Research Article Open Access

Analysis of the Use of Thermal Biomass on Healthcare Centers in Extremadura (Spain)

Sanz-Calcedo JG*University of Extremadura, College of Industrial Engineering, Avda de Elvas s/n, 06006 Badajoz, Spain

- *Corresponding Author:

- Sanz-Calcedo JG

Professor, University of Extremadura

College of Industrial Engineering

Avda de Elvas s/n, 06006 Badajoz, Spain

Tel: 34 924 289600

E-mail: jgsanz@unex.es

Received Date: December 19, 2016; Accepted Date: December 22, 2016; Published Date: December 26, 2016

Citation: Sanz-Calcedo JG (2016) Analysis of the Use of Thermal Biomass on Healthcare Centers in Extremadura (Spain). J Archit Eng Tech 5: 182. doi: 10.4172/2168-9717.1000182

Copyright: © 2016 Sanz-Calcedo JG. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Architectural Engineering Technology

Abstract

Hospital are shown to be suitable facilities for installation of thermal production systems based on biomass, provided their high rates of hot domestic water consumption as well as the high heating and cooling energy needs. Given the particular features of this type of buildings, amortization would be guaranteed by continuous operation of equipment. In addition, it is enhanced that the promotion of biomass as renewable energy source might help create and consolidate a native biomass market (at emerging stage at beginning of this project and currently at consolidation stage) which will eventually serve to improve economic development in rural areas.

Keywords

Healthcare centre; Biomass; Energy efficiency; Environmental performance

Introduction

The installation of systems based on thermal power generation from biomass in the building sector is one of main current challenges faced by the renewable energy sector, which remains underdeveloped in Spain for the particular case of biomass [1]. However, technology regarding biomass energy conversion was proved to ensure efficient operation [2].

The contribution of biomass as energy source in Europe was reported as 82.341 Mtoe by 2012 [3], which represents an approximate average of 0.165 toe per capita. In Spain, however, the consumption of biomass in the same year was 4.833 Mtoe, which averages 0.107 toes per inhabitant. This means that Spanish biomass consumption for energy production is 35% lower than the European average.

The implementation of biomass energy technologies is strongly favoured by their application to public buildings frequently visited by large numbers of users. This is the case of hospitals, buildings in continuous operation that show very high rates of influx.

The thermal energy consumption in Spanish hospitals, if heating and hot domestic water energy needs are accounted for, approaches 40% of the total primary energy consumption of each building [4].

The main goal sought by the production of thermal energy at hospitals is to ensure maximum comfort conditions for patients and staff, taking into account costs, fuel supply conditions and environmental impact. Measures to improve energy efficiency of a hospital should also account for climatic and local conditions [5] as well as indoor climate environment [6] and cost-effectiveness. In addition, it should not contravene other essential requirements of this type of buildings, such as accessibility, security in electric supply [6] and reliability of facilities.

The use of biomass as fuel is observed to meet the abovementioned requirements. Moreover, biomass energy techniques would promote the use of a widely available renewable energy source in the Autonomous Community of Extremadura [7], and would also serve to suitably change wastes into raw material for energy purposes [8]. However, the background to the use of biomass [9] has few precedents in the particular case of hospitals [10-12].

Vanhoudt et al. demonstrated that in a hospital in Belgium, it is possible to save up to 71% of primary energy system by using thermal energy storage in combination with a heat pump compared to a gasbased boilers and installation water cooling machine [13]. Santamaria et al. carried out a detailed analysis of audits regarding 30 health care buildings in Greece (Hellas) to quantify the potential global energy saving as 20% [14]. That is, it is possible to save substantial energy in these buildings.

─?ongradac et al. proposed a tool for assessing the heating and cooling energy consumption in hospitals, that its main advantage is a very simple usage, which implies knowing and entering parameters that are easy to find [15]. This in turn entails a certain inaccuracy in the calculation, but which is neither large nor significant, considering that the main emphasis of use of this tool is to determine the possible savings. The same authors in 2014 explored in an Emergency Center in Serbia, that when the savings are known in advance, the competent person will make a much easier decision on installation, the cost of necessary work and equipment, without having the assistance from professional advisors [15].

The aim of this study is to evaluate the feasibility of renewable energy obtained from biomass for the production of heat and cold at healthcare centers. The technical aspects including reliability and maintainability, and the problems associated to the application of renewable energies obtained from biomass in public buildings are also assessed.

Methodology

Two building facilities were analyzed in order to achieve a significant data record: a burning olive stones power unit designed to partially satisfy the thermal demand of Zafra Hospital (in Badajoz), and two biomass boilers fed with almond shells used for heat or heatcool production (in winter and summer, respectively). The latter equipment corresponds to a simple absorption machine installed at an administration building of the Public Health Service of Extremadura [16].

Periodic energy audits were conducted during the course of the present study in order to carry out in situ analyses of the situation in terms of energy management. These records served as start up technical background to perform the projected works [17].

To analyze the reliability and maintainability of the equipment, each component was accounted for in the maintenance plan of the building, and specific timings for maintenance tasks were appropriately set. Daily repairing and maintenance operations on biomass boiler and ancillary equipment were carefully timed. In addition, data regarding global efficiency of the installation was monitored.

The data collection process was completed with specific information obtained from the archival files of the Engineering and Maintenance Service.

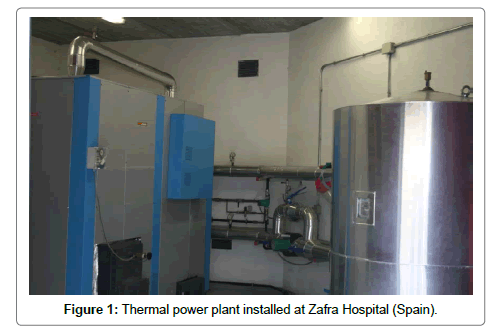

Thermal power plant in hospital

The biomass boiler was installed as complementary equipment to the existing units for heat and domestic hot water production. In particular, it is the 430 Bioselect model from Lassian Manufacturer, with 430 kW output, made of sheet steel with a three-step vertical flue cleaning system, and operates at a pressure of 4 bar. The biomass burner is modulating cascade type, with automatic ignition and ash pusher system, and incorporates a retrieval system of solid particles based on the cyclone effect. Figure 1 shows a view of such power plant.

A 2,000 l buffer tank was installed as heat sink to prevent multiple burner starts, in order to regulate the heating energy demand and therefore achieve a greater efficiency. This way, the performance was optimized and operating life of facilities was extended [18]. The operating temperature was regulated at 84°C.

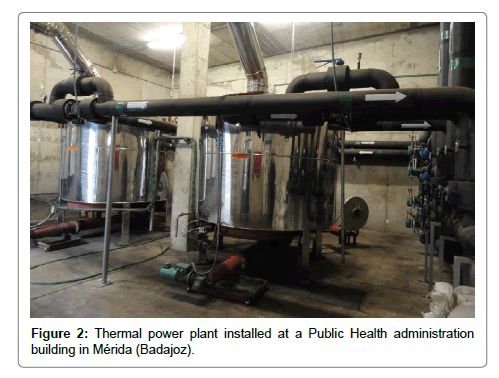

Thermal power plant in administration building

Heat energy was obtained by two identical Spanish Vulcano manufacturer boilers, 465 kW thermal power each, supplied with almond shells obtained from local agrifood industries. A 70 m³ storing tank was installed in a separated room. Figure 2 shows a view of the two boilers.

Cooling was achieved by a Carrier water chiller, 545 kW nominal cooling capacity, simple absorption cycle effect with lithium bromide as absorbent and water as coolant, fed by hot water from the abovementioned boilers and equipped with a 1,203 kW power cooling tower.

The designed operating protocol was inertial, i.e. there is no an immediate response to the thermal requirements of the building neither from the absorption engine nor from the biomass boilers, nor is there immediate response to installation shutdown. For that reason, a storage system was installed to partially make up for the lack if instantaneous response, as well as to help reach the activation temperature of the generator.

The device was also equipped with a hot water (92°C) storage system consisting of three tanks of 10,000 l capacity each. This accumulation guaranteed, on the one hand, that enough thermal power would be supplied to the generator as to reach the boiler temperature regime. On the other hand, it also allowed a 400 kW momentum in heating mode for the building during the winter season.

The facility includes four cold water storage tanks 5,000 liters each which contain water at 7°C used for initial star up. This corresponds to 15% of partiality of the absorption engine [19,20].

Results

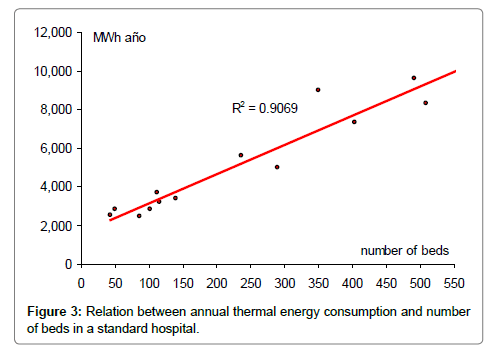

The average consumption of natural gas and diesel oil from various public hospitals in Extremadura (Spain) was analyzed in order to estimate the thermal energy need of a standard hospital, which was found to be proportional to its number of beds.

Figure 3 shows a scatter plot of the two abovementioned variables. Basic data processing tools were used to carry out a linear fit (R2=0.9069) leading to the following expression:

y=15.08 x + 1,657 (1)

y being the average annual consumption in standard operation and occupation conditions, expressed in MWh, and x being the number of beds in hospital.

The results achieved in the present study are discussed in the forthcoming subsections, according to different relevant aspects.

Biomass fuel

Different types of biomass material are available in Extremadura, according to local market availability. The most common are the following: olive stone, pruning from olive and fruit trees to make wood chips, wood cuts from forestry industry, shell nuts, forest residues and concentrates on vine and pellets.

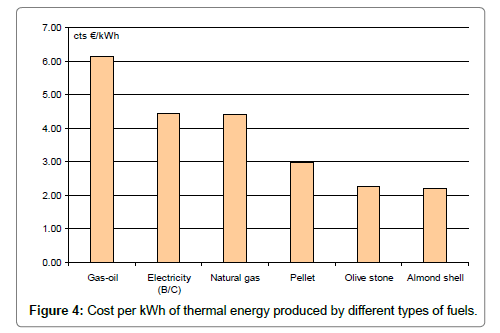

We proceeded to assess the economic cost per kilowatt hour on the use of different fuels, considering the transportation costs to the point of supply, compared with the costs of non-renewable fuels (diesel and natural gas), taking into account market prices (December 2011) for a consumption equivalent to that provided annually in a 100-bed hospital [21,22].

The biofuels tested to verify feasibility requirements in hospitals were crushed olive pits, almond shells and different types of pellets.

Figure 4 represents the final costs of different fuels expressed in cents€ per kWh unit produced heat energy. Olive stone was observed to be 20%, 41% and 50% cheaper than pellet, natural gas and gas-oil, respectively (The efficiency of solid fuel boilers assumed to be 6% lower than that of the other types of boiler [23].

In the medium to long term, the strong increasing trend of the hydrocarbon production costs (and derivatives) is expected to enlarge the gap with respect to biofuels, for which production costs tend to stabilization as byproducts transformation industries approach consolidation.

Crushed olive stone is a type of fuel directly obtained from the olive milling process, and is therefore a byproduct from olive oil industry. On another note, almond shell is a byproduct from the agrifood industry obtained from shelling operations. Table 1 lists the main physical and chemical features of these two biomass fuels.

| Parameters | Olive stone | Almond shell |

|---|---|---|

| Size (mm) | <5 | <11 |

| Density (kg/m3) | 680 | 400 |

| Humidity (%) | 7.10 | 8.00 |

| PCI (kWh/kg) | 4.87 | 4.75 |

| Ash (%) | 0.55 | 0.97 |

| Volatile (%) | 74.25 | 75.04 |

| Sulphur (%) | 0.04 | 0.02 |

| Chlorine (%) | 0.064 | 0.02 |

| Fixed carbon (%) | 19.49 | 18.40 |

Table 1: Physic-chemical characterization of biofuels.

Maintenance

Preventive maintenance of biomass installations involves activities like cleaning, regulation and ashtray emptying. These additional tasks were averaged to take 60 minutes a day. Such maintenance leads to a 120% increase if compared to standard thermal energy production facilities (diesel or natural gas) in hospitals.

Moreover, the technology applied to biomass boilers has elsewhere been shown to be less reliable than that of standard natural gas or diesel boilers, particularly at early operating periods. The lower availability of biomass boilers [24] should therefore be balanced by duplication of biomass facilities and/or installation of a standard fuel support unit.

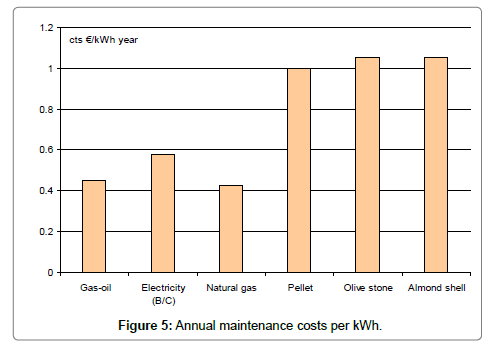

The bar-diagram in Figure 5 represents costs due to maintenance operations for several types of fuels typically used for heat production.

Investment

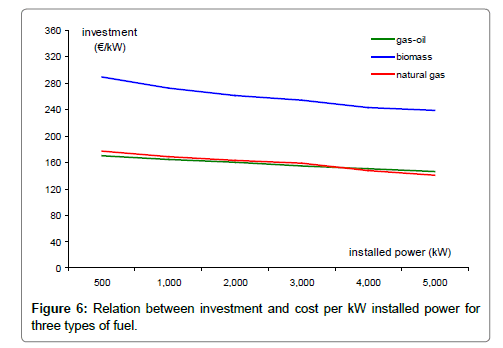

Detailed calculations were performed in order to determine the investment per unit useful energy for both conventional (diesel and natural gas) and biomass energy facilities.

As observed in Figure 6, the higher the installed power of the biomass facilities, the lower the costs needed to implement the installation.

Environmental balance

Net carbon dioxide emissions during combustion of biomass are almost negligible, as the plant is able to retain plant during its growth more CO2 than is released in the combustion (IPCC, 207). As for the other pollutants, emissions are so low that they are considered negligible, so that practically emitted by diesel or natural gas, agree with it avoided being replaced by biomass.

As can be seen in Table 2, the heat production by biomass alone increases the emission of particles into the atmosphere, mainly consisting of fly ash carbon (although the term particle includes those constituents, except pure water, present in the atmosphere in solid or liquid phases, larger than that of simple molecules and less than 100 microns). Still, the rate of emitted particles was found to be below the allowable limits for installation of solid fuel [25].

| Emissions (kg) | Zafra Hospital | Administration building |

|---|---|---|

| NO2 | -5,852.81 | -7,316.01 |

| SO2 | -303.53 | -379.42 |

| CO | -1,249.17 | -1,561.46 |

| CO2 | -242,829.00 | -303,537.00 |

| Particles | + 140.72 | +175.90 |

| Ash | +3,276.27 | +4,095.33 |

Table 2: Annual environmental balance.

Amortization

A comparative analysis of the biomass installation and the diesel equipment which was operating at the hospital was carried out aimed at evaluating the economic viability of the project. For such purpose, the annual cost of each fuel needed to produce the same thermal energy in the hospital was determined.

As shown in Table 3, the total estimated savings over the life expectancy of the equipment (Sartori), were found as 231,310€, leading to a payback period of 5.4 years, less than that of other types of energy facilities based on solar energy gain. Note that the pay-back time achieved for the Public Health administration building was determined as 5.56 years.

| Indicator | Zafra Hospital | Administration building |

|---|---|---|

| Investment | 177,000€ | 352,000€ |

| Grant | 51,600€ | 0 |

| Installation cost | 125,400€ | 352,000€ |

| Annual saving | 23,131€ | 63,270€ |

| Pay-back time | 5,4 years | 5,56 years |

| Saving (10 years) | 231,310€ | 632,700€ |

Table 3: Economic balance of biomass boiler.

Conclusions

Hospital buildings have been regarded as suitable locations for the installation of thermal energy production equipment based on biomass supply, provided their high annual demand of hot domestic water and thermal energy. Moreover, refund of investment is strongly favoured by continuous operation of the building facilities.

There continuous presence of maintenance staff in the hospitals rooms where boilers are installed allows spending as much time as necessary in additional maintenance operations arising from boiler house cleaning and ash removal. Specific lifelong training programs for maintenance staff is therefore crucial for the implementation and development of renewable energy units.

On another note, promoting renewable energy sources through the use of biomass in hospital facilities might help the consolidation of a local biomass market, which would eventually enhance rural economic growth, promote socioeconomic development and reduce the dependence on foreign fuel supply.

However, it should also be pointed out that biomass energy units need larger storage room, and that biomass boilers yield is lower than that of conventional ones.

Let us finally note that the high annual production of ash from the biomass boilers generates interesting expectations derived from its moderate liming and fertilizing capacities. Moreover, it suggests an important route to appreciation of the abovementioned waste, provided that it proved to improve the nutritional status of plants [26] by significantly favouring soil porosity and the water retention capacity.

Acknowledgments

The authors wish to thank the Extremadura Energy Agency for collaboration during the development of the present work, which was supported by Project GR 10099 from the Regional Government of Extremadura and the European FEDER funds. The architects that drafted the project and the staff responsible for project management are also deeply acknowledged.

References

- Benedicto GL (2003) Instalaciones combinadas de energía solar térmica y biomasa en edificios. Equipamiento y Servicios Municipales 105:16-25.

- Idea (2007) Energía de la Biomasa. Instituto para la Diversificación y el Ahorro de la Energía, Madrid.

- Observ ER (2006) Solid biomassbarometer. In 6 reportstate of renewableenergies in Europe.

- CalcedoGSJ, Garrido S,Pérez C, López F(2007) Energy Management in HealthServices. Hospital Engineering34: 31-38.

