Cellulase and Xylanase Production by Pleurotus sp. on Mixed Substrate System

Received: 02-May-2017 / Accepted Date: 22-May-2018 / Published Date: 29-May-2018 DOI: 10.4172/2155-952X.1000283

Keywords: P.florida; P.djamor; Cellulose; Xylanase; Fermentation

Introduction

Pleurotus sp. are wood destroying saprophytic fungi which occur widely in the tropical and temperate zones [1]. Species of Pleurotus are commonly known as “Oyster Mushroom”. P.sajor-caju, P.fabellatus, P.erungii, P.citrinipileatus are commonly cultivated [2]. Bioconversion of lignocellulosic residues through mushroom cultivation offers the potential of converting them into protein rich, palatable food [3]. As early as straw is found to be a good substrate for growing Pleurotus [4] since that time, it’s use has been studied in most of the rice producing countries of the world. The ability of Pleurotus species to excrete hydrolyzing and oxidizing enzymes has enabled them to flourish over a wide range of natural lignocellulosic waste materials [5,6]. India has great future to cultivate mushrooms. It can be artificially cultivated on different agricultural waste like paddy straw, wheat straw, sugar cane bagasse and etc.,. The artificial cultivation of oyster mushroom has not only economically efficient for farmers and has the ability to produce extracellular lignocelluloytic enzyme like cellulase, xylanase, lignin peroxidase, manganese peroxidase and laccase [7,8].

In recent years, the lignolytic degradation and extra-cellular enzyme production by Pleurotus sp. has been extensively studied. The enzyme excretion have varied during colonization and fructification stages of Pleurotus growth [9]. To overcome these crises, various methods have been used for the production of extra-cellular enzyme [10]. Enumerated the advantages of extra-cellular enzymes production by Pleurotus through Solid State Fermentation (SSF) [11]. Showed about ligninolytic and celluloytic enzyme pattern and activities were influenced by substrate. Thus, the capacity of particular substrate to induce or increase production of lignocellulases is another factor that indirectly confers ability of extra-cellular enzymes production. The present study is focused on the production of cellulase and xylanase enzymes using Pleurotus florida and P.djamor on sugarcane bagasse, wheat bran and sugarcane bagasse mixed with wheat bran (co substrate) through Solid State Fermentation.

Materials and Methods

Pure cultures and maintenances

Pure culture of Pleurotus flordia and P.djamor were obtained from Tamilnadu Agriculture University, Coimbatore, Tamilnadu, India. They are maintained in Maltose Extract (ME) Medium, at pH 5.8 and incubated for at 250C and are sub-cultured regular interval of three weeks.

Substrate preparation and inoculation

Agriculture residues, Sugarcane bagasse and wheat bran were procured locally and allowed to dry. The agricultural residues were milled and powders made which were passes through 1 mm sieve.

Determination of cellulose and hemicellulose

Cellulose is estimated colorimetrically by the method described by [12]. Pure cellulose is used as the standard and it is obtained from Sigma-Aldrich. Hemicellulose is estimated colorimeterically by the method described by [13]. Pure xylose is used as the standard and it is obtained from Sigma-Aldrich.

Solid state fermentation studies

Ten gram of the substrate by dry weight is taken in 250ml flask and 60% of moisture is set for the substrate with distilled water and sterilized at 1210C for 30min. After cooling, each flask is inoculated with five agar discs from the edges of actively growing colonies of P.florida and P.djamor. After inoculation, the flasks were incubated at 27 ± 10C. SSF is carried out in once every seven days.

Enzyme extraction

Sodium citrate buffer is used for enzyme extraction. The substrate is squeezed with sodium citrate using cheese cloth to get the culture filtrate. This is used as an enzyme source and is stored in refrigerator at 00C until use. Enzymatic assays are done in triplicate.

Cellulase and xylanase assay

Carboxymethylcellulose (low viscosity) and Oat spelt xyaln were used as a substrate to determine the cellulase and xylanase activity respectively. The amount of reducing sugars released during the reaction time is determined by the DNS methods as mentioned by [14].

