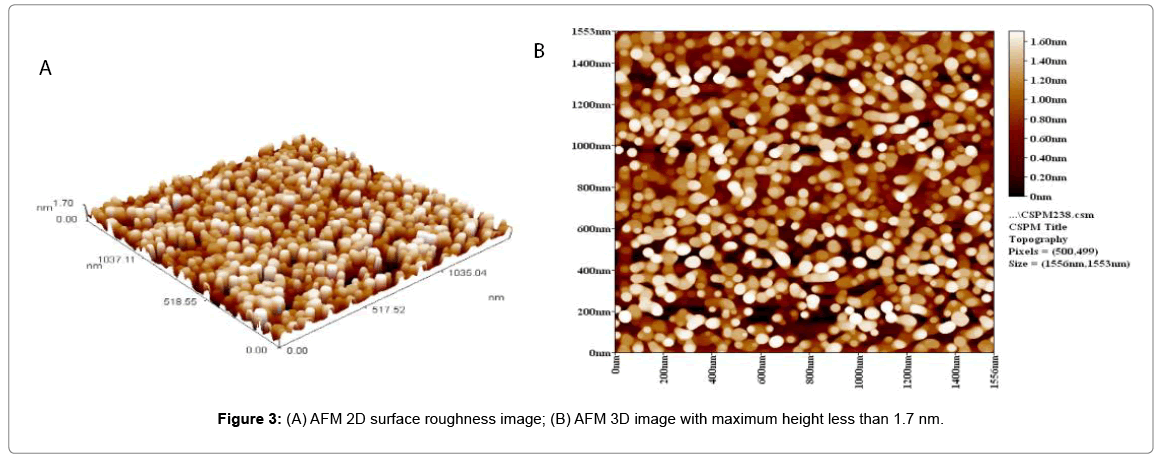

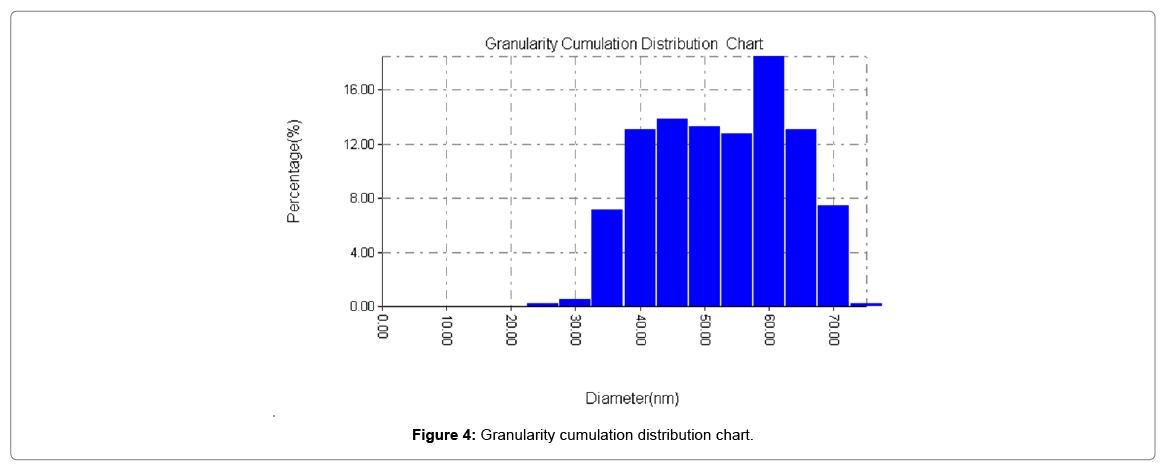

AFM (atomic force microscopy): Surface examination of the ZnO NPs test was analyzed utilizing Scanning test microscopy constitutes a group of cutting edge systems for surface investigation [19,20]. AFM has formed into a multifunctional procedure reasonable for portrayal of geography, 3D roughness (x, y and z) and surface, surface unpleasantness 2D, and different properties on scales from several microns to nanometers (Figures 3 and 4 and Table 1).

| Diameter (nm) < | Volume (%) | Cumulation (%) | Diameter (nm) < | Volume (%) | Cumulation (%) | Diameter (nm) < | Volume (%) | Cumulation (%) |

|---|---|---|---|---|---|---|---|---|

| 25 | 0.26 | 0.26 | 45 | 13.81 | 34.78 | 65 | 13.04 | 92.33 |

| 30 | 0.51 | 0.77 | 50 | 13.3 | 48.08 | 70 | 7.42 | 99.74 |

| 35 | 7.16 | 7.93 | 55 | 12.79 | 60.87 | 75 | 0.26 | 100 |

| 40 | 13.04 | 20.97 | 60 | 18.41 | 79.28 |

Table 1: Granularity cumulation distribution.

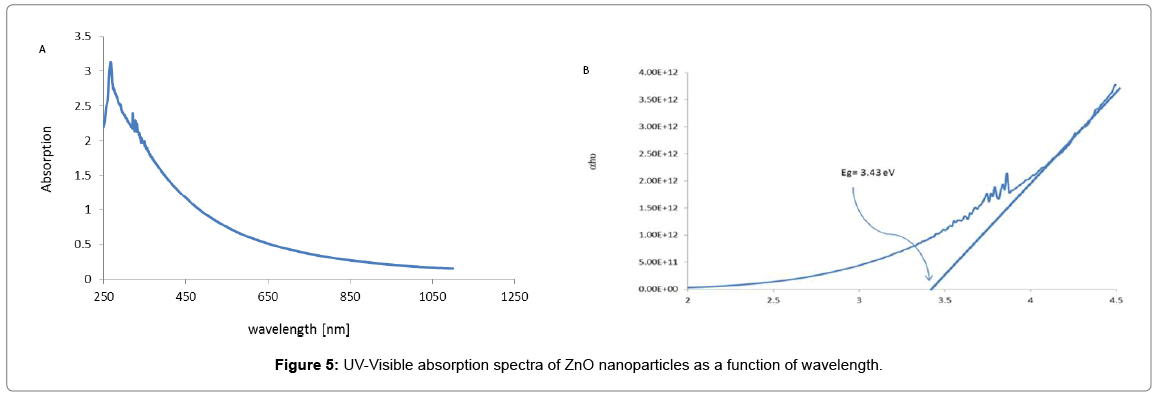

UV-spectrum: Shows Figure 1a the UV-Visible absorption spectra of ZnO nanoparticles as a function of wavelength. The absorption spectrum shows a sharp absorbance onset at 266 nm, which in dictates an almost uniform size of the nanoparticles. However, upon a change in particle size or particle shape, as a light shift in the absorption was observed. Our result is approximately nearly near values with those of other authors [15,21]. This behavior is typical for many semiconductors due to internal electric fields within the crystal and inelastic scattering of charge carriers by phonons Absorption coefficient (α) associated with the strong absorption region of the sample was calculated from absorbent (A) and the sample thickness (t) was used the relation:

α=2.303A/t

The direct band gap of ZnO is estimated from the plot of [(αhν) 2 vs. hν] where hν is the photon energy and α are the ratio of the absorption coefficient to the scattering coefficient and found to be 3.43 EV as calculated from the Figure 1b. This value is very close to the standard value (=3.3 eV). Other researchers have been reported by Alwan et al. [15] which indicate lower band gap (2.935 eV) (Figure 5).

Mechanical tribology: The surface roughness results of the prepared samples of ZnO/Polystyrene is obtained and revealed that the surface roughness of samples that are of different weight is the acceptable surface (low roughness range).This result enables the ZnO/polystyrene nanocomposite to be ready for use in various applications (Table 2).

| ZnO/polystyrene nanocomposite sample weight composition (g) | Surface roughness (µm) |

|---|---|

| 0.056/0.8 | 0.363 |

| 0.056/1 | 0.295 |

| 0.056/2 | 0.61 |

| 0.056/2.5 | 0.54 |

| 0.056/3 | 0.207 |

Table 2: Surface roughness results.

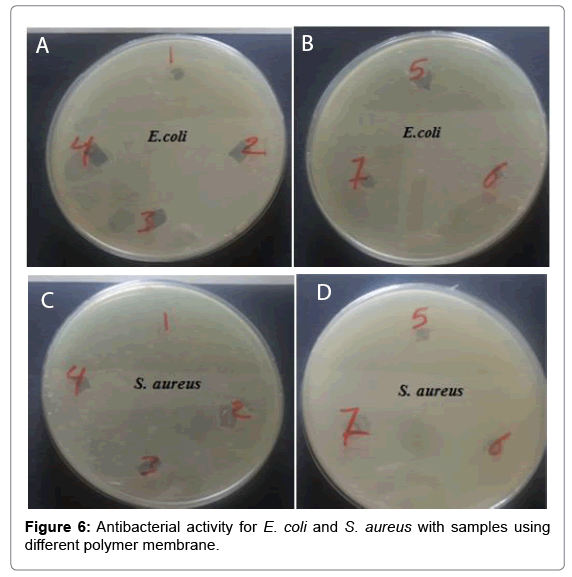

Culture and antibacterial test: Bacterial cultures like E. coli and S. aureus were obtained from Nano-biotechnology lab of Nanotechnology and advanced material research center. We determined the optical densities of the growing cultures by measuring Optical Density (OD) at 600 nm to obtain a culture of bacteria at 107 cell/ml concentration. The antibacterial test is making by disc diffusion method. Nutrient Agar (N.A) was used to cultivate bacteria. The media was autoclaved and cooled. The Nutrient Agar media was poured in the Petri discs and kept for 30 min for solidification. After 30 min 100 μl of two different cultures pour onto the agar plate separately, allowed to solidify. Then a paper disc cut from each polymer membrane is made and put over each placed in a plate of E. coli and S. aureus. Then the cultured agar plates were incubated at 37°C for 24 h of incubation to study the zone of inhibition and adhesion of bacteria with each polymer.

Results

Moreover, in this test we use the different member of polymer with different concentrations to test their antimicrobial activity against E. coli and S. aureus as shown in Figures 6a and 6b. As shown in Figure 6a, we found that each membrane leads to form the adhesion state of the cell membrane of E. coli with each polymer depending on the type of polymer using in each type and also leads to killing the bacteria as shown in samples (1-7). Besides, Figure 6b, also show the samples (1-7) results in the same state of adhesion the cell membrane of S. aureus with each polymer membrane depending on the type of membrane using in this test and killing the bacteria.

Since, the results of their antimicrobial activity, improve that the polymer membrane results in increasing the adhesion state against E. coli and S. aureus depending on the synthesis method (Figure 6).

Conclusion

In the present study, a simple method for the preparation of ZnO nanoparticles and preparation ZnO nanocomposite film/PS has been developed for the expression of functional properties. ZnO NP has found the average particle size to be 21.15 nm using Scherer’s equation and 727- 900 nm obtained from SEM measurement. From AFM reveals a particle size of 18.41 nm. The UV-Visible study shows blue shift absorption at ~266 nm. Allowed direct band gap energy of ZnO nanoparticles are found to be very closer (3.43 eV) as compared to the standard (3.3 eV). ZnO nanocomposite film/PS, the surface roughness has and the treated fabric shows antibacte¬rial activity for fabric polystyrene. Thus the fabric may be able to protect the body against solar radiation, bacterial action and for other technological applications.

References

- Suruchi, Vinod R (2012) Investigation of thermo electret state polyurethane-Cds nanocomposite. International Journal of Mechanical Engineering and Technology (IJMET) 3: 258-256.

- Luo J, Li X, Hou Q (2007) High-efficiency white-light emission from a single copolymer: Fluorescent blue, green and red chromophores on a conjugated polymer backbone. Adv Mater 19: 1113-1117.

- Zhen HY, Xu W, King W, Chen Q, Xu Y, et al. (2006) White-light emission from a single polymer with singlet and triplet chromophores on the backbone. Macromol Rapid Commun 27: 2095-2100

- Shaffer M, Koziol K (2002) Polystyrene grafted multi-walled carbon nanotubes. Chem Commun 18: 2074.

- Walker JP, Asher SA (2005) Acetylcholinesterase-based organophosphate nerve agent sensing photonic crystal. Anal Chem 77: 1596-1600.

- Yi GC, Wang C, Park WI (2005) ZnO nanorods: synthesis, characterization and applications. Semicond Sci-Tech 20: 22-34.

- Ghoshal T, Kar S, Chaudhuri S (2007) ZnO doughnuts: Controlled synthesis, growth mechanism and optical properties. Crystal Growth and Design 7: 136–141

- Schwartz DA, Norberg NS, Nguyen QP, Parker JM, Gamelin DR (2003) Magnetic quantum dots: Synthesis, spectroscopy and magnetism of Co2+- and Ni2+-doped ZnO nanocrystals. J Am Chem Soc 125: 13205-13218

- Chen CY, Chiang CL (2008) Preparation of cotton fibers with antibacterial silver nanoparticles. Mater Lett 62: 3607-3609.

- Applerot G, Lipovsky A, Dror R, Perkins N, Nitzan Y, et al. (2009) Enhanced antibacterial activity of nano-crystalline ZnO due to increased ROS-mediated cell injury. Adv Funct Mater 19: 1-11.

- Huang Z, Zheng X, Yan D, Yin G, Liao X, et al. (2008) Toxicological effect of ZnO nanoparticles based on bacteria. J Nanopart Res 9: 479-489

- Nair S, Sasidharan A, DivyaRani VV, Menon D, Nair S, et al. (2009) Role of size scale of ZnO nanoparticles and microparticles on toxicity toward bacteria and osteoblast cancer cells. J Mater Sci Mater Med 20: 235-241

- Mirhosseini M, Firouabadi FB (2013) Antibacterial activity of zinc oxide nanoparticle suspensions on food-borne pathogens. Int J Dairy Technol 66: 291-295.

- http://www.smtcorp.com/scanning-electron-microscopy

- Alwan RM, Kadhim QA, Sahan KM, Ali RA, Mahdi RJ, et al. (2015) Synthesis of zinc oxide nanoparticles via sol-gel route and their characterization. Nanosci Nanotechnol 5: 1-6.

- Hong RY, Chen LL, Li JH, Li HZ, Zheng Y, et al. (2007) Preparation and application of polystyrene-grafted ZnO nanoparticles. Polym Adv Technol 18: 901-909.

- Sangeetha N, Kumara GL (2013) Extracellular synthesis of zinc oxide nanoparticles using Seaweeds of the Gulf of manner, Indiana. J Nanobiotechnol 11: 1-11

- Kathirvelu S, Louis D (2009) UV protection finishing of textiles using ZnO nanoparticles. Indian Journal of Fiber and Textile Research 34: 207-273.

- Chen CJ (1993) Introduction to scanning tunneling microscopy. Princeton: Princeton Univ. Press.

- Magonov SN, Whangbo MH (1996) Surface analysis with STM and AFM. Weiheim: VCH.

- Guo L, Cheng XY, Yan YJ, Ge WK (2001) Synthesis and optical properties of crystalline polymer-capped ZnO nanorods. Materials Science and Engineering 16: 123-127.

Relevant Topics

- Agricultural biotechnology

- Animal biotechnology

- Applied Biotechnology

- Biocatalysis

- Biofabrication

- Biomaterial implants

- Biomaterial-Based Drug Delivery Systems

- Bioprinting of Tissue Constructs

- Biotechnology applications

- Cardiovascular biomaterials

- CRISPR-Cas9 in Biotechnology

- Nano biotechnology

- Smart Biomaterials

- White/industrial biotechnology

Recommended Journals

Article Tools

Article Usage

- Total views: 3938

- [From(publication date):

September-2017 - Aug 24, 2025] - Breakdown by view type

- HTML page views : 2998

- PDF downloads : 940