- Huang YL, Mclaughlin CP (1989) Relativeefficiency in rural primaryhealthcare: anapplication of data envelopmentanalysis. HealthServiceResearch 24: 143-158.

- Vargas F, Gallego I (2005) Calidad Ambiental Interior: Bienestar, Confort y Salud. Revista Española de Salud Pública. 79: 18-24.

- Yoshida S, Ito K, Yokohama R(2007) Sensitivityanalysis in structureoptimization of energysupplysystemsfor a hospital. EnergyConversion and Management 48: 2836-2843.

- López F (2007)Evaluation of BiomassProduction in Extremadura. Agencia Extremeña de la Energía.

- Idae (2007) Biomasa Edificios. Instituto para la Diversificación y el Ahorro de la Energía. Madrid.

- Ruiz A(2003) Modeling of biomassplantsforelectricpowergeneration. Universidad de Extremadura.

- CalcedoGSJ, Cuadros F, López F(2011)Efficiency of a biomass boiler in a hospital. Use of crushed olives bonesforheatproduction 86: 343-349.

- González STV(2009) Installation of Biomass of the Hospital of the East of Asturias. 16º Congreso Nacional de Hospitales, Cáceres.

- Vanhoudt D, Desmedt J,BaelVJ, Robeyn N, HoesH (2011)Anaquiferthermalstoragesystem in a Belgian hospital: Long-term experimental evaluation of energy and costsavings. Energy and Buildings 43: 3657-3665.

- Santamouris M, Dascalaki E, Balaras C, Argiriou A, Gaglia A(1994)Energy performance and energyconservation in healthcarebuildings in Hellas. EnergyConversion and Management 35: 293-305.

- ─?ongradac V, Prebira─Źevi─? B, Jorgovanovi─? N, Staniši─? D (2012)Assessingtheenergyconsumptionforheating and cooling in hospitals. Energy and Buildings 48: 146-154.

- ─?ongradaca V, Prebira─Źevi─?b B, Petrova─Źki N(2014) Methods forassessingenergysavings in hospitalsusingvarious control techniques. Energy and Buildings 69: 85-92.

- Martínez RF, Gómez VE (2006) Eficiencia energética en edificios. Certificación y Auditorías Energéticas Thomson.Editorial Paraninfo.

- Thormark C(2002)A lowenergybuilding in a lifecycleitsembodiedenergy, energyneedforoperation and recyclingpotential. LundInstitute of Technology. Building and Environment 37: 429-435.

- Pérez C, Rodríguez LF, CelmaRA(2005) Potencial of forestbiomass in Extremadura andenergyexploitation. NationalCongressonRenewableEnergy, Murcia.

- Rojas S, Ruiz A, Miranda T, Mondragão FL, Pargana G, et al. (1999) Energypotential of concentratedwastefromthe vine in Extremadura and Alentejo. Junta de Extremadura.

- Rodríguez F, García Sanz-Calcedo J, Pérez C (2006) “Gestión Energética en Centros Sanitarios”. El Médico 997: 12-18.

- Bouchy F (1999)MaintenancemanagementEvaluation and mutation. Évolution et mutation. Asociación Española de Normalización.

- Intergovernmental Panel OnClimateChange (2007) TheFourthAssessmentReport. Organización Meteorológica Mundial.

- López F, Cuadros F, Segador C, Ruiz A, CalcedoGSJ, et al. (2011) The Peter buildingAnexample of integration of renewableenergies in thebuilding. Dyna Ingeniería e Industria 86: 212-221.

- Sartori I, Hestnes AG(2007) Energy use in thelifecycle of conventional and low-energybuildings: A reviewarticle. Energy and Buildings 39: 249-257.

- Omil B, Piñeiro V, Merino A (2007) Trace elements in soils and plants in temperateforestplantationssubjectedto single and multipleapplications of mixedwoodash. Science of the Total Environment 381:157-168.

Relevant Topics

- Architect

- Architectural Drawing

- Architectural Engineering

- Building design

- Building Information Modeling (BIM)

- Concrete

- Construction

- Construction Engineering

- Construction Estimating Software

- Engineering Drawing

- Fabric Formwork

- Interior Design

- Interior Designing

- Landscape Architecture

- Smart Buildings

- Sociology of Architecture

- Structural Analysis

- Sustainable Design

- Urban Design

- Urban Planner

Recommended Journals

Article Tools

Article Usage

- Total views: 3484

- [From(publication date):

December-2016 - Sep 03, 2025] - Breakdown by view type

- HTML page views : 2600

- PDF downloads : 884