Result

In the present investigation, Pleurotus flordia and P.djamor are used to evaluate the production of lignocellulolytic enzyme viz., cellulase and xylanase and efficiency of cellulose and hemicellulose degradation through solid state fermentation using Sugarcane bagasse, Wheat bran and mixture of Sugarcane bagasse with Wheat bran as a substrate. Five different composition of substrate is prepared by using Sugarcane bagasse with Wheat bran viz., 100% SB, 75% SB+ 25% WB, 50% SB+ 50% WB, 25% SB+ 75% WB, and 100% WB. In this study, celllulase and xylanase production is studied and also estimate the cellulose and hemicellulose during spawn run stage of Pleurotus growth.

Chemical composition of sugarcane bagasse and wheat barn

The future scope and importance of the fermentation biotechnology industry will depend upon the lignocellulose raw materials [15]. Therefore much attention is given to analysis of the chemical composition of lignocellulosic biomass (Table 1). Shows the Cellulose, Hemicellulose and Lignin composition of sugarcane bagasse and wheat bran. Sugarcane bagasse has higher cellulose and lignin contents. Wheat bran has attained highest hemicellulose content.

| Substrate | Cellulose | Hemicellulose | Lignin |

|---|---|---|---|

| Sugarcane Bagasse | 28.8 | 26.7 | 22.4 |

| Wheat Bran | 21.5 | 35.8 | 18.4 |

Table 1: Chemical composition of the substrates: (% dry weight).

Degradation of cellulose and production cellulase by P.flordia and P.djamor

White rot fungi are the most efficient ligninolytic microorganisms, and they are excellent producers of ligninolytic enzymes in the fermentation of agricultural materials due to their compositions [16]. After one week growth period nearly 20% of cellulose content is degraded by Pleurotus sp. Sugarcane bagasse shows highest amount of cellulose degradation pattern by both species of Pleurotus on 28 days growth. At the same time, Wheat bran shows least cellulose degradation on 28 days growth. Mixture composition of sugarcane bagasse with wheat bran stood in mid-level in cellulose degradation by Pleurotus sp. at end.P.djamor shows superior in cellulose degradation in 100% sugarcane bagasse as a substrate (Table 2).

| Substrate | P.florida | P. djamor | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 7th day | 14th day | 21th day | 28th day | 7th day | 14th day | 21th day | 28th day | |||

| 100% Sugarcane Bagasse (SB) | 20.62 | 32.45 | 52.45 | 65.5 | 21.25 | 35.45 | 57.54 | 68.45 | ||

| 75% SB+ 25% WB | 18.75 | 25.45 | 32.45 | 58.25 | 18.25 | 29.45 | 39.45 | 65.25 | ||

| 50% SB + 50% WB | 17.95 | 31.24 | 39.45 | 55.25 | 19.45 | 35.45 | 58.45 | 62.45 | ||

| 25% SB + 75% WB | 19.54 | 28.45 | 38.45 | 57.70 | 18.75 | 25.45 | 49.45 | 61.75 | ||

| 100% Wheat Bran (WB) | 21.45 | 32.45 | 41.45 | 49.50 | 22.45 | 35.45 | 49.45 | 55.75 | ||

Table 2: Degradation percentage of cellulose content in the substrate after Pleurotus sp. growth.

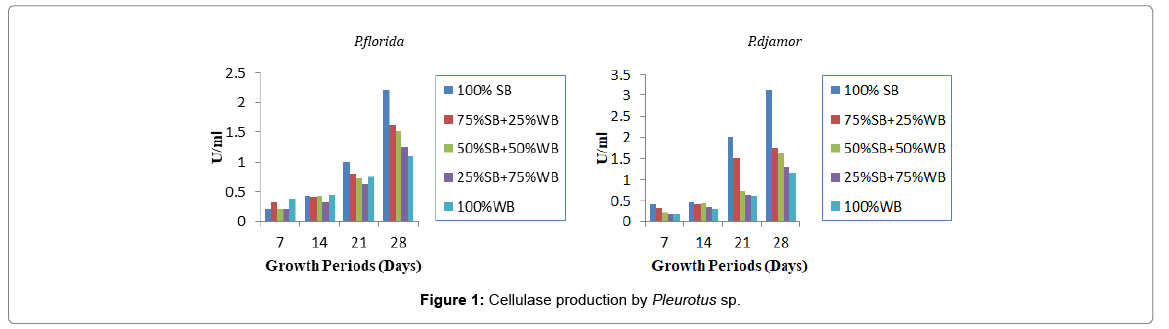

Among the two mushrooms, P.djamor produced more cellulase enzyme (Figure 1). During initial time, both mushrooms produces approximately same amount of cellulase enzyme. From 21st day onwards P.djamor shows superior on cellulase production on 100% sugarcane bagasse as substrate. Comparing to other substrate, sugarcane bagasse is most suitable substrate for cellulase enzyme production. Mixture compositions of sugarcane with wheat bran and wheat bran alone have no significant on cellulase production at the end of 28th days cultivation. But at the same till 14 days cultivation there is no significant difference in cellulase production.

Degradation of Hemi-cellulose and production cellulase by P.flordia and P.djamor

Hemicellulose is the second most abundant polysaccharide after cellulose. Hemicelluloses are biodegraded to monomeric sugars and acetic acid. Endo-1,4-β-xylanase and xylan 1,4-β-xylosidase are the important enzyme to degrade the hemicellulose. Accessory enzymes viz., xylanesterases, ferulic and ρ-coumaricesterases, α-1- arabinofuranosidases and α-4-O-methyl glucuronosidases also acing synergistically to efficiently hydrolyze the agricultural xylan and wood xylan [17].

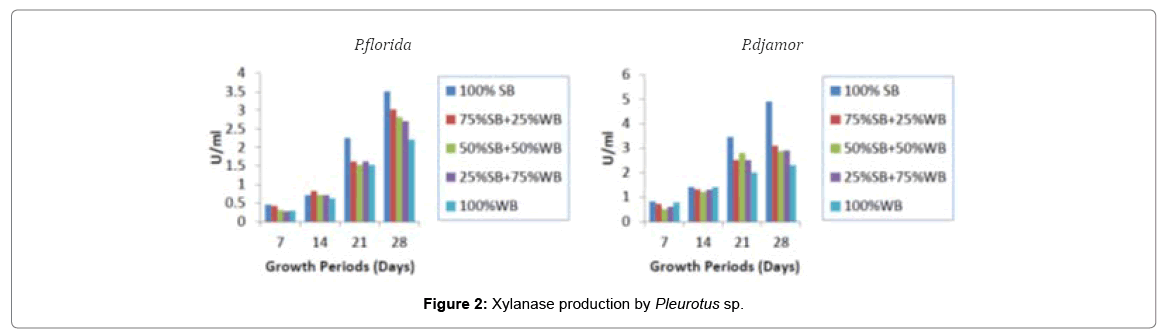

Analysis of chemical composition of wheat bran indicated that wheat bran has the highest hemicellulose content than the sugarcane bagasse. Wheat bran nearly has 35% dry weight of hemicellulose content. Hemicellulose degradation process is also same to cellulose degradation. Here also after one week growth period nearly 20% of hemicellulose content is degraded by Pleurotus sp. At last nearly 65% of hemicellulose content is degraded by two Pleurotussp. In difference, P.floridais attained 65.5% of hemicellulose degradation when substrate as 100% sugarcane bagasse at the end of 28th day culture. In contrast, P.djamor is attained 67.45% of hemicellulose degradation when wheat bran alone used as substrate Table 3. Degradation percentage of Hemicellulose content in the substrate after Pleurotus sp. growth. Xylanase production in P.djamor is found to be highest after 7 days of growth (Figure 2). 100% Sugarcane bagasse supported maximum xylanase production when compared with mixture sugarcane baagasee and wheat brone alone. Xylanase production by P.florida also steadily increased during the growth.

| Substrate | P.florida | P. djamor | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 7th day | 14th day | 21th day | 28th day | 7th day | 14th day | 21th day | 28th day | |||

| 100% Sugarcane Bagasse (SB) | 22.45 | 35.45 | 55.55 | 65.50 | 25.45 | 35.50 | 54.50 | 65.75 | ||

| 75% SB+ 25% WB | 24.25 | 34.45 | 51.25 | 62.25 | 25.45 | 35.45 | 50.25 | 63.45 | ||

| 50% SB + 50% WB | 25.25 | 35.50 | 48.45 | 58.45 | 26.45 | 38.45 | 49.25 | 61.25 | ||

| 25% SB + 75% WB | 23.15 | 38.45 | 49.2 | 52.45 | 24.25 | 31.45 | 51.45 | 60.75 | ||

| 100% Wheat Bran (WB) | 20.50 | 31.45 | 45.45 | 49.25 | 21.45 | 32.45 | 52.75 | 67.45 | ||

Table 3: Degradation percentage of hemi-cellulose content in the substrate after Pleurotus sp. growth.

Discussion

Two different species of Pleurotus species are compared for their ability to produce lignocellulolytic enzyme viz, cellulase and xylanase on sugarcane bagasse, wheat brone and mixture of sugarcane bagasse with wheat bran. The main aim of the most research works is the bioconversion of plant residues into valuable products. In plant residues, lignin content is the important parameter for the digestibility of lignocelluloses materials [18]. In this study, sugarcane bagasse shows highest lignin content compare to wheat borne [19,20] are also reported that sugarcane bagasse contains more lignin content when compare to wheat bran.

The production of cellulase and xylanase enzyme and digestion of cellulose and hemi-cellulose by P.florida and P.djamor may be influence the lignin content of the substrate. Cellulase production is more on when sugarcane bagasse alone used as substrate by P.florida and P. djamor. Mean while cellulase production is impeded on wheat bran alone and mixture of sugarcane bagasse with wheat bran by P.florida and P.djamor. Similarly xylanase production was also more on sugarcane bagasse and lesser on wheat bran and sugarcane bagasse with wheat bran by Pleurotus sp. Many reports suggested and point out the role of Pleurotus sp. in cellulase and xylanase production on agricultural residues [21] also reported that mixes of agro waste are neutralized the optimization of cellulase and xylanase production [22]. Suggested that enzyme activity is strongly depends upon the composition of the substrate [23]. Pointed out the role of lignin in the substrate on the production of cellulase and xylanase.

Conclusion

In this study, P.djamor has played dominant role in cellulase and xylanase production and also sugarcane bagasse is the most suitable substrate for cellulase production. In contrast, wheat bran is the most suitable substrate for xylanase production. Meanwhile, the sugarcane bagasse with wheat bran has no significant effect for enzyme production.

Acknowledgement

This research work is supported by Virudhunagar Hindu Nadar’s Senthikumara Nadar College (Autonomous) Managing board, Virudhunagar-626001, Tamilnadu, India.

References

- Wood DA, Smith JF (1988) The cultivation of mushrooms (part I). Mushroom J 188: 633-637.

- Parmasto E (1987) Pleurotus citrinopileatus, one of the favourites. Mycologist1: 106-107.

- Madan M, Bisaria R (1984) Bioconversion of different agro-residues into edible protein by Pleurotus sajor-caju. Appl Biochem Biotechnol9: 395.

- Bano Z, Srivastava HC (1962) Studies on cultivation of Pleurotus species on paddy straw. Food Sci11: 363-365.

- Toyama N, Ogawa K (1975) Comparattive studies on celluloytic and oxidizing enzyme activities of edible and inedible wood rotters. Mushroom Sci1: 760.

- Ulezlo IV, Upcrova TN, Fenikova R (1975) Oxidative enzymes of the lignin-degrading fungus Pleurotus osteratus. Prikl Biokhim Microbiol11: 535-538.

- Cohen R, Yarden O, Hadar Y (2002) Lignocellulose affects Mn2+ regulation of peroxidase transcript levels in solid-state cultures of Pleurotus ostreatus. Appl Environ Microbiol68: 3156-3158.

- Moyson E, Verachtert H (1991) Growth of higher fungi on wheat straw and their impact on the digestibility of the substrate. Appl Microbiol Biotechnol 36: 421-424.

- Valdez M, Oziel D, Flores EOG, GarcÃa JAM, Chavira JS et al. (2008) Use of Pleurotus pulmonarius to change the nutritional quality of wheat straw. I Effect on chemical composition 33: 435.

- Fan L, Ricardo SC, Pandey A (2008) Current developments in solid-state fermentation 253-274.

- Papinutti VL, Diorio LA, Forchiassin F (2003) Production of laccase and manganese peroxidase by Fomes sclerodermeus grown on wheat bran. J Ind Microbiol Biotechnol 30: 157-160.

- Updegraff DM (1971) Utilization of cellulose from waste paper by myrothecium verrucaria. Biotechnol Bioeng 13: 77-97.

- Deschatelets L, Yu EKC (1986) A simple pentose assay for biomass conversion studies. Appl Microbiol Biotechnol 24: 379-385.

- Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31: 426-428.

- Dale BE (1987) Lignocellulose conversion and the future of fermentation biotechnology. Trends in Biotechnology 5: 287-291.

- Akpinar M, Urek RO (2012) Production of ligninolytic enzymes by solid-state fermentation using Pleurotus eryngii. Prep Biochem Biotechnol 42: 582-597.

- Perez J, Munoz-Dorado J, de la Rubia T, Martinez J (2002) Biodegradation and biological treatments of cellulose, hemicellulose and lignin: An overview. Int Microbiol 5: 53-63.

- Zadrazil F (1999) Is conversion of ligninocellulosics into feed with white rot fungi realizable? Practical problems of scale-up and technology transfer. Mushroom Sci 15: 919-928.

- Singh R, Varma AJ, Seeta Laxman R, Rao M (2009) Hydrolysis of cellulose derived from steam exploded bagasse by Penicillium cellulases: Comparison with commercial cellulase. Bioresour Technol 100: 6679-6681.

- Miron J, Yosef E, Ben-Ghedalia D (2001) Composition and in vitro digestibility of monosaccharide constituents of selected byproduct feeds. J Agric Food Chem 49: 2322-2326.

- Masutti D, Borgognone A, Scardovi F, Vaccari C, Setti L (2015) Effects on the enzymes production from different mixes of agro-food wastes. Chem Eng Trans 43: 487-4982.

- Tirado-González DN, Jáuregui-Rincón J, Tirado-Estrada GG, MartÃnez-Hernández PA, Guevara-Lara F et al. (2016) Production of cellulases and xylanases by white-rot fungi cultured in corn stover media for ruminant feed applications. Anim Feed Sci Technol 221:147-156

- González-Bautista E, Santana-Morales JC, RÃos-Fránquez FJ, Poggi-Varaldo HM, Ramos-Valdivia AC et al. (2017) Phenolic compounds inhibit cellulase and xylanase activities of cellulomonas flavigena PR-22 during saccharification of sugarcane bagasse. Fuel 196: 32-35.

Citation: Premkumar G, Muthuramkumar S, Kannan M, Varatharaju G, Rajarathinam K (2018) Cellulase and Xylanase Production by Pleurotus sp. on Mixed Substrate System. J Biotechnol Biomater 8: 283. DOI: 10.4172/2155-952X.1000283

Copyright: © 2018 Premkumar G, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 7078

- [From(publication date): 0-2018 - Dec 20, 2025]

- Breakdown by view type

- HTML page views: 5937

- PDF downloads: 1141