Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

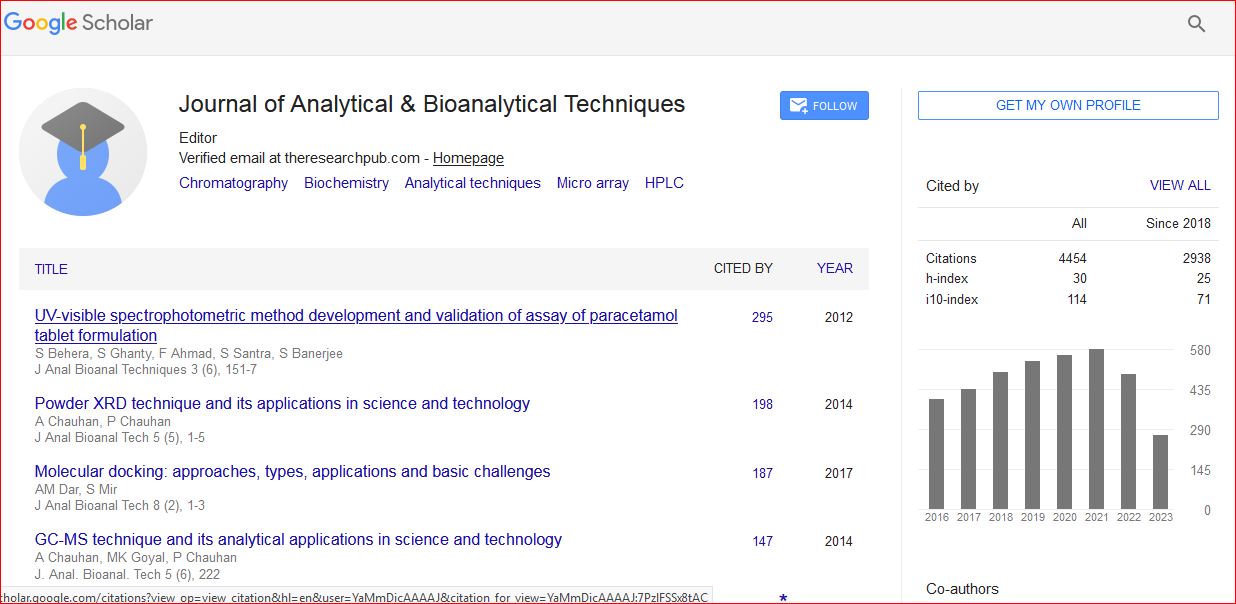

Google Scholar citation report

Citations : 6413

Journal of Analytical & Bioanalytical Techniques peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Academic Journals Database

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- ResearchBible

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Euro Pub

- ICMJE

Useful Links

Related Subjects

Share This Page

Structural and functional analysis of key proteins involved in ESX-1 secretion system of M.tuberculosis: Novel targets for drug developments

3rd International Conference and Exhibition on Analytical & Bioanalytical Techniques

Ajay K. Saxena

ScientificTracks Abstracts: J Anal Bioanal Techniques

Abstract

Flavour is usually the result of the presence, within complex matrices, of many volatile and nonvolatile components with diverse chemical and physicochemical properties. A vast array of compounds may be responsible for the aroma of food products, such as alcohols, aldehydes, esters, dicarbonyls, short to medium chain-free fatty acids, methyl ketones, lactones, phenolic compounds and sulphur compounds. The use of enzymes to improve the traditional chemical processes of food manufacture has been developed in the past few years for the production of nonvolatile components. Lipases are the most versatile biocatalysts and bring about a range of bioconversion reactions such as hydrolysis, interesterification, esterification, alcoholysis and aminolysis (V.c. aragao et al., 2011). Since lipases are widely used in food industries, it is necessary to study their performance during the esterification reaction. Accurate control of lipase concentration, alcohol and/or acid concentration, temperature and reaction time is required to maximize the production of flavour ester. In the study, the esterification percentage of the enzymatic synthesis of ethyl butyrate production has been evaluated by using factorial design and response surface methodology. In order to establish the optimal conditions of esterification, temperature, ethanol/butyric acid molar ratio, enzyme concentration and butyric acid concentration were evaluated in a fractional factorial design (2 4 �1) followed by a 24 central composite rotatable design (CCRD) , response surface methodology (V.C. ARAG�O et al.; 2011) and compared with genetic algorithms which is an stochastic evolutionary optimization technique. These type of evolutionary algorithms have gained popularity in solving optimization problems. Genetic algorithm which is more effective regardless of the nature of the objective functions and constraints and have been well known to provide global optimal solutions. Three basic operations used in GA: Reproduction, Crossover and Mutation. The results indicate the genetic algorithm is able to generate the optimal conditions for maximum esterification percentage within reasonable number of cycles. The performance of the model is evaluated by comparing GA predictions with the RSM model.Biography

J. S. Eswari has obtained her M.Tech Biotechnology from IIT, Kharagpur. Currently working as Woman-Scientist at IICT, Hyderabad and pursuing Ph.D from IIT, Hyderabad. Published few papers in reputed journals and worked in sponsored projects. P Swapna Reddy has obtained her M.Tech Chemical Plant Design from NIT Karnataka. Currently working as Senior Research Fellow at IICT, Hyderabad and pursuing Ph.D from IIT, Bombay. Published few papers in reputed journals and international conferences.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi