Research Article Open Access

Transfer and Reaerosolization of Biological Contaminant following Field Technician Servicing of an Aerosol Sampler

Richard J. Byers1*, Steven R. Medley2, Michael L. Dickens1, Kent C. Hofacre1, Melanie A. Samsonow1 and Monique L. van Hoek2

1Battelle Memorial Institute, 505 King Ave, Columbus, OH 43201, USA

- *Corresponding Author:

- Richard J. Byers

Battelle Memorial Institute, 505 King Ave

Columbus, OH 43201, USA

Tel: 614-424-7296

E-mail: byersr@battelle.org

Received Date: December 01, 2012; Accepted Date: February 01, 2013; Published Date: February 05, 2013

Citation: Byers RJ, Medley SR, Dickens M, Hofacre K, Samsonow M, et al. (2013) Transfer and Reaerosolization of Biological Contaminant following Field Technicia Servicing of an Aerosol Sampler. J Bioterr Biodef S3:011. doi: 10.4172/2157-2526.S3-011

Copyright: © 2013 Byers RJ, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Bioterrorism & Biodefense

Abstract

Over the last several years, aerosol samplers have been fielded in many locations to collect biological agents in the air, providing a sample that, once analyzed, will alert safety and public health officials of potential bioterrorism events. If a biological agent was present at the sampling location, the collector and surrounding area may be contaminated due to bioaerosol deposition, possibly posing a hazard to the technician maintaining the aerosol sampler. The technician may, in turn, serve as a source for cross-contamination to clean areas subsequently visited, potentially producing a hazard to others if transferred to indoor settings, such as a job site or analysis laboratory. To investigate our hypothesis about these potential exposure sources and cross-contamination, a study was performed to: (1) examine biological material transfer from a contaminated site to an individual; and (2) determine aerosol resuspension levels due to typical personnel activity at a contaminated, paved bioaerosol sampling site. Analysis of air samples indicated reaerosolization of spore-containing particles upon disturbance of a contaminated site by a field technician, and analysis of swatches taken from the technician’s clothing indicated substantial transfer of spores. These results provide insight into sources of cross-contamination and potential steps to mitigate consequences of infectious contaminant transfer, and also demonstrate potential exposure hazards for technicians servicing fielded bioaerosol collectors.

Keywords

Bioaerosol; Aerosol sampler; Reaerosolization; Spores; Cross-contamination

Introduction

Aerosol contaminants deposited on a surface are transferred by two primary means–direct surface contact and reaerosolization. When a surface contaminated with deposited aerosol is contacted, a portion of the particulate material will be transferred. The amount transferred is dependent upon several factors, with amount of pressure applied, static charge, moisture levels, contact frequency, contact motion, particle size and surface roughness being among the most significant [1]. Once particles are transferred to the clothing and/or gloves of a person, deposited particles may reaerosolize by several mechanisms, such as vibration and air flow [2]. As mentioned, physical characteristics of the surface and particles, as well as the environmental conditions, will affect reaerosolization potential. With the multitude of variables, it is difficult to predict the amount (or fraction) of contaminant that will be transferred.

Resuspension of spore-laden particles can produce respiratory, ocular, and dermal hazards for the contaminated individual as well as others in the area. Contaminant transfer and reaerosolization of biological particles not only lead to localized hazards but also to potential cross-contamination due to secondary transfer, which can have significant impacts. Transfer of Bacillus anthracis spores from a primary source to textiles has been long recognized as a potential means of exposure and cross-contamination [3]. According to McKernan et al. [4], during the initial response to the 2001 B. anthracis letters, first responders inadvertently cross-contaminated several areas within a multi-level congressional building. Vacuum and wipe samples from the first responders’ locker room, equipment storage spaces, and distant office areas within the building all indicated presence of spores even though these areas were supplied by separate air handling systems. Samples from these same responders’ vehicles also indicated the presence of spores, as several surface samples produced positive results for B. anthracis. Positive samples from the responders’ staging areas and vehicles were shown to be associated with a contaminated gear bag and equipment that had come into contact with the organism while staged or decontaminated (detergent and water solution only) at the contamination reduction zone. Prior to establishing exclusion (hot), contamination reduction (warm), and (cold) support zones, the response team evacuated exposed personnel from the contaminated office suite through the same areas where the exclusion and support zones were established. Past research has explored particle resuspension processes, particularly indoor reaerosolization [5-7] from various surfaces such as carpets [8-11], due to air flows caused by ventilation systems and various human activities [12]. For instance, the 2001 U.S. B. anthracis mail release was studied to determine the reaerosolization process via mail sorters and everyday human activities [13,14]. Results from indoor reaerosolization studies demonstrate that air flow and human activities constitute the principal causes of particle resuspension from surfaces. Resuspension of particles from outdoor surfaces, such as concrete and grass, due to ambient winds has also been studied [15]. The outdoor B. anthracis release at Sverdlovsk, Russia, in 1979 was studied in depth to estimate the amount of deposited material that potentially reaerosolized and how landscape and wind patterns affected the resuspension [16,17]. Studies generally show that human activity enhances particle resuspension [18,19]. Unfortunately, literature is scarce in the way of offering measurement details to characterize possible bioweapons release scenarios and the contaminated environments that may follow [20,21]. While some investigations have recognized that deposited bioaerosol material may reaerosolize by forces that disturb settled particles, the extent of the respiratory hazard from secondary aerosols is largely unknown and merits further study [20,21]. Such investigations will contribute to characterizing the degree to which biological contaminant particles reaerosolize, and also guide development of effective decontamination strategies [12].

Due to potential hazards associated with reaerosolized spores, we sought to quantitate resuspension levels and particle transfer from a contaminated site to the technician to provide specific and actionable data for policy makers. By understanding the transfer of contaminants via both contact and reaerosolization, appropriate procedures can be established to mitigate consequences of infectious particle transfer and inhalation exposure during servicing of fielded bioaerosol collectors. In regard to “reaerosolization” and “resuspension,” the two terms are used interchangeably throughout this paper, both indicating when deposited particles are put back into an aerosol state.

Experimental Design

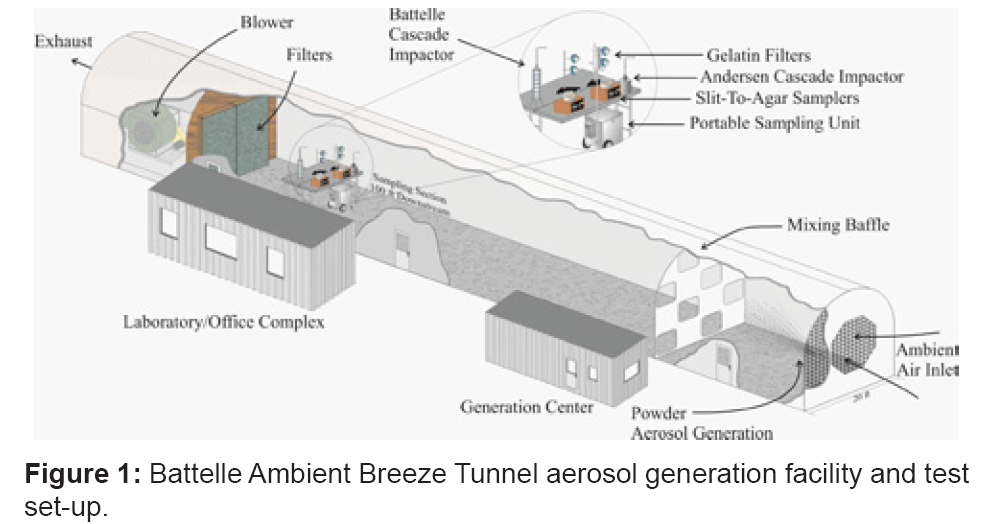

The experiments to determine the amount of spore material transferred to an individual via contact and reaerosolization were conducted at Battelle Memorial Institute’s Ambient Breeze Tunnel (ABT) facility in West Jefferson, OH. The facility consists of a large (46 m×6 m×6 m) tunnel designed for conducting bioaerosol releases in outdoor conditions (with wind speeds up to 2 m/s) and thus was well suited for simulating a bioaerosol cloud to which a fielded bioaerosol sampler may be exposed. The experimental set up is illustrated in figure 1. The bioaerosol sampler (described in more detail below) was placed within the ABT. The dry powder aerosol was generated and allowed to mix with the ambient air stream. A mixing baffle, located immediately downwind of the aerosol dispersion device, enhanced the mixing of the aerosol and ambient air. The surrogate aerosol then traveled downstream to the sampling site, and particles that were not deposited inside the ABT and on the sampling equipment were collected by a large filter bank encasing the ABT blower. Surface contamination in the ABT due to the initial bioaerosol was measured by placing glass slides in the test area to collect deposited particles. Once the cloud passed the reference instrumentation, the technician waited at least 10 minutes before entering the ABT to allow the aerosol to completely pass through the area. Previous testing in the ABT (data not shown) has shown that background conditions are reached within 2 minutes after dissemination is complete. After 10 minutes, the airflow in the ABT was stopped prior to the technician entering the site. This was done to isolate the source of the resuspension by eliminating wind speed as a variable.

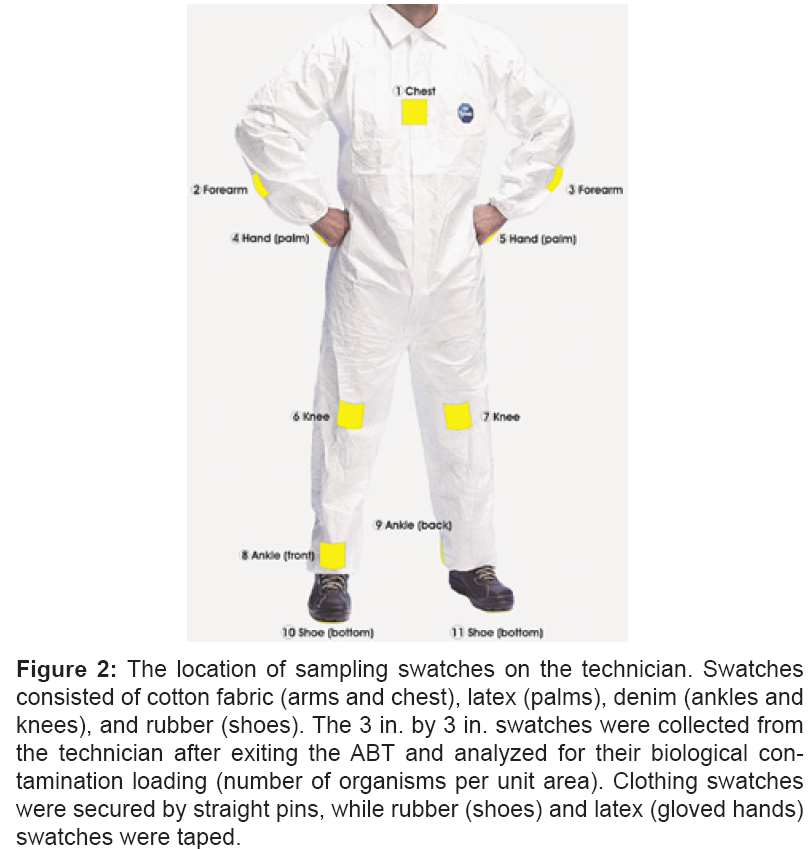

After entering the ABT, the technician performed common, routine maintenance on the bioaerosol sampler. These maintenance tasks included opening the bioaerosol sampler, turning off the power, removing the filter cap, removing the filter holder, replacing the filter and holder with a new set, reopening the unit, switching on the power, and making notes in the log book. For many fielded bioaerosol samplers, it is common practice for test technicians to wear street clothing and latex gloves when gathering samples. Therefore, during contamination transfer tests, the technician wore latex gloves, jeans, a cotton long sleeve jersey, and flat-soled shoes, as well as swatches of these materials. The 3 in. by 3 in. swatches of material were collected from the technician after exiting the ABT and analyzed for their biological contamination loading (number of organisms per unit area). Swatches consisted of cotton fabric (arms and chest), latex (palms), denim (ankles and knees), and rubber (shoes). The swatches were affixed to areas on the technician’s clothes that would normally be expected to come in contact with contaminated surfaces during the retrieval/replacement of the sampling media within the bioaerosol collector. Clothing swatches were secured by straight pins, while rubber (shoes) and latex (gloved hands) swatches were taped. The location of swatches is illustrated in figure 2.

Figure 2: The location of sampling swatches on the technician. Swatches consisted of cotton fabric (arms and chest), latex (palms), denim (ankles and knees), and rubber (shoes). The 3 in. by 3 in. swatches were collected from the technician after exiting the ABT and analyzed for their biological contamination loading (number of organisms per unit area). Clothing swatches were secured by straight pins, while rubber (shoes) and latex (gloved hands) swatches were taped.

During retrieval and reinstallation of the bioaerosol collector filter, the technician intentionally made contact with several swatches onto surfaces of the PSU and upon the ABT floor. However, ankles watches made no contact with any surface, allowing particle transfer to occur only by deposition of particles that the technician resuspended during walking. Swatches attached to shoe bottoms and palms came into contact with the ground and collector instrument, respectively. While it can be assumed that the technician unintentionally contacted other areas during the process, the focus was on the areas that would likely be subjected to the most surface contact. Analysis of the swatches was then completed to estimate the quantity of contaminant transferred to the technician’s clothing. In addition to the amount of contaminant transferred to the technician from surfaces contacted, test results included the size distribution and quantity of reaerosolized spore particles.

Materials

The biological agent surrogate used for all tests was a Bacillus thuringiensis var. kurstaki (Btk) powder that contained Spores of the organism, Btk protein crystals, and nutrient media remnants and no fillers (Valent Biosciences, IL). Due to the large quantities of material used during these tests, it was not feasible to prepare a pure powder of single spores. The preparation yielded a concentration of 5.3E+10 colony forming units (CFU)/g upon spread-plate enumeration. Btk is commonly used as a stimulant for the biological agent B. anthracis, based on similar morphology of spores [22,23]. B. thuringiensis is a gram positive, spore-forming rod, 1–1.2 μm in width and 3–5 μm in length, with spores ranging from 0.74–1.08 μm in width and 1.6–2.7 μm in length [24]. Phenotypically, Btk is very similar to B. anthracis, both belonging to the B. cereus group and having the same cell size, morphology, and formation of oval spores in a centrally located non-swollen sporangium [25]. Spores of B. thuringiensis also have comparable aerodynamic properties to those of B. anthracis, having spores that are similar in length, diameter, and volume to strains of B. anthracis [26].

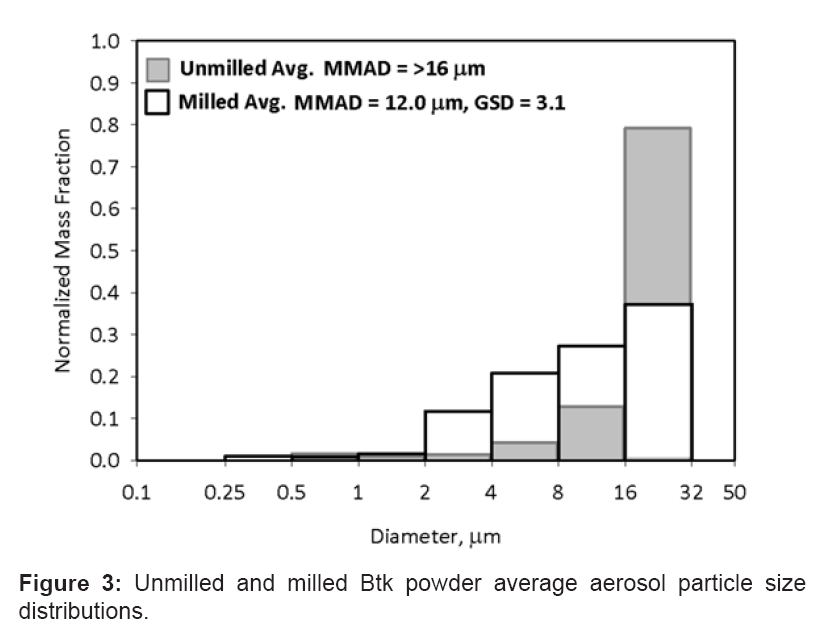

The bulk Btk powder had a Mass Median Aerodynamic Diameter (MMAD) of 49 μm and contained no fluidizing additive to help the powder flow and keep from agglomerating. After two tests were conducted, the powder was milled to reduce the median particle size so that a larger percentage of the Btk aerosol would be in the respirable range (taken to be less than 10 μm). A Lab mill (8000 ball mill, Advanced Ceramics Manufacturing, Tucson, AZ) was used with a 500 mL polyethylene baffled milling jar and 5 mm stainless steel grinding balls to mill the Btk powder. A baffled milling jar was used to promote tumbling rather than rolling within the jar during operation. Powder (125 mL) was loaded into the jar with 250 mL of grinding balls to reach a target fill of 25% powder and 50% grinding media, and the mill was operated continuously for four hours. The powder was collected and a portion analyzed to determine the particle size and bulk spore concentration. As a result of milling the powder, the B. thuringiensis concentration was reduced from 5.3E+10 colony forming units CFU/g to 1.3E+10 CFU/g. The milling reduced the MMAD from 49 μm to 18 μm and increased the percentage of the mass in the respirable size range. Table 1 displays the average results from testing of the powders. All size distribution measurements were performed using an Amherst Process Instruments (API, Amherst, MA) Aerosizer® LD with an Aerodisperser® attachment. Two polystyrene microsphere particle size calibration standards (10 μm and 100 μm, Duke Scientific Dri-cal standards) were run before testing to verify performance of the instrument.

| Formulation | MMAD, µm | GSDa | Mass % <10 µm | Mass % <5 µm |

|---|---|---|---|---|

| UnmilledBtk | 49 | 1.6 | <5% | <5% |

| Milled Btk | 18 | 1.5 | 12% | <5% |

aGSD–geometric standard deviation

Table 1: Average Particle Size Distribution of Pre- and Post-milled Btk powder.

Dissemination of the Btk powder was not designed to mimic a specific event but was intended to be a reasonable facsimile of a bioterrorism scenario. The powder was aerosolized using a Venturi eductor (Fox Valve, Dover, NJ). The eductor, operating at 60 psi, draws the powder into the inlet through the suction created by the Venturi effect and expels it at a high rate of speed. Eductors have been shown to be effective means of de-agglomerating bulk powders during the dissemination process [27,28]. The airborne concentration of Btk spores was determined by making the assumptions described below and coupling them with characteristics of the ABT. The ABT has been well characterized over its decade of use. The turbulence created at the ambient air inlet and the mixing baffle thoroughly mix the generated particles with the incoming air, and the aerosol continues to diffuse as it travels 100 feet downstream to the sampling zone. Characterization tests have shown the aerosol concentration is spatially consistent across the sampling zone, with a coefficient of variation of ± 11%.

The generic bioterrorism scenario considered was a stationary release using an agricultural sprayer at a height of 2 m, under neutral atmospheric conditions and a wind speed of 3.1 m/s. The assumptions made were used to set the parameters for a simple Gaussian plume dispersion model. The Gaussian plume model was used to estimate the downwind concentration of released material, C(x,y,z), and is given by equation 1.

Equation 1:

,

,

Where x, y, and z are the downwind location coordinates, u is the ambient wind speed, Q is the mass release rate, h is the height above ground of the release, and the σ variables define the dispersion of the cloud, based upon the ambient conditions [29]. The key assumption made was the original payload mass of one kilogram. This value falls within the minimum and maximum range used for most publicly available literature on the subject [30-34]. Based on these assumptions, an airborne concentration of 2.5 mg/m3 was predicted for a distance of 500 m downwind of the release site at a height of 3 m above the ground. Relating this to the ABT, 8.5 g of Btk powder would need to be disseminated within one minute. Taking into account some inefficiency in the generation and dissemination, 10 g of the powder were disseminated to produce the contaminant cloud. It should be noted that changing any of the assumed parameters can have a significant effect on the downwind air concentration, so the data should not be considered absolute but within a reasonable and possible range.

Instrumentation

Two sets of instrumentation were used to characterize concentration and size distribution of aerosolized Btk in the ABT within the technician’s breathing zone (approx. 1.7 m). One set captured particles from the primary bioaerosol, while the second set measured any reaerosolized material. In addition to the active samplers, passive swatch samples were collected to quantify the initial contamination transfer to the technician.

The first set of instruments included a Battelle Cascade Impactor, a Portable Sampling Unit (HI-Q Environmental Products Company), and gelatin filters (Pall Gelman, 47 mm, 0.35 μm pore size). The Battelle Cascade Impactor (BCI) is a seven-stage particle sampler used to determine particle size distribution and particle mass concentration of the initial aerosol in the ABT. The geometry of each stage, combined with the controlled 12.5 liter per minute (L.min-1) airflow through the device, provide for particle size cut-points of 16, 8, 4, 2, 1, and 0.5 μm; a backup filter collects particles smaller than 0.5 μm. Particles impact onto glass slides covered in petroleum jelly, which can then be extracted into buffer and analyzed. The Portable Sampling Unit (PSU), a standard bioaerosol sampling device, operates up to 200 L.min-1 and collects ambient particles onto a variety of filters. For this investigation, the PSU was operated at 100 L.min-1 with a 47 mm Teflon® filter. The gelatin filters were placed in holders and drew air samples at approximately 12.5 L.min-1.

The second set of samplers consisted of two slit-to-agar (STA) samplers (Mattson-Garvin, Homosassa Springs, FL) and an Andersen Cascade Impactor (ACI, Thermo Scientific, Franklin, MA). The STA sampler operates by accelerating particles in the air through a small slit and impacting the particles directlyonto a 150 mm Tryptic Soy Agar (TSA) plate that rotates once every two minutes. The STA provided a bioaerosol concentration in units of Agent Containing Particles per Liter of Air (ACPLA). The ACI is a six-stage viable particle sampler used to determine particle size distribution and concentration of the culturable bioaerosol reaerosolized in the ABT. For the six stages (glass Petri dishes containing TSA), the particle size cut-points were 7, 4.7, 3.3, 2.1, 1.1, and 0.65 μm. The first STA operated for two minutes, followed by the next STA for an additional two minutes. After the technician completed the PSU filter removal/replacement process and exited the ABT, the instruments continued sampling for an additional 30 seconds. The entire process, from entering to exiting the ABT, was performed in 3. 5 minutes.

Sample Analysis

Samples from swatches, filters, and the BCI were extracted in 1X Phosphate Buffered Saline+0.1% TritonX-100 (PBST). Swatch and filter samples were placed into 50 mL conical tubes in the field; once in the laboratory, 10 mL of PBST were added to each, and they were vortexed on high speed for 30 seconds. The BCI glass slides were removed from the impactor in the field and stored in sterile specimen cups. In the laboratory, 10 mL of PBST were added to each cup. The samples were then incubated at 30°C for 15 minutes with shaking at 100 RPM prior to collecting and analyzing the liquid sample. A 2 mL aliquot of each sample extract was sonicated for 25 seconds at 40% amperage (10-11 W) using a Fisher Sonic Dismembrator Model-100 probe sonicator to break apart spore agglomerates into individual spores in order to minimize sample variation. The sonication probe was cleaned between samples by wiping the probe with a 15% bleach solution, followed by distilled water and isopropanol rinses, and then allowed to dry. Previous studies conducted at Battelle have demonstrated that this method is an effective means of cleaning the sonication probe and preventing crosscontamination to subsequent samples. The sonicated samples were diluted 1:10 in PBST and inoculated in triplicate onto TSA. All plates were incubated approximately 18 hours at 30°C prior to manual colony counting and data analysis. The STA and ACI agar plate samples were also incubated at 30°C for approximately 18 hours prior to manual colony counting and data analysis. Because the filter, impactor, and swatch samples were sonicated, each count, or CFU, was assumed to correspond to a single spore. This allowed for a correlation between CFU collected on the filters, BCI, and swatches.

Data Analysis

The information collected was used to quantify the transfer of spore contamination from the sampling site to the technician. To determine the initial Btk aerosol concentration collected by the samplers from the raw results, the number of CFU collected was divided by the air sampling rate and sample time, as shown in equation 2. An extraction efficiency of 100% was assumed for each sample collected (including the swatches) since a separate study was not performed to assess the efficiency.

Equation 2:

In addition to the airborne concentration data from the gelatin filter samples and the PSU, the particle size distribution was measured with a BCI during primary aerosol generation and an ACI during PSU maintenance activities by the technician. The initial bioaerosol size distribution was calculated from the culturable analysis of the collected material on each size-dependent stage of the BCI. The data was reported in terms of MMAD and a geometric standard deviation (GSD). The MMAD is defined as the diameter at which 50% of the mass lies both above and below that size; the GSD is defined as the ratio of the diameter at which 84% of the mass lies below that size and the MMAD [35]. A similar analysis was performed with the ACI plate count results. The key difference in the analysis is that the ACI particle counts are used to calculate the Number Median Aerodynamic Diameter (NMAD) as opposed to the MMAD. The distinction is due to the fact that because the particles are directly impacted into agar, no sonication or other manipulation is done to the sample. Therefore, the particle that impacts, though it may consist of multiple CFUs, is counted as only a single Agent Containing Particle (ACP). Data from the ACI, STA samplers, and additional gelatin filter were used to quantify reaerosolization of Btk spores during PSU maintenance activities. The results from all of the sample analysis provided a comprehensive picture of initial cloud characteristics and the transfer of contaminant to the test technician.

Procedure

The ABT was pressure washed prior to the study. Btk had not been used in any recent testing within the tunnel. Three independent aerosol settling (Aerosol Settling Tests) tests (n=3) were conducted to determine an approximate amount of Btk surface seeding within the ABT. A total of six additional tests (Technician Tests) were conducted to characterize spore contaminant transfer and resuspension. The first two of these six tests used the unmilled version of the Btk powder, while the remaining four tests used the milled version. Each test was conducted by first disseminating the powder over one minute with the bioaerosol samplers (two gelatin filters, one BCI, and one PSU) operating. The gelatin filters and BCI were operated for a total of five minutes to ensure that the entire cloud was captured, while the PSU continued sampling until the technician entered the tunnel and manually turned off the power. At the conclusion of the five minutes of sampling, the technician waited an additional ten minutes prior to entering the ABT. During this time, the eleven swatches were affixed to the technician using pins and tape. Swatches were placed in the following locations: left and right forearms, palms, knees and soles of shoes, chest, front left ankle, and back right ankle. After the ten minutes had elapsed, the air movement in the ABT was stopped and the technician entered the ABT as the ACI, gelatin filter, and first STA were activated. The first STA sampler was stopped after two minutes (one complete rotation), and the next STA started. After 3.5 minutes of PSU maintenance activities in the ABT, the technician exited the tunnel with the PSU filter holder. All sampling was stopped 30 seconds after the technician exited the tunnel.

Results

The samples from the PSU, gelatin filters, and BCI were used to calculate the initial bioaerosol concentration in the ABT during each Technician Test. The total number of CFU collected on the swatches was then compared to the bioaerosol concentration, as shown in table 2. The unmilled powder tests had airborne concentrations, on average, lower than the milled powder tests. It should be noted that the comparison is based upon the results of only two tests with the unmilled powder. The results from the two tests are discussed to highlight an interesting aspect found during the course of testing, but the strength of the comparison between the two powder versions is limited by the number of tests conducted.

| Test ID | ABT Temperature, °F | ABT Relative Humidity, % | Airborne Concentration, CFU/LAIR | Swatch Total, CFU |

|---|---|---|---|---|

| T1 (unmilled) | 85 | 26 | 1.9E+04 | 1.3E+06 |

| T2 (unmilled) | 77 | 32 | 2.2E+04 | 1.4E+06 |

| T3 | 54 | 40 | 3.4E+04 | 2.3E+06 |

| T4 | 61 | 29 | 2.6E+04 | 2.6E+06 |

| T5 | 64 | 25 | 1.9E+04 | 2.6E+06 |

| T6 | 70 | 15 | 3.0E+04 | 2.4E+06 |

| UnmilledBtk Avg. | 81 | 29 | 2.0E+04 | 1.3E+06 |

| Milled Btk Avg. | 62 | 27 | 2.7E+04 | 2.5E+06 |

| Total Test Avg. | 69 | 28 | 2.5E+04 | 2.1E+06 |

Table 2: Bioaerosol Concentration and Swatch Contamination.

Particle size distribution of the bioaerosol

As noted above, the size distribution of the two powders was considerably different, likely leading to the different bioaerosol concentrations. Figure 3 shows the average BCI results from the unmilled and milled powders. The aerosolized unmilled powder was collected predominantly on the first stage of the BCI (>16 μm), which did not allow for an accurate determination of the median diameter. The differences in the two versions of the powder are shown in the figure 3, illustrating that only 20% of the unmilled powder was less than 16 μm in diameter, whereas 63% of the aerosolized milled powder was less than 16 μm. The bioaerosol size distribution test results for the milled powder are shown in table 3.

| Particle Size Distribution | Test 3 | Test 4 | Test 5 | Test 6 | Average |

|---|---|---|---|---|---|

| MMAD, µm | 12.6 | 11.2 | 11.5 | 12.7 | 12.0 |

| GSD | 4.5 | 2.6 | 2.6 | 2.6 | 3.1 |

Table 3: Bioaerosol Particle Size Distribution (Milled).

For these tests, the initial airborne concentration was measured, along with the surface contamination at the site and the amount of contaminant transferred to the technician. As the technician entered the area and performed standard PSU maintenance actions, the localized reaerosolization of the biological particles was also measured. Because two forms of the Btk powder were used [unmilled (Technician Tests T1, T2) and milled (Technician Tests T3-T6)], the behavioral differences between the powders were also investigated. Differences were clearly evident in the size distribution of the bulk and aerosolized powders. The bulk unmilled powder had a MMAD of 49 μm compared to 18 μm for the milled powder. Similarly, the spore-containing particles of the aerosolized unmilled powder had a MMAD greater than 16 μm, while the milled powder had a MMAD of 12 μm. No further processing of the powder was done to enhance flowability, as the intent was to have a less sophisticated preparation. This was deemed appropriate since the material used was not highly refined powder.

Contaminant transfer to swatches

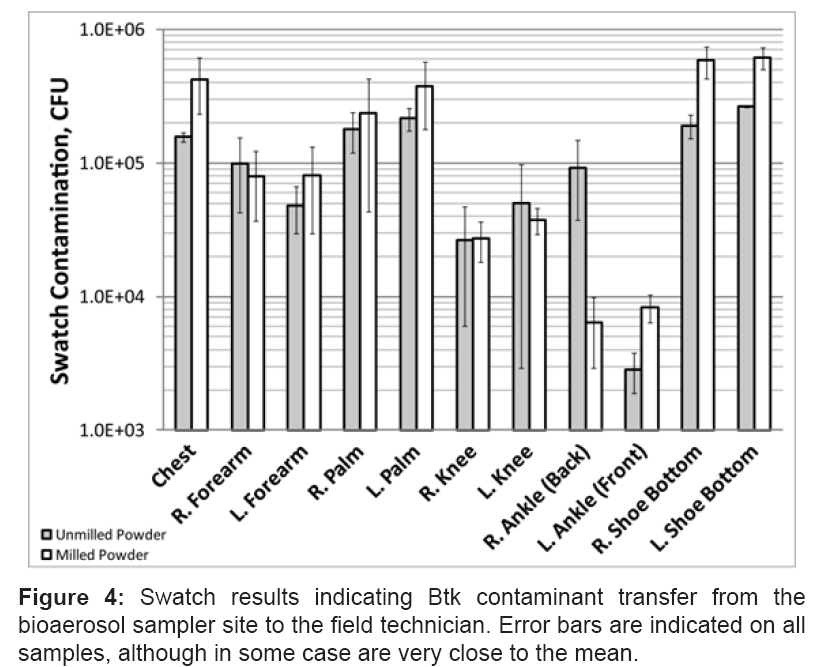

The average bioaerosol concentration for the milled powder tests was 2.7E+04 CFU/LAIR as compared to 2.0E+04 CFU/LAIR for the unmilled powder. The total number of CFU collected on the swatches for the milled powder tests was 2.5E+06, as compared to 1.3E+06 for the unmilled powder tests. The swatches that collected the highest number of spores were affixed to the shoe bottoms, as was expected. The swatches attached to the technician’s ankles collected the least, which also was expected as these swatches did not physically contact any of the contaminated surfaces. Swatches on the hands and chest also collected a considerable number of spores. Figure 4 shows the average results from all of the swatches for all of the tests, and table 4 shows the average results from each test. The unexpected result was that the swatches attached to the technician’s ankles, which did not contact any surfaces, collected spores. This implied that a considerable number of spores were reaerosolized by walking and collected on the ankles.

| Swatch Location | Unmilled Powder | Milled Powder | ||||

|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | |

| Chest | 1.5E+05 | 1.7E+05 | 2.3E+05 | 3.6E+05 | 6.9E+05 | 4.2E+05 |

| R. Forearm | 1.4E+05 | 5.9E+04 | 1.1E+05 | 5.0E+04 | 3.6E+04 | 1.2E+05 |

| L. Forearm | 3.5E+04 | 6.1E+04 | 8.8E+04 | 1.1E+04 | 9.1E+04 | 1.3E+05 |

| R. Palm | 1.4E+05 | 2.2E+05 | 2.3E+05 | 5.0E+05 | 1.9E+05 | 3.4E+04 |

| L. Palm | 1.9E+05 | 2.5E+05 | 1.8E+05 | 3.3E+05 | 6.4E+05 | 3.4E+05 |

| R. Knee | 1.2E+04 | 4.1E+04 | 2.3E+04 | 4.0E+04 | 2.6E+04 | 1.9E+04 |

| L. Knee | 1.7E+04 | 8.4E+04 | 3.0E+04 | 4.8E+04 | 3.2E+04 | 4.0E+04 |

| R. Ankle (Back) | 1.3E+05 | 5.3E+04 | 5.3E+03 | 5.7E+03 | 3.2E+03 | 1.1E+04 |

| L. Ankle (Front) | 2.2E+03 | 3.5E+03 | 1.1E+04 | 7.8E+03 | 7.1E+03 | 7.2E+03 |

| R. Shoe Bottom | 2.2E+05 | 1.6E+05 | 7.8E+05 | 5.5E+05 | 4.0E+05 | 6.1E+05 |

| L. Shoe Bottom | 2.6E+05 | 2.6E+05 | 5.8E+05 | 7.2E+05 | 4.7E+05 | 7.0E+05 |

Table 4: CFU Collected Per Swatch.

Surface contamination in the ABT

Surface contamination was measured at six locations in the ABT–four on the ground and two along the instrument support table (technician head-height). Glass slides (37 mm), coated with a waterbased lubricant to prevent particle bounce, and were placed on clean surfaces at these locations to measure the actual aerosol deposition. The biomaterial deposited upon surfaces was measured in three independent tests (Aerosol Settling Tests) using the milled powder, and was compared to bioaerosol concentration in the Technician Tests for further development of the correlation between bioaerosol concentration and contaminant transfer. The average airborne concentration for the three Aerosol Settling Tests, as collected with the PSU, was 4.6E+04 CFU/LAIR. This concentration is higher than the average concentration for the four milled Technician tests (2.7E+04), although bulk amount of product aerosolized, dissemination method, and wind speed were the same. While the reason for this difference is unclear, it is possible that higher humidity levels during the three Aerosol Settling tests may have induced condensational and/or hygroscopic particle growth, and thus a shorter time-of-flight, increasing particle concentration within the sampling zone of the downrange instrument suite. Average surface contamination from the three Aerosol Settling (milled powder) releases was 2.4E+03 CFU/cm2. The swatch results showed the average deposition due to contact transfer or reaerosolization during the Technician Tests on an area basis was 3.9E+03 CFU/cm2 for the milled powder tests (Table 4). This demonstrates that a significant amount of deposited material transferred to the technician. Since the average number of spores collected by the swatches was higher than the surface deposition (based upon area), it was apparent that repeated contact with the surfaces led to higher transfer.

Reaerosolization results

The amount of material reaerosolized was measured using the STA samplers, a gelatin filter, and, for a subset of tests, an ACI sampler. STA and ACI samplers detect down to one agent containing particle. The gelatin filters, which in practice have a quantifiable limit (QL) of 50 CFU/LAIR, yielded results from two tests that had bioaerosol concentrations above the QL: Tests 3 and 6. Test 3 showed a reaerosolized concentration of 50 CFU/LAIR and Test 6, a reaerosolized concentration of 73 CFU/LAIR. For the unmilled powder, the average number of ACP collected over the four minute sampling time was 96, with an average of 0.3 ACPLA. For the milled powder, the average number of ACP collected was 175, with an average of 0.6 ACPLA. The correlation between ACPLA and CFU/LAIR is not well defined; however, a range of values was determined through testing. For this testing, four milled Btk bioaerosol clouds were generated, and the concentration measured using gelatin filters and STAs. The number of CFU collected on the filters was compared to the total number of ACP collected on the STA plates. For each ACP, 36–80 CFUs were collected by the filters. Therefore, for the four tests with the milled powder, the average number of CFU for each ACP was 56. Using this average value as an approximate correlation, the milled powder reaerosolization concentration was 35 CFU/LAIR. This value is only used as a rough estimate of the concentration of reaerosolized biomaterial.

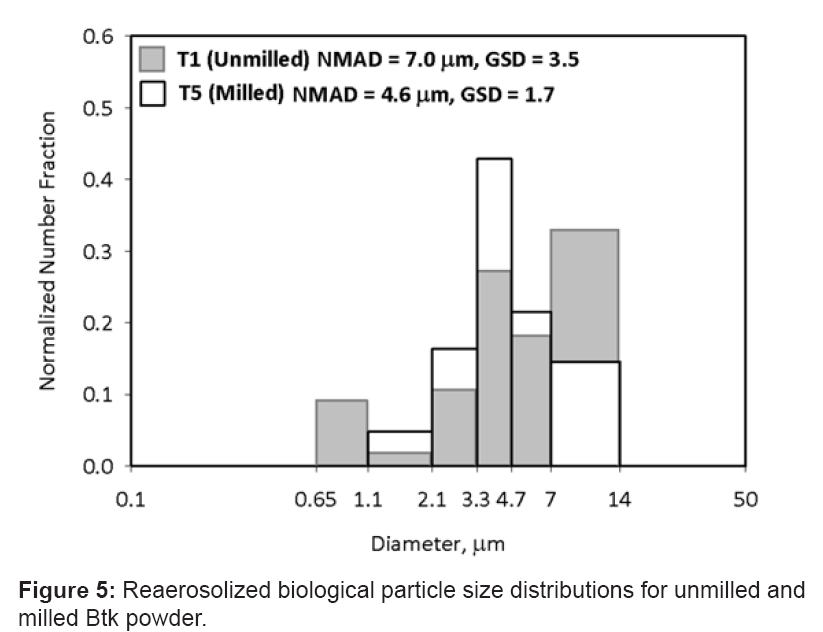

The size distribution of the reaerosolized materials differed for the two powders. The ACI data show that the milled reaerosolized material had a particle size distribution significantly smaller than that of the unmilled powder. Histograms from the tests where the ACI was operated are shown in figure 5. The data show that the milled powder test (T5) had a reaerosolized NMAD of 4.6 μm with a GSD of 1.7, while the reaerosolized unmilled powder (T1) had an NMAD of 7.0 μm and a GSD of 3.5.

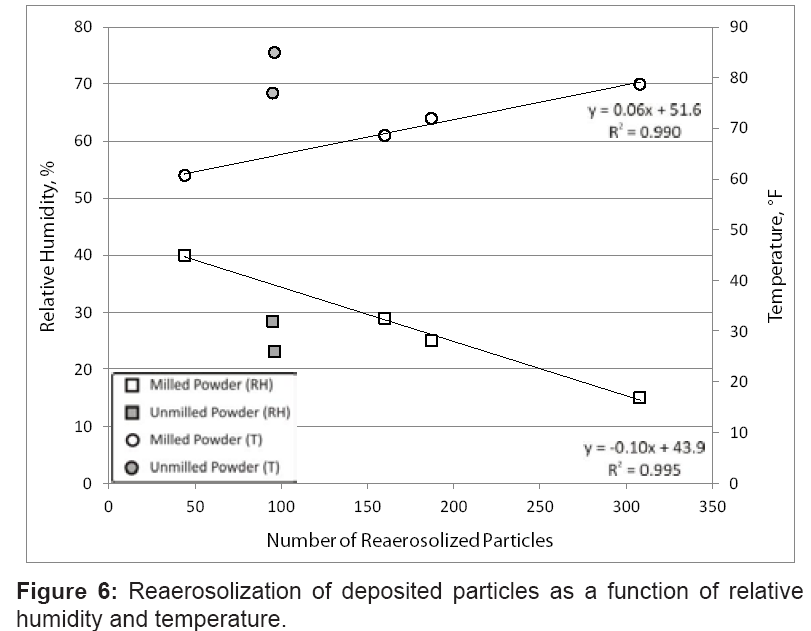

In figure 6, the correlation is shown between the reaerosolized milled particles, the relative humidity, and the ambient temperature. The relative humidity and/or temperature at the test site appeared to have a direct effect upon the amount of material reaerosolized. It should be noted that the ABT draws ambient air, such that no control over the environmental conditions was possible. The number of reaerosolized particles measured followed an inverse linear trend with relative humidity for the milled powder, with the maximum number of particles measured at the lowest relative humidity. Conversely, the number of reaerosolized particles also followed an increasing linear trend with temperature. As the temperature increased, the number of particles reaerosolized increased for the milled powder. The limited data for the unmilled powder do not follow either trend. It is possible that the size of the deposited particles dominated the reaerosolization potential for the individual unmilled particles.

The ambient conditions (relative humidity and/or temperature) appeared to influence the amount of material reaerosolized for the milled powder. Previous studies have found the relationship between relative humidity and reaerosolization inconclusive [36]; however, those tests were conducted at relative humidity levels in the range of 40 to 70%. With more moisture present in the air than this study, particles in the Gomes study may have exhibited more surface and interparticulate adhesion. As the relative humidity increased from 15 to 40% in this testing, the number of resuspended contaminant particles decreased linearly. As the temperature decreased from 70 to 54°F, the number of particles measured also linearly decreased. With no airflow at the test site, the relative humidity and temperature were the only environmental variables. It is unclear which of the parameters (or combination of the two) had an effect on resuspension, but relative humidity may be a significant factor.

Discussion

This study was performed to help address the knowledge gap in the area of transfer and reaerosolization of biological threat materials. Six tests were conducted to quantify the number of bacterial spores that could be transferred from a contaminated bioaerosol sampler site to a field technician through direct contact and reaerosolization. Very few studies exist in the open source forum that attempt to quantify contamination transfer and reaerosolization by measuring the occurrence of each from a known spore-seeded surface. Even fewer studies are available that examine spore transfer and resuspension from a surrogate as closely related to B. anthracis as is B. thuringiensis. The current work incorporated both of these attributes, thus offering additional context and information to publicly available peer-reviewed literature. This research also provides insight into the hazardous conditions that may ensue after a bioaerosol release from a fairly unsophisticated powder preparation. The results of this study serve to support diligence in responder health and safety measures even if the contaminant is absent of fluidizing agents and fine milling with a MMAD ≤ 10 μm.

The total amount of contaminant collected on the swatches on the field technician for the milled powder tests was 2.5E+06CFU. For the unmilled powder, the swatches collected 1.3E+06 CFU. Direct surface contact with the contaminated area led to the highest level of contaminant transfer to the field technician, with the bottoms of shoes generally containing the highest number of spores. However, the number of particles reaerosolized by walking that attached to the technician’s clothing (ankles) was significant as well. This implies that direct contact with the deposited particles is not the only way significant contamination can be transferred.

Testing also included measurement of reaerosolized Btk particles at the contaminated site while the technician actively performed sampler maintenance activities. These measurements were taken within the technician’s breathing zone, defined as a nominal spherical air parcel 1 m in diameter around the head [37], to assess inhalation hazard. For the unmilled powder, the average airborne concentration of agent containing particles was 0.3 ACPLA. For the milled powder, the average was 0. 6 ACPLA, which corresponded to an approximate spore concentration of 35 CFU/LAIR. The maximum measured reaerosolized concentration was 73 CFU/LAIR. Extended exposure to this concentration of airborne B. anthracis spores could pose serious risks for a population with diverse health status [38,39].

Further study in the area of secondary contaminant transfer would offer greater strength to this preliminary effort. One area of interest is the effect that relative humidity and temperature had upon reaerosolization, as these factors appeared to have a significant influence. More testing would add statistical strength to this observation. An additional area of interest is the potential hazard that exists from spore transfer to clean indoor areas by contaminated personnel, and subsequent resuspension levels. Investigation into this type of scenario may prove beneficial when determining remediation strategies for isolated releases in large indoor venues, or when biologically contaminated individuals enter previously clean facilities.

Upon determination that the collector sampled a bioweapon agent, consideration should be given to Post-exposure Prophylaxis (PEP) for implicated field technicians. The possibility of contaminant tracking and/or shedding from field staff to subsequently visited interior spaces should be considered and characterization of such indoor environments should be done to estimate exposure risk and identify additional recipients of PEP.

References

- Brouwer DH, Kroese R, Van Hemmen JJ (1999) Transfer of contaminants from surface to hands: experimental assessment of linearity of the exposure process, adherence to the skin, and area exposed during fixed pressure and repeated contact with surfaces contaminated with a powder. Appl Occup Environ Hyg 14: 231-239.

- Qian J, Ferro AR (2008) Resuspension of dust particles in a chamber and associated environmental factors. Aerosol Sci Technol 42: 566-578.

- Enticknap JB, Galbraith NS, Tomlinson AJ, Elias-Jones TF (1968) Pulmonary anthrax caused by contaminated sacks. Br J Ind Med 25: 72-74.

- McKernan JL, Taylor L, McCammon JB, Hartle RW, Gressel MG (2003) Cross-contamination issues during a biological emergency response effort: lessons learned. Int J Emerg Manag 1: 363-373.

- Karlsson E, Fängmark I, Berglund T (1996) Resuspension of an indoor aerosol. Journal of Aerosol Science 27: S441-S442.

- Karlsson E, Berglund T, Strömqvist M, Nordstrand M, Fängmark I (1999) The effect of resuspension caused by human activities on the indoor concentration of biological aerosols. J Aerosol Sci.

- Thatcher TL, Layton DW (1995) Deposition, resuspension, and penetration of particles within a residence. Atmos Environ 29: 1487-1497.

- Oberoi RC, Choi J-I, Edwards JR, Rosati JA, Thornburg J, et al. (2010) Human-induced particle re-suspension in a room. Aerosol Sci Technol 44: 216-229.

- Rosati JA, Thornburg J, Rodes C (2008) Resuspension of particulate matter from carpet due to human activity. Aerosol Sci Technol 42: 472-482.

- Thornburg J (2007) Resuspension and tracking of particulate matter from carpet due to human activity. U.S. Environmental Protection Agency.

- Thornburg J, Rodes C, Rosati JA (2009) Resuspension of fibers from indoor surfaces due to human activity. U.S. Environmental Protection Agency, Homeland Security Research, USA.

- Krauter P, Biermann A (2007) Reaerosolization of fluidized spores in ventilation systems. Appl Environ Microbiol 73: 2165-2172.

- Dull PM, Wilson KE, Kournikakis B, Whitney EA, Boulet CA, et al. (2002) Bacillus anthracis aerosolization associated with a contaminated mail sorting machine. Emerg Infect Dis 8: 1044-1047.

- Weis CP, Intrepido AJ, Miller AK, Cowin PG, Durno MA, et al. (2002) Secondary aerosolization of viable Bacillus anthracis spores in a contaminated US Senate Office. JAMA 288: 2853-2858.

- Nicholson KW (1993) Wind Tunnel experiments on the resuspension of particulate material. Atmospheric Environment. Part A. General Topics 27: 181-188.

- Meselson M, Guillemin J, Hugh-Jones M, Langmuir A, Popova I, et al. (1994) The Sverdlovsk anthrax outbreak of 1979. Science 266: 1202-1208.

- Wilkening DA (2006) Sverdlovsk revisited: modeling human inhalation anthrax. Proc Natl Acad Sci USA 103: 7589-7594.

- Ferro AR, Kopperud RJ, Hildemann LM (2004) Source strengths for indoor human activities that resuspend particulate matter. Environ Sci Technol 38: 1759-1764.

- Hambraeus A, Bengtsson S, Laurell G (1978) Bacterial contamination in a modern operating suite. 3. Importance of floor contamination as a source of airborne bacteria. J Hyg (Lond) 80: 169-174.

- Stuempfle AK, Fischer BW (OptiMetrics Inc. Abingdon, MD). Biological aerosol hazard assessments of emergency responders in specific scenarios. Final report Sep 2002 - Jan 2004. Aberdeen Proving Ground (MD): Edgewood Chemical Biological Center, U.S. Army Research, Development and Engineering Command. Aug 2009. 96 p. Report No.: ECBC-CR-101 (OMI-762). Contract No.: DAAD13-02-F-0028.

- Stuempfle AK, Stuempfle KL, Pennsyle RO, Fischer BW, Dunkel MD. (OptiMetrics Inc. Abingdon, MD). Hazards from a terrorist release of a biological agent in ventilated enclosures and from chemical warfare agents and toxic industrial chemicals in selected scenarios. Final report Aug 2001 - Dec 2002. Aberdeen Proving Ground, MD: Edgewood Chemical Biological Center, U.S. Army Research, Development and Engineering Command. Aug 2009. 93 p. Report No.: ECBC-CR-100 (OMI-739). Contract No.: DAAD13-01-F-0021.

- Greenberg DL, Busch JD, Keim P, Wagner DM (2010) Identifying experimental surrogates for Bacillus anthracis spores: a review. Investig Genet 1: 4.

- Drobniewski FA (1993) Bacillus cereus and related species. Clin Microbiol Rev 6: 324-338.

- Plomp M, Leighton TJ, Wheeler KE, Malkin AJ (2005) Architecture and high-resolution structure of Bacillus thuringiensis and Bacillus cereus spore coat surfaces. Langmuir 21: 7892-7898.

- Todar K (2008) Bacillus anthracis and Anthrax. Todar's Online Textbook of Bacteriology.

- Carrera M, Zandomeni RO, Fitzgibbon J, Sagripanti JL (2007) Difference between the spore sizes of Bacillus anthracis and other Bacillus species. J Appl Microbiol 102: 303-312.

- Tang P, Fletcher DF, Chan HK, Raper JA (2008) Simple and cost-effective powder disperser for aerosol particle size measurement. Powder Technology 187: 27-36.

- Hinds WC (1999) Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles. (2ndedn), John Wiley & Sons, Inc., New York, 387-388.

- Seinfeld JH, Pandis SN (1998) Atmospheric Chemistry and Physics: From Air Pollution to Climate Change. John Wiley & Sons, Inc., New York, 916-925.

- Wein LM, Craft DL, Kaplan EH (2003) Emergency response to an anthrax attack. Proceedings of the National Academy of Sciences of the United States of America 100: 4346-4351.

- Cami A, Wallstrom GL, Hogan WR (2009) Measuring the effect of commuting on the performance of the Bayesian Aerosol Release Detector. BMC Med Inform Decis Mak 9: S7.

- Bellamy RJ, Freedman AR (2001) Bioterrorism. QJM 94: 227-234.

- Wein LM, Liu Y, Leighton TJ (2005) HEPA/vaccine plan for indoor anthrax remediation. Emerg Infect Dis 11: 69-76.

- https://researchr.org/publication/KongWH08/bibtex.

- Marple VA, Rubow KL, Olson BA (1993) Inertial, gravitational, centrifugal, and thermal collection techniques in Aerosol Measurement: Principles, Techniques, and Applications, Willeke K and Baron PA, edn, Van Nostrand Reinhold, New York, 225-227.

- Gomes C, Freihaut J, Bahnfleth W (2007) Resuspension of allergen-containing particles under mechanical and aerodynamic disturbances from human walking. Atmos Environ 41: 5257-5270.

- Kulkarni P, Baron PA, Willeke K (2011) Aerosol Measurement: Principles, Techniques, and Applications. John Wiley and Sons, Inc., New York, Kindle Edition, Locations 28261-28262.

- Gutting BW, Nichols TL, Channel SR, Gearhart JM, Andrews GA, et al. (2012) Inhalational anthrax (Ames aerosol) in naïve and vaccinated New Zealand rabbits: characterizing the spread of bacteria from lung deposition to bacteremia. Front Cell Infect Microbiol 2: 87.

- Taft SC, Hines SA (2012) Benchmark dose analysis for Bacillus anthracis inhalation exposures in the nonhuman primate. Risk Anal 32: 1750-1768.

Relevant Topics

- Anthrax Bioterrorism

- Bio surveilliance

- Biodefense

- Biohazards

- Biological Preparedness

- Biological Warfare

- Biological weapons

- Biorisk

- Bioterrorism

- Bioterrorism Agents

- Biothreat Agents

- Disease surveillance

- Emerging infectious disease

- Epidemiology of Breast Cancer

- Information Security

- Mass Prophylaxis

- Nuclear Terrorism

- Probabilistic risk assessment

- United States biological defense program

- Vaccines

Recommended Journals

Article Tools

Article Usage

- Total views: 15424

- [From(publication date):

specialissue-2013 - Dec 20, 2025] - Breakdown by view type

- HTML page views : 10697

- PDF downloads : 4727