Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

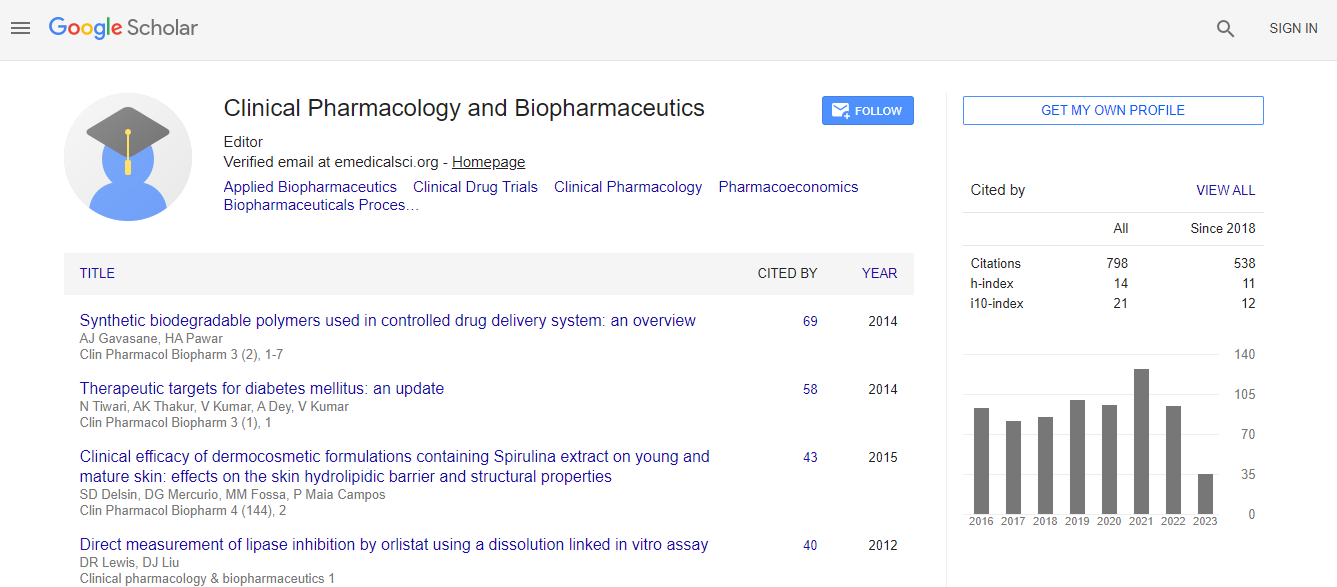

Google Scholar citation report

Citations : 790

Clinical Pharmacology & Biopharmaceutics received 790 citations as per Google Scholar report

Clinical Pharmacology & Biopharmaceutics peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Bioprocess development: Upstream and downstream technologies

International Conference and Expo on Biopharmaceutics

Monica-C-Chuong

MCPHS University, USA

Keynote: Clin Pharmacol Biopharm

Abstract

The traditional applications of biotechnology/bioprocessing are mostly in the area of food, bakery products, alcoholic beverage, which are still important up to this date. The commercial success of production of the penicillin lead to the ideal and contamination-free environment bioprocessing and the advance to genetic engineering of microbial, animal and plant cells to produce recombinant proteins or metabolites. Vistas in recombinant DNA techniques, gene manipulation, cell fusion and tissue culture make micro batch reactors no longer hindrance. However, the scale-up technique to translate a scientific invention into commercial reality is not that easy as yet due to the complexity of biological systems and hardship in control. If utilization of mathematical modeling of the rate of cell growth, product formation and substrate uptake, and vigorous evaluations and monitoring of various process parameters in aseptic environmental conditions may bring pilot-scale step may be completed successfully, then the industrial-scale operations commences. This aim of this presentation is to enlighten biotechnologists with some engineering disciplines and to enable the communication on a professional level with bioprocess engineers in both upstream and downstream technologies within the given presentation time. In upstream technology, different reactors (batch reactor, continuous reactors, fed-batch/semi-batch reactors, fluidized bed reactor, immobilized cell bioreactors, airlift reactor), media design, and mixing will be elucidated. In downstream processing operations (also known as unit operations) involve using adsorption, centrifugation, chromatography, crystallization, drying, evaporation, filtration, flocculation, homogenization, microfiltration, milling, precipitation, sedimentation, solvent extraction and ultrafiltration for cell removal, cell disruption, cell debris removal, primary isolation, product enrichment and final isolation and treatment of effluents.Biography

Monica-C-Chuong is an Associate Professor of Pharmaceutics at the MCPHS University, Boston, MA, teaching Controlled Drug Delivery, Bioprocess Unit Operations, Pharmaceutical Technology, Introduction to Cosmetic and Personal Care Products, Pharmaceutical Particulate Science and Pharmaceutics Laboratories. She received her PhD in Pharmaceutics from University of Houston and postdoctoral training in Solid Dosage Formulation, Oregon State University. Her research interests are HPLC assay development, in vitro drug release, solid, percutaneous dosage forms and personal care products. She served as the chairperson of AAPS Northeast Regional Discussion Group in 2012, secretary of AAPS Chem & Bio API Manufacturing Technology Focus Group 2014-15. She is also a member of Society of Cosmetic Chemists.

Email: monica.chuong@mcphs.edu

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi